Precision Engineered: Jlypt’s Comprehensive Range of CNC Machine Products

Section 1: The CNC Product Spectrum in Modern Manufacturing

1.1 Defining CNC Machine Products

Contemporary CNC solutions encompass three primary categories:

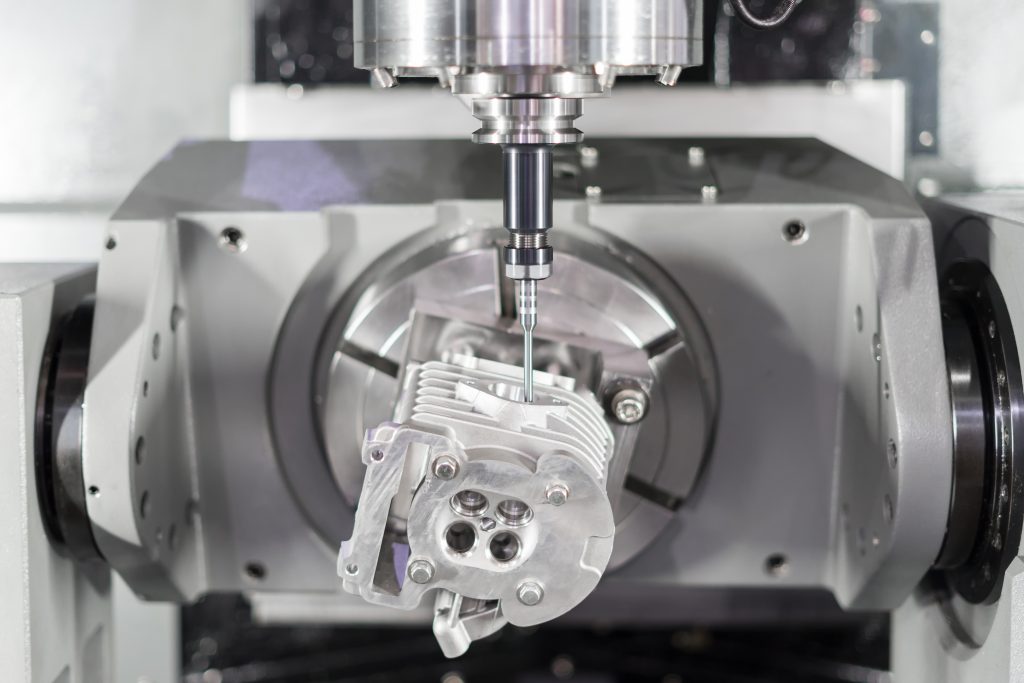

1. Machining Centers

- 5-axis vertical machining centers (Travel: X-40″, Y-24″, Z-20″)

- Horizontal boring mills (Spindle diameter: 130mm)

- Micro-machining systems (±1μm accuracy)

2. Turning Systems

- Multi-tasking turn-mill centers (12-station turret)

- Swiss-type automatic lathes (Ø32mm capacity)

- Chuckers for high-volume production

3. Specialized Equipment

- EDM machines (Ra 0.8μm surface finish)

- Laser cutting systems (0.004″ kerf width)

- Waterjet cutting (60,000 PSI pressure)

At Jlypt, we maintain 87 operational CNC units across our 35,000 sq.ft facility, including:

- 14 Makino a61nx horizontal mills

- 9 Mazak Integrex i-200S

- 4 GF Machining HSM 500 LP

Section 2: Technical Specifications of Jlypt’s CNC Products

2.1 Performance Metrics

Our CNC machine products consistently achieve:

- Positioning accuracy: 0.00008″ (2μm)

- Maximum spindle speed: 42,000 RPM

- Rapid traverse rate: 2,362 IPM

- Surface finish capability: 4μin Ra

2.2 Material Compatibility

Engineered for challenging materials:

- Aerospace alloys: Ti-6Al-4V, Inconel 718

- Medical-grade materials: CoCrMo, PEEK

- Automotive composites: Carbon fiber, aluminum

Request product specifications

Section 3: Industry-Specific CNC Solutions

3.1 Aerospace Components

- Turbine blades with 0.005″ wall thickness

- Wing spar fittings (78″ length capacity)

- Landing gear components (HRc 50+ hardness)

3.2 Medical Device Manufacturing

- Orthopedic implants (0.8μm Ra finish)

- Surgical instruments (Micro-features to 0.002″)

- Dental prosthetics (16μm layer resolution)

Section 4: The Future of CNC Products (2025-2030 Outlook)

4.1 Emerging Technologies

- AI-powered adaptive control systems

- Hybrid additive-subtractive manufacturing

- Quantum metrology integration

4.2 Sustainability Initiatives

- Energy-recovery spindles (38% reduction)

- Dry machining techniques

- Closed-loop coolant systems

Contact our engineering team: [email protected] | https://www.jlypt.com