CNC Machining Parts: Engineering Excellence for Demanding Industries

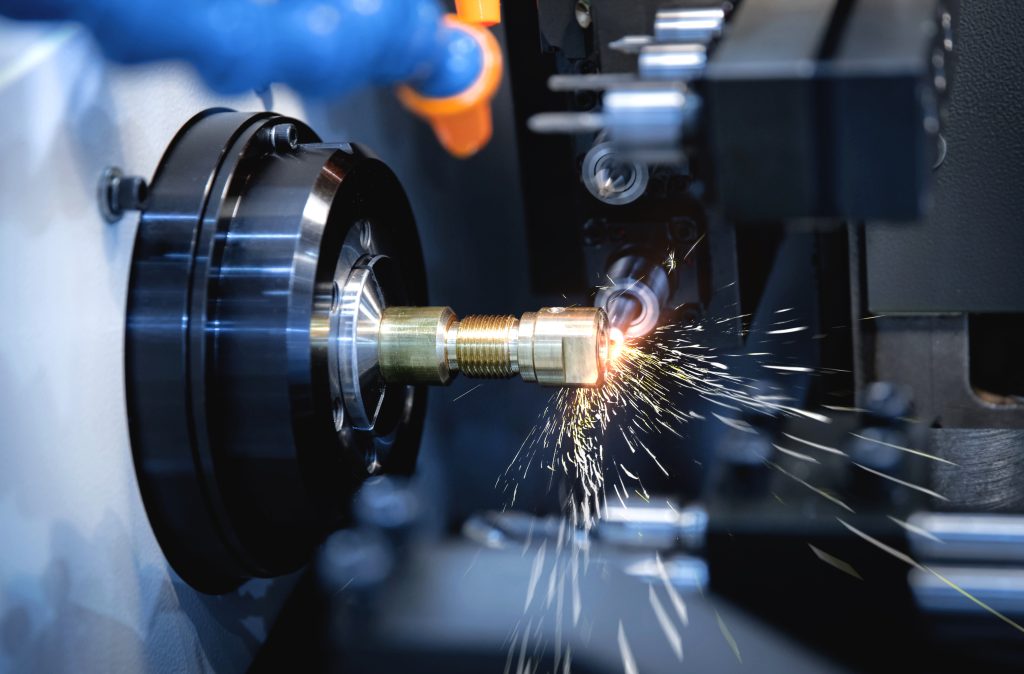

In industries where precision is paramount, CNC machining parts form the backbone of innovation. These components—crafted from metals, plastics, or composites using Computer Numerical Control (CNC) technology—deliver micron-level accuracy for applications ranging from jet engines to life-saving medical devices. At JLYPT, we specialize in manufacturing CNC machining parts that meet the rigorous demands of aerospace, medical, and automotive sectors, combining advanced technology with decades of expertise.

This article explores the intricacies of CNC machining parts, their applications, and how JLYPT’s solutions push the boundaries of precision manufacturing.

What Are CNC Machining Parts?

CNC machining parts are components produced through subtractive manufacturing, where computer-controlled machines remove material from a workpiece to achieve precise geometries. Key characteristics include:

-

Tight Tolerances: As narrow as ±0.002 mm for aerospace and medical applications.

-

Material Versatility: Machinable materials include titanium, Inconel, PEEK, and aluminum.

-

Complex Geometries: Achieved via multi-axis CNC milling, turning, or EDM.

For example, JLYPT produces Inconel 718 turbine blades with cooling channels 0.1 mm wide, ensuring optimal performance in jet engines.

Industries Transformed by CNC Machining Parts

1. Aerospace: Precision Under Extreme Conditions

-

Engine Components: Turbine disks (René 88DT) withstand 800°C and 15,000 RPM.

-

Satellite Hardware: Aluminum 6061-T6 brackets with 0.005 mm positional accuracy.

-

Case Study: Reduced a spacecraft’s actuator housing weight by 30% using topology-optimized titanium parts.

2. Medical: Life-Saving Accuracy

-

Orthopedic Implants: Ti-6Al-4V ELI hip stems with Ra 0.4 µm surface finishes.

-

Surgical Tools: Stainless steel 316L forceps with 0.01 mm tip precision.

-

Compliance: Meets FDA 21 CFR Part 820 and ISO 13485 standards.

3. Automotive: Speed and Durability

-

EV Battery Housings: Aluminum A380 enclosures machined to IP67 waterproof standards.

-

Transmission Gears: Case-hardened 20MnCr5 steel gears with AGMA Q10 certification.

Technical Mastery in Producing CNC Machining Parts

1. Advanced Machining Techniques

-

5-Axis Simultaneous Machining: Craft impellers with complex curvatures in a single setup.

-

Swiss-Type Turning: Machine Ø0.2 mm Nitinol guidewires for medical catheters.

-

High-Speed Milling: Achieve mirror finishes (Ra < 0.2 µm) on optical components.

2. Material Innovation

-

Superalloys: Inconel 625 for corrosive environments.

-

Composites: Carbon fiber-reinforced polymers (CFRP) for lightweight aerospace structures.

3. Quality Assurance

-

In-Process Inspection: On-machine probing validates dimensions hourly.

-

CMM Verification: 3D scans ensure compliance with GD&T standards.

-

Certifications: AS9100 (aerospace), ISO 13485 (medical), IATF 16949 (automotive).

Case Study: Medical Device Breakthrough

Challenge: A client needed 500 spinal fusion cages (Ti-6Al-4V ELI) with porous surfaces (Ra < 0.8 µm) in 20 days.

JLYPT’s Solution:

-

Tooling: Diamond-coated end mills for burr-free edges.

-

Process: Adaptive toolpaths to maintain surface integrity.

-

Result: Delivered in 18 days, achieving 100% FDA compliance and zero scrap.

Sustainability in CNC Machining Parts Production

-

Recycled Materials: 90% of aluminum and titanium waste reused.

-

Energy Efficiency: Regenerative drives reduce power consumption by 25%.

-

Eco-Friendly Coolants: Non-toxic, ISO 14001-compliant fluids.

Why Partner with JLYPT?

-

Rapid Prototyping: Functional samples in 5-7 days.

-

High-Volume Production: 50,000+ parts/month with SPC-controlled consistency.

-

Global Logistics: DDP shipping to 50+ countries with real-time tracking.

Explore JLYPT’s CNC Machining Services

The Future of CNC Machining Parts

Emerging trends include:

-

AI-Driven Optimization: Self-correcting toolpaths reduce cycle times by 20%.

-

Hybrid Manufacturing: Combine 3D printing and CNC finishing for complex parts.

-

Nano-Machining: Sub-micron accuracy for microfluidic devices.

Conclusion: Precision Engineered for Tomorrow’s Challenges

CNC machining parts are more than components—they are the foundation of technological progress. At JLYPT, we blend cutting-edge machinery, material science, and rigorous quality control to deliver parts that exceed expectations. From aerospace turbines to medical breakthroughs, our expertise ensures your projects thrive in the most demanding environments.

Ready to elevate your manufacturing? Contact JLYPT today for a quote.