The Comprehensive Guide to CNC Turning Services for Prototype Development

Executive Summary

CNC turning services have revolutionized prototype development by enabling rapid production of high-precision cylindrical components with exceptional accuracy and repeatability. This subtractive manufacturing process utilizes computer-controlled lathes to create prototypes that accurately represent final production parts in terms of dimensional accuracy, material properties, and functional performance. CNC turning is particularly valuable for producing prototypes of rotational symmetric parts, complex cylindrical geometries, and components requiring precise axial features. This comprehensive guide explores the technical capabilities, materials, applications, and strategic advantages of CNC turning services for prototype development across industries including automotive, aerospace, medical devices, and consumer electronics. By leveraging advanced CNC turning technologies, manufacturers can significantly reduce product development cycles, validate designs with functional prototypes, and accelerate time-to-market while maintaining the highest quality standards.

1 Introduction to CNC Turning for Prototyping

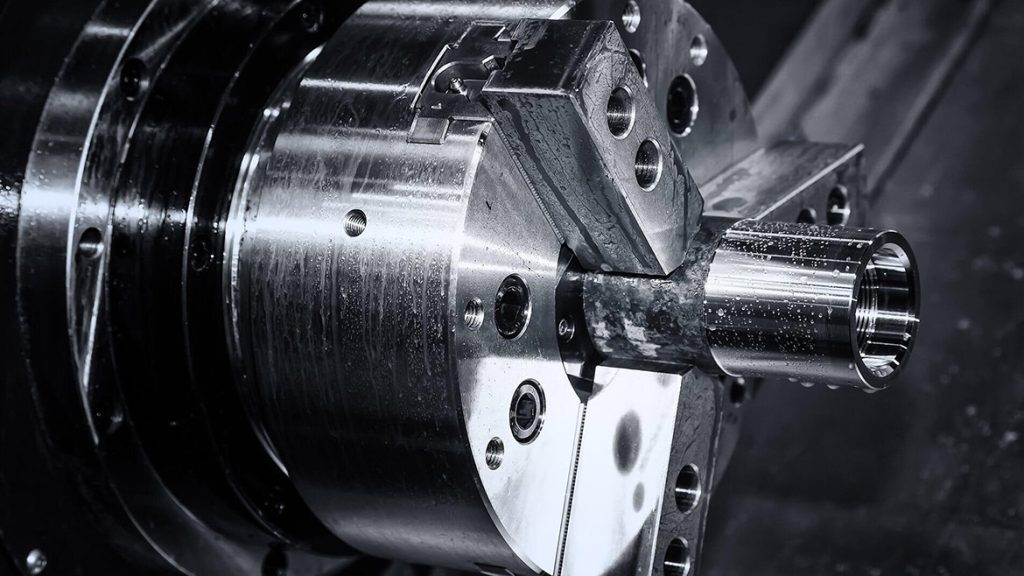

CNC turning represents a fundamental manufacturing process in prototype development, specializing in the production of rotationally symmetric components through the precise removal of material from a rotating workpiece. Unlike additive manufacturing methods that build parts layer by layer, CNC turning creates prototypes by subtracting material using stationary cutting tools, resulting in superior surface finishes, dimensional stability, and mechanical properties that closely mimic production components. The process involves securing material in a collet or chuck that rotates at high speeds while computer-controlled tools move along multiple axes to shape the material into the desired geometry.

The significance of CNC turning in prototyping lies in its ability to produce functional prototypes that accurately represent final production parts in both form and function. While 3D printing technologies have gained popularity for rapid visual prototyping, CNC turned prototypes provide manufacturing-grade quality that can undergo functional testing, fit checks, and performance validation under real-world conditions. This capability is particularly valuable for components that must withstand structural loads, thermal stresses, or precision interactions with other assembly components.

Modern CNC turning centers have evolved significantly from traditional lathes, incorporating multi-axis capabilities, live tooling, sub-spindles, and automated material handling systems that enable the production of highly complex prototypes in a single setup. These advanced machines can perform not only turning operations but also milling, drilling, tapping, and boring, making them exceptionally versatile for prototype manufacturing. The integration of CAD/CAM systems allows for seamless translation of digital designs into physical prototypes with tolerances reaching ±0.0005 inches (±0.0127 mm) and surface finishes as fine as 8 Ra µin (0.2 Ra µm).

2 Technical Advantages of CNC Turning for Prototypes

CNC turning services offer numerous technical advantages for prototype development that make them indispensable in product design and validation processes:

Material Versatility: CNC turning supports an extensive range of engineering-grade materials including aluminum alloys, stainless steels, brass, copper, titanium, and various engineering plastics. This versatility allows designers to create prototypes using the exact materials specified for production parts, ensuring accurate performance validation and testing results. The ability to machine exotic materials and high-performance alloys makes CNC turning particularly valuable for aerospace, medical, and automotive applications where material properties directly impact functionality.

Superior Surface Finish: Unlike additive manufacturing processes that typically exhibit layered surface textures, CNC turning produces excellent surface finishes directly from the machine, often eliminating the need for secondary operations. Modern CNC lathes can achieve surface finishes as fine as 8 Ra µin (0.2 Ra µm) through optimized cutting parameters, proper tool selection, and advanced tool path strategies. This quality is crucial for prototypes that require aesthetic appeal, fluid dynamic performance, or sealing surface functionality.

Dimensional Accuracy and Repeatability: CNC turning centers provide exceptional dimensional control and repeatability across multiple prototype iterations. With positioning accuracy typically within 0.0001 inches (0.0025 mm) and repeatability of 0.000050 inches (0.00127 mm), turned prototypes can be produced with tolerances that match or exceed final production requirements. This precision ensures that prototype performance accurately predicts production part behavior, reducing the risk of design changes during manufacturing transition.

Rapid Iteration Capabilities: While often perceived as slower than additive methods for single parts, CNC turning actually provides faster turnaround for multiple design iterations due to its high material removal rates and minimal setup requirements between operations. Once the initial programming is complete, producing additional prototype iterations requires only material changes and minor parameter adjustments, enabling rapid design validation and functional testing cycles.

Functional Testing Compatibility: Turned prototypes possess identical material properties to production parts since they’re manufactured from solid material stock rather than built up layer by layer. This integrity allows prototypes to undergo rigorous functional testing, environmental simulation, and life cycle validation that would destroy or deform 3D printed components. The ability to test prototypes under real operating conditions significantly de-risks the product development process.

Table: Comparison of Prototyping Methods for Cylindrical Components

| Parameter | CNC Turning | 3D Printing | Injection Molding | Traditional Machining |

|---|---|---|---|---|

| Dimensional Accuracy | ±0.0005″ (±0.0127mm) | ±0.005″ (±0.127mm) | ±0.002″ (±0.0508mm) | ±0.001″ (±0.0254mm) |

| Surface Finish | 8-125 Ra µin (0.2-3.2 Ra µm) | 125-500 Ra µin (3.2-12.5 Ra µm) | 32-125 Ra µin (0.8-3.2 Ra µm) | 32-250 Ra µin (0.8-6.3 Ra µm) |

| Material Options | Extensive metals & plastics | Limited by technology | Thermoplastics only | Extensive metals & plastics |

| Lead Time | 1-5 days | 1-3 days | 2-4 weeks | 2-3 weeks |

| Cost per Part (Low Vol) | $$ | $ | $$$$ | $$$ |

| Functional Testing | Excellent | Poor | Excellent | Good |

| Maximum Complexity | High | Very High | Moderate | Moderate |

3 Materials Selection for Turned Prototypes

The selection of appropriate materials is critical for successful prototype development through CNC turning. Different materials offer varying mechanical properties, machinability characteristics, and cost considerations that influence their suitability for specific applications:

Aluminum Alloys: Aluminum represents the most commonly used material for turned prototypes due to its excellent machinability, favorable strength-to-weight ratio, and cost-effectiveness. Series 6061 aluminum offers good overall mechanical properties and corrosion resistance, making it suitable for a wide range of prototype applications. Series 7075 provides higher strength for demanding applications, while series 2024 offers excellent fatigue resistance for aerospace components.

Stainless Steels: Various grades of stainless steel provide corrosion resistance, high strength, and durability for prototypes that must withstand harsh environments or significant mechanical stress. Grade 304 offers good general-purpose corrosion resistance, while grade 316 provides superior resistance to chlorides and acids. Precipitation-hardening grades such as 17-4 PH can be heat treated after machining to achieve very high strength levels.

Brass and Copper Alloys: These materials offer excellent electrical conductivity, thermal conductivity, and corrosion resistance, making them ideal for electronic components, plumbing fixtures, and decorative applications. Brass provides superior machinability among metallic materials, often allowing for higher production rates and tighter tolerances. Copper alloys are frequently specified for prototypes requiring electrical or thermal management functionality.

Engineering Plastics: Various plastic materials can be turned on CNC lathes to create prototypes with specific chemical resistance, electrical insulation, or weight reduction requirements. Materials such as PEEK, Delrin (POM), Nylon (PA), and UHMW offer unique combinations of properties that make them suitable for specialized applications across medical, aerospace, and consumer product industries.

Exotic and Specialty Alloys: For extreme applications, materials such as titanium, inconel, monel, and hastelloy can be machined to create prototypes that must withstand elevated temperatures, corrosive environments, or maintain functionality under extreme mechanical stress. While these materials present machining challenges and higher costs, they are essential for aerospace, medical implant, and chemical processing applications.

Table: Material Selection Guide for Turned Prototypes

| Material | Tensile Strength (MPa) | Hardness | Machinability Rating | Best Applications | Surface Finish Quality |

|---|---|---|---|---|---|

| Aluminum 6061 | 125-290 | 65 HB | Excellent (100%) | General purpose, structural | Excellent |

| Stainless 304 | 505-860 | 70-90 HRB | Fair (40%) | Corrosive environments | Very Good |

| Stainless 316 | 515-860 | 70-90 HRB | Fair (35%) | Chemical exposure | Very Good |

| Brass C360 | 340-470 | 65 HRB | Excellent (180%) | Electrical, decorative | Excellent |

| Titanium Grade 2 | 345-550 | 120-200 HB | Poor (25%) | Aerospace, medical | Good |

| PEEK | 90-100 | 85-90 HRR | Good (60%) | High-temp, chemical | Excellent |

| Delrin (POM) | 50-80 | 80-85 HRR | Excellent (150%) | Low friction, precision | Excellent |

| Copper C110 | 220-455 | 40-45 HRB | Fair (20%) | Electrical conductivity | Good |

4 CNC Turning Technologies for Prototyping

Modern CNC turning centers incorporate advanced technologies that significantly enhance their capabilities for prototype manufacturing:

Multi-Axis Turning Centers: Contemporary CNC lathes often feature multiple axes of motion beyond the traditional two-axis configuration. These advanced machines may incorporate Y-axis capability, secondary spindles, and B-axis tool orientation that enable complex machining operations to be completed in a single setup. The elimination of multiple setups reduces cumulative error, improves accuracy, and significantly shortens prototype lead times.

Live Tooling: Motorized live tools transform CNC lathes into sophisticated turning centers capable of performing milling, drilling, tapping, and contouring operations without removing the part from the machine. This capability is particularly valuable for prototypes requiring cross-holes, keyways, flats, grooves, or other features that would traditionally require secondary operations on different machines. Live tooling reduces handling, minimizes setup time, and improves overall accuracy.

Sub-Spindle Technology: Opposed spindles allow for complete machining of parts in a single handling by transferring workpieces from the main spindle to a secondary spindle for backside operations. This technology enables the production of complex prototypes with features on both ends without manual intervention, improving accuracy and reducing processing time. The ability to machine complete parts in one operation is particularly valuable for prototypes requiring precise concentricity between features.

Automated Material Handling: Bar feeders, gantry loaders, and robot integration enable continuous operation of CNC turning centers with minimal operator intervention. For prototype applications, these automation systems allow for extended unattended operation, particularly valuable when producing multiple iterations or small batches of prototypes. Automated handling also ensures consistent loading pressure and orientation, improving repeatability between prototype versions.

Advanced Control Systems: Modern CNC controls feature conversational programming, simulation capabilities, and adaptive control systems that optimize the turning process in real-time. These systems monitor cutting forces, tool wear, and thermal conditions, automatically adjusting parameters to maintain optimal cutting conditions and ensure consistent results throughout the prototyping process. The integration of CAD/CAM systems allows for direct translation of digital designs into machining instructions without intermediate programming steps.

5 Applications and Case Studies

CNC turning services support prototype development across virtually every manufacturing sector. The following case studies illustrate real-world applications of turned prototypes:

Case Study 1: Automotive Transmission Component

An automotive manufacturer required functional prototypes of a transmission input shaft for a new electric vehicle platform. The component needed to withstand high torque loads while maintaining precise gear engagement characteristics and operating within strict noise, vibration, and harshness (NVH) parameters.

Challenge: Produce five functional prototypes for testing within two weeks, with material properties matching the final production design in 4140 hardened steel. The prototypes required precision splines, bearing journals with tolerances of ±0.0005 inches (±0.0127 mm), and surface hardness of 45-50 HRC.

Solution: JL YPT utilized a multi-axis turning center with integrated hardening capability. The shafts were turned from 4140 pre-hardened steel, with the turning process followed by induction hardening of specific journals and final precision grinding of critical surfaces. The entire process was completed within eight business days, allowing the customer to begin testing ahead of schedule.

Results: The turned prototypes provided accurate performance data that revealed a resonance issue at specific RPM ranges. The design was modified with slight dimensional adjustments that eliminated the problem before production tooling was commissioned. The early detection saved an estimated $250,000 in potential rework costs and prevented a four-week schedule delay.

Case Study 2: Medical Device Surgical Instrument

A medical device company needed prototypes of a minimally invasive surgical tool for customer evaluation and regulatory submission. The instrument required precise articulation, smooth operation, and biocompatibility for sterile field use.

Challenge: Produce twenty-five fully functional surgical instrument prototypes in titanium Ti-6Al-4V with complex articulation features, internal passages for irrigation and aspiration, and anodized surfaces for color coding. All components needed to meet surgical instrument standards with complete documentation for regulatory submission.

Solution: JL YPT employed Swiss-type turning centers with live tooling capabilities to machine the complex miniature components. The turning process maintained tolerances of ±0.0002 inches (±0.005 mm) on critical features, with subsequent anodizing providing the required color coding and improved surface durability. All processes were documented with full traceability for regulatory submission.

Results: The prototypes performed excellently in surgeon evaluations and laboratory testing, leading to design approval without modifications. The regulatory submission was accepted without questions regarding manufacturing quality, and the device proceeded directly to production with the same manufacturing processes validated during prototyping.

Case Study 3: Aerospace Fuel System Component

An aerospace developer required prototypes of a fuel management valve for a new aircraft propulsion system. The component needed to handle jet fuel at various temperatures and pressures while maintaining precise flow control and absolute leak integrity.

Challenge: Manufacture ten functional prototypes in aluminum 7075 with an internal complex network of passages, precision mating surfaces, and mounting features. All fuel-wetted surfaces required finishes of 16 Ra µin (0.4 Ra µm) or better, with helium leak testing to aerospace standards.

Solution: JL YPT utilized a multi-axis turning center with Y-axis capability and high-pressure coolant to machine the complex internal geometries. The turning process was followed by manual polishing of critical surfaces and specialized cleaning for aerospace applications. Each component underwent full functional testing including flow testing and helium leak detection.

Results: The prototypes provided performance data that validated the design approach and revealed opportunities for efficiency improvements. The test data allowed engineers to optimize the design before committing to expensive production tooling, reducing weight by 18% while maintaining all performance requirements.

6 Quality Assurance and Metrology

Quality assurance represents a critical aspect of CNC turning services for prototypes, ensuring that components meet design specifications and provide accurate validation data:

First Article Inspection: Comprehensive dimensional verification of initial prototype components ensures that all features conform to design specifications before proceeding with additional iterations or testing. This process typically involves complete geometric dimensioning and tolerancing (GD&T) verification using coordinate measuring machines (CMM) and specialized metrology equipment.

Material Certification: Traceability documentation confirms that prototype materials meet specified requirements for composition, mechanical properties, and heat treatment. This certification is particularly important for regulated industries such as aerospace and medical devices where material properties directly impact safety and performance.

Surface Finish Verification: Profilometers and surface roughness testers quantitatively measure surface characteristics to ensure they meet specified requirements for functionality, aesthetics, or subsequent processing. This verification is essential for prototypes that must simulate production part performance in sealing, friction, or fluid flow applications.

Functional Testing: Application-specific testing validates that prototypes perform as intended under simulated operating conditions. This may include pressure testing, flow testing, wear testing, or other validation procedures that ensure the design will function correctly before committing to production tooling.

Documentation and Reporting: Comprehensive inspection reports provide detailed records of prototype conformity to design specifications, supporting design validation and regulatory submission processes. These reports typically include dimensional data, material certifications, surface finish measurements, and results of any functional testing performed.

7 Conclusion: Strategic Advantages of CNC Turned Prototypes

CNC turning services provide numerous strategic advantages for prototype development that extend beyond simple part production:

Risk Mitigation: By producing prototypes that accurately represent production parts in form, fit, and function, CNC turning significantly reduces the risks associated with new product introduction. Design flaws, manufacturing challenges, and performance issues can be identified and addressed before committing to expensive production tooling, preventing costly revisions and schedule delays.

Accelerated Time-to-Market: The ability to rapidly produce functional prototypes allows for parallel development of manufacturing processes and supply chain elements while design validation is underway. This concurrent engineering approach can significantly compress overall product development cycles, providing competitive advantages in fast-moving markets.

Cost Optimization: While CNC turned prototypes may have higher initial costs compared to 3D printed alternatives, they often provide lower total development costs by identifying issues early and ensuring smooth transition to production. The right-first-time approach minimizes expensive engineering changes during production ramp-up and prevents field failures that could damage brand reputation.

Supply Chain Validation: Prototyping with CNC turning allows manufacturers to validate manufacturing processes, supplier capabilities, and quality systems before production begins. This validation ensures a smooth transition to volume manufacturing and reduces the surprises that often occur when moving from prototype to production.

Customer Confidence: High-quality prototypes provide tangible evidence of design maturity and manufacturing capability, building customer confidence and facilitating approval processes. The ability to demonstrate functional prototypes often accelerates purchasing decisions and supports marketing efforts before production capacity is available.

At JL YPT, we combine state-of-the-art CNC turning technology with extensive prototyping experience to help our customers develop better products faster. Our facilities include advanced turning centers with multi-axis capabilities, live tooling, and automated handling systems that enable us to produce even the most complex prototypes with precision and efficiency. Our engineering team provides design for manufacturability feedback, material selection guidance, and application expertise across multiple industries.

Ready to discuss your prototype turning project? Contact JL YPT today to leverage our CNC turning expertise for your prototype development needs.