Engineering Excellence: Advanced Custom Machined Parts for the Automotive Performance Industry

The automotive performance sector represents the absolute frontier of mechanical engineering innovation, where every component must deliver maximum performance under extreme conditions. In this high-stakes environment, standard production parts simply cannot meet the demanding requirements of competitive motorsports or high-performance street applications. At JLYPT CNC Machining, we have positioned ourselves as the premier manufacturing partner for leaders in the automotive performance sector by delivering exceptional custom machined parts for the automotive performance industry that combine cutting-edge materials, precision engineering, and uncompromising quality control.

This comprehensive technical analysis examines the sophisticated manufacturing methodologies, material science applications, and engineering considerations that define world-class custom machined parts for the automotive performance industry. We will explore how strategic implementation of advanced CNC technologies, combined with metallurgical expertise, enables the creation of components that withstand extreme operating conditions while delivering measurable performance advantages.

Technical Imperatives for Performance Automotive Components

The development of custom machined parts for the automotive performance industry requires addressing engineering challenges that far exceed conventional automotive requirements. Successful components must simultaneously satisfy multiple critical parameters:

Performance Under Extreme Operating Conditions

High-performance automotive applications subject components to conditions rarely encountered in consumer vehicles:

-

Thermal Management: Components must maintain structural integrity and dimensional stability across temperature extremes from cryogenic conditions in fuel and cooling systems to extreme heat in exhaust and turbocharger applications exceeding 900°C

-

Dynamic Loading: Parts experience complex multi-axis loading conditions with rapid cycling between tension, compression, and torsion forces

-

Fatigue Resistance: Components must withstand high-cycle fatigue from vibration and low-cycle fatigue from thermal cycling throughout their operational lifespan

-

Wear Resistance: Moving components require exceptional surface durability under high load and limited lubrication scenarios

Weight Optimization and Structural Efficiency

The power-to-weight ratio remains a fundamental determinant of vehicle performance. Our approach to custom machined parts for the automotive performance industry emphasizes:

-

Topology Optimization: Advanced computational methods to design structures with optimized material placement based on finite element analysis (FEA)

-

Hollow and Thin-Wall Construction: Manufacturing techniques that maintain strength while eliminating unnecessary mass through strategic material removal

-

Material Selection Strategy: Choosing advanced alloys and composites with superior strength-to-weight ratios for specific applications

-

Integrated Functionality: Combining multiple components into single, weight-optimized designs that reduce part count and assembly complexity

Advanced Manufacturing Technologies for Performance Applications

Different performance applications demand specialized manufacturing approaches. Our technology portfolio enables us to match the optimal process to each component’s specific requirements.

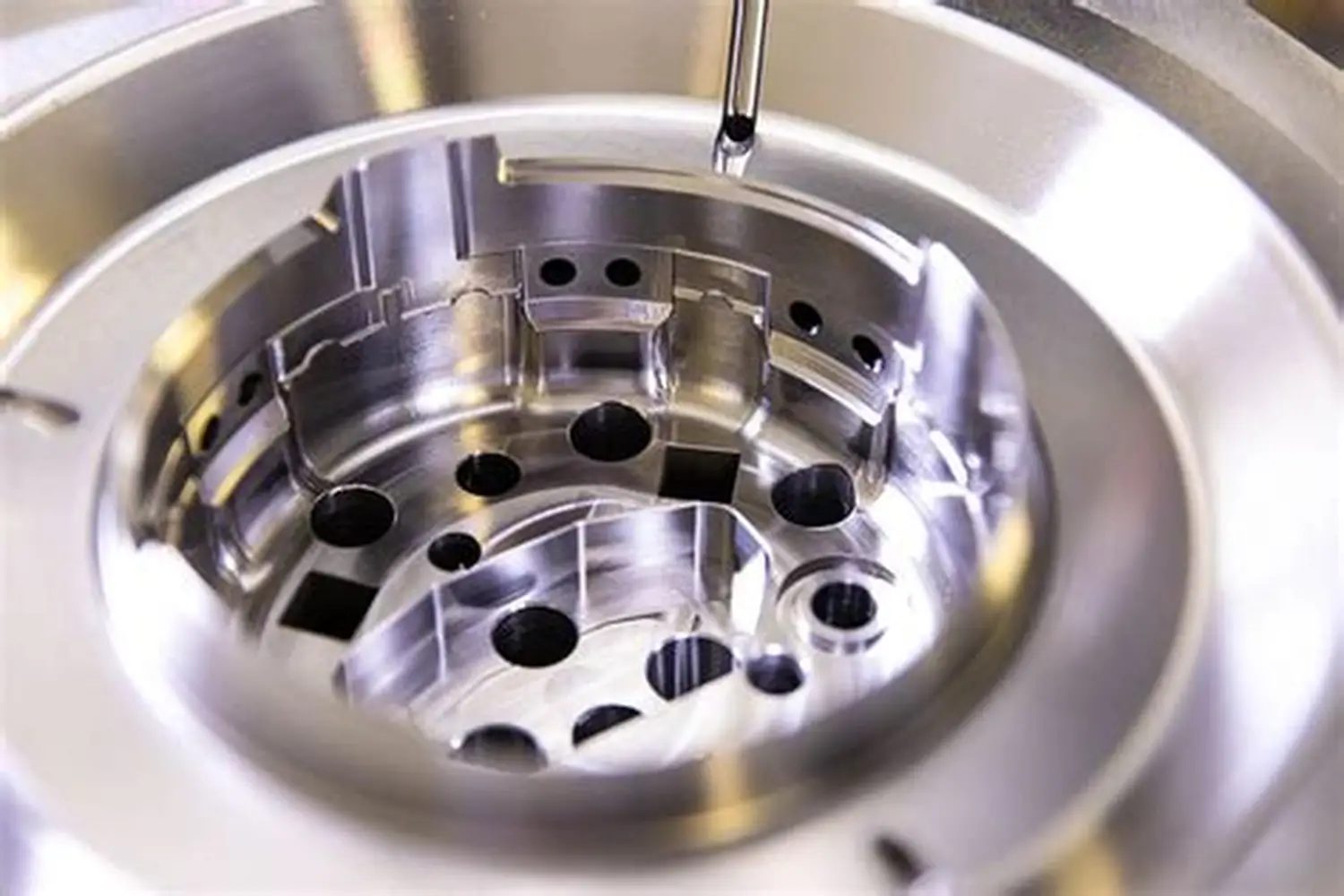

5-Axis Simultaneous Machining for Complex Geometries

For components with complex aerodynamic surfaces, internal cooling channels, and optimized structural shapes, 5-axis simultaneous machining provides unparalleled capabilities:

-

Complex Contour Machining: Production of organic shapes for intake manifolds, cylinder heads, and aerodynamic components with continuous toolpath optimization

-

Single-Setup Manufacturing: Complete machining from all angles eliminates cumulative errors from multiple fixturing operations

-

Undercut Features: Machining of re-entrant angles and internal features impossible with 3-axis equipment

-

Optimized Tool Engagement: Continuous 5-axis movement maintains ideal cutting conditions for superior surface finishes and extended tool life

Multi-Axis Turning with Live Tooling

For rotational components requiring complex off-axis features, our multi-axis turning centers with live tooling capabilities provide complete machining solutions:

-

Complete Part Processing: Turning, milling, drilling, and threading operations in single setup with reduced cycle times

-

Complex Feature Integration: Machining of non-radial holes, slots, and profiles on cylindrical components with precise angular relationships

-

Concentricity Maintenance: Exceptional control of rotational alignment for balanced high-speed components through minimized workpiece handling

-

Efficient Production: Reduced handling and setup time for complex rotational parts with maintained dimensional relationships

High-Speed Hard Machining

For components requiring exceptional dimensional stability under thermal load, we employ high-speed machining strategies for hardened materials:

-

Post-Heat Treatment Machining: Final machining of components after hardening to 45+ HRC with specialized tooling and techniques

-

Minimal Distortion: Strategic material removal maintains heat-treated dimensional stability through balanced cutting forces

-

Superior Surface Integrity: High-speed techniques produce surfaces with minimal residual stress and improved fatigue resistance

-

Elimination of Secondary Operations: Direct production of finished components from hardened stock reduces processing time and potential errors

Material Science for Performance Applications

The selection of appropriate materials represents a critical decision point in developing custom machined parts for the automotive performance industry. Our expertise encompasses a wide range of high-performance materials:

Aluminum Alloys for Lightweight Structures

-

6061-T6: Excellent all-around properties for brackets, fittings, and structural components with good machinability and strength

-

7075-T6: Superior strength for highly stressed components including suspension parts and chassis reinforcements with fatigue resistance

-

2024-T3: High strength-to-weight ratio for aerospace-inspired applications requiring exceptional performance

Titanium Alloys for Extreme Environments

-

Ti-6Al-4V: Exceptional strength-to-weight ratio and corrosion resistance for valvetrain, connecting rod, and exhaust applications

-

Ti-6Al-4V ELI: Enhanced fracture toughness for critical safety components subject to impact loading

-

CP Grade 2: Superior formability for complex exhaust and thermal management systems requiring corrosion resistance

High-Performance Steels and Specialty Alloys

-

4140/4340 Steel: High strength and toughness for drivetrain and suspension components requiring durability

-

Stainless Steels (304, 316, 17-4PH): Corrosion resistance for fuel systems and exterior components with maintained appearance

-

Inconel 718: Extreme temperature capability for turbocharger and exhaust applications exceeding 700°C

-

Magnesium Alloys: Ultra-lightweight applications where aluminum cannot meet weight targets with adequate stiffness

Critical Performance Applications and Manufacturing Solutions

The table below details specific automotive performance applications and the manufacturing approaches required for each:

| Application Area | Performance Requirements | Material Selection | Manufacturing Approach |

|---|---|---|---|

| Turbocharger Systems | Extreme temperature stability, creep resistance, high-cycle fatigue resistance | Inconel 718, Titanium alloys, High-temperature stainless steels | 5-axis machining of complex volutes, precision balancing of rotating assemblies, specialized heat treatment |

| Valvetrain Components | Minimal mass, high wear resistance, temperature stability | Titanium alloys, Tool steels, Ceramic composites | Micro-precision machining, specialized heat treatment, superfinishing of wear surfaces, strict geometrical tolerances |

| Suspension Components | High stiffness-to-weight ratio, fatigue resistance, precise geometric control | 7075 Aluminum, 4340 Steel, Carbon composites | 5-axis machining of complex pickup points, stress relief features, anodizing for wear protection, surface treatments |

| Drivetrain Components | Extreme torque capacity, wear resistance, precise spline and gear geometry | 4340 Steel, Carbon steels, Beryllium copper | Multi-axis turning with live tooling, gear hobbing, specialized thermal treatments, precision grinding |

| Brake System Components | Thermal stability, structural integrity under extreme loads, precise dimensional control | 6061 Aluminum, 304 Stainless, High-temperature composites | Vacuum chucking for distortion-free machining, thermal stress relief cycles, precision surface finishing |

| Fuel System Components | Chemical resistance, precise flow characteristics, leak-free operation | 300 Series stainless, Anodized aluminum, PTFE composites | High-precision milling of orifices and flow paths, specialized sealing surface finishes, strict cleanliness protocols |

For comprehensive material property data and performance characteristics, we regularly consult the ASM Aerospace Specification Metals database to ensure optimal material selection for each application.

Comprehensive Case Studies: Performance-Driven Solutions

Case Study 1: Billet Aluminum Sequential Transmission System

-

Challenge: A championship-winning motorsports team required a custom sequential transmission system for their time attack vehicle. The system needed to withstand 1,200 Nm of torque while reducing shift times to under 30 milliseconds and cutting 40% of the weight compared to their existing system.

-

Manufacturing Solution: We engineered the main transmission casing from 7075-T651 aluminum, employing 5-axis machining to create optimized internal reinforcement structures. The design incorporated topological optimization to eliminate unnecessary material while maintaining structural integrity. Critical bearing surfaces were machined using our hard machining capabilities to maintain dimensional stability under load.

-

Technical Outcomes: The completed transmission system achieved a 43% weight reduction while increasing torsional stiffness by 22%. The precision-machined shift drum and fork interfaces reduced shift times to 27 milliseconds, contributing to measurable lap time improvements. The system completed the racing season without a single mechanical failure despite extreme operating conditions.

-

Internal Link: Learn more about our capabilities for complex drivetrain components through our Precision CNC Machining Services.

Case Study 2: Titanium Turbocharger Turbine Housing

-

Challenge: A specialty turbocharger manufacturer needed to solve thermal fatigue issues with their cast turbine housings in extreme applications. The cast components were cracking after limited thermal cycles, creating reliability issues in endurance racing applications.

-

Manufacturing Solution: We developed a billet titanium housing manufactured from Ti-6Al-4V using our 5-axis machining capabilities. The design incorporated strategic wall thickness variations to manage thermal gradients and used computational fluid dynamics to optimize the volute geometry. We implemented specialized toolpath strategies to manage the challenging machining characteristics of titanium.

-

Technical Outcomes: The titanium housing eliminated thermal cracking issues entirely, with units completing multiple endurance races without failure. The improved surface finish and precise geometric control reduced turbo lag by 11% and increased peak efficiency by 3%. Despite higher material costs, the reliability improvement made the solution cost-effective for professional racing applications.

-

External Resource: For detailed information on titanium machining best practices, we reference resources from the Titanium Industries Technical Resource Center.

Case Study 3: Carbon Composite Hybrid Brake Caliper

-

Challenge: An automotive engineering firm developing a hypercar platform needed to reduce unsprung mass while maintaining extreme braking performance. The solution required combining lightweight materials with precision metallic components in a single integrated assembly.

-

Manufacturing Solution: We developed a hybrid design featuring a carbon composite main body with precision-machined 7075 aluminum mounting inserts and 4340 steel pistons. The manufacturing process required developing specialized fixturing to machine the aluminum inserts with exacting interface tolerances for bonding to the composite structure. The steel pistons required honing to precise diameters with specialized surface treatments for consistent performance.

-

Technical Outcomes: The hybrid caliper achieved a 52% weight reduction compared to equivalent performing aluminum monoblock calipers. The design maintained stiffness characteristics within 15% of all-metal equivalents while providing superior thermal isolation. The solution contributed to a 2.3% reduction in unsprung mass, improving suspension response and overall vehicle dynamics.

Quality Assurance and Performance Validation

The development of custom machined parts for the automotive performance industry demands validation methodologies that ensure reliability under extreme conditions:

-

First Article Inspection: Comprehensive dimensional validation using coordinate measuring machines (CMM) with comparison to CAD data and surface analysis

-

Material Verification: Spectroscopic analysis to confirm alloy composition and mechanical testing to validate material properties against specifications

-

Non-Destructive Testing: Liquid penetrant and magnetic particle inspection for detection of surface defects in critical components subject to high stress

-

Performance Validation: Functional testing under simulated operating conditions including thermal cycling and load testing to validate design assumptions

-

Statistical Process Control: Monitoring of critical dimensions throughout production runs to maintain consistency and identify process trends

The Future of Performance Automotive Manufacturing

The field of custom machined parts for the automotive performance industry continues to evolve with emerging technologies and methodologies:

-

Additive Hybrid Manufacturing: Combining 3D printing with precision machining for optimized structures impossible with either technology alone

-

Advanced Composite Integration: Developing methods for joining composite structures with metallic components in optimized hybrid assemblies

-

AI-Driven Optimization: Using machine learning algorithms to generate performance-optimized geometries beyond human design capabilities

-

Digital Twin Development: Creating virtual models that simulate component performance under real-world conditions before manufacturing

-

Sustainable Performance: Developing manufacturing approaches that reduce environmental impact while maintaining performance standards

Conclusion: Precision Engineering for Performance Advancement

The creation of high-performance automotive components represents one of the most demanding applications of precision manufacturing. Success requires more than simply operating advanced machinery—it demands deep understanding of materials science, structural mechanics, thermal management, and the specific requirements of motorsport and high-performance automotive applications.

At JLYPT CNC Machining, our approach to custom machined parts for the automotive performance industry combines technical expertise with practical racing experience. We understand that milliseconds matter, grams count, and reliability is non-negotiable. By integrating advanced manufacturing technologies with rigorous engineering validation, we deliver components that provide measurable performance advantages in the world’s most demanding automotive environments.

Ready to enhance your performance vehicle with precision-engineered components? Contact JLYPT CNC Machining today to discuss how our expertise in custom machined parts for the automotive performance industry can help you achieve your performance goals with reliability and precision.