The Complete Guide to CNC Machining for Defense Industry Components: Precision Manufacturing for National Security

Executive Summary

CNC machining for defense industry components represents the highest standard of precision manufacturing, where exceptional accuracy, reliability, and compliance are not just requirements but necessities for national security. The defense sector demands manufacturing capabilities that exceed commercial standards, with tight tolerances reaching ±0.0001 inches, exceptional material performance under extreme conditions, and strict documentation for complete traceability. This comprehensive guide explores the technical capabilities, compliance requirements, and manufacturing strategies for producing defense components that meet rigorous military specifications (MIL-SPEC). From aerospace systems and weapons platforms to communications equipment and vehicle systems, CNC machining provides the foundation for modern defense technology, enabling the precision, reliability, and performance required in the most demanding operational environments.

1 Introduction to Defense Industry CNC Machining

CNC machining for defense components involves manufacturing parts that meet stringent military specifications and quality standards for use in national security applications. The defense industry requires manufacturing partners capable of producing mission-critical components with exceptional precision, reliability, and traceability. These components must perform flawlessly in extreme environments while meeting strict regulatory requirements, including ITAR (International Traffic in Arms Regulations) compliance and MIL-SPEC (Military Specifications) standards.

The defense manufacturing sector encompasses several key areas, each with unique requirements and challenges. Aerospace and aviation components include structural elements, engine parts, and avionics for military aircraft, drones, and satellites. Ground vehicle systems involve components for tanks, armored vehicles, and tactical transportation. Naval applications require parts that withstand marine environments while maintaining precision operation. Weapons systems demand components with exceptional reliability and safety characteristics. Communications and electronics need precision housings and components for secure military communications.

The evolution of defense manufacturing has seen significant advancements in materials technology, precision engineering, and digital manufacturing. Modern defense contractors require manufacturing partners with capabilities including multi-axis machining (5-axis simultaneous processing), advanced metrology, material expertise (including exotic alloys and composites), and comprehensive quality systems that ensure compliance with defense industry standards.

2 Technical Requirements for Defense Components

Defense industry components must meet exceptionally high technical requirements that far exceed commercial manufacturing standards:

Precision Tolerances: Defense components typically require tolerances between ±0.0005 inches (±0.0127mm) for standard features and ±0.0001 inches (±0.0025mm) for critical interfaces. These tight tolerances ensure proper function in precision mechanisms, weapons systems, and guidance equipment where minimal deviations can significantly impact performance.

Material Performance: Defense applications require materials that maintain properties under extreme conditions including temperature extremes (-65°F to 350°F), high stress, corrosive environments, and impact scenarios. Common materials include stainless steels (416, 17-4 PH, 15-5 PH), titanium alloys (Ti-6Al-4V), aluminum alloys (7075, 6061), nickel alloys (Inconel), and specialty materials (beryllium copper, tungsten alloys).

Surface Finish Requirements: Component surfaces must meet specific finish requirements ranging from Ra 0.2μm for sealing surfaces and bearing interfaces to Ra 1.6μm for structural components. Special finishes including anodizing, passivation, electroless nickel plating, and specialized coatings enhance corrosion resistance, wear resistance, and environmental protection.

Structural Integrity: Defense components must maintain structural integrity under dynamic loading, vibration, shock, and thermal cycling. This requires careful attention to material grain structure, stress relief processes, and manufacturing techniques that minimize residual stresses and ensure consistent performance.

Environmental Sealing: Many defense components require environmental sealing against moisture, dust, chemicals, and electromagnetic interference. Precision machined features ensure proper sealing surface geometry, flatness, and finish for reliable environmental protection.

Table: Defense Industry CNC Machining Technical Standards

| Standard Type | Standard Number | Application | Key Requirements |

|---|---|---|---|

| Precision Tolerance | MIL-STD-120 | Gaging and Measurement | Measurement standards and practices |

| Surface Finish | MIL-STD-10 | Surface Texture | Surface roughness standards |

| Material Specification | MIL-SPEC various | Material Properties | Material composition and performance |

| Quality Assurance | MIL-I-45208A | Inspection System | Quality program requirements |

| Electroplating | MIL-STD-171 | Finishing Processes | Plating and coating specifications |

| Dimensioning | ASME Y14.5 | Geometric Tolerancing | GD&T standards |

| Aerospace | AS9100 | Quality Management | Aerospace quality systems |

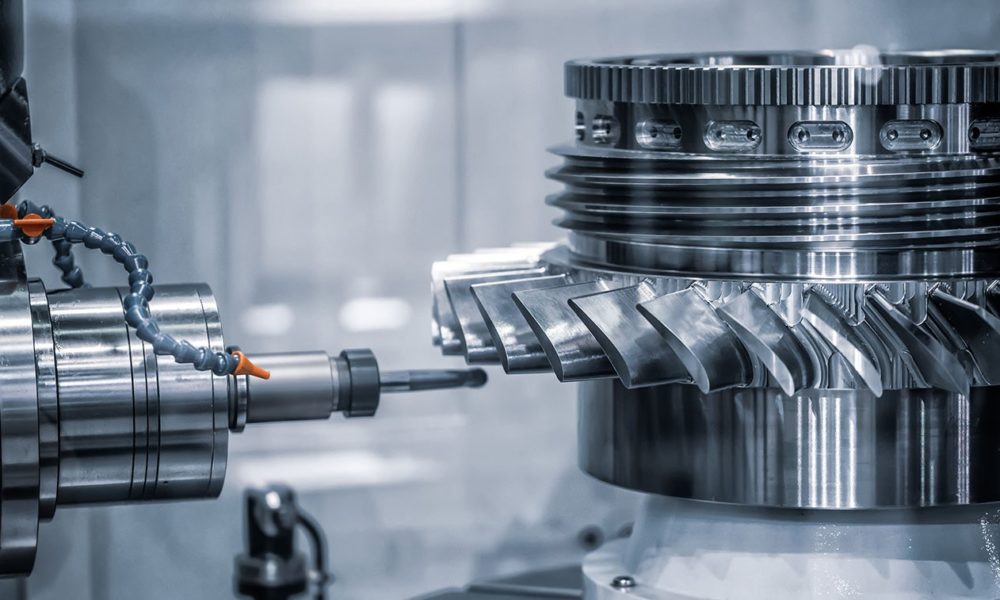

3 CNC Technologies for Defense Manufacturing

Modern defense component manufacturing utilizes advanced CNC technologies that provide the precision, efficiency, and capability required for complex defense applications:

5-Axis Simultaneous Machining: 5-axis CNC machining centers enable complete machining of complex components in a single setup, eliminating cumulative errors from multiple repositioning operations. This capability is essential for aerospace structures, weapon system components, and complex enclosures that require precise relationships between features machined from multiple angles. The simultaneous movement of five axes allows for complex contours and geometries that would be impossible with 3-axis machining.

Multi-Function Machining Centers: Mill-turn centers and multi-function machines combine turning, milling, drilling, and tapping capabilities in a single setup, enabling complete machining of complex components without handling between operations. These systems typically include dual spindles, multiple turrets, and Y-axis capabilities that provide exceptional flexibility for complex defense components.

High-Speed Machining: HSM capabilities with spindle speeds to 30,000 RPM and rapid traverse rates to 2,000 IPM enable efficient machining of aluminum components, composite materials, and thin-wall structures common in aerospace and defense applications. High-speed machining provides superior surface finishes and reduces machining stresses in critical components.

Swiss-Type Machining: CNC Swiss screw machines excel at producing long, slender components with exceptional precision. The guide bushing support enables machining of parts with length-to-diameter ratios up to 20:1 while maintaining tolerances to ±0.0001 inches. This capability is ideal for precision shafts, fasteners, and connector components used in defense systems.

Automated Manufacturing Systems: Robotic integration, pallet changers, and automated material handling enable lights-out manufacturing of defense components with minimal human intervention. These systems maintain consistent quality while improving efficiency and reducing costs for medium to high-volume production.

Table: CNC Equipment for Defense Component Manufacturing

| Machine Type | Key Capabilities | Typical Applications | Defense Industry Advantages |

|---|---|---|---|

| 5-Axis Machining Centers | Simultaneous 5-axis motion, ±0.0001″ accuracy | Aerospace structures, complex components | Single setup complexity, exceptional accuracy |

| Multi-Function Mill-Turn | Turning, milling, drilling in one setup | Rotational components, complex geometries | Reduced handling, improved accuracy |

| CNC Swiss Screw Machines | Guide bushing support, 20:1 L:D ratio | Precision shafts, fasteners, connectors | Superior precision for slender parts |

| Horizontal Machining Centers | 4-axis capability, pallet changers | Medium to large components | High-volume production efficiency |

| Gantry Machines | Large work envelope, high rigidity | Large structural components | Handling large defense components |

| High-Speed Machining Centers | 30,000 RPM spindles, 2,000 IPM rapid traverse | Aluminum structures, thin walls | Efficient material removal, fine finishes |

4 Materials for Defense Applications

Defense components require materials with specific properties that ensure performance under demanding operational conditions:

Aluminum Alloys: 7075 aluminum offers high strength with good fatigue resistance for aerospace structures and vehicle components. 6061 aluminum provides excellent machinability and corrosion resistance for enclosures and structural components. Aluminum alloys are typically used where light weight and good strength-to-weight ratio are priorities.

Stainless Steels: 416 stainless steel offers excellent machinability and good corrosion resistance for precision components. 17-4 PH and 15-5 PH provide high strength through precipitation hardening with good corrosion resistance for critical structural components. 316 stainless offers superior corrosion resistance for marine applications.

Titanium Alloys: Ti-6Al-4V provides exceptional strength-to-weight ratio and corrosion resistance for aerospace applications. Titanium maintains strength at elevated temperatures and offers excellent compatibility with composite materials, making it ideal for modern aerospace structures.

Nickel Alloys: Inconel 718 and similar nickel-based superalloys maintain strength and corrosion resistance at elevated temperatures, making them suitable for engine components, exhaust systems, and high-temperature applications.

Specialty Materials: Beryllium copper offers exceptional electrical conductivity and spring properties for electrical connectors and spring components. Tungsten alloys provide high density and radiation shielding for specialized applications. Composites including carbon fiber and fiberglass provide high strength and light weight for structural applications.

Table: Materials for Defense Component Manufacturing

| Material | Key Properties | Typical Applications | Machining Considerations |

|---|---|---|---|

| 7075 Aluminum | High strength, good fatigue resistance | Aerospace structures, vehicle components | Good machinability, requires sharp tools |

| 416 Stainless Steel | Excellent machinability, good corrosion resistance | Precision components, fasteners | Free-machining grade, good chip control |

| 17-4 PH Stainless | High strength, precipitation hardenable | Structural components, fittings | Machined in solution treated condition |

| Ti-6Al-4V Titanium | High strength-to-weight ratio, corrosion resistant | Aerospace components, implants | Low thermal conductivity, requires sharp tools |

| Inconel 718 | High temperature strength, corrosion resistant | Engine components, exhaust systems | Work hardens, requires rigid setup |

| Beryllium Copper | Excellent conductivity, spring properties | Electrical connectors, springs | Requires containment for chips/dust |

| PEEK | High strength, chemical resistance | Insulators, bearings, seals | Requires sharp tools, controlled temperature |

5 Quality Assurance and Compliance

Quality assurance for defense components requires comprehensive systems that ensure compliance with military specifications and regulatory requirements:

ITAR Compliance: The International Traffic in Arms Regulations (ITAR) controls the export and import of defense-related articles and services. ITAR-compliant manufacturing facilities must implement physical security measures, cybersecurity protocols, employee screening, and documentation controls that prevent unauthorized access to defense-related technical data.

MIL-SPEC Standards: Military specifications define requirements for materials, processes, and quality systems for defense components. Compliance with MIL-SPEC standards requires documented processes, material traceability, process validation, and comprehensive inspection to verify compliance with all applicable specifications.

Nadcap Accreditation: The National Aerospace and Defense Contractors Accreditation Program provides special process accreditation for critical processes including heat treating, welding, non-destructive testing, chemical processing, and coatings. Nadcap accreditation demonstrates capability in these specialized processes for aerospace and defense applications.

AS9100 Quality Systems: The AS9100 series of quality management standards defines requirements for aerospace and defense quality systems. AS9100 certification requires risk management, configuration management, preventive action, and continuous improvement processes tailored to aerospace and defense applications.

First Article Inspection: AS9102 First Article Inspection requires comprehensive verification of initial production parts to ensure all design requirements are met before beginning production. This process includes complete dimensional verification, material certification, functional testing, and process documentation to validate manufacturing capability.

Statistical Process Control: SPC methodologies monitor process stability and capability through control charts and capability indices. Defense manufacturing typically requires Cpk values of 1.33 or higher for critical characteristics, demonstrating that processes are capable of consistently meeting requirements.

6 Applications and Case Studies

CNC machining for defense components serves critical functions across all branches of military service and defense applications:

Case Study 1: Aerospace Guidance System Components

A defense contractor required precision housing components for aircraft guidance systems from aluminum 7075 with complex internal passages and precision mounting features for sensor installation.

Challenge: Manufacture 5,000 units annually with bore geometry held within 0.0005″ straightness and positional tolerance of 0.001″ between mounting features. Components required anodized finishes and needed to maintain dimensional stability across temperature extremes from -65°F to 250°F.

Solution: 5-axis machining centers with high-pressure coolant through the tools produced the complex internal geometries and mounting features. The process included specific toolpath strategies to minimize residual stress and ensure stability after anodizing. In-process verification of critical features ensured compliance before proceeding to subsequent operations.

Results: The components demonstrated consistent performance across temperature extremes, with all units passing functional testing. The manufacturing process achieved first-pass acceptance of all critical characteristics, and the components have performed without failure in service for over 10,000 flight hours.

Case Study 2: Weapons System Components

A weapons manufacturer required firing mechanism components from 17-4 PH stainless steel with precision sear surfaces and trigger interfaces that would withstand repeated operation without failure.

Challenge: Produce 25,000 units annually with critical engagement surfaces held to 0.0002″ profile tolerance and surface finish of Ra 0.4μm on all functional surfaces. Components required heat treatment to 44 HRC after machining and shot peening for stress relief.

Solution: CNC Swiss screw machines with high-pressure coolant produced the complex geometries with the required precision. In-process gaging verified critical features on 100% of parts, while automated sorting organized completed parts by production lot. Heat treatment and shot peening processes were validated to ensure consistent results.

Results: The production process achieved Cpk values exceeding 2.0 for all critical features, with annual production of 26,000 units. The components demonstrated exceptional reliability in testing, exceeding lifecycle requirements by 300%. The manufacturing process validated during production served as the foundation for scale-up to higher volumes.

Case Study 3: Naval Communication Equipment

A naval systems provider required waterproof enclosures for shipboard communication equipment from 316 stainless steel with environmental sealing to MIL-STD-810 requirements and EMI shielding for secure communications.

Challenge: Manufacture 2,000 units with flatness of 0.001″ on sealing surfaces and dimensional stability in saltwater environments. Components required passivation after machining and needed to maintain EMI integrity while withstanding vibration and shock loads.

Solution: Horizontal machining centers with pallet changers enabled efficient machining of all features without repositioning. Specialized tooling maintained precise flatness on sealing surfaces, while in-process verification ensured compliance with dimensional requirements. Passivation and EMI testing validated environmental and electrical performance.

Results: The enclosures achieved IP68 environmental rating and EMI shielding effectiveness of 100 dB across required frequencies. The components have performed without failure in naval service for over five years, withstanding harsh marine environments while maintaining communications security.

7 Future Trends in Defense Manufacturing

The field of defense manufacturing continues to evolve with several emerging trends shaping future capabilities and requirements:

Additive Manufacturing Integration: The combination of additive manufacturing for complex features and CNC machining for precision surfaces creates new possibilities for defense components. This hybrid approach is particularly valuable for conformal cooling channels, lightweight structures, and rapid prototyping of defense systems.

Digital Thread Implementation: The digital thread concept connects design, manufacturing, and quality data throughout the product lifecycle, providing complete traceability and visibility. This approach enables model-based definition, paperless manufacturing, and real-time quality monitoring that improves efficiency and quality while reducing costs.

Advanced Materials Development: New materials including metal matrix composites, ceramic composites, and nanostructured materials offer improved performance for defense applications. These materials provide enhanced strength-to-weight ratios, temperature resistance, and environmental durability for next-generation defense systems.

Artificial Intelligence and Machine Learning: AI-powered optimization of machining parameters, predictive maintenance, and quality prediction enhance the efficiency and reliability of defense manufacturing processes. Computer vision systems automatically detect surface defects and dimensional deviations, while natural language processing converts technical specifications into machining instructions.

Sustainable Manufacturing Practices: Energy-efficient equipment, recycling of machining coolants and chips, and optimized material usage reduce the environmental impact of defense manufacturing. Lightweighting techniques reduce material consumption and energy use during product lifecycle, while closed-loop manufacturing systems achieve near-zero waste in manufacturing operations.

8 Conclusion: Strategic Importance of Defense Manufacturing Capabilities

CNC machining for defense industry components provides critical manufacturing capabilities that support national security and technological superiority. The exceptional precision, reliability, and performance of CNC-machined defense components enable the advanced systems that protect national interests and ensure military effectiveness.

The continuing evolution of CNC technologies, advanced materials, and digital manufacturing is enhancing the capabilities available for defense applications while improving efficiency and reducing costs. Manufacturers that invest in these advanced capabilities position themselves to support current defense needs while developing the technologies that will address future challenges.

The strategic importance of domestic defense manufacturing capabilities cannot be overstated. Maintaining advanced manufacturing expertise and capacity within national borders ensures supply chain security, technological advantage, and operational independence that are essential for national security. By investing in advanced CNC machining capabilities and developing partnerships with defense contractors, manufacturers contribute to both national security and economic strength.

At JL YPT, we combine state-of-the-art CNC machining capabilities with extensive experience in defense manufacturing. Our facilities include ITAR-compliant manufacturing, advanced CNC equipment, and comprehensive quality systems that ensure your defense components meet the highest standards of precision, quality, and reliability.

Ready to discuss your defense manufacturing requirements? Contact JL YPT today to leverage our expertise for your most critical defense components.