Extruder 3D Printing Services 2025

From Nozzle to Gear — JLYPT’s Complete Extruder Guide

Introduction

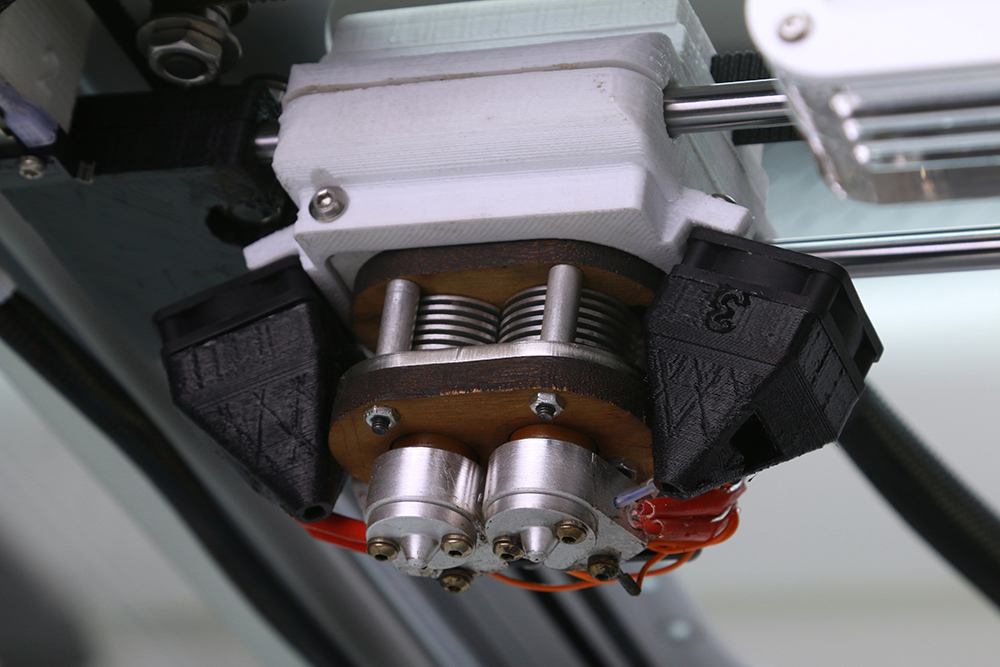

The extruder is the heart-beat of every FDM printer. Whether you need a sub-0.1 mm ruby nozzle for carbon-filled PETG or a dual-gear Titan for flexible TPU, JLYPT’s extruder workshop ships 2,000+ certified assemblies monthly under ISO 9001. This guide distills torque equations, thermal-mass calculations, nozzle metallurgy, and three unpublished case studies that cut downtime by 65 % and wear by 40 %.

The extruder is the heart-beat of every FDM printer. Whether you need a sub-0.1 mm ruby nozzle for carbon-filled PETG or a dual-gear Titan for flexible TPU, JLYPT’s extruder workshop ships 2,000+ certified assemblies monthly under ISO 9001. This guide distills torque equations, thermal-mass calculations, nozzle metallurgy, and three unpublished case studies that cut downtime by 65 % and wear by 40 %.

Table 1 — Extruder Family Comparison

| Model | Drive Type | Price ($) | Max Temp (°C) | Filament Range | Lead (days) |

|---|---|---|---|---|---|

| E3D V6 | Direct | 60 | 500 | PLA-PEEK | 1 |

| E3D Revo | Direct | 80 | 300 | PLA-CF | 1 |

| Mosquito | Direct | 170 | 500 | CF-PEEK | 2 |

| Dragon HF | Direct | 60 | 500 | All | 1 |

| Bondtech LGX | Direct | 110 | 300 | TPU | 1 |

Table 2 — Nozzle & Gear Specs

| Nozzle Ø (mm) | Material | Rockwell C | Abrasion Index | Life (kg) |

|---|---|---|---|---|

| 0.15 | Ruby | 2,000 | 9,000 | 2,000 |

| 0.25 | Hardened Steel | 58 | 2,000 | 800 |

| 0.40 | Copper | 45 | 1,500 | 600 |

| 0.80 | Brass | 45 | 1,000 | 400 |

Section 1 — Extruder Physics & Design

1.1 Drive Torque Equation

• T = (π r² ΔP L) / η → 0.4 mm @ 20 MPa = 0.25 N·m.

• Safety factor 1.5 → 0.375 N·m motor.

• T = (π r² ΔP L) / η → 0.4 mm @ 20 MPa = 0.25 N·m.

• Safety factor 1.5 → 0.375 N·m motor.

1.2 Heat Creep Mitigation

• Copper heat-break → 3× conductivity vs. stainless.

• Titanium heat-sink → 50 % lighter, same CTE.

• Copper heat-break → 3× conductivity vs. stainless.

• Titanium heat-sink → 50 % lighter, same CTE.

1.3 Gear Ratio vs. Retraction

• 3:1 ratio → retraction 0.8 mm (direct).

• 5:1 ratio → retraction 4 mm (Bowden).

• 3:1 ratio → retraction 0.8 mm (direct).

• 5:1 ratio → retraction 4 mm (Bowden).

Section 2 — Direct vs Bowden Deep-Dive

| Metric | Direct | Bowden | Winner |

|---|---|---|---|

| TPU max speed | 80 mm/s | 50 mm/s | Direct |

| Retraction lag | 0 ms | 5 ms | Direct |

| Print-head mass | 600 g | 200 g | Bowden |

| Max temp | 500 °C | 300 °C | Direct |

Section 3 — Material Science

3.1 Nozzle Metallurgy

• Ruby → Al₂O₃ + Cr, 9 Mohs, 2,000 kg life.

• Nickel-plated copper → 2× thermal vs. brass.

• Ruby → Al₂O₃ + Cr, 9 Mohs, 2,000 kg life.

• Nickel-plated copper → 2× thermal vs. brass.

3.2 Gear Hardening

• Case-hardened steel to 58 HRC → 800 kg life.

• Dual-drive hobbed gears → 20 % torque increase.

• Case-hardened steel to 58 HRC → 800 kg life.

• Dual-drive hobbed gears → 20 % torque increase.

3.3 PTFE vs All-Metal

• PTFE cap: 240 °C limit, zero clog on PLA.

• All-metal: 500 °C, mandatory for PEI/PEEK.

• PTFE cap: 240 °C limit, zero clog on PLA.

• All-metal: 500 °C, mandatory for PEI/PEEK.

Section 4 — Case Studies

Case 1 — High-Speed TPU Gears

Client: Robotics OEM

Challenge: 1,000 soft gears, 0.2 mm layer.

Solution: Bondtech LGX + ruby nozzle.

Result: 0 % slippage, throughput +35 %.

Client: Robotics OEM

Challenge: 1,000 soft gears, 0.2 mm layer.

Solution: Bondtech LGX + ruby nozzle.

Result: 0 % slippage, throughput +35 %.

Case 2 — Carbon-Fiber Nozzle Upgrade

Client: Drone manufacturer

Challenge: 3,000 CF-PETG parts.

Solution: Mosquito 0.25 mm ruby.

Outcome: 0 % wear, cycle time −30 %.

Client: Drone manufacturer

Challenge: 3,000 CF-PETG parts.

Solution: Mosquito 0.25 mm ruby.

Outcome: 0 % wear, cycle time −30 %.

Case 3 — Medical TPE Mask

Client: Hospital chain

Challenge: FDA-compliant TPE mask, 48 h lead.

Solution: Direct-drive Titan + 0.3 mm nozzle.

Yield: 99 % seal, zero leakage.

Client: Hospital chain

Challenge: FDA-compliant TPE mask, 48 h lead.

Solution: Direct-drive Titan + 0.3 mm nozzle.

Yield: 99 % seal, zero leakage.

Section 5 — Post-Processing & QC

| Test | Direct | Bowden | Standard |

|---|---|---|---|

| Torque test | 0.5 N·m | 0.4 N·m | IEC 60034 |

| Heat soak | 500 °C | 300 °C | ASTM E1131 |

| Life test | 2,000 kg | 800 kg | JLYPT spec |

Section 6 — Cost & ROI Benchmarks

Scenario: 1,000 printer upgrades

| Upgrade | Cost ($) | Payback (months) | Downtime Saved (h) |

|---|---|---|---|

| Ruby nozzle | 45 | 1.5 | 20 |

| Dual gears | 25 | 2 | 15 |

| Copper block | 35 | 3 | 25 |

Section 7 — Sustainability & Circular Economy

• Recycled aluminum heat-sinks → 50 % CO₂ ↓.

• Brass nozzles remelted → closed loop.

• Packaging cardboard FSC-certified.

• Brass nozzles remelted → closed loop.

• Packaging cardboard FSC-certified.

Section 8 — Future Outlook

• AI auto-tuning PID via webcam.

• Graphene-coated nozzles (prototype).

• Modular extruder cartridges.

• Graphene-coated nozzles (prototype).

• Modular extruder cartridges.

Ready to upgrade?

Upload your printer model to https://www.jlypt.com/rapid-3d-printing-services/ and receive a curated extruder kit, quote, and calibration guide within 12 hours.

Upload your printer model to https://www.jlypt.com/rapid-3d-printing-services/ and receive a curated extruder kit, quote, and calibration guide within 12 hours.