The Complete Guide to High Volume Precision CNC Machining: Scaling Precision for Mass Production

Executive Summary

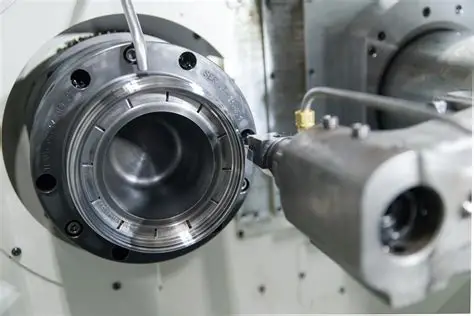

High volume precision CNC machining represents the pinnacle of manufacturing excellence, combining the accuracy and repeatability of computer numerical control technology with the efficiency and scalability required for mass production. This advanced manufacturing approach enables the production of thousands to millions of precision components with tolerances reaching ±0.005mm and surface finishes as fine as Ra 0.4μm while maintaining consistent quality across entire production runs. The integration of automated manufacturing systems, advanced tool management, and statistical process control allows high volume CNC machining to achieve economies of scale typically associated with casting or molding processes, but with the design flexibility and precision only possible through subtractive manufacturing. This comprehensive guide explores the technical capabilities, manufacturing strategies, and quality systems that make high volume precision CNC machining an essential capability for industries including automotive, aerospace, medical devices, and consumer electronics where both volume and precision are critical requirements.

1 Introduction to High Volume Precision CNC Machining

High volume precision CNC machining bridges the gap between prototype-scale manufacturing and mass production, typically involving production runs from 10,000 to 1,000,000+ units annually. This manufacturing approach combines the design flexibility of CNC machining with the economic efficiency required for large-scale production, enabling manufacturers to produce complex precision components without the high tooling costs and long lead times associated with casting, molding, or stamping processes.

The evolution of high volume CNC machining has been driven by advancements in machine tool technology, automation systems, and manufacturing software. Modern CNC machining centers designed for high volume production incorporate pallet changers, robotic integration, and tool management systems that enable continuous operation with minimal human intervention. These systems can maintain micron-level precision across extended production runs while achieving equipment utilization rates exceeding 85% through lights-out manufacturing capabilities.

The economic advantages of high volume precision CNC machining become apparent when comparing total cost across various manufacturing methods. While CNC machining typically has a higher per-part cost than casting or molding for very high volumes, the elimination of tooling costs, faster time-to-market, and design flexibility often make it the most cost-effective solution for production quantities up to 100,000 units, particularly for components with complex geometries, tight tolerances, or frequent design changes.

2 Technical Capabilities for High Volume Production

High volume precision CNC machining requires specialized equipment and processes designed to maintain accuracy and consistency across extended production runs while achieving the economic efficiency necessary for mass production.

Machine Tool Configuration: High volume CNC machining centers feature reinforced bed structures with mineral casting or polymer concrete components that provide exceptional vibration damping and thermal stability during continuous operation. These machines incorporate high-speed spindles (15,000-30,000 RPM) with liquid cooling systems that maintain temperature stability within ±1°C, ensuring consistent precision during extended production runs. Linear motor drives provide rapid positioning speeds exceeding 60 m/min with repetition accuracy of ±0.002mm, while scale feedback systems compensate for thermal expansion and mechanical wear in real-time.

Automation Systems: Automated manufacturing cells integrate pallet changers with 4-12 pallet capacity, allowing continuous production while operators load and unload workpieces. Robotic integration provides complete automation of part handling, with vision systems ensuring proper orientation and force sensing verifying correct clamping pressure. Conveyor systems transport finished parts to secondary operations or packaging stations, while automated quality control stations perform 100% inspection of critical features using probe systems or vision inspection.

Tool Management: High volume machining utilizes high-capacity tool magazines with 120-300 tool positions, reducing tool change frequency and enabling extended unmanned operation. RFID tool identification tracks tool usage and remaining life, while automatic tool measurement systems compensate for tool wear during production. High-pressure coolant systems (70-100 bar) directed through the tool extend tool life and improve chip evacuation, particularly when machining difficult materials like titanium or Inconel.

Table: High Volume CNC Machining Capabilities by Material

| Material | Production Rate (parts/hr) | Typical Tolerance | Surface Finish (Ra) | Tool Life (minutes) | Primary Applications |

|---|---|---|---|---|---|

| Aluminum 6061 | 50-120 | ±0.025mm | 0.8-1.6μm | 180-240 | Automotive, aerospace, electronics |

| Stainless 304 | 25-60 | ±0.038mm | 0.8-3.2μm | 90-150 | Medical, food processing, marine |

| Steel 4140 | 20-50 | ±0.050mm | 1.6-3.2μm | 75-120 | Automotive, industrial equipment |

| Titanium Ti-6Al-4V | 15-35 | ±0.025mm | 0.8-1.6μm | 45-90 | Aerospace, medical implants |

| PEEK | 40-80 | ±0.050mm | 1.6-3.2μm | 240-360 | Medical, semiconductor, aerospace |

3 Manufacturing Strategies for High Volume Production

Successful implementation of high volume precision CNC machining requires specialized manufacturing strategies that optimize efficiency, quality, and cost-effectiveness across extended production runs.

Production Cell Design: High volume manufacturing cells are designed around balanced workflow principles where machining operations are distributed across multiple stations to eliminate bottlenecks. Dedicated machining cells typically include 3-5 CNC machines served by a centralized automation system that distributes workpieces based on machine availability and current workload. Flexible manufacturing systems can be reconfigured for different part families through quick-change fixtures and modular tooling that reduce changeover time to less than 30 minutes.

Process Optimization: High volume processes utilize high-efficiency machining strategies including trochoidal milling, high-speed machining, and hard milling that maximize material removal rates while minimizing tool wear and cycle times. Cycle time analysis identifies and eliminates non-value-added time through optimized tool paths, reduced air cutting, and simultaneous operations. Design for manufacturability reviews ensure parts are optimized for high volume production through standardized features, reduced setup requirements, and minimized secondary operations.

Supply Chain Integration: High volume manufacturing requires just-in-time material delivery with kanban systems ensuring continuous material availability without excessive inventory. Supplier qualification processes certify material providers for consistent quality and reliable delivery, while advanced planning systems synchronize production schedules with customer demand to minimize finished goods inventory. Quality at source methodologies empower operators to verify quality and make process adjustments without waiting for quality department approval.

4 Quality Assurance Systems

Maintaining consistent quality across high volume production runs requires robust quality systems that integrate prevention, detection, and correction methodologies throughout the manufacturing process.

Statistical Process Control: SPC systems monitor key process parameters including tool wear, dimensional accuracy, and surface finish using control charts that track process stability and capability. Gage repeatability and reproducibility studies quantify measurement system variation, while process capability indices (Cp, Cpk) quantify how well processes meet specification requirements. Automated data collection from machine tools and measurement equipment provides real-time process monitoring with automated alerts when processes approach control limits.

Inspection Methodology: High volume production utilizes layered inspection strategies with first-piece validation, in-process verification, and final audit ensuring comprehensive quality assurance. Coordinate measuring machines with automatic part loading perform comprehensive dimensional verification of sample parts from each production lot, while vision systems and laser scanners provide 100% inspection of critical features on all parts. Functional testing verifies that components perform as intended in their application environment, particularly for safety-critical components.

Traceability Systems: Unique part identification using data matrix codes or RFID tags enables complete traceability of each component throughout its lifecycle. Paperless quality systems document inspection results, material certifications, and process parameters for each production lot, providing comprehensive quality records that support regulatory compliance and customer requirements. Supplier quality management systems extend traceability to raw materials and purchased components, ensuring complete visibility across the supply chain.

Table: Quality System Requirements for High Volume CNC Machining

| Quality Element | Implementation Method | Measurement Frequency | Acceptance Criteria | Documentation Requirements |

|---|---|---|---|---|

| Dimensional Accuracy | CMM with automated reporting | 1-5% of production | Cp ≥ 1.33, Cpk ≥ 1.00 | Full dimensional report with deviation map |

| Surface Finish | Portable profilometer | 1-3% of production | Ra within specification | Surface texture analysis report |

| Material Verification | XRF analyzer | 100% of material lots | Composition within spec | Material certification with traceability |

| Functional Testing | Automated test equipment | 100% of production | Meets performance specs | Test results with pass/fail criteria |

| Packaging Verification | Visual inspection audit | 0.5-1% of shipments | Correct packaging | Packaging inspection report |

5 Applications and Case Studies

High volume precision CNC machining serves critical functions across diverse industries where both production volume and precision are essential requirements.

Case Study 1: Automotive Transmission Components

A major automotive manufacturer required planetary gear carriers for a new hybrid transmission design. The components needed to maintain gear alignment accuracy within 0.015mm while withstanding torque loads exceeding 450 N·m in continuous operation.

Challenge: Produce 250,000 units annually with zero defects while achieving cost targets 15% below previous designs. The production process needed to accommodate three design variants with changeover times under 45 minutes between variants.

Solution: JL YPT implemented a dedicated manufacturing cell with four 5-axis machining centers served by a robotic part handling system. Quick-change fixtures reduced changeover time to 30 minutes, while adaptive machining technology compensated for material variation and tool wear. In-process gaging verified critical features on 100% of parts, with automated sorting diverting any non-conforming parts for analysis.

Results: The production cell achieved 99.4% first-pass yield with annual production of 262,000 units. Process capability indices of Cp=1.87 and Cpk=1.52 exceeded quality requirements, while total cost was reduced by 18% through improved tool life and reduced scrap rate. The system successfully accommodated engineering changes during production without significant downtime or quality impact.

Case Study 2: Medical Device Components

A medical device company needed spinal implant components from titanium Ti-6Al-4V with porous surface structures to promote bone integration. The components required biocompatible surface finishes and dimensional accuracy within 0.025mm to ensure proper implant function.

Challenge: Manufacture 150,000 units annually with complete traceability and validation documentation for FDA approval. The manufacturing process needed to maintain sterile surface conditions throughout production and packaging.

Solution: Dedicated cleanroom manufacturing cells with climate control maintained appropriate environmental conditions. Automated machining systems with integrated washing and passivation processed components without human handling, while vision inspection verified critical features on 100% of parts. RFID tracking provided complete traceability from raw material to finished component.

Results: The manufacturing system achieved FDA validation with comprehensive process documentation. Production quality consistently exceeded requirements with Cpk values exceeding 2.0 for all critical features. The automated system achieved 98.7% overall equipment effectiveness with annual production of 157,000 units. The validated process enabled rapid regulatory approval in additional international markets.

Case Study 3: Aerospace Fastener Components

An aerospace manufacturer required specialized fastener components from Inconel 718 for jet engine applications. The components needed to maintain structural integrity at temperatures exceeding 650°C while meeting aerospace quality standards including NADCAP certification.

Challenge: Produce 500,000 units annually with lot traceability and complete material certification for each production batch. The manufacturing process needed to accommodate frequent lot size changes (500-5,000 units) without impacting efficiency or quality.

Solution: Flexible manufacturing cells with modular fixturing accommodated different lot sizes with minimal changeover time. High-pressure cooling (100 bar) enabled efficient machining of Inconel 718, while adaptive control maintained consistent quality across extended production runs. Automated sorting organized completed parts by production lot, with laser marking applying permanent identification to each component.

Results: The manufacturing system achieved NADCAP certification with excellent audit results. Production volume reached 520,000 units annually with on-time delivery performance of 99.8%. The flexible system accommodated 47 different lot size changes during the first year of operation without impacting overall equipment effectiveness. Quality performance exceeded customer requirements with PPM of 12 for delivered components.

6 Economic Considerations for High Volume Production

The economics of high volume precision CNC machining differ significantly from both prototype manufacturing and alternative mass production methods, requiring careful analysis of multiple cost factors.

Cost Structure Analysis: High volume CNC machining costs include equipment depreciation, tooling consumption, direct labor, material costs, and overhead allocation. The equipment utilization rate significantly impacts cost per part, with high-volume operations typically achieving 85-95% utilization through lights-out manufacturing and reduced changeover time. Tooling costs represent 5-15% of total manufacturing cost, influenced by material machinability, cutting parameters, and tool management practices.

Break-Even Analysis: Comparing CNC machining to alternative processes requires break-even analysis that considers both fixed costs (equipment, tooling, setup) and variable costs (material, operation time). For complex components with tight tolerances, CNC machining often provides lower total cost at volumes up to 100,000 units compared to casting or molding processes that require expensive tooling and setup. The economic lot size for CNC machining has increased significantly with automation, making it competitive at higher volumes than previously possible.

Total Cost of Ownership: Comprehensive cost analysis must consider quality costs (scrap, rework, inspection), inventory costs (carrying cost, obsolescence), and flexibility value (design changes, product variants). CNC machining typically provides advantages in quality cost through reduced scrap rates and flexibility value through rapid response to design changes or demand fluctuations. These factors often make CNC machining the lowest total cost option even when per-part machining cost appears higher than alternatives.

7 Future Trends in High Volume CNC Machining

The field of high volume precision CNC machining continues to evolve with several emerging trends shaping its future development.

Digital Manufacturing Integration: The convergence of CAD/CAM systems, manufacturing execution systems, and enterprise resource planning creates integrated digital environments that optimize the entire production process from design to delivery. Digital twin technology creates virtual replicas of physical manufacturing systems, enabling simulation and optimization before implementation. Additive and subtractive hybridization combines 3D printing for complex features with CNC machining for precision surfaces, creating new possibilities for part geometries and production efficiency.

Artificial Intelligence and Machine Learning: AI-powered optimization of machining parameters, predictive maintenance, and quality prediction enhance the efficiency and reliability of high volume production processes. Computer vision systems automatically detect tool wear, surface defects, and dimensional deviations, while natural language processing converts verbal instructions into machine code for simplified programming. Generative design algorithms create components optimized for both function and manufacturability, reducing weight and material usage while maintaining strength.

Sustainable Manufacturing Practices: Energy-efficient equipment, recycling of machining coolants and chips, and optimized material usage reduce the environmental impact of high volume production. Carbon footprint tracking provides transparency regarding environmental impact, while lightweighting techniques reduce material consumption and energy use during product lifecycle. Closed-loop manufacturing systems recycle cutting fluids and metal chips, achieving near-zero waste in manufacturing operations.

8 Conclusion: Strategic Advantages of High Volume CNC Machining

High volume precision CNC machining provides numerous strategic advantages that make it the preferred choice for production applications where volume, precision, and flexibility are simultaneously required.

Quality Leadership: The capability to maintain micron-level precision across production runs of hundreds of thousands of components enables manufacturers to achieve quality levels impossible with alternative processes. Consistent process capability with Cpk values exceeding 1.67 ensures that quality requirements are met with minimal inspection and virtually no scrap.

Supply Chain Resilience: The ability to produce components in high volumes with short lead times reduces dependence on extended global supply chains. This resilience has become increasingly valuable in the face of disruptions and uncertainties in traditional manufacturing models, providing supply chain stability and reduced risk.

Innovation Acceleration: The combination of design flexibility and production scalability enables faster innovation cycles, allowing companies to introduce new products and design improvements without the constraints of fixed tooling. This capability is particularly valuable in fast-moving markets where product lifecycles are shortening and customization demands are increasing.

Total Cost Advantage: When considering total cost of ownership including tooling, quality, inventory, and flexibility, high volume CNC machining often provides the lowest total cost for production quantities up to 100,000 units for complex components. The elimination of tooling costs and reduced time-to-market provide additional economic advantages that extend beyond simple per-part cost comparisons.

At JL YPT, we combine state-of-the-art CNC machining capabilities with extensive experience in high volume production across diverse industries. Our facilities include advanced machining centers, comprehensive automation systems, and digital quality assurance equipment that ensure your high volume production runs meet the highest standards of quality, precision, and efficiency.

Ready to discuss your high volume CNC production needs? Contact JL YPT today to leverage our expertise for your next manufacturing project.