Precision CNC Machining for Custom Injection Molding Tooling: A Comprehensive Guide

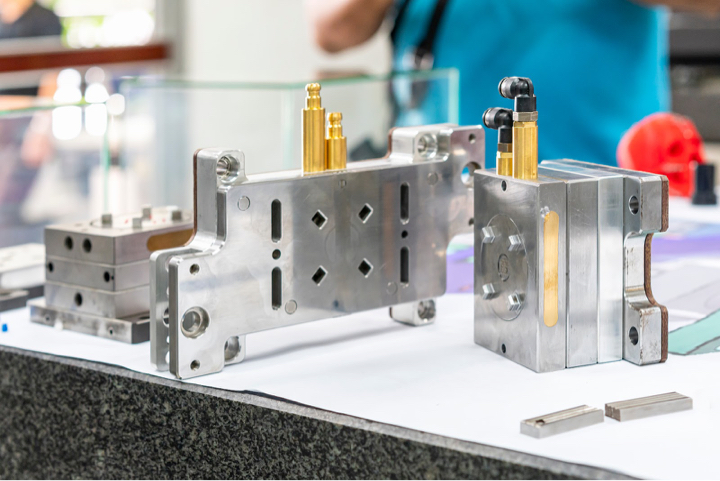

In the world of manufacturing, the quality of your injection molded components begins long before molten material enters the mold cavity—it starts with the precision of your custom injection molding tooling.

Custom injection molding tooling maker capabilities represent the foundation of successful plastic injection molding operations across industries. As specialized providers of CNC machining services, we understand the critical relationship between precision mold manufacturing and high-quality molded components. This comprehensive guide explores how advanced CNC technologies deliver injection molds with exceptional accuracy, durability, and performance characteristics that directly impact production efficiency and part quality.

The creation of injection molds demands more than just material removal—it requires sophisticated engineering knowledge, understanding of material behavior, and mastery of multi-axis machining techniques. From initial design to final polish, the mold manufacturing process leverages CNC technology to create tools that withstand millions of cycles while maintaining dimensional stability and surface quality.

The Strategic Importance of Precision Mold Manufacturing

Injection molding dominates plastic manufacturing for good reason—the process delivers exceptional efficiency, repeatability, and cost-effectiveness at scale. However, these advantages depend entirely on the quality of the custom injection mold itself. The mold represents both the largest initial investment and the primary determinant of production success.

Why CNC Excellence Matters in Mold Manufacturing

The transition from CAD model to production-ready mold demands capabilities that only advanced CNC machining can provide:

-

Complex Geometry Management: Mold cavities often incorporate intricate features, undercuts, and subtle drafts that require simultaneous multi-axis control

-

Surface Finish Requirements: As-machined surface quality directly impacts part release characteristics and final appearance

-

Dimensional Accuracy: Critical shut-off surfaces, sliding components, and alignment features demand tolerances within ±0.005mm to ±0.025mm

-

Material Expertise: Mold steels ranging from P20 to hardened H13 require specific machining strategies and tooling approaches

The relationship between mold base machining and subsequent production performance extends beyond simple geometry replication. Factors including thermal conductivity, wear resistance, and corrosion protection all depend on machining approaches that preserve material properties while achieving required dimensions.

CNC Technologies for Advanced Mold Manufacturing

Modern mold shops leverage multiple CNC technologies specifically optimized for tooling applications. Each approach offers distinct advantages for particular mold components and stages of the manufacturing process.

Multi-Axis Machining Systems

The evolution from 3-axis to multi-axis machining has transformed mold manufacturing capabilities:

Table 1: CNC Machining Capabilities for Injection Mold Manufacturing

| Machining Technology | Axis Configuration | Typical Mold Applications | Tolerance Capability | Surface Finish (Ra) |

|---|---|---|---|---|

| 3-Axis Milling | X, Y, Z linear axes | Simple mold bases, flat surfaces, standard features | ±0.025mm to ±0.125mm | 1.6-3.2 μm |

| 5-Axis Simultaneous Milling | 3 linear + 2 rotational axes | Complex cores, cavities, undrafted surfaces | ±0.01mm to ±0.05mm | 0.4-1.6 μm |

| High-Speed Machining | 3-5 axes with elevated RPM | Detailed textures, fine features, hardened materials | ±0.005mm to ±0.025mm | 0.2-0.8 μm |

| Mill-Turn Centers | Combined milling and turning | Ejector pins, leader pins, rotary components | ±0.005mm to ±0.02mm | 0.4-1.6 μm |

5-axis simultaneous machining has proven particularly transformative for complex mold components. As demonstrated by manufacturers like Schaub Tool, the combination of high-speed milling and EDM technologies enables production of sophisticated molds with overall tolerance requirements within ±10μm while maintaining optimal surface characteristics.

Electrical Discharge Machining (EDM) Integration

While not strictly CNC milling, EDM represents a critical complementary technology in mold manufacturing:

-

Wire EDM: Precision cutting of mold plates, sharp internal corners, and complex through-features

-

Sinker EDM: Cavity creation in hardened materials, intricate details, and deep ribs

-

Micro-EDM: Extremely fine features, texturing, and corrections

The most efficient mold manufacturers strategically combine milling and EDM processes based on geometric requirements, material characteristics, and economic considerations. As evidenced by industry practice, this hybrid approach often sees “milling and EDM each accounting for approximately 30% of the overall production time”.

Material Selection for Injection Mold Components

The choice of mold material significantly impacts both manufacturing approach and production performance. Successful custom injection molding tooling makers match material properties to application requirements through strategic selection.

Mold Steel Characteristics and Applications

Table 2: Mold Steel Selection Guide for Injection Molding Applications

| Material Category | Specific Grades | Hardness (HRC) | Typical Applications | Machining Considerations |

|---|---|---|---|---|

| Pre-Hardened Steels | P20, 718 | 28-36 | Consumer products, medium-volume production | Excellent machinability, minimal heat treatment |

| Through-Hardening Steels | H13, S7 | 40-54 | High-volume production, engineering resins | Moderate machinability, good polishability |

| Stainless Mold Steels | 420SS, 17-4PH | 30-52 | Medical, optical, corrosive materials | Abrasive, requires specialized tooling |

| Maraging Steels | 18Ni300 | 48-54 | High-wear applications, abrasive materials | Difficult machining, exceptional durability |

| Aluminum Alloys | 7075, 6061 | 65-95 HB | Prototype molds, low-volume production | Excellent machinability, limited life |

Machining Parameters for Mold Materials

Each mold material family demands specific machining approaches:

-

Pre-Hardened Steels: Moderate cutting speeds with emphasis on tool life and dimensional stability

-

Hardened Steels: Reduced cutting parameters, specialized tool geometries, and rigid setups

-

Aluminum Alloys: High-speed machining capabilities with attention to burr minimization

-

Stainless Grades: Continuous cutting action, sharp tooling, and thermal management

The integration of high-speed machining technologies has enabled direct machining of hardened mold steels in many applications, reducing or eliminating the need for EDM operations and associated electrode manufacturing.

Critical Mold Components and Their Machining Requirements

Successful mold manufacturing requires understanding the specific function, tolerance, and surface finish requirements for each mold component.

Core and Cavity Machining

The core and cavity represent the most critical mold components, directly forming the molded part:

-

Geometry Complexity: Often incorporates undercuts, complex surfaces, and fine details

-

Surface Requirements: Ranges from texture-ready to high-polish for optical applications

-

Dimensional Control: Critical features typically held within ±0.01mm to ±0.025mm

-

Material Selection: Varies from pre-hardened steels to through-hardened grades based on volume

Modern approaches often utilize 5-axis machining for these components to minimize setups and maintain continuous tool engagement on complex geometries.

Mold Base and Support Components

The mold base provides the structural foundation and alignment for all other components:

-

Flatness and Parallelism: Critical for even clamping and part thickness control

-

Interfacing Features: Sliding fits, press fits, and clearance fits each demand specific tolerances

-

Standardization: Increasing use of standardized components with custom-machined interfaces

-

Material Considerations: Typically pre-hardened steels for stability and cost-effectiveness

As demonstrated by manufacturers like GF Agie Charmilles, the implementation of “palletized workholding and preset tooling” significantly reduces setup times while maintaining critical alignment requirements.

Ejection and Lifter Systems

Components that facilitate part removal require precise machining and smooth operation:

-

Angled Surfaces: Draft angles and sliding interfaces demand precise angular control

-

Clearance Management: Optimal gaps prevent flash while ensuring reliable movement

-

Wear Resistance: Often manufactured from hardened materials for extended life

-

Surface Finish: Smooth operation requires specific surface characteristics on sliding components

Advanced Machining Techniques for Mold Manufacturing

Beyond standard milling operations, several specialized techniques enhance mold quality, reduce manufacturing time, and improve production outcomes.

High-Speed Machining Applications

The implementation of elevated spindle speeds and optimized toolpaths delivers significant advantages:

-

Reduced Handwork: Finer stepovers and improved surface finishes minimize manual polishing

-

Hard Material Machining: Direct machining of hardened steels up to 54 HRC

-

Thin-Feature Integrity: Lower cutting forces preserve delicate ribs and sharp corners

-

Cycle Time Reduction: Increased material removal rates and improved efficiency

As one mold manufacturer noted, implementation of advanced milling technologies provided “high feed speeds and extraordinary process stability in finishing”.

Probing and In-Process Verification

Integration of measurement technologies directly within machining processes ensures quality and reduces non-conformance:

-

Workpiece Verification: Confirmation of stock condition and feature location before machining

-

Tool Condition Monitoring: Detection of broken tools and wear compensation

-

In-Process Measurement: Intermediate verification of critical dimensions between operations

-

Adaptive Compensation: Automatic adjustment of toolpaths based on measured conditions

Following the example of companies like LeanWerks, implementation of probe systems with both standard and extended-range capabilities enables comprehensive in-process verification.

Real-World Case Studies: Precision Mold Manufacturing in Action

Case Study 1: Aerospace-Grade Component Mold

A manufacturer of specialized aerospace components required injection molds for a high-temperature thermoplastic composite with exceptionally tight dimensional requirements.

Challenge: Produce a multi-cavity mold system capable of maintaining ±0.015mm dimensional stability across all critical features while withstanding continuous operation at 200°C and 25,000 psi injection pressure.

Technical Solution: The implementation combined multiple advanced approaches:

-

Material Selection: Through-hardened H13 steel with specialized surface treatment

-

5-Axis Machining: Complete cavity machining in hardened condition using high-speed strategies

-

Temperature Management: Conformal cooling channels created via additive manufacturing and finished by micro-machining

-

Surface Enhancement: Progressive polishing to optical finish on critical surfaces

Results: The completed mold system achieved all dimensional requirements with cycle time reduction of 22% through optimized cooling. The project demonstrated 100% part acceptance through first article inspection and maintained production tolerances through 500,000 cycles.

Case Study 2: Medical Device Micro-Mold

A surgical device company needed injection mold tools for a disposable medical component with micro-features and stringent regulatory requirements.

Challenge: Machine mold components with feature sizes down to 0.1mm, surface finishes of 0.1μm Ra, and overall tolerances of ±0.005mm on critical alignment features.

Technical Solution: The project implemented specialized micro-machining capabilities:

-

Micro-Tooling: Diamond-coated end mills as small as 0.05mm diameter

-

Vibration Control: Specialized workholding and machining parameters to minimize chatter

-

Thermal Stability: Environmental control to maintain temperature within ±1°C during machining

-

Measurement Integration: In-process verification using vision-based measurement systems

Results: The micro-mold achieved all feature size and surface finish requirements, enabling production of components that passed FDA validation. The project established a new capability benchmark for the mold shop and led to additional medical industry opportunities.

Case Study 3: High-Volume Automotive Mold

An automotive supplier required a family of molds for interior components with accelerated delivery timeline and production capacity of 2+ million cycles.

Challenge: Design and manufacture a multi-cavity mold system with accelerated cooling, automated component insertion, and quick-change features within 40% reduced timeline compared to industry standards.

Technical Solution: The implementation focused on manufacturing efficiency and production optimization:

-

Parallel Processing: Simultaneous machining of multiple components across dedicated workcells

-

Standardized Components: Strategic use of modified standard elements to reduce custom machining

-

Automated Features: Robotic interfaces and quick-change components machined as integral elements

-

Advanced Texturing: Direct machining of surface textures to eliminate secondary operations

Results: The mold system was delivered 35% faster than original projections while achieving production rates 18% higher than requirement. The implementation demonstrated how strategic machining approaches can compress delivery timelines while enhancing production performance.

Quality Assurance in Precision Mold Manufacturing

The critical nature of injection molds demands comprehensive quality verification throughout the manufacturing process.

Measurement and Verification Technologies

Modern mold shops employ multiple measurement technologies to ensure component compliance:

-

Coordinate Measuring Machines: Volumetric accuracy verification of complex geometries

-

Surface Profilometry: Quantitative measurement of surface texture and finish

-

Optical Comparators: Rapid verification of 2D geometries and relationships

-

Laser Scanning: Comprehensive 3D data collection for comparison to CAD models

Documentation and Traceability

Complete documentation provides the foundation for future maintenance and replication:

-

First Article Inspection: Comprehensive measurement reports for customer review

-

Material Certification: Traceable material documentation with heat lot information

-

Process Records: Machining parameters and inspection results for critical features

-

Surface Finish Mapping: Quantitative data for critical surfaces

Implementing Manufacturing Excellence: Strategic Considerations

Successfully delivering precision mold components requires more than technical capability—it demands strategic approaches to manufacturing planning and execution.

Design for Manufacturing Collaboration

Early engagement between mold designer and manufacturer delivers significant benefits:

-

Manufacturability Analysis: Identification of potential machining challenges during design phase

-

Tolerance Optimization: Strategic allocation of tolerances based on function and manufacturability

-

Component Standardization: Identification of opportunities for modified standard components

-

Process Planning: Development of manufacturing strategy before programming begins

Technology Investment Strategy

Strategic equipment selection and implementation maximizes return on investment:

-

Capability Matching: Alignment of equipment capabilities with target market requirements

-

Workflow Integration: Seamless data flow from design through manufacturing and inspection

-

Tooling Management: Comprehensive approach to cutting tool selection and maintenance

-

Workholding Optimization: Flexible fixturing systems that accommodate diverse components

Conclusion

Precision CNC machining represents the foundation of quality in custom injection molding tooling maker capabilities. The relationship between machining excellence and molding success extends from initial mold construction through millions of production cycles. By leveraging advanced CNC technologies, implementing strategic manufacturing approaches, and maintaining rigorous quality standards, mold manufacturers deliver tools that optimize production efficiency, part quality, and overall project economics.

The most successful mold manufacturing partnerships recognize that injection molds represent significant investments where machining quality directly impacts return. By selecting manufacturing partners with demonstrated technical capabilities, comprehensive quality systems, and strategic manufacturing approaches, companies ensure their molding operations begin with the optimal foundation.

For components requiring exceptional precision, material expertise, and comprehensive manufacturing capabilities, our integrated CNC machining services deliver the expertise and technology required for successful injection mold manufacturing. Contact our engineering team to discuss how our mold manufacturing capabilities can enhance your next injection molding project.