Diamond-Like Carbon Coating (DLC) – The New Standard for Extreme Surface Finishing

Diamond-Like Carbon Coating (DLC) is rapidly becoming the go-to solution for engineers who need ultra-low friction, exceptional hardness, and chemical inertness in one thin film. At JLY Precision Tech, we deposit hydrogen-free (ta-C) and hydrogenated (a-C:H) DLC layers via cathodic-arc PVD, delivering repeatable quality from prototype to high-volume runs.

Why Diamond-Like Carbon Coating (DLC) Beats Traditional Finishes

| Property |

Hard Chrome |

Electroless Ni-P |

TiN PVD |

DLC (ta-C) |

| Thickness (µm) |

5–100 |

5–50 |

1–5 |

0.5–4 |

| Hardness (HV) |

800–1 100 |

500–700 |

1 800–2 000 |

2 500–3 000 |

| Friction vs. steel (dry) |

0.25 |

0.3 |

0.4 |

0.05–0.15 |

| Salt-spray (h) |

48 |

96 |

200 |

1 000+ |

| REACH compliance |

Restricted |

OK |

OK |

OK |

Diamond-Like Carbon Coating (DLC) Process Flow in Shenzhen

-

Plasma etch – removes oxides and micro-roughens the surface

-

Bond layer – 50 nm Cr or CrN for adhesion on steel, Ti, Al

-

DLC deposition – arc-evaporated graphite at 200 °C

-

Post-polish – optional CMP to Ra ≤ 0.02 µm

Diamond-Like Carbon Coating (DLC) in Action – 3 Case Studies

Case Study 1 – High-Pressure Diesel Piston

Client: Tier-1 EU OEM

Issue: Galling at 2 500 bar

DLC Solution: 2 µm ta-C + Cr interlayer

Result: Zero seizure after 1 000 h; torque down 22 %

Case Study 2 – Ophthalmic Scalpel

Client: Japan Med Device Start-up

Issue: 30 µm edge retention

DLC Solution: 500 nm a-C:H on martensitic stainless

Result: Edge radius growth < 5 µm; CE-marked product

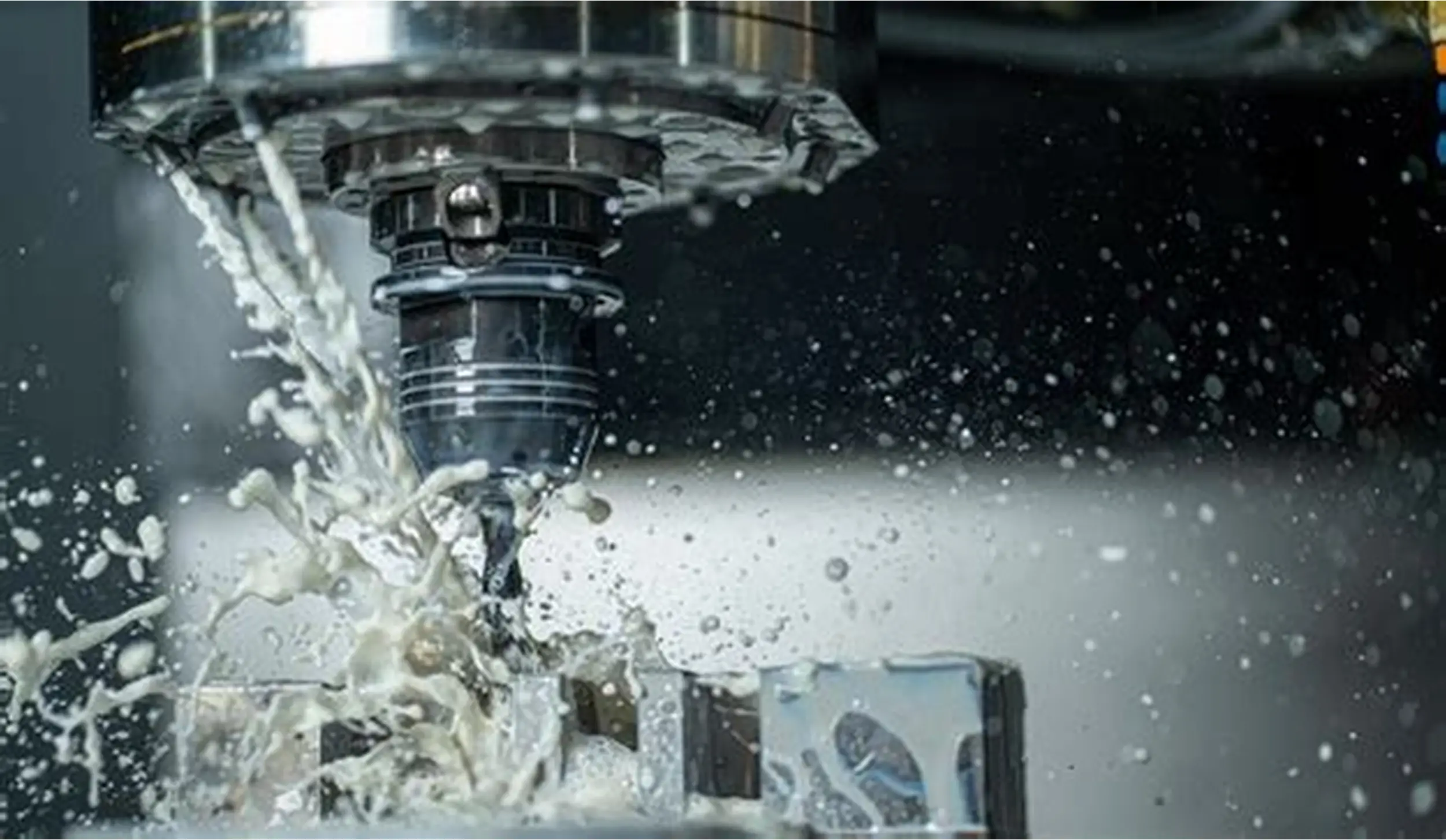

Case Study 3 – CNC Router Linear Rails

Client: US Woodworking OEM

Issue: Abrasive MDF dust

DLC Solution: 1.2 µm ta-C + burnish Ra 0.04 µm

Result: Service interval 6 → 24 months; 60 % savings

Sub-Heading: Diamond-Like Carbon Coating (DLC) vs. External Benchmarks

For a deeper dive into DLC tribology, see the authoritative review by Robertson in Materials Science and Engineering (DOI:10.1016/j.mser.2022.100800). JLY Precision Tech aligns its process parameters with these peer-reviewed findings.

Diamond-Like Carbon Coating (DLC) Adoption Map 2024-2026

| Sector |

2024 Rate |

2026 Forecast |

Key Parts |

| Automotive |

8 % |

22 % |

Injectors, gears |

| Medical |

18 % |

35 % |

Scalpels, drills |

| Packaging |

5 % |

15 % |

Slitter knives |

| Aerospace |

12 % |

28 % |

Flap tracks |

Frequently Asked Questions About Diamond-Like Carbon Coating (DLC)

Q: Will DLC darken under UV?

A: No—Diamond-Like Carbon Coating (DLC) colour is intrinsic; no dyes to fade.

Q: Can DLC be stripped and recoated?

A: Yes, oxygen plasma removes DLC without harming base dimensions.

Ready to Upgrade to Diamond-Like Carbon Coating (DLC)?

-

-

Specify load, temperature, mating material

-

Receive DFM + coating plan within 48 h

-

No MOQ, volume pricing from 100 pcs