Defense Contract Machining: Mastering ITAR Compliance for CNC Manufacturing

Navigating the Complex Landscape of Defense Contract Machining

In the high-stakes world of defense manufacturing, ITAR compliance isn’t simply another certification—it’s a fundamental requirement for participation. The International Traffic in Arms Regulations (ITAR) represents a comprehensive framework controlling defense-related articles and services on the United States Munitions List (USML), creating both challenges and opportunities for CNC machining providers .

For defense contractors, selecting a machining partner with legitimate ITAR compliance is mission-critical. The regulations extend beyond simple documentation, requiring rigorous protocols for data security, personnel screening, and supply chain management. Even companies with advanced technical capabilities and AS9100 certification find themselves excluded from defense contracts without proper ITAR registration .

At our CNC machining facility, we’ve built our defense contract division around a culture of compliance that matches our technical expertise. This comprehensive guide explores the intersection of precision machining and regulatory compliance, providing defense contractors with the insights needed to select partners capable of meeting both their technical and security requirements.

Understanding ITAR: Beyond Basic Compliance

The Fundamentals of International Traffic in Arms Regulations

ITAR constitutes a set of regulations administered by the U.S. Department of State’s Directorate of Defense Trade Controls (DDTC) that control the export and import of defense-related articles and services . These regulations define not only physical military hardware but also the technical data required for their development, production, or operation .

The core principle underlying ITAR is restriction of access to defense-related technical information exclusively to U.S. persons—a specifically defined term encompassing U.S. citizens and permanent residents . This fundamental requirement impacts virtually every aspect of operations for defense manufacturing suppliers, from employee hiring to information technology infrastructure.

The Expanding Scope of ITAR Compliance

Many manufacturers mistakenly believe ITAR compliance relates only to finished defense products. In reality, the regulations extend throughout the entire supply chain, affecting companies that may never deliver directly to the Department of Defense . This comprehensive scope means that subcontractors at multiple tiers must maintain equivalent compliance standards.

The implications of non-compliance extend beyond lost business opportunities. Violations can result in severe penalties including substantial fines, loss of government contracts, and reputational damage that can devastate a manufacturing business . Perhaps most significantly, the regulations establish a “see something, say something” obligation, requiring companies to monitor their entire supply chain for potential compliance issues .

Essential Certifications for Defense Contract Machining

Building a Compliant Foundation

Beyond ITAR registration, defense contractors should expect their machining partners to maintain additional certifications that demonstrate commitment to quality and security:

Table: Essential Defense Manufacturing Certifications

| Certification | Focus Area | Defense Application |

|---|---|---|

| ITAR Registration | Compliance with defense trade controls | Required for manufacturing USML items and accessing technical data |

| AS9100 | Aerospace quality management system | Standard for aviation, space, and defense industries |

| ISO 9001 | Quality management systems | Foundation for consistent quality processes |

| NIST SP 800-171 | Protection of controlled unclassified information | Required for handling sensitive defense information |

| NADCAP | Special process accreditation | Often required for processes like non-destructive testing |

Successful defense manufacturing suppliers like JW Machine maintain multiple certifications including AS9100, ISO 9001, and ITAR registration to position themselves for defense opportunities . These overlapping certifications create a comprehensive framework for quality, traceability, and security that defense contractors should expect from their machining partners.

The ITAR Compliance Framework in Practice

Establishing ITAR compliance requires more than simple registration with the DDTC. It demands implementation of comprehensive protocols across multiple business functions:

-

Personnel Security: Verification of U.S. person status for employees accessing controlled technical data

-

Physical Security: Controlled access to facilities and storage areas for defense components

-

Information Security: Protection of digital technical data through encryption, access controls, and monitoring

-

Export Controls: Systems to prevent unauthorized transfers of technical data to foreign persons

-

Supply Chain Management: Due diligence on suppliers and contractors to ensure compliance throughout manufacturing

Technical Capabilities for Defense Manufacturing

Precision Machining Technologies

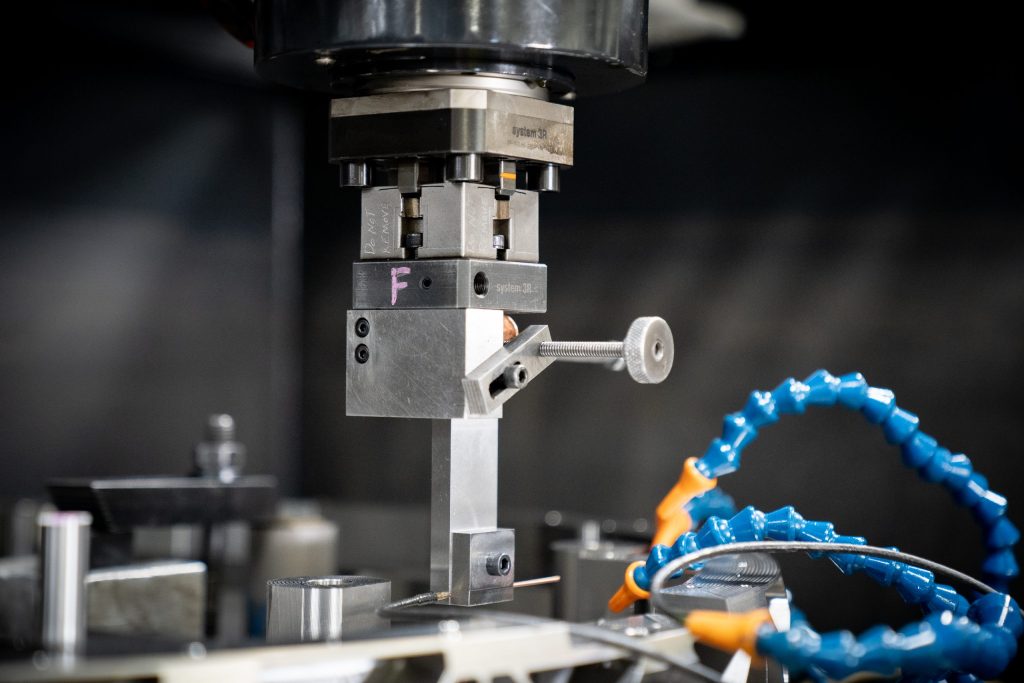

Defense applications frequently demand exceptional precision and capability with advanced materials. Modern defense contractors require machining partners with capabilities extending beyond standard three-axis machining to include advanced multi-axis systems capable of processing complex geometries in single setups.

Companies serving defense markets successfully, like those in the Camozzi Group, utilize advanced machining centers with capabilities for large-scale components—up to 32 meters in length—while maintaining precision tolerances . These capabilities prove essential for defense applications ranging from structural components to specialized enclosures.

Material Expertise for Defense Applications

Defense components frequently utilize specialized materials with specific machining characteristics and regulatory considerations:

-

Aluminum Alloys: Offering excellent strength-to-weight ratios for aerospace and vehicle applications

-

Titanium Alloys: Providing high strength and corrosion resistance for demanding environments

-

Stainless Steels: Delivering durability and corrosion resistance for military hardware

-

High-Strength Composites: Demanding specialized tooling and machining approaches

-

Exotic Alloys: Requiring specific tool geometries and machining parameters

Each material family presents unique machining challenges and requires both technical expertise and documentation rigor for defense applications. Established defense manufacturers demonstrate capabilities across this material spectrum, with specific experience in the documentation requirements for defense contracts .

Quality Assurance in Defense Manufacturing

Rigorous Documentation and Traceability

Defense manufacturing demands comprehensive documentation extending from material certification through final inspection. This “digital thread” ensures complete traceability for every component, a critical requirement for mission-critical defense applications.

The quality standards in defense manufacturing exceed commercial requirements, with expectations for first-article validation, statistical process control, and detailed manufacturing process records. These practices, embodied in standards like AS9100, create the foundation for defense manufacturing excellence .

Advanced Metrology and Verification

Modern defense manufacturing utilizes sophisticated measurement technologies to verify component compliance with design specifications. These include:

-

Coordinate Measuring Machines (CMM): For comprehensive dimensional verification

-

Laser Scanning: Capturing complex surface geometries

-

Optical Comparators: For rapid 2D feature verification

-

Specialized Fixturing: Replicating assembly conditions for functional testing

The integration of these verification technologies with ITAR-compliant data management ensures both quality and security throughout the manufacturing process.

Case Studies: ITAR-Compliant Machining Success

Case Study 1: Aerospace Component Manufacturing

Challenge: A defense prime contractor required complex structural components for a missile system, demanding both ITAR compliance and exceptional dimensional stability under varying environmental conditions.

Solution: Implementation of a multi-stage machining process incorporating:

-

Five-axis simultaneous machining for complex geometries

-

In-process verification using integrated probing

-

Comprehensive material traceability protocols

-

Secure data management compliant with ITAR requirements

Results: The components met all dimensional and documentation requirements, with the ITAR-compliant processes ensuring protection of sensitive technical data throughout the manufacturing process.

Case Study 2: Naval Defense Component Production

Challenge: A naval systems integrator needed sonar housing components capable of withstanding extreme ocean pressures while maintaining precise alignment of internal components.

Solution: Development of a specialized machining approach featuring:

-

Custom tooling solutions for difficult-to-machine materials

-

Strict access controls for both physical manufacturing and digital design data

-

Comprehensive documentation for material traceability and process validation

-

Third-party verification of ITAR compliance protocols

Results: The components exceeded performance requirements while maintaining complete compliance with ITAR regulations, enabling the systems integrator to meet both technical and regulatory obligations.

Case Study 3: Ground Vehicle Armor System

Challenge: A defense vehicle manufacturer required advanced armor components with complex mounting features and precise dimensional requirements for integration with existing vehicle systems.

Solution: Implementation of a secure manufacturing cell featuring:

-

Dedicated machines for defense manufacturing

-

Segmented network infrastructure for technical data protection

-

Comprehensive personnel screening and training

-

Advanced tooling strategies for hardened materials

Results: The armor system components met all ballistic protection requirements while maintaining the dimensional accuracy necessary for vehicle integration. The ITAR-compliant manufacturing processes ensured protection of sensitive design information throughout production.

Implementing ITAR Compliance in CNC Operations

Building a Culture of Compliance

Successful ITAR compliance extends beyond written procedures to establish a security-conscious culture throughout the organization. This requires:

-

Comprehensive Training: Regular security briefings for all employees

-

Clear Accountability: Designated compliance officers with organizational authority

-

Continuous Monitoring: Regular audits and assessments of compliance protocols

-

Incident Response: Established procedures for potential compliance violations

Companies like JW Machine have established themselves as defense industry leaders by building this culture of compliance alongside their technical capabilities .

Technical Implementation Strategies

Implementing ITAR compliance requires both organizational and technical measures, including:

-

Access Control Systems: Physical security measures for manufacturing facilities

-

Data Segmentation: Isolated network infrastructure for controlled technical data

-

Document Management: Controlled storage and distribution for technical documentation

-

Visitor Protocols: Procedures for managing non-U.S. persons in facilities

-

Export Controls: Systems for reviewing international shipments

The Business Case for ITAR-Compliant Machining

Market Access and Growth Opportunities

ITAR compliance represents not just a regulatory requirement but a strategic business decision that opens significant market opportunities. With the defense sector maintaining stringent supplier requirements, compliant manufacturers position themselves for sustained growth in a stable market.

M&R Engineering demonstrated this strategic value when their AS9100 and ITAR compliance helped them retain existing defense contracts while simultaneously attracting new clients requiring certified suppliers . This dual benefit—retention and growth—strengthens the business case for compliance investment.

Risk Mitigation and Supply Chain Security

Beyond revenue opportunities, ITAR compliance provides significant risk mitigation for defense contractors concerned about supply chain security. Compliant suppliers demonstrate commitment to regulatory adherence, reducing overall program risk for prime contractors.

The comprehensive documentation and process controls required for ITAR compliance additionally create manufacturing consistency that benefits quality and reliability—factors directly impacting program success in defense applications.

Future Trends in Defense Manufacturing Compliance

Evolving Regulatory Requirements

The defense regulatory landscape continues evolving, with increasing emphasis on cybersecurity and supply chain resilience. Recent updates to frameworks like NIST SP 800-171 reflect the growing intersection between traditional manufacturing expertise and information security capabilities.

Forward-looking defense manufacturers are anticipating these trends by implementing advanced security measures that exceed current minimum requirements, positioning themselves as partners of choice for next-generation defense programs.

Technological Integration

Emerging technologies like digital twins and additive manufacturing are creating new compliance considerations for defense manufacturers . The integration of these technologies with ITAR requirements demands both technical and regulatory expertise—a combination that will increasingly differentiate leading defense manufacturing suppliers.

Conclusion: Selecting Your ITAR-Compliant Machining Partner

Defense contract machining demands a unique combination of technical expertise, quality commitment, and regulatory compliance. ITAR requirements create a foundational element of defense manufacturing, impacting everything from personnel policies to information technology infrastructure.

When evaluating potential machining partners for defense applications, consider both their technical capabilities and their compliance maturity. Look for documented ITAR registration, complementary certifications like AS9100, and evidence of a security-conscious culture throughout their organization.

The case studies presented demonstrate that successful defense manufacturing requires integration of compliance and capability. By selecting partners with both technical excellence and regulatory diligence, defense contractors can ensure program success while maintaining the security standards essential for national defense.

For your next defense component project, partner with a machining provider that understands both the technical complexities and compliance requirements of defense manufacturing. Contact us today to discuss how our ITAR-compliant CNC machining services can address your specific defense application requirements.