Low Volume Electronic Enclosure Machining: Precision CNC Solutions for Prototype and Small Batch Production

The Critical Role of Precision Machining in Electronic Enclosure Development

The electronics industry moves at an unprecedented pace, with technological advancements constantly reshaping product requirements and market expectations. In this rapidly evolving landscape, low volume electronic enclosure machining has emerged as a strategic solution for companies seeking to bridge the gap between prototype validation and full-scale production. As specialized CNC machining providers, we understand that electronic enclosures must fulfill complex requirements that extend far beyond basic protection—they integrate thermal management, EMI shielding, aesthetic considerations, and precise component interfacing while maintaining strict dimensional stability.

The manufacturing of electronic enclosures presents unique challenges that demand specialized expertise. From achieving proper EMI/RFI shielding through precise dimensional control to implementing effective thermal management strategies through optimized geometry and material selection, every aspect requires careful consideration. This comprehensive guide explores the technical specifications, material considerations, and manufacturing approaches that define excellence in low volume electronic enclosure machining.

Understanding Electronic Enclosure Requirements

Beyond Basic Housing: Multifunctional Demands

Modern electronic enclosures serve multiple critical functions that directly impact device performance and reliability:

Table 1: Key Electronic Enclosure Requirements and Manufacturing Implications

| Requirement | Technical Considerations | Manufacturing Impact |

|---|---|---|

| EMI/RFI Shielding | Continuous seam integrity, conductive surface paths, material conductivity | Demands tight tolerance control, specialized finishing processes |

| Thermal Management | Heat dissipation features, surface area optimization, material thermal properties | Requires precise machining of fins, channels, and mounting surfaces |

| IP Rating Compliance | Gasket groove accuracy, fastener spacing, surface flatness | Necessitates tight tolerances and consistent surface finishes |

| Component Integration | Precise mounting features, connector cutouts, board retention | Mandates accurate feature location and geometric control |

| Aesthetic Requirements | Surface finish quality, texture consistency, brand identification | Demands specialized tooling strategies and finishing processes |

The combination of these requirements creates unique manufacturing challenges that demand specialized expertise. Unlike standard mechanical components, electronic enclosures must balance multiple, sometimes competing, requirements while maintaining cost-effectiveness for low volume production.

Enclosure Types and Applications

Electronic enclosures span diverse applications, each with specific requirements:

-

Consumer Electronics: Balancing aesthetic appeal with structural integrity and miniaturization

-

Industrial Control Systems: Emphasizing durability, ingress protection, and EMI compatibility

-

Telecommunications Equipment: Prioritizing thermal performance and RF transparency/opacity in specific bands

-

Medical Devices: Requiring biocompatible materials and specialized surface finishes

-

Aerospace and Defense Electronics: Demanding extreme environmental resistance and reliability

Advanced CNC Technologies for Electronic Enclosure Machining

Multi-Axis Machining Capabilities

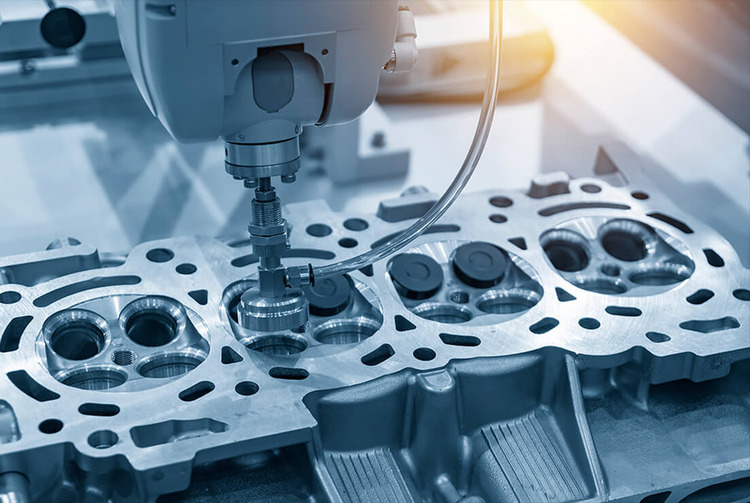

The evolution of five-axis CNC systems has revolutionized electronic enclosure manufacturing by enabling complete processing of complex geometries in single setups. This technology eliminates cumulative errors associated with multiple repositioning operations and significantly improves accuracy for enclosure components with complex features.

Five-axis machining is particularly valuable for electronic enclosures incorporating integrated cooling fins, complex connector panels, and organic form factors that would be impractical to produce with conventional three-axis equipment. The ability to maintain tool perpendicularity to complex surfaces ensures optimal surface finishes and dimensional accuracy across all enclosure faces.

High-Speed Machining for Superior Surface Quality

Advanced toolpath strategies like trochoidal milling and adaptive clearing have transformed the machining of aluminum alloys and engineering plastics common in electronic enclosures. These techniques maintain constant tool engagement, reducing heat generation and extending tool life while achieving superior surface finishes critical for both aesthetic and functional requirements.

The implementation of high-speed machining strategies directly impacts enclosure quality, with surface finishes reaching Ra 0.8μm or better on critical sealing surfaces. This exceptional surface quality ensures proper gasket compression and EMI gasket performance while minimizing the need for secondary finishing operations.

Precision Micro-Machining for Miniature Features

The trend toward electronics miniaturization has increased demand for micro-machining capabilities in enclosure manufacturing. Small connectors, ventilation patterns, and component access features require extremely precise machining with tight tolerances:

-

Small Feature Machining: Producing details as small as 0.5mm with positional accuracy within 0.025mm

-

Micro-tooling Expertise: Specialized tooling with diameters from 0.1mm to 3.0mm for intricate features

-

High-Speed Spindles: Capabilities up to 50,000 RPM for clean micro-feature generation

-

Advanced Workholding: Specialized fixtures that securely hold complex enclosure geometries without distortion

Material Selection for Electronic Enclosures

Engineering Materials for Specific Applications

Selecting appropriate materials is crucial for electronic enclosure performance, as material properties directly impact shielding effectiveness, thermal performance, and durability:

Table 2: Common Materials for Electronic Enclosures

| Material | Key Properties | Electronic Applications | Machining Considerations |

|---|---|---|---|

| Aluminum Alloys | Excellent strength-to-weight ratio, good thermal conductivity, natural EMI shielding | Consumer electronics, industrial controls, telecommunications | High cutting speeds possible, requires sharp tools to prevent material adhesion |

| Stainless Steel | High strength, excellent corrosion resistance, superior EMI shielding | Medical devices, military electronics, harsh environments | Work-hardening tendency demands consistent feed rates and sharp tooling |

| Magnesium Alloys | Exceptional strength-to-weight ratio, good stiffness, EMI shielding | Portable electronics, aerospace avionics | Special handling required for chip control and dust management |

| Engineering Plastics | Electrical insulation, corrosion resistance, design flexibility | Industrial controls, consumer products, prototype enclosures | Lower cutting forces, but require sharp tools to prevent deformation |

| Copper Alloys | Excellent electrical/thermal conductivity, antimicrobial properties | RF enclosures, thermal management components | Gumminess requires specialized tool geometries and surface treatments |

The manufacturing process for electronic enclosures typically begins with material selection based on functional requirements, operating environment, and regulatory compliance. This careful selection process ensures that enclosures will perform reliably in their intended application while meeting all performance requirements.

Advanced Materials for Demanding Applications

As electronic technologies advance, manufacturers are increasingly turning to specialized materials that offer enhanced performance characteristics:

-

Dielectric Coatings: Selective application to control RF transparency while maintaining corrosion protection

-

Thermal Management Composites: Materials with enhanced thermal conductivity for high-power applications

-

EMI Shielding Treatments: Specialized surface finishes that enhance shielding effectiveness

-

Harsh Environment Alloys: Materials with enhanced corrosion resistance for industrial and outdoor applications

Quality Assurance for Electronic Enclosures

Comprehensive Measurement and Validation

Rigorous inspection protocols ensure electronic enclosures meet precise dimensional and performance requirements before delivery. Advanced measurement technologies play a critical role in validating enclosure accuracy:

-

Coordinate Measuring Machines (CMM): Volumetric accuracy up to 0.0003mm for complex geometric features

-

Surface Roughness Analysis: Verification of surface finish specifications critical for sealing and appearance

-

Optical Comparators: Rapid 2D feature verification without contact

-

Custom Fixturing: Simulation of assembly conditions for functional validation

Specialized enclosure manufacturers employ comprehensive inspection methodologies to verify all critical dimensions and features. This commitment to measurement precision ensures that enclosures will perform as intended in the final electronic systems.

Statistical Process Control for Manufacturing Consistency

Implementing statistical process control (SPC) methodologies throughout the manufacturing process ensures consistent quality across all enclosure components:

-

First-Article Inspection: Comprehensive verification of all dimensions on initial parts

-

In-Process Controls: Regular measurement of critical dimensions at predetermined intervals

-

Capability Studies (Cp/Cpk): Quantitative assessment of process capability for all controlled dimensions

-

Full Traceability: Material certifications and process documentation for each production batch

These systematic approaches to quality assurance create the foundation for reliable, consistent enclosure performance throughout production runs.

Case Studies: Electronic Enclosure Manufacturing Excellence

Case Study 1: Aerospace Avionics Enclosure

Challenge: An aerospace systems integrator needed a lightweight enclosure for a new avionics module. The enclosure required exceptional thermal performance, effective EMI shielding, and compliance with stringent aerospace standards while maintaining minimal weight.

Solution: Our team implemented a multi-stage manufacturing approach incorporating:

-

Five-axis simultaneous machining of the primary enclosure from aluminum alloy

-

Precision milling of integrated cooling fins with optimized aspect ratios

-

Machining of continuous EMI gasket grooves with tight dimensional control

-

Comprehensive measurement of all critical features using CMM and surface analysis

Results: The enclosure achieved all performance requirements with a 25% weight reduction compared to the previous design. The integrated thermal management features maintained component temperatures within specified limits, while the EMI sealing demonstrated 60dB shielding effectiveness across the required frequency spectrum.

Case Study 2: Medical Monitoring Device Enclosure

Challenge: A medical device company needed a biocompatible enclosure for a new patient monitoring system. The enclosure required seamless aesthetics, IP67 rating for fluid resistance, and compatibility with repeated sterilization cycles.

Solution: We developed a specialized manufacturing process featuring:

-

CNC machining of primary enclosure components from medical-grade stainless steel

-

Precision milling of gasket grooves with continuous radius profiles

-

Implementation of hidden fastener features for clean aesthetics

-

Electropolishing for final surface enhancement and passivation

Results: The enclosure met all functional requirements with complete documentation for regulatory submission. The precise dimensional control ensured reliable IP67 performance, while the aesthetic quality supported the company’s premium market positioning.

Case Study 3: Industrial IoT Gateway Enclosure

Challenge: An industrial automation provider needed a durable enclosure for a new IoT gateway device. The enclosure required multiple connector interfaces, effective thermal management for outdoor operation, and compatibility with industrial mounting systems.

Solution: Our comprehensive approach included:

-

DFM analysis to optimize designs for both manufacturability and performance

-

CNC machining of the primary enclosure from aluminum with selective thermal conductive paths

-

Precision machining of multiple connector cutouts with tight positional tolerances

-

Integration of mounting features compatible with standard industrial hardware

-

Application of specialized surface treatment for environmental protection

Results: The enclosure provided reliable performance in industrial environments with excellent thermal characteristics. The precision connector interfaces ensured reliable mating with field cabling, while the robust construction met the durability requirements for industrial installation.

The Business Impact of Low Volume Enclosure Machining

Accelerated Product Development Cycles

Low volume CNC machining delivers significant time-to-market advantages for electronic product development:

-

Rapid Prototyping: Functional enclosures available in days rather than weeks

-

Design Flexibility: Quick implementation of engineering changes without tooling modifications

-

Risk Reduction: Physical validation of enclosure performance before production commitment

-

Market Testing: Ability to produce small batches for field trials and market evaluation

These advantages enable electronics companies to compress development schedules while making more informed decisions based on actual performance data.

Cost Management Strategies

For product development organizations, understanding enclosure manufacturing economics is crucial for financial planning:

-

Efficient Capital Utilization: Avoidance of high mold costs during development phases

-

Scalable Investment: Manufacturing costs that align with project maturity and market uncertainty

-

Total Cost Analysis: Consideration of both direct manufacturing costs and time-to-market value

-

Supply Chain Flexibility: Ability to respond quickly to changing market demands

Many manufacturers offer prototyping packages at optimized rates to help validate enclosure designs before committing to production quantities.

Future Trends in Electronic Enclosure Manufacturing

Advanced Manufacturing Technologies

Emerging technologies are transforming electronic enclosure manufacturing capabilities:

-

Additive and Subtractive Hybrid: Combining 3D printing for complex internal features with CNC machining for precision surfaces

-

AI-Driven Optimization: Machine learning algorithms that dynamically adjust machining parameters based on real-time sensor data

-

Digital Twin Technology: Virtual modeling of the manufacturing process to predict outcomes before physical cutting

-

Sustainable Manufacturing: Implementing environmentally conscious processes and material usage

Industry 4.0 Integration

The adoption of Industry 4.0 principles is transforming electronic enclosure manufacturing through enhanced connectivity, data analytics, and digital workflow integration. These technologies support the creation of “digital twins” that simulate both manufacturing processes and enclosure performance, reducing physical iteration requirements.

Advanced enclosure manufacturers are implementing increasingly digital workflows, with some offering online monitoring of production status and instant manufacturability feedback that accelerates the design-to-part process.

Conclusion: Partnering for Enclosure Manufacturing Success

Low volume electronic enclosure machining represents a specialized segment of precision manufacturing that demands both technical expertise and practical experience. The unique requirements of electronic enclosures—balancing aesthetic appeal, environmental protection, thermal management, and EMI control—make their manufacturing particularly challenging. However, with the right manufacturing partner, these challenges can be transformed into competitive advantages.

At our manufacturing facility, we’ve combined state-of-the-art CNC technology with deep electronics industry knowledge to establish leadership in electronic enclosure manufacturing. Our comprehensive approach addresses every aspect of the manufacturing process, from initial design consultation through final inspection and delivery, with particular emphasis on quality assurance and documentation.

The case studies presented demonstrate our capability to solve complex manufacturing challenges while maintaining the highest standards for precision and reliability. As electronic technologies continue to evolve toward increasingly demanding applications, we remain committed to investing in advanced equipment and methodologies that enhance our enclosure manufacturing capabilities.

For your next electronic enclosure project, partner with a manufacturer that understands both the technical complexities and practical considerations of electronics packaging. Contact us today to discuss how our low volume electronic enclosure machining capabilities can address your specific application requirements.