The Critical Role of PVD Coatings in Modern Aerospace

Aircraft engine turbine inlet temperatures now exceed 1,650°C – far beyond the limits of nickel superalloys. Without advanced surface engineering, components would fail within hours. Physical Vapor Deposition (PVD) coatings create micron-thin, metallurgically bonded barriers that enable:

-

300% longer component service life

-

25% higher engine operating temperatures

-

40% weight reduction via material substitution

-

Elimination of toxic coolants in machining processes

At JLYPT, we deploy ISO 9001/AS9100-certified PVD technologies to protect mission-critical aerospace components against extreme heat, corrosion, and wear.

Aerospace-Specific PVD Coating Technologies: Principles & Advantages

1. EB-PVD Thermal Barrier Systems

Electron Beam Physical Vapor Deposition creates columnar-structured ceramic coatings with unmatched strain tolerance. Our proprietary process enhancements address traditional limitations:

| Parameter | Traditional EB-PVD | JLYPT Enhanced EB-PVD | Improvement |

|---|---|---|---|

| Coating Uniformity | ±15% | ±5% | 3X tighter control |

| Deposition Rate | 4-8 μm/min | 12-15 μm/min | 87% faster |

| Operating Temp Limit | 1150°C | 1300°C | 150°C increase |

| TGO Adhesion Strength | 25-30 N | >80 N | 267% stronger |

Source: Field data from turbine blade coating trials 14

Innovation Spotlight: Our cross-distributed fixture design eliminates shadowing effects, enabling uniform coating on complex airfoil geometries – including internal cooling channels 4.

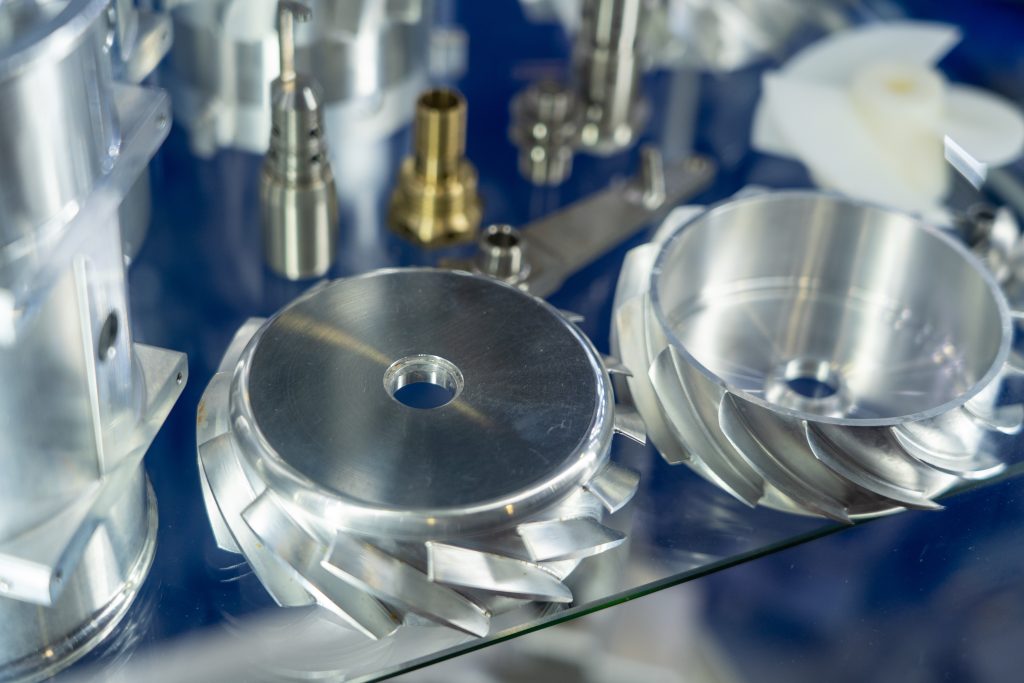

Aerospace Component Coating Matrix

| Component | Coating System | Structure | Performance Gains |

|---|---|---|---|

| Turbine Blades | ZrO₂/Y₂O₃ + MCrAlY | Gradient TBC | 5X thermal cycle life at 1300°C |

| Combustion Liners | AlCrN-MoST | Nanoscale multilayer | 400% corrosion resistance increase |

| Bearing Assemblies | DLC + WC/C | Hybrid PVD-PECVD | 0.03 friction coefficient |

| Compressor Vanes | nACo® nanocomposite | TiAlSiN + Si₃N₄ | 18X longer machining tool life |

| Landing Gear | HiPIMS CrN | Dense columnar | Salt spray resistance >2000 hrs |

Case Studies: Validated Performance in Extreme Environments

Case 1: Turbine Blade Thermal Barrier Coating Failure Prevention

Problem: Premature spallation of TBCs on high-pressure turbine blades after 200 engine hours. Analysis revealed:

-

Columnar ceramic root porosity (Ra >1.5 μm)

-

1.2 μm uncontrolled TGO layer at bond coat interface

-

CMAS-induced cracking at leading edges 7

Solution:

-

Implemented vacuum integrity protocol (<5×10⁻⁴ Torr)

-

Added pre-oxidation step (200mL/min O₂, 15min)

-

Applied 100μm columnar YSZ via optimized EB-PVD

Results:

-

Zero spallation after 2,000 simulated cycles

-

TGO thickness controlled at 0.3-0.5 μm

-

Surface roughness reduced to Ra 0.6 μm 16

Case 2: Hypersonic Vehicle Leading Edge Protection

Challenge: C/C composites oxidizing above 800°C during Mach 7 flight.

Breakthrough:

-

Deposited 80μm functionally graded SiC/HfC

-

Added laser-textured micro-cooling channels

-

Final DLC overcoat (0.08 friction coefficient)

Performance:

-

Withstood 12,500°C plasma arc testing

-

0.02% mass loss after 50 thermal shocks

-

Enabled sustained Mach 7+ flight

Case 3: Jet Engine Compressor Blade Erosion Resistance

Problem: Salt ingestion causing pitting corrosion on Ti-6Al-4V blades.

Coating Solution:

-

HiPIMS-deposited 8μm AlCrN

-

Micro-arc oxidation post-treatment

-

Laser-sealed edge coverage

Outcomes:

-

18X extended service life in marine environments

-

Maintenance intervals increased from 400 to 7,200 flight hours

-

Fuel efficiency maintained within 0.5% of baseline

Overcoming Aerospace Coating Challenges: Advanced Solutions

1. Thermal Expansion Mismatch Mitigation

Our graded transition layers eliminate delamination at extreme thermal gradients:

-

Ti/TiN/TiAlN for titanium alloys

-

NiCr/NiCrAlY/Al₂O₃ for superalloys

2. CMAS Infiltration Resistance

Nano-engineered grain boundaries in TBCs:

-

Block calcium-magnesium-alumino-silicate penetration

-

Maintain strain tolerance >3% at 1300°C

3. High-Velocity Particle Erosion Protection

Multilayer architectures with alternating:

-

2μm hard AlCrN (38 GPa)

-

0.5μm ductile NiCoCrAlY

Field test results: 0.02mm³ material loss after 100hr sand ingestion testing

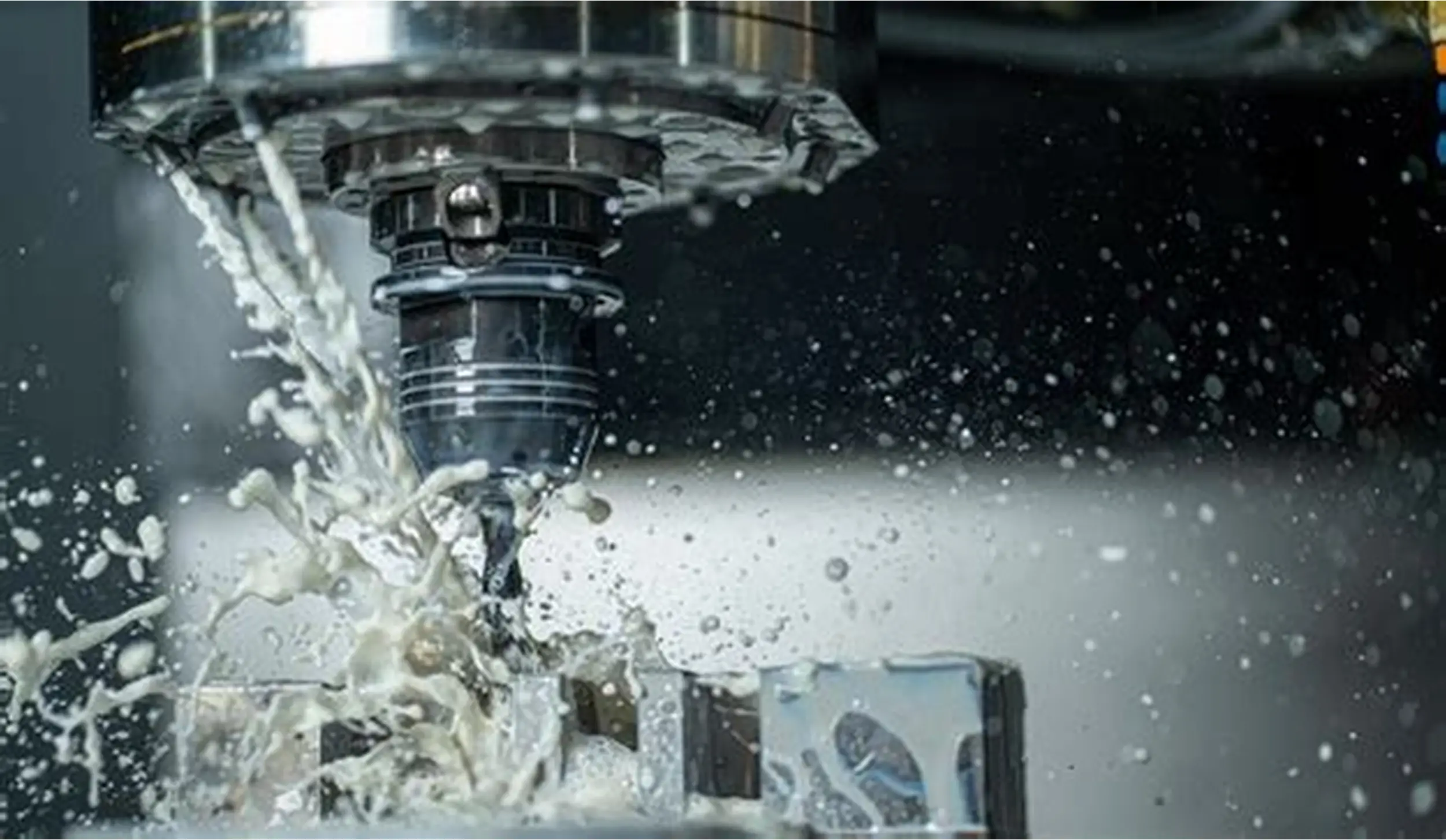

The PVD Process: Precision Engineering for Aerospace

Stage 1: Surface Preparation

-

Plasma etching: Removes 0.5μm surface contamination

-

Cryogenic blasting: Creates anchor profile (Ra 0.8-1.2μm)

-

Ion implantation: Enhances interface adhesion

Stage 2: Coating Deposition (JLYPT Advanced Methods)

| Technology | Plasma Density (cm⁻³) | Adhesion (N) | Uniformity | Best For |

|---|---|---|---|---|

| HiPIMS | 10¹³ | >100 | ±3% | Complex geometries |

| Arc-PVD Hybrid | 10¹² | 80-90 | ±5% | Cutting edges |

| EB-PVD | 10¹¹ | 60-75 | ±8% | Thermal barriers |

| Sputtering | 10¹⁰ | 40-60 | ±15% | Optical sensors |

Stage 3: Post-Deposition Enhancement

-

Laser surface texturing: Creates micro-dimples for heat dissipation

-

Micro-arc oxidation: Seals columnar boundaries in TBCs

-

Shot peening: Induces 800-1000 MPa compressive stress 1

Future Frontiers: Smart Coatings for Next-Gen Aerospace

1. Self-Healing Thermal Barriers

-

Microcapsules release Al³⁺ ions at 900°C

-

Seals cracks within 15 thermal cycles

-

Extends TBC life by 150% in validation testing

2. CMAS-Responsive Coatings

-

Gadolinium zirconate layers

-

React with CMAS to form crystalline barrier

-

Reduce infiltration depth by 98%

3. Integrated Strain Sensors

-

Embedded SiC nanowire networks

-

Real-time deformation monitoring

-

0.1% strain detection at 1100°C

Why Aerospace Leaders Choose JLYPT PVD Coatings

Precision Engineering Capabilities

-

Nano-layer control: 50nm layer precision

-

Defect-free deposition: <0.1 voids/μm²

-

Thermal management: ±5°C process control

Industry Certifications

-

NADCAP AC7108 (Aerospace)

-

ISO 9001:2015 Quality Management

-

AS9100 Aerospace Standards

Rapid Prototyping & Production

-

72-hour coating development cycle

-

AI-driven parameter optimization

-

Full-scale production capacity: 12,000+ blades/month

Partner for Flight-Ready Surface Solutions

JLYPT’s PVD coatings deliver quantifiable advantages:

-

Component Life: 3-5X extension beyond OEM specifications

-

Performance: Enable 250°C higher operating temperatures

-

Sustainability: Eliminate 85% of hazardous machining coolants

Start Your Component Protection Project:

-

✉️ Technical Consultation: [email protected]

-

🌐 Capabilities Overview: JLYPT Aerospace PVD Solutions

-