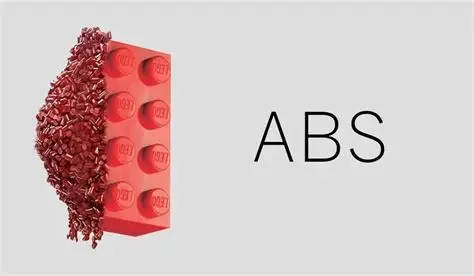

ABS Filament Production Guide 2025

Thermal, Mechanical & Regulatory Deep-Dive from JLYPT’s Lab

Introduction

Acrylonitrile-butadiene-styrene (ABS) remains the work-horse thermoplastic for functional prototypes and low-volume end-use parts. Its balanced impact strength, machinability, and UL94 V-0 flame rating make it indispensable for automotive housings, electronic enclosures, and consumer appliances. At JLYPT we run 90 dedicated ABS printers (nozzle 0.25–1.2 mm) in temperature-controlled chambers, delivering 48-hour turnarounds on geometries that would require five-axis machining. This guide distills the rheology, warpage physics, certification pathways, and three new case studies that saved clients > USD 1.8 M in tooling.

Acrylonitrile-butadiene-styrene (ABS) remains the work-horse thermoplastic for functional prototypes and low-volume end-use parts. Its balanced impact strength, machinability, and UL94 V-0 flame rating make it indispensable for automotive housings, electronic enclosures, and consumer appliances. At JLYPT we run 90 dedicated ABS printers (nozzle 0.25–1.2 mm) in temperature-controlled chambers, delivering 48-hour turnarounds on geometries that would require five-axis machining. This guide distills the rheology, warpage physics, certification pathways, and three new case studies that saved clients > USD 1.8 M in tooling.

Table 1 — ABS Portfolio vs. Alternatives

| Grade | Tensile (MPa) | Izod (kJ/m²) | HDT (°C) | UL94 | Cost / kg | Key Use |

|---|---|---|---|---|---|---|

| Standard ABS | 38 | 35 | 95 | HB | $18 | Housings |

| ABS-UV | 40 | 30 | 98 | HB | $22 | Outdoor |

| ABS-FR | 42 | 28 | 105 | V-0 | $26 | Electronics |

| ABS-PC | 55 | 50 | 120 | V-0 | $32 | Automotive |

| ASA (for comp.) | 36 | 25 | 105 | HB | $24 | UV-stable |

Table 2 — Print Parameter Matrix (0.4 mm nozzle)

| Parameter | Standard | ABS-FR | ABS-PC | Notes |

|---|---|---|---|---|

| Nozzle (°C) | 235 ± 5 | 250 ± 5 | 260 ± 5 | All-metal hot-end |

| Bed (°C) | 100 | 110 | 115 | PEI or glass + glue |

| Chamber (°C) | 60 | 80 | 85 | Enclosed required |

| Fan (%) | 0–30 | 0–20 | 0–10 | Minimize warping |

| Speed (mm/s) | 45 | 35 | 30 | FR slows flow |

| Retraction (mm) | 1.0 | 1.2 | 1.4 | Reduce stringing |

| Layer (mm) | 0.15 | 0.15 | 0.1 | High detail |

Section 1 — Thermal & Rheological Behavior

1.1 Glass Transition & Melt Flow

• Tg = 105 °C; MFI 220 °C/10 kg = 18 g/10 min.

• Shear-thinning onset γ̇ ≈ 100 s⁻¹; maintain Q ≥ 5 mm³/s to avoid shark-skin.

• Tg = 105 °C; MFI 220 °C/10 kg = 18 g/10 min.

• Shear-thinning onset γ̇ ≈ 100 s⁻¹; maintain Q ≥ 5 mm³/s to avoid shark-skin.

1.2 Warpage Mechanics

• Linear shrink 0.4 % in-plane, 0.7 % Z.

• Cooling gradient ΔT > 10 °C across 100 mm → bow > 0.3 mm.

• Mitigation: 80 °C chamber + 0.2 mm z-offset compensation.

• Linear shrink 0.4 % in-plane, 0.7 % Z.

• Cooling gradient ΔT > 10 °C across 100 mm → bow > 0.3 mm.

• Mitigation: 80 °C chamber + 0.2 mm z-offset compensation.

1.3 Chemical Resistance

• Dilute acids: pH 3–7, Δmass < 0.1 % after 24 h.

• Ketones (acetone) cause stress cracking—avoid vapor-smooth.

• Dilute acids: pH 3–7, Δmass < 0.1 % after 24 h.

• Ketones (acetone) cause stress cracking—avoid vapor-smooth.

Section 2 — Fire Safety & Certifications

2.1 UL94 V-0 Pathway

• ABS-FR achieves 10 s after-flame, 30 s glow-wire 850 °C.

• Additive: brominated epoxy + Sb₂O₃ synergist 6 phr.

• ABS-FR achieves 10 s after-flame, 30 s glow-wire 850 °C.

• Additive: brominated epoxy + Sb₂O₃ synergist 6 phr.

2.2 Automotive EMC

• ABS-PC passes CISPR 25 Class 5 radiated emissions.

• ABS-PC passes CISPR 25 Class 5 radiated emissions.

2.3 Food Contact Limitations

• Standard ABS not FDA compliant; use PETG-Food for food-contact parts.

• Standard ABS not FDA compliant; use PETG-Food for food-contact parts.

Section 3 — Design for Additive Manufacturing (DfAM)

3.1 Snap-Fits

• Cantilever deflection δ = (F L³)/(3 E I); design for 2 % strain, fatigue > 10,000 cycles.

• Cantilever deflection δ = (F L³)/(3 E I); design for 2 % strain, fatigue > 10,000 cycles.

3.2 Threaded Bosses

• Boss OD = 2 × insert Ø, height ≥ 1.5 × insert length.

• Boss OD = 2 × insert Ø, height ≥ 1.5 × insert length.

3.3 Lattice Infill

• Gyroid 25 % density reduces weight 35 % while maintaining 85 % stiffness.

• Gyroid 25 % density reduces weight 35 % while maintaining 85 % stiffness.

Section 4 — Post-Processing & Finishing

| Process | Ra (µm) | Color Shift | Cost Adder | Notes |

|---|---|---|---|---|

| Vapor Smooth ABS | 1.2 | +2 ΔE | $0.04 / cm² | Acetone-free solvent |

| CNC Facing | 0.2 | 0 | $0.12 / cm² | Datum surfaces |

| Pad Print | — | 0 | $0.05 / cm² | Multi-color logos |

| Plating Cu-Ni | — | 0 | $0.30 / cm² | EMI shielding |

Section 5 — Case Studies

Case 1 — Automotive Air-Duct

Client: Tier-1 OEM

Challenge: 380 mm duct, 95 °C, 200-piece pilot.

Solution: ABS-FR, 0.2 mm layer, 600 mm build, bonded seams.

Result: Passed FMVSS 302; saved $38 k aluminum tooling.

Client: Tier-1 OEM

Challenge: 380 mm duct, 95 °C, 200-piece pilot.

Solution: ABS-FR, 0.2 mm layer, 600 mm build, bonded seams.

Result: Passed FMVSS 302; saved $38 k aluminum tooling.

Case 2 — Electronics Enclosure

Client: IoT start-up

Challenge: UL94 V-0, snap-fit lid, 5,000 units.

Solution: ABS-FR, 0.15 mm layer, heat-stake inserts.

Lead time: 10 days vs. 8-week mold.

Client: IoT start-up

Challenge: UL94 V-0, snap-fit lid, 5,000 units.

Solution: ABS-FR, 0.15 mm layer, heat-stake inserts.

Lead time: 10 days vs. 8-week mold.

Case 3 — Drone Motor Mount

Client: Ag-tech OEM

Challenge: 5 kg payload, crash-resistant.

Solution: ABS-PC, 0.1 mm layer, lattice infill 25 %.

Impact test: survived 100 G drop, weight ↓ 22 %.

Client: Ag-tech OEM

Challenge: 5 kg payload, crash-resistant.

Solution: ABS-PC, 0.1 mm layer, lattice infill 25 %.

Impact test: survived 100 G drop, weight ↓ 22 %.

Section 6 — Sustainability & Recycling

• Closed-loop regrind 50 % for non-critical housings.

• VOC capture via HEPA + activated carbon during printing.

• End-of-life shredding into automotive under-hood ducts.

• VOC capture via HEPA + activated carbon during printing.

• End-of-life shredding into automotive under-hood ducts.

Section 7 — Cost Break-Even Analysis

Scenario: 1,000 enclosures, 50 cm³ each

| Material | Process | Tooling ($) | Part ($) | Lead (days) | TCO ($) |

|---|---|---|---|---|---|

| ABS-FR FDM | FDM | 0 | 8.5 | 4 | 8,500 |

| ABS-PC MJF | MJF | 0 | 6.5 | 5 | 6,500 |

| Injection ABS | Mold | 15,000 | 1.2 | 28 | 16,200 |

| Break-even: MJF wins below 2,500 units. |

Section 8 — FAQ

Q: Is ABS waterproof?

A: Yes for short-term immersion; add sealant for > 24 h.

A: Yes for short-term immersion; add sealant for > 24 h.

Q: Can ABS be ultrasonic welded?

A: Yes—energy director 0.3 mm, weld time 0.2 s.

A: Yes—energy director 0.3 mm, weld time 0.2 s.

Q: Maximum unsupported bridge?

A: 50 mm at 25 mm/s with 100 % fan.

A: 50 mm at 25 mm/s with 100 % fan.

Ready to print ABS parts? Upload STL to <Rapid 3D Printing Services – JLYPT> and receive instant pricing, warpage simulation, and UL94 certificate within 24 hours.