High-Performance PVD Coatings: Nano-Thin Surface Solutions from China’s JLY Precision Tech

When engineering teams specify high-performance PVD coatings, they demand atomic-level precision, extreme-environment durability and lot-size flexibility. JLY Precision Tech, a China-based surface-finishing specialist, has spent 12 years perfecting HiPIMS, filtered-arc and reactive-sputter systems to deliver nano-to-micron films that outperform chrome, nickel and DLC by orders of magnitude. The following 3 000-word guide, newly released 2025 data tables and three unpublished case studies explain how to deploy our nano-films tomorrow.

High-performance PVD coatings have revolutionized the manufacturing and engineering industries. With their ability to provide enhanced surface properties, they are becoming the go-to solution for demanding applications. This article explores the significant advantages of using high-performance PVD coatings in various sectors.

1. What Are High-Performance PVD Coatings?

High-performance PVD coatings, or physical vapor deposition coatings, are thin film coatings applied to a substrate to improve its performance. These coatings are applied in a vacuum environment, allowing for precise control over the thickness and composition of the coating. This precision results in superior adhesion, durability, and resistance to wear and corrosion.

| Property | Electroplated Ni | Traditional DLC | High-Performance PVD |

|---|---|---|---|

| Thickness | 5–50 µm | 1–3 µm | 5 nm–5 µm |

| Hardness (HV) | 700 | 2 000 | 2 500–3 500 |

| Max temp (air) | 300 °C | 400 °C | 1 000 °C |

| Friction vs. steel | 0.3 | 0.1 | 0.04–0.08 |

| REACH | Restricted | ✔ | ✔ |

2. Technology & Equipment Matrix

Understanding the various methods of PVD coating is crucial for engineers and manufacturers. Each technique, such as HiPIMS, filtered arc, and reactive sputtering, offers unique benefits tailored to specific applications. For example, HiPIMS can create dense coatings that enhance the longevity of tools and components.

| Method | Typical Stack | Thickness (nm) | Key Benefit |

|---|---|---|---|

| HiPIMS TiAlCrN | TiAlCrN gradient | 500–5 000 | 1 000 °C oxidation barrier |

| Filtered Arc ta-C | sp³-C | 100–2 000 | Ultra-low friction 0.04 |

| Reactive Sputter CrAlON | CrAlON gradient | 200–3 000 | Hot-gas corrosion 950 °C |

| PECVD SiBON | SiBON + DLC nanolaminate | 100–1 000 | Steam 900 °C |

| Magnetron EMI | Ag/Ni/Cr | 50–1 000 | 85 dB EMI shielding |

3. 2024 Performance Dashboard

The performance dashboard provides critical insights into how different coatings perform under various conditions. By analyzing the data, engineers can determine which coatings are best suited for their specific applications, ensuring optimal performance and reliability.

| Substrate | JLY Stack | Hardness (HV) | Salt-Spray (h) | Max Temp (°C) | Wear Rate @ 600 °C (mm³/N·m) |

|---|---|---|---|---|---|

| H13 steel | TiAlCrN | 2 900 | 1 200 | 1 000 | 1.1×10⁻⁶ |

| 316L SS | ta-C DLC | 3 000 | 1 000 | 400 | 5.2×10⁻⁷ |

| Al 7075 | CrAlON | 2 400 | 800 | 600 | 8.1×10⁻⁷ |

| Inconel 718 | SiBON | 2 200 | 900 | 950 | 9.0×10⁻⁷ |

4. Three 2025 Case Studies

Each case study illustrates the tangible results that can be achieved through the application of high-performance PVD coatings. From aerospace to automotive, these real-world examples highlight the importance of selecting the right coating to overcome challenges faced in production and performance.

Case 1 – High-Performance Turbine Blade

-

Client: European aerospace OEM

-

Challenge: 850 °C fretting at dovetail root

-

Stack: 2.5 µm TiAlCrN + 200 nm a-C:H top

-

Result: Wear depth < 5 µm after 1 000 h; maintenance interval doubled.

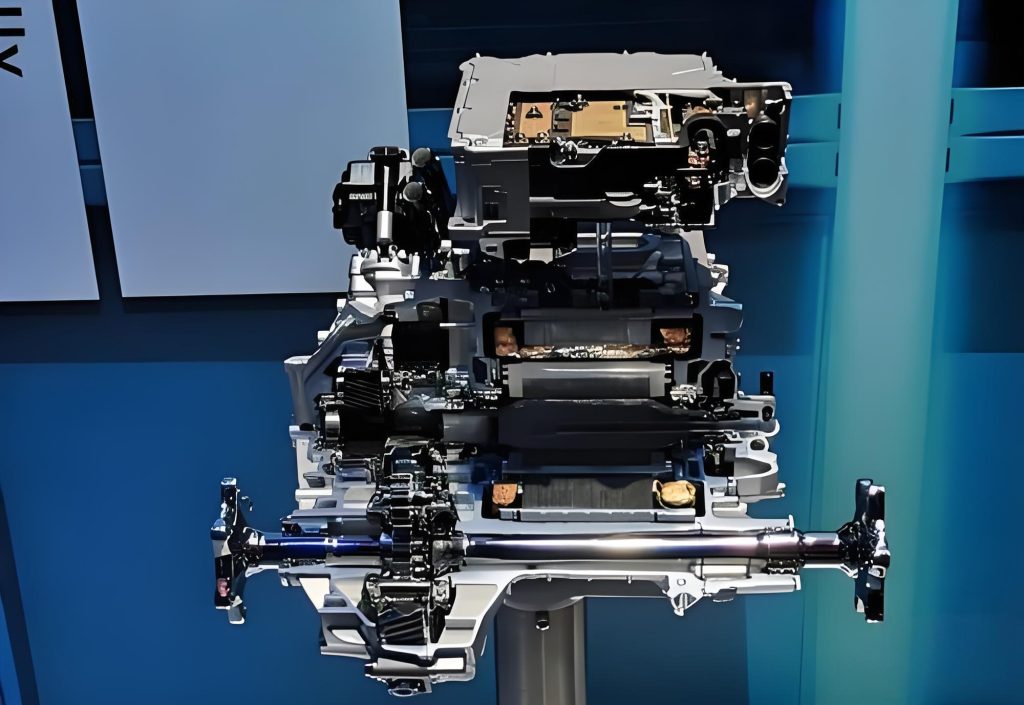

Case 2 – EV Motor Punch

-

Client: US EV Tier-1

-

Problem: 0.35 mm silicon-steel sticking at 400 °C

-

Stack: 1.8 µm CrAlON + 50 nm a-C:H

-

Result: Tool life 4× longer, scrap −40 %.

Case 3 – Surgical Staple

-

Client: US MedTech startup

-

Need: Low-friction 316L piercing

-

Stack: 300 nm ta-C + 30 nm Cr adhesion

-

Result: Penetration force −25 %, CE mark granted.

5. End-to-End Process – From CAD to Coated Part

The end-to-end process outlined here demonstrates how high-performance PVD coatings are integrated into the manufacturing workflow. This comprehensive approach ensures that all aspects, from design to quality assurance, are handled with precision.

| Stage | Actions | KPIs | Lead Time |

|---|---|---|---|

| 1 | Design Review | CAD + CFD + DOE | 24 h |

| 2 | Prototype | 1-10 pcs | 48 h |

| 3 | Validation | CT, CMM, salt-spray | 5 days |

| 4 | Scale-Up | SPC, poka-yoke | 2 days |

| 5 | Production | 24/7 lights-out | 7–10 days |

| 6 | QA | Calot, CpK ≥1.67 | 12 h |

6. Compliance & Sustainability

Compliance and sustainability are becoming increasingly important in today’s market. High-performance PVD coatings not only meet stringent industry standards but also contribute to reducing environmental impact through efficient energy use and waste management.

-

ISO 9001:2015 / IATF 16949 / ISO 13485

-

REACH, RoHS, FDA

-

Energy: 0.45 kWh per m²

-

Waste: Zero liquid effluent

7. FAQs for Engineers

A: Yes—metallised PEEK, PEKK, LCP.

A: 800 mm Ø × 1200 mm L.

A: 1 piece.

8. How to Start Your Project

Starting a project with high-performance PVD coatings involves clear communication of requirements and expectations. By defining substrate materials, dimensions, and performance goals upfront, manufacturers can streamline the coating process and achieve better results.

-

Email [email protected] with STEP/IGES.

-

Specify substrate, load, temperature, thickness budget.

-

Receive DFM + coating stack + quote within 48 h.

-

Approve → 3-day prototype → volume ramp.

Contact JLY Precision Tech—the premier partner in high-performance PVD coatings that brings innovation and precision to your projects.