Precision Custom Fixtures and Gauges Manufacturing: Advanced CNC Solutions for Industrial Applications

Introduction: The Critical Role of Precision Tooling in Modern Manufacturing

In today’s competitive industrial landscape, custom fixtures and gauges represent the unsung heroes of manufacturing excellence. These specialized tools form the foundation of quality control, production efficiency, and manufacturing consistency across industries from aerospace to medical devices. As a specialized CNC machining service provider, we understand that precision tooling isn’t merely a supporting element—it’s a strategic asset that directly impacts product quality, production throughput, and ultimately, your bottom line.

The manufacturing of custom fixtures and gauges demands an exceptional level of technical expertise and precision engineering. Unlike standard components, these tools are designed to perform specific functions within unique manufacturing ecosystems, requiring meticulous attention to dimensional stability, material properties, and functional reliability. This comprehensive guide explores the technical considerations, manufacturing methodologies, and practical applications of custom fixtures and gauges manufacturing, providing engineering professionals with actionable insights for their next tooling project.

Understanding Custom Fixtures and Gauges

Defining Precision Tooling Components

Custom fixtures and gauges serve distinct but complementary roles in manufacturing environments:

-

Fixtures: Work-holding devices that securely position and support workpieces during manufacturing operations, ensuring consistent positioning across production runs. High-quality fixtures maintain dimensional stability under cutting forces and thermal variations .

-

Gauges: Measurement instruments that verify dimensional accuracy and ensure components meet specified tolerances. Precision gauges range from simple plug gauges to complex custom measurement fixtures with multiple critical dimensions .

The fundamental distinction lies in their primary function: fixtures control position and stability during manufacturing processes, while gauges validate dimensional compliance after processing. Both require exceptional precision and durability to perform effectively in industrial environments.

The Manufacturing Ecosystem for Precision Tooling

Successful fixture and gauge manufacturing requires integration across multiple disciplines:

Table: Essential Capabilities for Precision Tooling Manufacturing

| Capability Category | Specific Requirements | Impact on Tooling Performance |

|---|---|---|

| Design Engineering | CAD/CAM proficiency, GD&T expertise, functional analysis | Ensures optimal tooling design before manufacturing begins |

| Material Selection | Knowledge of tool steels, aluminum alloys, specialty materials | Affects tooling durability, stability, and performance |

| Precision Machining | Multi-axis CNC, high-speed machining, micro-machining | Determines dimensional accuracy and surface quality |

| Quality Verification | CMM inspection, optical comparators, surface roughness testers | Validates tooling accuracy and performance capabilities |

| Secondary Processing | Heat treatment, surface enhancements, stabilization | Enhances durability and functional characteristics |

Advanced CNC Technologies for Tooling Manufacturing

Multi-Axis Machining Capabilities

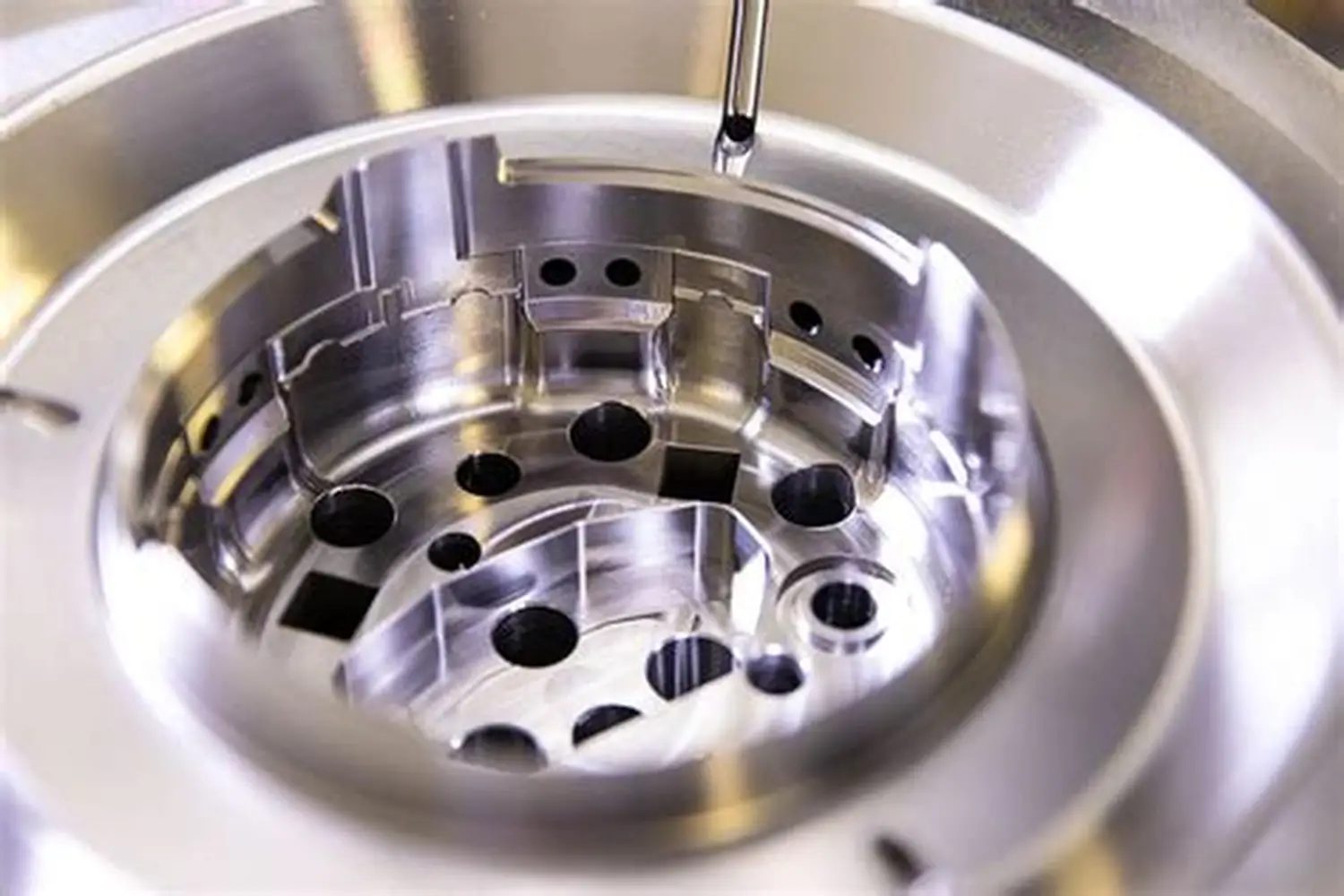

The evolution of five-axis CNC systems has revolutionized fixture and gauge manufacturing by enabling complete processing of complex geometries in single setups. This technology eliminates cumulative errors associated with multiple repositioning operations and significantly improves accuracy for complex tooling components .

Modern CNC machining centers like the DMG five-axis systems provide the simultaneous movement necessary for intricate gauge geometries and complex fixture contours. This capability is particularly valuable for tooling with organic shapes, compound angles, or multiple reference surfaces that would be impractical to produce with conventional three-axis equipment .

High-Speed Machining for Superior Surface Finishes

Advanced toolpath strategies like trochoidal milling and adaptive clearing have transformed the machining of tool steels and other materials common in fixture and gauge manufacturing. These techniques maintain constant tool engagement, reducing heat generation and extending tool life while achieving superior surface finishes critical for measurement applications .

The implementation of high-speed machining strategies directly impacts gauge performance, with surface finishes reaching Ra 0.5μm or better . This exceptional surface quality minimizes friction during measurement operations and enhances durability in production environments.

Precision Grinding and Finishing Operations

While CNC milling creates the fundamental geometry of fixtures and gauges, precision grinding operations deliver the final dimensional accuracy and surface quality. Surface grinding of gauge reference planes and fixture mounting surfaces ensures flatness and parallelism within tight tolerances, often exceeding ±0.002mm .

The integration of multiple processes—milling, turning, grinding, and EDM—enables comprehensive tooling manufacturing capabilities. As demonstrated by leading manufacturers, this integrated approach ensures that all tooling requirements can be met within a controlled manufacturing environment .

Material Selection for Fixtures and Gauges

Engineering Materials for Demanding Applications

Selecting appropriate materials is crucial for fixture and gauge performance, as material properties directly impact accuracy, durability, and functional reliability:

Table: Common Materials for Custom Fixtures and Gauges

| Material | Key Properties | Tooling Applications | Machining Considerations |

|---|---|---|---|

| Tool Steels | High hardness, excellent wear resistance, good dimensional stability | Gauge bodies, fixture components subject to wear | Requires appropriate tooling and machining parameters to prevent work hardening |

| Aluminum Alloys | Good strength-to-weight ratio, machinability, corrosion resistance | Fixture bodies, lightweight gauges, prototype tooling | High cutting speeds possible, requires sharp tools to prevent material adhesion |

| Stainless Steel | Corrosion resistance, stability, non-magnetic properties | Measurement gauges, fixtures for corrosive environments | Work-hardening tendency demands consistent feed rates and sharp tooling |

| Cast Iron | Excellent vibration damping, stability, wear resistance | Machine bases, large fixture foundations | Graphite structure requires specialized tooling to control dust |

| Engineering Plastics | Low friction, self-lubricating, electrical insulation | Wear surfaces, non-marring contact points, insulating elements | Lower cutting forces, but require sharp tools to prevent deformation |

The manufacturing process for precision tooling typically begins with material selection based on functional requirements, production environment, and expected service life. This careful selection process ensures that fixtures and gauges will perform reliably in their intended application .

Material Certification and Traceability

For precision tooling applications, material traceability is essential throughout the manufacturing process. Reputable manufacturers provide comprehensive documentation including material certifications, test reports, and processing records that create a complete chain of custody from raw material to finished tooling .

This documentation becomes particularly important for tooling used in regulated industries like aerospace and medical devices, where verification of material properties and processing history is often required .

Quality Assurance for Precision Tooling

Comprehensive Measurement and Validation

Rigorous inspection protocols ensure fixtures and gauges meet precise dimensional and performance requirements before delivery. Advanced measurement technologies play a critical role in validating tooling accuracy:

-

Coordinate Measuring Machines (CMM): Volumetric accuracy up to 0.0003mm for complex geometric features

-

Optical Comparators: Rapid 2D feature verification without contact

-

Surface Roughness Analysis: Verification of surface finish specifications critical for measurement applications

-

Laser Scanning: Comprehensive 3D data collection for complex contoured surfaces

Specialized tooling manufacturers employ comprehensive inspection methodologies, with dedicated metrology lab facilities in some cases . This commitment to measurement precision ensures that fixtures and gauges perform as intended in production environments.

Statistical Process Control for Manufacturing Consistency

Implementing statistical process control (SPC) methodologies throughout the manufacturing process ensures consistent quality across all tooling components:

-

First-Article Inspection: Comprehensive verification of all dimensions on initial parts

-

In-Process Controls: Regular measurement of critical dimensions at predetermined intervals

-

Capability Studies (Cp/Cpk): Quantitative assessment of process capability for all controlled dimensions

-

Full Traceability: Material certifications and process documentation for each tooling component

These systematic approaches to quality assurance create the foundation for reliable, consistent tooling performance throughout extended production runs.

Industry Applications: Case Studies in Tooling Excellence

Case Study 1: Automotive Inspection Fixture System

Challenge: An automotive components manufacturer needed a comprehensive inspection fixture system for quality verification of complex transmission housings. The system required exceptional dimensional stability, precise locating features, and compatibility with existing coordinate measuring equipment.

Solution: Our team implemented a multi-stage manufacturing approach incorporating:

-

Five-axis simultaneous machining of the primary fixture structure from aluminum alloy

-

Precision boring of locating bushing holes with positional accuracy within 0.005mm

-

Incorporation of hardened steel wear surfaces at critical contact points

-

Comprehensive measurement of all critical features using CMM and laser tracking

Results: The inspection fixture system achieved all dimensional requirements, reducing measurement cycle times by 65% while improving measurement consistency. The precise locating features ensured repeatable positioning of transmission housings, enabling reliable quality data collection.

Case Study 2: Aerospace Composite Layup Tooling

Challenge: An aerospace manufacturer needed large composite layup tools for aircraft structural components. The tools required exceptional thermal stability at elevated curing temperatures, precise contour accuracy, and vacuum integrity throughout extended production cycles.

Solution: We developed a specialized manufacturing process featuring:

-

Selection of invar alloy for minimal thermal expansion at curing temperatures

-

Large-format five-axis machining of complex aerodynamic contours

-

Precision machining of vacuum channels and sealing surfaces

-

Comprehensive leak testing and thermal cycle validation

Results: The composite layup tools met all functional requirements, maintaining dimensional stability through hundreds of cure cycles. The precise contour accuracy ensured consistent composite part geometry, while the reliable vacuum integrity prevented production delays due to leak-related issues.

Case Study 3: Medical Device Assembly Fixture

Challenge: A medical device company needed precision assembly fixtures for a new surgical instrument platform. The fixtures required biocompatible materials, precise component location, and smooth operation for rapid assembly while maintaining critical tolerances.

Solution: Our comprehensive approach included:

-

DFM analysis to optimize fixture designs for both manufacturability and assembly ergonomics

-

CNC machining of primary fixture components from stainless steel with electropolished finishes

-

Incorporation of quick-change components to accommodate instrument variants

-

Validation of fixture performance through multiple assembly cycles

Results: The assembly fixtures enabled rapid, consistent instrument assembly while maintaining all critical dimensional requirements. The precision locating features ensured proper component alignment, contributing to reduced assembly time and improved product quality.

The Business Impact of Precision Tooling

Production Efficiency and Quality Improvement

Beyond their immediate function, custom fixtures and gauges deliver significant operational benefits throughout manufacturing operations:

-

Reduced Setup Times: Precision fixtures decrease part positioning and alignment time during changeovers

-

Improved Process Capability: Consistent part location enables more predictable machining outcomes

-

Enhanced Quality Control: Accurate gauges provide reliable data for statistical process control

-

Reduced Scrap and Rework: Proper tooling prevents errors before they occur in production

-

Accelerated Training: Well-designed fixtures simplify operations for new operators

These cumulative benefits translate to improved manufacturing efficiency, higher quality output, and reduced operational costs throughout the production lifecycle.

Cost Management Strategies

For manufacturing organizations, understanding tooling economics is crucial for financial planning:

-

Initial Investment vs. Long-term Value: Precision tooling represents front-loaded investment with returns realized through improved efficiency and quality

-

Lifecycle Cost Considerations: Durable tooling materials and proper maintenance extend service life, reducing replacement frequency

-

Total Cost of Ownership: Comprehensive evaluation should include impact on production efficiency, quality metrics, and operational flexibility

Many manufacturers offer prototyping packages at optimized rates to help validate tooling designs before committing to full production .

Future Trends in Tooling Manufacturing

Digital Integration and Industry 4.0

The adoption of Industry 4.0 principles is transforming fixture and gauge manufacturing through enhanced connectivity, data analytics, and digital workflow integration. These technologies support the creation of “digital twins” that simulate both manufacturing processes and tooling performance, reducing physical iteration requirements.

Advanced tooling manufacturers are implementing increasingly digital workflows, with some offering online monitoring of production status and instant manufacturability feedback that accelerates the design-to-part process .

Advanced Materials and Manufacturing Technologies

Emerging materials and manufacturing technologies are expanding tooling possibilities:

-

Additive Manufacturing: Enables complex internal geometries and conformal cooling channels in fixture bodies

-

Advanced Composite Materials: Deliver enhanced strength-to-weight ratios for large fixture applications

-

Specialized Surface Treatments: Provide enhanced properties for specific operating environments

-

Smart Tooling: Incorporates sensors and data collection directly into fixture designs

These technological advances continue to expand the boundaries of what’s possible in custom fixture and gauge manufacturing, enabling more capable and durable tooling solutions.

Conclusion: Partnering for Tooling Success

Custom fixtures and gauges represent a specialized segment of precision manufacturing that demands both technical expertise and practical experience. The unique requirements of industrial tooling—exceptional precision, durability, and functional reliability—make their manufacturing particularly challenging. However, with the right manufacturing partner, these challenges can be transformed into competitive advantages.

At our manufacturing facility, we’ve combined state-of-the-art CNC technology with deep tooling knowledge to establish leadership in custom fixture and gauge manufacturing. Our comprehensive approach addresses every aspect of the manufacturing process, from initial design consultation through final inspection and delivery, with particular emphasis on quality assurance and documentation.

The case studies presented demonstrate our capability to solve complex manufacturing challenges while maintaining the highest standards for precision and reliability. As manufacturing technology continues to evolve toward increasingly demanding applications, we remain committed to investing in advanced equipment and methodologies that enhance our tooling manufacturing capabilities.

For your next custom fixture or gauge project, partner with a manufacturer that understands both the technical complexities and practical considerations of industrial tooling. Contact us today to discuss how our custom manufacturing capabilities can address your specific tooling requirements.