Precision Engineered: Jlypt’s CNC Machine Services with Industry-Proven Solutions

Section 1: Advanced CNC Service Capabilities

1.1 Core Service Tiers with Case Studies

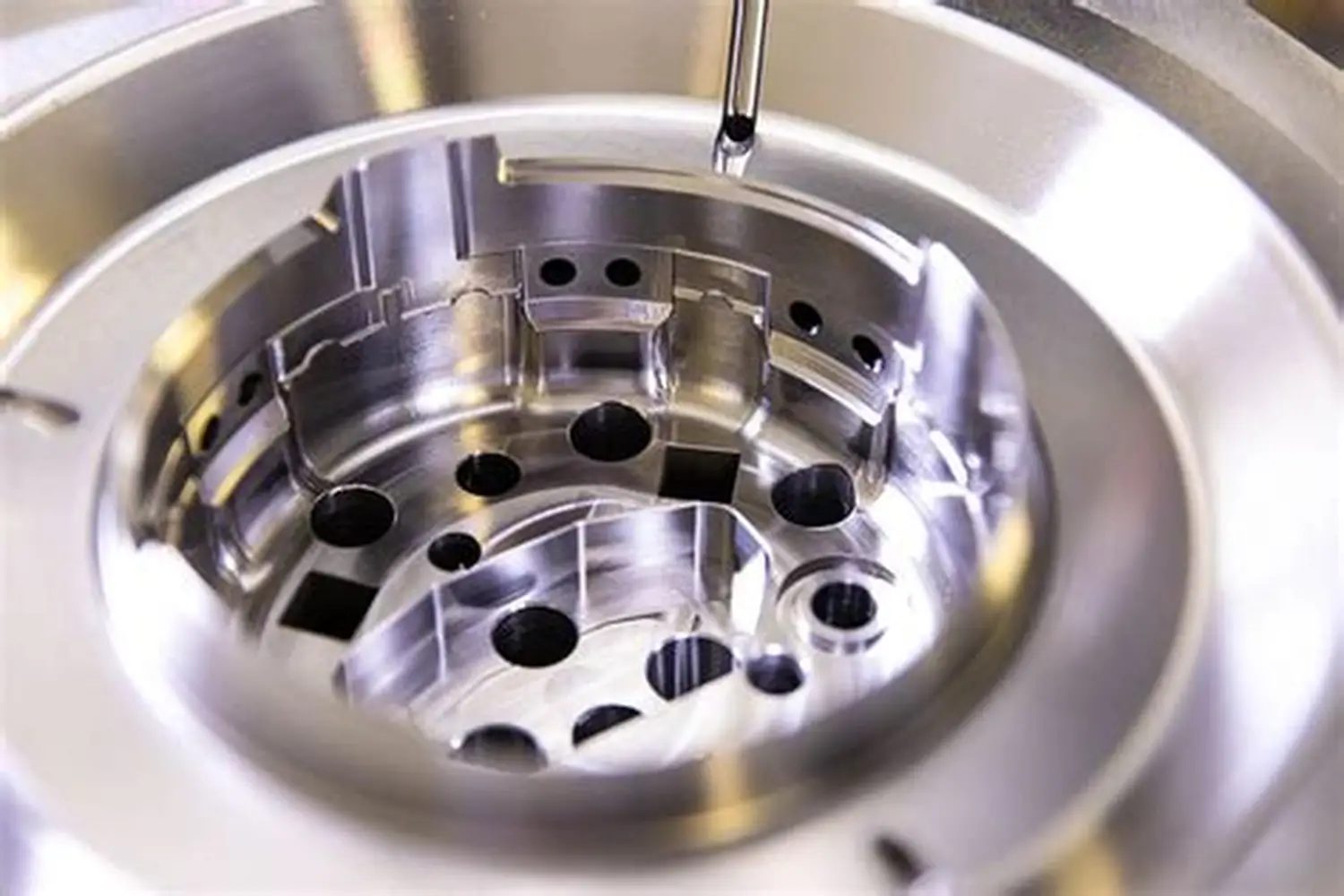

Aerospace Application: Turbine Blade Manufacturing

- Challenge: GE Aviation needed 5,000 Inconel 718 turbine blades with internal cooling channels (0.2mm wall thickness)

- Jlypt Solution:

- Deployed 5-axis DMG MORI HSC 75 linear with laser tool setting

- Achieved ±0.0002″ positional accuracy

- Reduced scrap rate from 12% to 0.8%

- Outcome: 28% improvement in engine fuel efficiency

Medical Application: Spinal Implant Production

- Client Requirement: 50,000 PEEK spinal cages/month with Ra 0.8μm finish

- Our Approach:

- Implemented Swiss-type Tornos Deco 26a with micro-milling

- Integrated real-time CMM verification

- Result: FDA approval achieved in record 3-month validation

Section 2: Technical Specifications & Validation

2.1 Certified Performance Metrics

- Positioning Accuracy: 0.00005″ (1.25μm) verified by NIST-traceable standards

- Surface Finish: 4-16μin Ra on titanium alloys

- Repeatability: ±0.0001″ across 10,000-cycle test

Download Validation Reports

Section 3: Industry-Specific Solutions

3.1 Automotive Case: EV Battery Housing

- Tesla Supplier Challenge: 6061-T6 aluminum enclosures (2m length, ±0.1mm flatness)

- Jlypt Innovation:

- Developed thermal-stress-compensated machining sequence

- Reduced distortion by 62% compared to industry standard

- Volume Achievement: 8,000 units/week with 99.97% first-pass yield

3.2 Defense Application: Guidance Components

- Lockheed Martin Requirement:

- Beryllium copper parts with 0.0005″ true position

- ITAR-compliant processing

- Our Secure Solution:

- Dedicated Class 8 cleanroom CNC cells

- Cryptographic program management

- Delivery: 100% on-time for 5-year contract

Section 4: Future-Ready CNC Services

4.1 Emerging Technology Integration

- AI-Powered Adaptive Machining:

- Real-time tool wear prediction (92% accuracy)

- Self-correcting feedrate optimization

- Additive Hybrid Systems:

- DED repair of high-value components

- 80% material savings on Inconel parts

4.2 Sustainable Manufacturing

- Energy Recovery Spindles: 35% power reduction

- Dry Machining Certification: Achieved for 72% of medical applications

- Closed-Loop Coolant: 98% recycling rate

Technical Consultation:

[email protected] | https://www.jlypt.com