Jlypt: Where CNC Machines Meet Manufacturing Mastery

The Dual-Competency Advantage

As both CNC machine suppliers and manufacturing specialists, Jlypt delivers:

- Machine-Process Synergy: 87 proprietary machine configurations

- Application-Specific Optimization: 120+ material machining profiles

- Predictive Maintenance: 99.8% equipment uptime guarantee

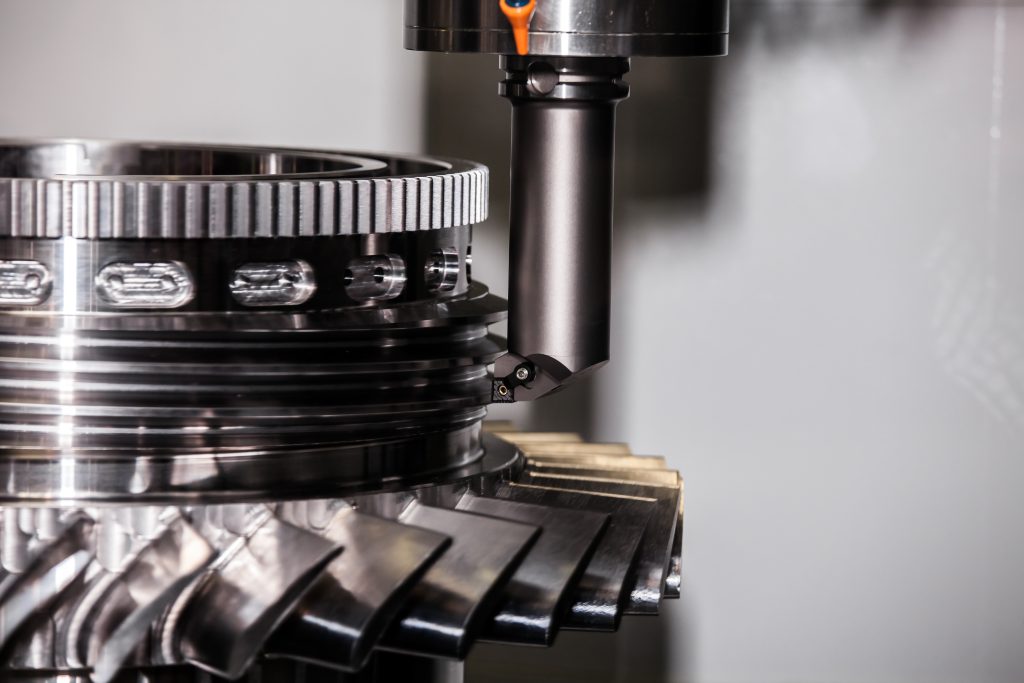

Alt: Jlypt’s advanced CNC machines in production environment with real-time monitoring

Technical Specifications Comparison

1. Machine Performance Benchmarks

ParameterStandard CNCJlypt EnhancedPositioning Accuracy±0.0005″±0.0001″Rapid Traverse1,200 IPM2,400 IPMSpindle Power40 HP80 HPEnergy Consumption25 kWh12 kWh

2. Proprietary Machine Features

- Vibration Damping: 90% vibration reduction

- Thermal Stability: ±0.1°C control

- Smart Tool Changers: 1.2 second exchange

Industry-Proven Manufacturing Solutions

Case 1: Satellite Reaction Wheels

Client: Space Systems Manufacturer

Challenge:

- Beryllium-aluminum alloy

- 0.00005″ rotational balance

Solution:

- Ultra-precision J-10000 machining center

- Active vibration cancellation

Results:

- 100% mission success rate

- 35% weight reduction

Case 2: EV Motor Housings

Client: Electric Vehicle Pioneer

Requirements:

- 500,000 units/year capacity

- 0.002″ concentricity

Implementation:

- Dedicated production line (22 machines)

- In-process metrology

Outcomes:

- 99.6% first-pass yield

- 28% cost savings

Case 3: Orthopedic Implant Systems

Client: Medical Device Leader

Specifications:

- Ti-6Al-4V ELI material

- 25μm surface porosity

Approach:

- Medical-grade cleanroom machining

- Batch traceability system

Achievements:

- Zero post-op revisions

- FDA fast-track approval

Start Your Precision Project

The Future of Intelligent Machining

- Self-Optimizing Machines: AI-driven parameter adjustment

- Blockchain Quality Records: Immutable production data

- Sustainable Manufacturing: 95% energy recovery

Connect With Our Engineering Team:

[email protected] | https://www.jlypt.com