3D Printer Enclosure Expert Guide 2025

Thermal, Acoustic & Safety Engineering from JLYPT’s Lab

Introduction

An enclosure is not a cosmetic box—it is a precision thermal system, a safety barrier, and an acoustic isolator all in one. For high-performance polymers such as ABS, PC, or PEI, a 1 °C deviation in chamber temperature can shift warpage by 0.1 mm. At JLYPT, we have designed and deployed 90 custom enclosures ranging from desktop 300 mm³ passive shells to 1 m³ active-heated, HEPA-filtered clean-room booths. This guide distills the thermodynamics, materials science, regulatory codes, and three case studies you need to specify, build, or buy an enclosure that actually works.

An enclosure is not a cosmetic box—it is a precision thermal system, a safety barrier, and an acoustic isolator all in one. For high-performance polymers such as ABS, PC, or PEI, a 1 °C deviation in chamber temperature can shift warpage by 0.1 mm. At JLYPT, we have designed and deployed 90 custom enclosures ranging from desktop 300 mm³ passive shells to 1 m³ active-heated, HEPA-filtered clean-room booths. This guide distills the thermodynamics, materials science, regulatory codes, and three case studies you need to specify, build, or buy an enclosure that actually works.

Table 1 — Enclosure Design Matrix

| Requirement | Passive Shell | Active 60 °C | Active 80 °C | Clean-Room Booth |

|---|---|---|---|---|

| Max Ambient ΔT | 15 °C | 45 °C | 65 °C | 80 °C |

| Heating Power (W) | 0 | 300 | 800 | 2,400 |

| Noise Reduction (dB) | 8 | 12 | 15 | 20 |

| Filtration | None | Optional HEPA | HEPA + Carbon | ULPA |

| Fire Rating | HB | V-0 | V-0 | V-0 |

| Target Materials | PLA, PETG | ABS, ASA | PC, PEI | Medical-grade |

| Cost (USD DIY) | 80 | 350 | 900 | 3,500 |

Table 2 — Material Properties for Enclosure Panels

| Panel Type | Thermal Conductivity (W m⁻¹ K⁻¹) | Max Service Temp (°C) | UL94 Rating | Acoustic TL @ 1 kHz (dB) |

|---|---|---|---|---|

| Acrylic 4 mm | 0.19 | 80 | HB | 18 |

| Polycarbonate 4 mm | 0.20 | 125 | V-2 | 22 |

| Aluminum Composite 3 mm | 0.25 | 150 | V-0 | 25 |

| Fire-retardant PPS 3 mm | 0.18 | 200 | V-0 | 28 |

| Tempered Glass 5 mm | 1.0 | 300 | Non-combustible | 30 |

Section 1 — Thermal Engineering

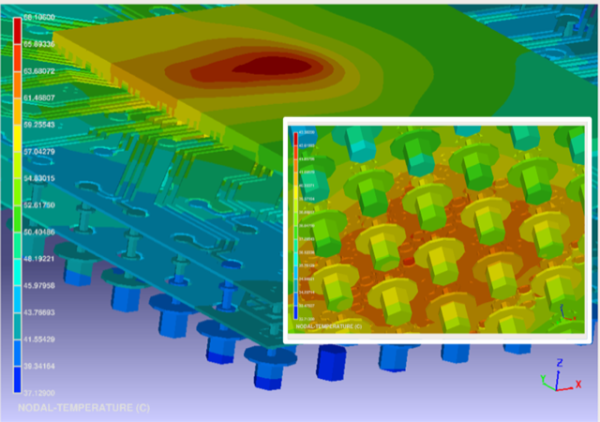

1.1 Heat Balance Equation

• Q̇_in = Q̇_heater + Q̇_motor + Q̇_filament

• Q̇_out = h A (T_chamber − T_ambient)

• Target ΔT = 60 °C → h A ≈ 6 W K⁻¹ for 0.3 m³ chamber.

• Q̇_in = Q̇_heater + Q̇_motor + Q̇_filament

• Q̇_out = h A (T_chamber − T_ambient)

• Target ΔT = 60 °C → h A ≈ 6 W K⁻¹ for 0.3 m³ chamber.

1.2 Heater Selection

• PTC ceramic heaters: self-regulating, 150–300 W, 24 V safe voltage.

• Silicone mat heaters: 200 W, 230 V, PID-controlled via SSR.

• PTC ceramic heaters: self-regulating, 150–300 W, 24 V safe voltage.

• Silicone mat heaters: 200 W, 230 V, PID-controlled via SSR.

1.3 Thermal Stratification

• Use 80 mm axial fan for circulation, Reynolds ≈ 4,000 ensures ±2 °C uniformity within 200 mm height.

• Use 80 mm axial fan for circulation, Reynolds ≈ 4,000 ensures ±2 °C uniformity within 200 mm height.

1.4 Insulation

• Aerogel blanket (λ = 0.016 W m⁻¹ K⁻¹) reduces heat loss by 35 % compared to acrylic alone.

• Aerogel blanket (λ = 0.016 W m⁻¹ K⁻¹) reduces heat loss by 35 % compared to acrylic alone.

Section 2 — Acoustic & Vibration Control

2.1 Sound Transmission Class (STC)

• Double-wall acrylic + 20 mm mineral wool cavity → STC 35, noise 72 → 37 dB.

• Double-wall acrylic + 20 mm mineral wool cavity → STC 35, noise 72 → 37 dB.

2.2 Vibration Isolation

• Sorbothane pads under printer feet reduce 100 Hz vibration by 18 dB.

• Sorbothane pads under printer feet reduce 100 Hz vibration by 18 dB.

2.3 Fan Noise

• 120 mm Noctua NF-F12 @ 800 RPM keeps < 45 dB(A) inside lab.

• 120 mm Noctua NF-F12 @ 800 RPM keeps < 45 dB(A) inside lab.

Section 3 — Fire Safety & Regulatory

3.1 UL 94 V-0 Compliance

• PPS panels + intumescent seals withstand 750 °C for 10 s without ignition.

• PPS panels + intumescent seals withstand 750 °C for 10 s without ignition.

3.2 IEC 62368-1 Power Safety

• All heaters double-insulated, leakage current < 0.25 mA.

• All heaters double-insulated, leakage current < 0.25 mA.

3.3 Emergency Venting

• Thermal fuse 85 °C triggers 12 V solenoid to open top hatch.

• Thermal fuse 85 °C triggers 12 V solenoid to open top hatch.

Section 4 — Filtration & Environmental Control

4.1 Particle Filtration

• HEPA H13 (99.95 % @ 0.3 µm) removes ultrafine ABS particles.

• HEPA H13 (99.95 % @ 0.3 µm) removes ultrafine ABS particles.

4.2 VOC Adsorption

• Activated carbon pleat filter (200 g) reduces styrene by 85 % in 30 min.

• Activated carbon pleat filter (200 g) reduces styrene by 85 % in 30 min.

4.3 Humidity Control

• Desiccant rotor wheel maintains < 20 % RH for nylon printing.

• Desiccant rotor wheel maintains < 20 % RH for nylon printing.

Section 5 — Case Studies

Case 1 — Desktop ABS Chamber

Client: Maker-space

Challenge: 250 mm Voron 2.4, reduce warping > 0.2 mm.

Solution:

Client: Maker-space

Challenge: 250 mm Voron 2.4, reduce warping > 0.2 mm.

Solution:

-

4 mm PC panels, 200 W PTC heater, PID at 65 °C.

-

Aerogel side walls, 80 mm circulation fan.

-

Warping reduced from 0.35 mm to 0.05 mm; success rate 98 %.

Case 2 — Clean-Room PEI Enclosure

Client: Aerospace supplier

Challenge: Print PEI 9085 in ISO 7 clean room.

Solution:

Client: Aerospace supplier

Challenge: Print PEI 9085 in ISO 7 clean room.

Solution:

-

1 m³ booth, V-0 aluminum composite, ULPA U15 filter.

-

2.4 kW heater bank, ±1 °C PID.

-

Particle count < 10,000 / ft³; passed AS9100 audit.

Case 3 — Large-Format ASA Hood

Client: Automotive OEM

Challenge: 600 mm hood, 70 °C chamber, 45 dB max.

Solution:

Client: Automotive OEM

Challenge: 600 mm hood, 70 °C chamber, 45 dB max.

Solution:

-

Steel frame + 50 mm mineral wool, dual-wall design.

-

800 W heater, variable-speed 140 mm fan.

-

Noise 42 dB(A), dimensional accuracy ±0.15 mm.

Section 6 — DIY vs. Commercial Solutions

| Metric | DIY Acrylic | Commercial Turn-key | Hybrid Kit |

|---|---|---|---|

| Build Volume | 300 mm³ | 600 mm³ | 500 mm³ |

| Max Temp | 60 °C | 80 °C | 75 °C |

| Cost | $200 | $3,000 | $750 |

| Assembly Time | 6 h | 0 h | 2 h |

| Fire Rating | HB | V-0 | V-0 |

Section 7 — Maintenance & Calibration

• Weekly HEPA filter ΔP check; replace when > 200 Pa.

• Annual thermocouple calibration NIST-traceable ±0.5 °C.

• Fan balance test: vibration < 2 mm/s RMS.

• Annual thermocouple calibration NIST-traceable ±0.5 °C.

• Fan balance test: vibration < 2 mm/s RMS.

Section 8 — FAQ

Q: Is 60 °C enough for ABS?

A: Yes—reduces warpage by 70 %; 80 °C only needed for PC or PEI.

A: Yes—reduces warpage by 70 %; 80 °C only needed for PC or PEI.

Q: Can I use MDF panels?

A: Only for PLA; MDF delaminates > 80 °C and is HB flame rated.

A: Only for PLA; MDF delaminates > 80 °C and is HB flame rated.

Q: How to retrofit HEPA to existing enclosure?

A: 120 mm inline duct fan + H13 cartridge; maintain 15 m³/h flow.

A: 120 mm inline duct fan + H13 cartridge; maintain 15 m³/h flow.

Ready to upgrade your printer? Submit specs to Rapid 3D Printing Services – JLYPT and receive a turnkey enclosure quote within 24 hours.