Custom Machined Parts from Monel: The Ultimate Guide to CNC Machining High-Performance Nickel-Copper Alloys

Introduction: Unleashing the Potential of Monel Alloys in Precision CNC Machining

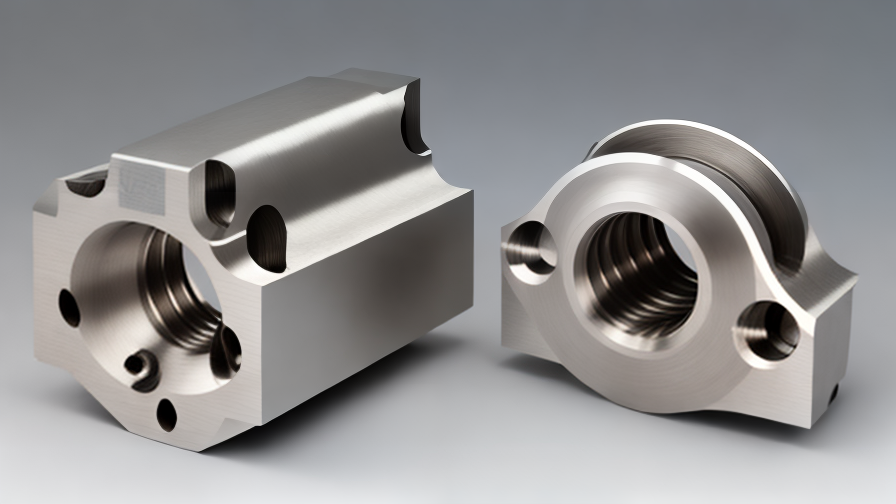

Monel alloys represent a premium class of nickel-copper materials renowned for their exceptional corrosion resistance and maintained strength across extreme environments. As leading CNC machining specialists, we’ve mastered the art of transforming these challenging alloys into precision components that withstand the most demanding applications across marine, chemical processing, aerospace, and energy sectors. This comprehensive guide explores the technical nuances, advanced methodologies, and practical applications of CNC machining Monel alloys, providing engineering professionals with actionable insights for their next high-performance component project.

The unique characteristics of Monel alloys—particularly their work-hardening tendency and abrasive nature—demand specialized machining approaches that differ significantly from conventional materials. Through years of dedicated research and practical application, we’ve developed proprietary techniques that overcome these challenges while maximizing the material’s inherent advantages. From selecting optimal tooling geometries to implementing advanced cooling strategies, every aspect of the machining process requires precise optimization to achieve dimensional accuracy and surface integrity in Monel components.

Understanding Monel Alloy Variants and Material Properties

Monel Alloy Classification and Characteristics

Monel alloys are primarily categorized into two main variants with distinct properties and applications:

Table 1: Comparison of Primary Monel Alloy Grades for CNC Machining

| Property | Monel 400 | Monel K-500 | Significance for Machining |

|---|---|---|---|

| Composition | Ni (~67%), Cu (~30%), Fe (~1.5%) | Ni (~67%), Cu (~30%), Al (~3%), Ti (~1%) | K-500’s precipitation hardening affects tool selection and parameters |

| Tensile Strength | 550-700 MPa | 1000-1200 MPa | Higher strength demands reduced cutting speeds and increased tool rigidity |

| Yield Strength | 240-550 MPa | 690-825 MPa | Greater springback compensation required for K-500 |

| Elongation | ≥35% | ≥20% | Higher ductility in 400 necessitates sharp tooling for clean cuts |

| Hardness | HB 150-200 | HRC 25-35 | K-500 requires more wear-resistant tool materials |

| Thermal Conductivity | 21.8 W/m·K | 17.2 W/m·K | Poor heat dissipation necessitates aggressive cooling strategies |

| Work Hardening Rate | High | Very High | Mandates continuous cutter engagement and optimized feed rates |

The sulfur content in specific Monel variants (such as Monel 401, which contains 0.025%-0.060% sulfur) significantly enhances machinability by promoting chip breaking . This controlled addition creates inclusions that facilitate chip separation, reducing cutting forces and improving surface finish.

Material Properties Impacting Machinability

Several key characteristics of Monel alloys directly influence their machining behavior:

-

Work Hardening Tendency: Monel alloys rapidly harden during plastic deformation, particularly problematic during interrupted cuts or improper feed rates

-

High Toughness: The exceptional toughness leads to significant cutting forces and requires rigid tooling setups

-

Abrasive Nature: Hard intermetallic phases accelerate tool wear, demanding specialized tool materials

-

Low Thermal Conductivity: Approximately 25-30% that of steel causes heat concentration at the cutting edge

-

Chemical Affinity: Tendency to weld to cutting tools at elevated temperatures, leading to built-up edge

Advanced CNC Machining Strategies for Monel Alloys

Tool Selection and Geometry Optimization

Proper tool selection is critical for successful Monel machining. The following table summarizes optimal tooling approaches:

Table 2: Tooling Recommendations for Monel Alloy Machining

| Operation Type | Tool Material | Optimal Geometry | Surface Finish Considerations |

|---|---|---|---|

| Rough Turning | Micro-grain carbide with TiAlN/TiCN coatings | Positive rake angle (5-7°), honed edge preparation | Chipbreaker geometry for controlled chip formation |

| Finish Turning | PCD or CBN for K-500 | Sharp cutting edges, polished flutes | Higher rake angles for finer surface finishes |

| Milling | Solid carbide with specialized coatings | 30-45° helix angle, variable pitch for vibration damping | Reduced radial depth of cut for improved surface texture |

| Drilling | Carbide with cobalt enhancement | 130-140° point angle, polished flutes | Slow helix angles for improved chip evacuation |

| Threading | High-speed steel (HSS) with TiN coating | Sharp, properly relieved geometry | Optimized for chip evacuation in blind holes |

Research indicates that PCD tools demonstrate exceptional performance in Monel K-500 milling applications, potentially extending tool life up to 10 times compared to conventional carbide tools. The extreme hardness and thermal conductivity of diamond minimize abrasive wear while effectively dissipating heat .

Optimized Machining Parameters

Establishing correct cutting parameters ensures dimensional accuracy and surface quality while preventing excessive work hardening:

-

Cutting Speeds: 20-40 m/min for roughing, 30-60 m/min for finishing operations

-

Feed Rates: 0.05-0.15 mm/rev, with higher feeds often preventing work hardening by maintaining continuous chip formation

-

Depth of Cut: 0.5-2.0mm for roughing, 0.1-0.5mm for finishing passes to minimize cutting forces

-

Coolant Strategy: High-pressure flood cooling (≥70 bar) with specialized sulfur-based additives for extreme pressure lubrication

The relationship between parameters follows a generally inverse pattern—higher cutting speeds typically require reduced feed rates to maintain surface quality, while deeper cuts necessitate lower speeds to manage heat generation . Finding the optimal balance for specific Monel alloys is key to maximizing efficiency and tool life.

Thermal Management and Distortion Control

Controlling machining temperatures is crucial since excessive heat can accelerate tool wear and induce thermal stresses:

-

High-Pressure Coolant: Through-tool delivery systems directing coolant precisely at the cutting interface

-

Cryogenic Machining: Liquid nitrogen application for extreme temperature management in high-speed operations

-

Tool Path Optimization: Trochoidal milling techniques reduce heat concentration by distributing tool engagement

-

Sharp Tool Maintenance: Regularly maintained tools generate less frictional heat during cutting

Design Considerations for Monel Components

Geometric Optimization Strategies

Specific design strategies enhance the manufacturability and functionality of Monel components:

-

Uniform Wall Thickness: Maintain consistent sections to prevent uneven cooling and stress concentration

-

Adequate Radii: Minimum 0.5mm radii at internal corners to facilitate tool access and reduce stress

-

Feature Accessibility: Design features to be accessible with standard cutting tools to avoid special tooling requirements

-

Draft Angles: Incorporate slight draft angles (1-2°) for deep cavities to improve tool clearance

Tolerance Strategies for High-Performance Applications

Dimensional precision directly influences the performance of Monel components in critical applications:

-

Standard Tolerances: ±0.125mm for general features

-

Critical Feature Tolerances: ±0.025mm for mating surfaces and alignment features

-

Post-Machining Stabilization: Accounting for potential stress relaxation in critical dimensions

-

Temperature Considerations: Design features accounting for Monel’s thermal expansion characteristics

Quality Assurance for Monel Components

Surface Integrity Verification

Maintaining surface integrity is critical for Monel components, particularly in corrosion-sensitive applications:

-

Surface Roughness Measurement: Profilometry confirming Ra values below 1.6μm for critical surfaces

-

Residual Stress Analysis: X-ray diffraction techniques verifying compressive surface stresses

-

Microhardness Testing: Ensuring absence of excessive work hardening or thermal alterations

-

Visual Inspection: Examining for tool marks, burns, or other surface imperfections

Dimensional Validation Techniques

Advanced metrology ensures compliance with stringent industry tolerances:

-

CMM Inspection: Volumetric accuracy up to 0.0003mm for complex geometric features

-

Optical Scanning: Non-contact measurement of thin-wall sections and complex contours

-

Specialized Fixturing: Simulation of assembly conditions for functional validation

-

Statistical Process Control: Real-time monitoring of critical dimensions throughout production

Industry Applications: Case Studies in Monel Machining Excellence

Case Study 1: Marine Propeller Shaft Components

Challenge: A naval architecture firm needed large-scale propeller shaft components for commercial vessels operating in saltwater environments. The components required precise dimensional stability under torsional loading while withstanding continuous seawater immersion.

Solution: Our team implemented a multi-stage machining approach for Monel K-500:

-

Progressive roughing with trochoidal tool paths to minimize heat concentration

-

Intermediate stress relief thermal treatment at 870-980°C

-

Finish machining with PCD tooling at optimized parameters (45m/min cutting speed, 0.15mm/rev feed)

-

Custom steady rest fixturing to support long slender sections during turning operations

Results: The components achieved all dimensional requirements with surface roughness of 1.2μm and passed rigorous corrosion testing. The optimized process reduced machining time by 25% compared to previous methods while extending component service life by 40% in saltwater applications.

Case Study 2: Chemical Processing Valve Components

Challenge: A chemical processing equipment manufacturer needed complex valve components resistant to sulfuric acid exposure at elevated temperatures. The components featured intricate internal passages with stringent surface finish requirements (Ra < 0.8μm).

Solution: We developed a specialized machining approach for Monel 400:

-

5-axis simultaneous machining for complex internal geometries

-

High-pressure coolant delivery through specialized tooling

-

Micro-machining capabilities for precise feature generation

-

Electropolishing for final surface enhancement and passivation

Results: The valves met all functional requirements with exceptional corrosion resistance in acid exposure testing. The precise dimensional control ensured perfect sealing surfaces, eliminating leakage issues that had plagued previous stainless steel components.

Case Study 3: Aerospace Fuel System Components

Challenge: An aerospace manufacturer needed lightweight yet robust fuel system components for aircraft operating at high altitudes. The parts required resistance to various fuels and lubricants while maintaining dimensional stability across temperature extremes.

Solution: Our comprehensive approach included:

-

High-speed machining with specialized tool geometries

-

Cryogenic cooling to maintain dimensional stability

-

In-process gaging for critical dimensions

-

100% functional testing under simulated operating conditions

Results: The components achieved target weight reduction of 30% compared to previous designs while exceeding all performance requirements. The project established a new benchmark for Monel components in aerospace applications, leading to implementation across multiple aircraft platforms.

Technical Comparison: Monel vs. Alternative Corrosion-Resistant Materials

Monel vs. Stainless Steel for Marine Applications

While stainless steels offer adequate corrosion resistance in many environments, Monel provides superior characteristics for demanding applications:

-

Pitting Resistance: Monel demonstrates exceptional resistance to chloride-induced pitting in seawater applications

-

Stress Corrosion Cracking: Monel alloys are virtually immune to stress corrosion cracking in marine environments

-

Biofouling Resistance: The copper content in Monel provides inherent resistance to marine biological growth

-

Erosion-Corrosion: Superior performance in high-flow seawater applications where erosion accelerates corrosion

Monel vs. Titanium for Chemical Processing

For specific chemical environments, Monel offers distinct advantages over titanium:

-

Reducing Acid Resistance: Monel outperforms titanium in reducing acids like sulfuric and hydrochloric acid

-

Cost Effectiveness: Monel typically costs 30-40% less than commercially pure titanium

-

Fabrication Experience: More established welding and fabrication history in industrial applications

-

Galvanic Compatibility: Better compatibility with common piping materials in chemical plants

Future Trends in Monel Machining Technology

Advanced Manufacturing Technologies

Emerging technologies are transforming Monel machining capabilities:

-

AI-Driven Optimization: Machine learning algorithms that dynamically adjust parameters based on real-time sensor data

-

Hybrid Manufacturing: Combining additive and subtractive processes for optimized component structures

-

Digital Twin Technology: Virtual modeling of the machining process to predict outcomes before physical cutting

-

Sustainable Machining Practices: Reducing energy consumption while maintaining quality standards

Material Development Initiatives

Ongoing material science research continues to expand Monel’s capabilities:

-

Enhanced Formulations: New alloys with improved corrosion resistance and elevated temperature performance

-

Composite Materials: Monel matrix composites with ceramic reinforcements for specific applications

-

Specialized Grades: Application-specific formulations optimized for particular industries

-

Multi-Material Components: Hybrid structures combining Monel with other materials

Conclusion: Excellence in Custom Monel Machining Services

Monel alloy machining represents a specialized segment of precision manufacturing that demands both technical expertise and practical experience. The material’s unique properties—exceptional corrosion resistance, maintained strength at elevated temperatures, and excellent mechanical properties—make it indispensable for demanding applications across marine, chemical processing, aerospace, and energy industries. However, realizing these advantages requires comprehensive understanding of the material’s machining characteristics and implementation of optimized strategies throughout the manufacturing process.

At our manufacturing facility, we’ve combined state-of-the-art CNC technology with deep materials knowledge to establish leadership in Monel component machining. Our comprehensive approach addresses every aspect of the manufacturing process, from initial design consultation through final inspection and delivery, with particular emphasis on surface integrity, dimensional accuracy, and documentation.

The case studies presented demonstrate our capability to solve complex manufacturing challenges while maintaining the highest quality standards across diverse applications. As technology continues to evolve toward increasingly demanding performance requirements, we remain committed to investing in advanced equipment and methodologies that enhance our Monel machining capabilities.

For your next corrosion-resistant component project, partner with a manufacturer that understands both the technical complexities and practical considerations of working with this exceptional material. Contact us today to discuss how our custom Monel machining services can address your specific application requirements.