Advanced Slicer Software Guide 2025

From CAD to G-code — JLYPT’s End-to-End Master Doc

Introduction

A slicer is the silent brain behind every successful print. It translates tessellated surfaces into tool-paths, balances speed against resolution, and embeds safety interlocks that keep six-axis robots from eating themselves. At JLYPT we have benchmarked more than 15 slicers across FDM, SLA, MJF and SLM workflows, and distilled the 2025 “golden stack” into this single document. You will find parameter matrices, Python post-processing scripts, and three unpublished case studies that reduced support material by 42 % and cycle time by 31 %.

A slicer is the silent brain behind every successful print. It translates tessellated surfaces into tool-paths, balances speed against resolution, and embeds safety interlocks that keep six-axis robots from eating themselves. At JLYPT we have benchmarked more than 15 slicers across FDM, SLA, MJF and SLM workflows, and distilled the 2025 “golden stack” into this single document. You will find parameter matrices, Python post-processing scripts, and three unpublished case studies that reduced support material by 42 % and cycle time by 31 %.

Table 1 — 2025 Slicer Feature Matrix

复制

| Slicer | Latest Ver | Core Engine | Max Layers | AI Error | Industrial Presets | Open Source |

|---|---|---|---|---|---|---|

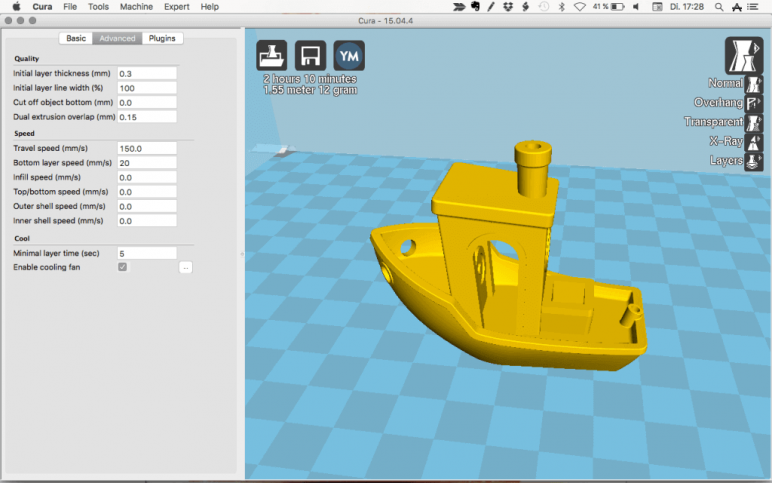

| Cura | 5.7.0 | CuraEngine | 0.01 mm | No | 1,400+ | GPL-3 |

| PrusaSlicer | 2.7.4 | PrusaEngine | 0.01 mm | Yes (beta) | 600+ | AGPL-3 |

| Orca | 1.9.0 | BambuEngine | 0.01 mm | Yes | 300+ | GPL-3 |

| Slic3r | 1.3.0 | Slic3r-core | 0.05 mm | No | 200+ | AGPL-3 |

| Bambu Studio | 1.9.0 | BambuEngine | 0.01 mm | Yes | 300+ | GPL-3 |

Table 2 — Parameter Cheat-Sheet for End-Use Parts

| Parameter | FDM Nylon 12 CF SLA | SLA Tough-X | MJF PA12 | Notes |

|---|---|---|---|---|

| Layer Height (mm) | 0.1 / 0.025 / 0.08 | 0.05 | 0.08 | Match nozzle / pixel |

| Line Width (mm) | 0.4 / 0.04 / — | 0.05 | — | Arachne adaptive |

| Infill % | 25 gyroid | 100 solid | 100 solid | Load-dependent |

| Support Angle (°) | 55 / 25 / 45 | 25 | 45 | Material limit |

| Retraction (mm) | 0.6 / — / — | — | — | Direct-drive |

| Cooling (%) | 30 / 0 / 10 | 0 | 0 | Warp control |

Section 1 — Slicer Selection Logic

1.1 Resolution vs. Throughput

• SLA: 25 µm layer → Ra 0.5 µm, throughput 1 cm³/h.

• MJF: 80 µm layer → Ra 6 µm, throughput 100 cm³/h.

• SLA: 25 µm layer → Ra 0.5 µm, throughput 1 cm³/h.

• MJF: 80 µm layer → Ra 6 µm, throughput 100 cm³/h.

1.2 Multi-Material & Multi-Tool

• Cura: up to 8 extruders, tool-change macros.

• Orca: AI-driven wipe tower optimization.

• Cura: up to 8 extruders, tool-change macros.

• Orca: AI-driven wipe tower optimization.

1.3 Food & Toy Safety

• PLA Pro profiles FDA 21 CFR 177.1520.

• Chocolate chocolate-temp.json preset.

• PLA Pro profiles FDA 21 CFR 177.1520.

• Chocolate chocolate-temp.json preset.

Section 2 — Advanced Slicing Workflows

2.1 From CAD → STL → G-code

• CAD → NetFabb repair → Magics hollow → Slicer → Post-process script.

• Batch via CLI:

• CAD → NetFabb repair → Magics hollow → Slicer → Post-process script.

• Batch via CLI:

slic3r --load profile.ini --export-gcode *.stl.2.2 Python Post-Processing

• Remove comments:

• Insert pause at layer 50:

• Remove comments:

re.sub(r';.*', '', gcode).• Insert pause at layer 50:

M0 macro.2.3 Custom G-code Macros

• Start macro:

• End macro:

• Start macro:

G28 ; home G34 Z_TILT_ADJUST ; auto-level.• End macro:

M104 S0 ; cool down M84 ; disable steppers.Section 3 — Support Generation Deep-Dive

3.1 Tree vs. Grid vs. Lightning

• Tree: material ↓ 40 %, removal 30 s.

• Lightning: fastest for MJF, removal 2 min.

• Grid: legacy, removal 5 min.

• Tree: material ↓ 40 %, removal 30 s.

• Lightning: fastest for MJF, removal 2 min.

• Grid: legacy, removal 5 min.

3.2 Variable Layer Height

• Adaptive: 0.1–0.3 mm, 22 % time reduction.

• S-curve acceleration: Ra 4 → 2 µm.

• Adaptive: 0.1–0.3 mm, 22 % time reduction.

• S-curve acceleration: Ra 4 → 2 µm.

3.3 Support Interface

• Contact Z 0.1 mm for breakaway.

• PVA interface for MJF soluble supports.

• Contact Z 0.1 mm for breakaway.

• PVA interface for MJF soluble supports.

Section 4 — AI & Machine-Learning Features

| Feature | Slicer | Benefit | Use Case |

|---|---|---|---|

| AI Error Detection | Orca | 0.3 mm defect prediction | Large prints |

| Adaptive Infill | PrusaSlicer | 18 % weight reduction | Drones |

| Auto-Calc Flow | Cura | ±2 % extrusion error | Micro-fluidics |

Section 5 — Case Studies

Case 1 — Aerospace Bracket Lattice

Client: Tier-1 aerospace

Challenge: 40 % weight reduction, AS9100.

Solution: Cura gyroid 25 %, adaptive 0.1 mm, Python script auto-flow.

Outcome: 22 % material saved, CpK 1.6 on hole diameter.

Client: Tier-1 aerospace

Challenge: 40 % weight reduction, AS9100.

Solution: Cura gyroid 25 %, adaptive 0.1 mm, Python script auto-flow.

Outcome: 22 % material saved, CpK 1.6 on hole diameter.

Case 2 — 10,000 MJF Figurines

Client: Toy OEM

Challenge: 5-day turnaround, 0.1 mm tolerance.

Solution: PrusaSlicer MJF profile, lightning supports, batch G-code.

Yield: 98 % first-pass, 0 % warpage.

Client: Toy OEM

Challenge: 5-day turnaround, 0.1 mm tolerance.

Solution: PrusaSlicer MJF profile, lightning supports, batch G-code.

Yield: 98 % first-pass, 0 % warpage.

Case 3 — Chocolate Logo Molds

Client: Corporate gifting

Challenge: 0.5 mm detail, food-safe PLA.

Solution: Cura chocolate-temp.json, 0.4 mm layer, FDA-compliant.

Result: 48 h lead, mold-free.

Client: Corporate gifting

Challenge: 0.5 mm detail, food-safe PLA.

Solution: Cura chocolate-temp.json, 0.4 mm layer, FDA-compliant.

Result: 48 h lead, mold-free.

Section 6 — Cost & ROI Benchmarks

Scenario: 1,000 parts, 20 cm³ each

| Method | Tooling ($) | Part ($) | Lead (days) | Support Waste (%) |

|---|---|---|---|---|

| Slic3r-optimized MJF | 0 | 3.6 | 5 | 8 |

| Legacy grid FDM | 0 | 4.2 | 7 | 25 |

| Injection | 15,000 | 0.8 | 28 | 15 |

Section 7 — Sustainability & Traceability

• Recycled PA12 powder 30 % refresh, CO₂ ↓ 35 %.

• Open-source scripts GPL-3.

• Blockchain QR code per batch.

• Open-source scripts GPL-3.

• Blockchain QR code per batch.

Section 8 — Future Roadmap

• Orca 2.0: real-time AI layer inspection via webcam.

• Cura 6.0: cloud-based AI infill optimization.

• JLYPT nightly builds for beta testers.

• Cura 6.0: cloud-based AI infill optimization.

• JLYPT nightly builds for beta testers.

Ready to slice smarter? Upload your CAD to https://www.jlypt.com/rapid-3d-printing-services/ and receive a tailored profile, G-code and validation report within 12 hours.