Accelerating Innovation: The Strategic Advantage of Quick-Turn CNC Machining Services in the USA

The manufacturing landscape is undergoing a profound transformation, driven by increasing demand for rapid prototyping, shortened product development cycles, and the need for supply chain resilience. In this dynamic environment, quick-turn CNC machining service in the USA has emerged as a critical enabler for companies seeking to maintain competitive advantage through speed, precision, and localized production capabilities. At JLYPT Precision, we have positioned ourselves at the forefront of this manufacturing evolution, providing comprehensive quick-turn CNC machining service in the USA that combines advanced technology with deep engineering expertise to deliver exceptional components with accelerated lead times.

This comprehensive analysis explores the technical capabilities, operational methodologies, and strategic advantages of modern quick-turn CNC machining service in the USA. We examine how the integration of advanced CNC technologies, streamlined workflows, and domestic manufacturing expertise enables companies across industries to accelerate innovation, reduce time-to-market, and respond dynamically to evolving market demands.

The Evolving Manufacturing Landscape and Demand for Speed

Recent industry developments underscore the growing importance of rapid manufacturing capabilities in the United States. According to the latest USMTO report, new orders for CNC machine tools and related technologies surged by 32.6% from February to March 2025, reaching $515.8 million . This represents a 33.8% increase compared to March 2024, with total manufacturing orders for the first quarter climbing to $1.255 billion – a 12.4% year-over-year increase . This robust performance indicates that manufacturing technology demand is beginning to recover after two years of moderate decline, with particularly strong growth in metal cutting equipment in the East North Central region, which saw orders jump 49.1% to $109.25 million .

Market Dynamics Driving Quick-Turn Adoption

Several factors are contributing to the increased demand for domestic quick-turn CNC machining service in the USA:

-

Compressed Development Cycles: Product development timelines across aerospace, medical device, and consumer electronics industries have accelerated dramatically, creating demand for manufacturing partners capable of supporting rapid iteration

-

Supply Chain Optimization: Companies are increasingly prioritizing domestic manufacturing to mitigate international supply chain risks, reduce logistics complexities, and improve responsiveness

-

Prototyping Efficiency: The ability to rapidly transform concepts into functional prototypes enables more thorough design validation and reduces overall development costs

-

Production Flexibility: Quick-turn capabilities provide manufacturing agility for low-volume production, bridge manufacturing, and emergency replacement parts

Technical Foundations of Rapid CNC Machining

The effectiveness of any quick-turn CNC machining service in the USA depends on the integration of advanced equipment, sophisticated programming, and optimized workflows:

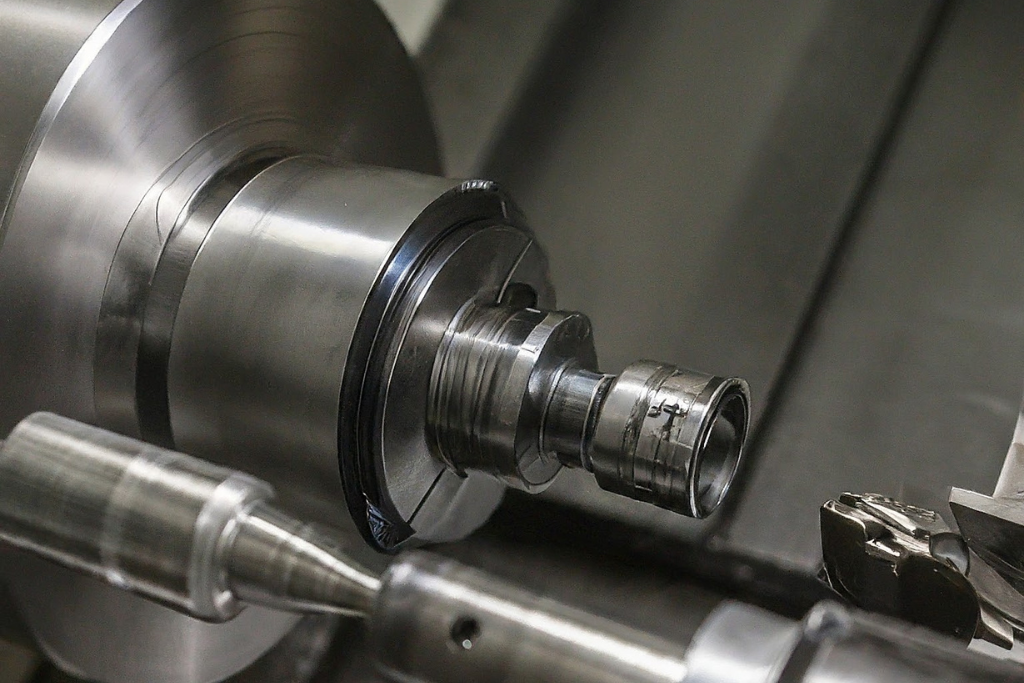

Advanced Equipment Capabilities

Modern quick-turn machining centers incorporate sophisticated technologies that enable both speed and precision:

-

High-Speed Machining Centers: Advanced CNC mills and lathes with spindle speeds exceeding 30,000 RPM, rapid traverse rates above 30,000 mm/min, and optimized acceleration/deceleration profiles

-

Multi-Axis Integration: 3+2 axis machining and full 5-axis simultaneous capabilities for complex geometries in single setups, significantly reducing handling and repositioning time

-

Automated Material Handling: Integrated pallet changers, robotic part loading/unloading, and automated tool changing systems that enable continuous operation

-

Advanced Control Systems: Next-generation CNC controllers with high-speed processing, look-ahead functionality, and adaptive machining capabilities

Precision and Tolerance Capabilities

Despite accelerated timelines, reputable providers of quick-turn CNC machining service in the USA maintain exceptional quality standards:

| Machining Process | Standard Tolerance | Precision Tolerance | Typical Applications |

|---|---|---|---|

| CNC Milling | ±0.025 mm (±0.001″) | ±0.0125 mm (±0.0005″) | Prototype housings, structural components, mechanical assemblies |

| CNC Turning | ±0.025 mm (±0.001″) | ±0.005 mm (±0.0002″) | Shafts, connectors, cylindrical components, fasteners |

| 5-Axis Machining | ±0.05 mm (±0.002″) | ±0.025 mm (±0.001″) | Complex contours, aerospace components, medical implants |

| Micro-Machining | ±0.0125 mm (±0.0005″) | ±0.005 mm (±0.0002″) | Medical device components, electronics, miniature assemblies |

Data compiled from industry standards and manufacturer specifications

Operational Methodologies for Accelerated Production

Achieving rapid turnaround times requires more than advanced equipment – it demands strategic implementation of optimized processes and workflows:

Digital Manufacturing Integration

Streamlined digital workflows form the backbone of effective quick-turn CNC machining service in the USA:

-

Automated Quoting Systems: AI-powered quoting engines that provide instant, accurate cost estimates based on CAD model analysis and manufacturing analytics

-

Integrated CAD/CAM: Seamless transition from customer design files to optimized toolpaths with automated feature recognition and machining strategy selection

-

Digital Twin Simulation: Virtual machining process verification that identifies potential collisions, optimizes toolpaths, and validates machining strategies before physical production

-

Real-Time Production Monitoring: Connected machine monitoring systems that track job progress, machine utilization, and potential delays throughout production

Production Optimization Strategies

Strategic approaches that compress traditional manufacturing timelines:

-

Concurrent Engineering: Parallel processing of design analysis, material preparation, and manufacturing planning to eliminate sequential delays

-

Adaptive Machining Strategies: Dynamic adjustment of cutting parameters based on real-time tool condition monitoring and material characteristics

-

Strategic Inventory Management: Maintenance of comprehensive raw material stocks in various alloys and engineering plastics to eliminate material procurement delays

-

Shift-Overlap Production: Staggered production schedules with coordinated handoffs between shifts to maintain continuous machining operations

Material Selection for Quick-Turn Applications

The availability of comprehensive material inventories is essential for responsive quick-turn CNC machining service in the USA:

Metallic Materials

-

Aluminum Alloys (6061-T6, 7075-T6): Excellent machinability with high strength-to-weight ratios for rapid processing with superior surface finishes

-

Stainless Steels (304, 316, 17-4PH): Corrosion resistance and mechanical properties suitable for demanding applications across medical, aerospace, and industrial sectors

-

Titanium Alloys (Ti-6Al-4V): High strength-to-weight ratio and exceptional corrosion resistance for aerospace, medical, and performance applications

-

Engineering Alloys (4130, 4140, 4340): Enhanced mechanical properties for high-stress applications in automotive, aerospace, and defense industries

Engineering Plastics

-

PEEK: Superior thermal and chemical resistance for demanding environmental conditions and high-temperature applications

-

Delrin (POM): Low friction and excellent dimensional stability for precision mechanical components and wear applications

-

Nylon: Good mechanical properties and wear resistance for functional prototypes and production components

-

Polycarbonate: High impact strength and transparency for visual prototypes, enclosures, and optical applications

Industry Applications and Case Studies

The versatility of quick-turn CNC machining service in the USA enables innovative solutions across multiple high-tech industries:

Case Study 1: Aerospace Actuation System Component

-

Challenge: An aerospace developer required functional prototypes of a critical flight control actuation component within 72 hours to support unexpected design changes identified during testing. The component needed to withstand extreme operational loads and maintain precise dimensional stability.

-

Solution: Our quick-turn CNC machining service in the USA team implemented a rapid manufacturing strategy using 7075-T651 aluminum with precision 5-axis machining. The process incorporated high-speed machining strategies and integrated inspection to maintain dimensional accuracy while compressing the production timeline.

-

Manufacturing Approach: The component was machined using simultaneous 5-axis strategies with adaptive toolpaths to optimize material removal rates while maintaining structural integrity. Critical bearing surfaces employed specialized finishing techniques to achieve required surface characteristics. In-process verification confirmed feature accuracy throughout machining.

-

Results: The completed component was delivered in 68 hours, enabling the customer to maintain their critical testing schedule. The prototype demonstrated perfect fit and function, validating the design modifications and supporting continued development without program delays.

Case Study 2: Medical Device Surgical Instrument

-

Challenge: A medical device company discovered a design flaw in a surgical instrument during clinical trials, requiring immediate design iteration and validation. The revised design needed biocompatible materials, precise ergonomic features, and validation within 5 days to support regulatory submissions.

-

Solution: We leveraged our quick-turn CNC machining service in the USA capabilities to produce the instrument from medical-grade stainless steel with electropolished surfaces. The process incorporated micro-machining for intricate features and specialized deburring for biocompatibility.

-

Manufacturing Approach: The instrument was manufactured using multi-axis machining centers with specialized tooling for medical applications. Critical features employed precision micro-machining with tolerances within ±0.005mm. The component underwent comprehensive cleaning and passivation to meet medical device requirements.

-

Results: The redesigned instrument was delivered in 4 days, enabling immediate clinical evaluation. The rapid turnaround supported successful regulatory submission and identified manufacturing optimizations that reduced production costs by 22% for the final design.

Case Study 3: Industrial Automation Component

-

Challenge: An industrial automation provider experienced unexpected failure of a critical motion control component, threatening production line shutdown. The replacement part required exotic materials, precise geometric tolerances, and immediate production to minimize facility downtime.

-

Solution: Our quick-turn CNC machining service in the USA team implemented emergency manufacturing protocols using 17-4PH stainless steel with solution treatment and aging to achieve required mechanical properties. The process prioritized critical features for sequential machining to enable partial delivery of essential elements.

-

Manufacturing Approach: The component utilized multi-axis turning with live tooling for complex off-axis features. Strategic sequencing enabled machining of critical mounting features within the first 24 hours, while secondary features were completed in parallel operations. Interim inspections validated essential dimensions throughout the process.

-

Results: Initial functional components were delivered within 36 hours, with complete components shipped in 78 hours. The rapid response prevented production line shutdown, saving the customer an estimated $425,000 in potential downtime costs.

Quality Assurance in Accelerated Manufacturing Environments

Maintaining rigorous quality standards while compressing production timelines requires sophisticated approaches to quality assurance:

-

First Article Inspection: Comprehensive dimensional validation using coordinate measuring machines with comparison to CAD data for initial production approval

-

In-Process Verification: Strategic inspection of critical features throughout the machining process to identify potential deviations early and enable corrective action

-

Statistical Process Control: Monitoring of key characteristics using control charts and process capability analysis to maintain consistency across production runs

-

Digital Documentation: Automated generation of inspection reports, material certifications, and manufacturing records to support quality verification and regulatory requirements

Economic Advantages of Domestic Quick-Turn Machining

Beyond speed, domestic quick-turn CNC machining service in the USA provides significant economic advantages:

-

Reduced Inventory Requirements: Just-in-time manufacturing capabilities minimize inventory carrying costs and warehouse requirements

-

Accelerated Time-to-Market: Compressed development and production cycles enable earlier product introduction and revenue generation

-

Risk Mitigation: Localized production reduces exposure to international supply chain disruptions, tariff fluctuations, and logistics uncertainties

-

Total Cost Optimization: While unit costs may be higher than offshore production, total program costs are often lower when considering accelerated timelines, reduced inventory, and risk mitigation

The Future of Quick-Turn CNC Machining

The field of quick-turn CNC machining service in the USA continues to evolve with emerging technologies and methodologies:

-

AI-Driven Optimization: Implementation of machine learning algorithms for predictive process planning, toolpath optimization, and maintenance scheduling

-

Digital Thread Integration: Seamless data flow from design through manufacturing and quality verification enabling unprecedented visibility and control

-

Additive-Subtractive Hybrid: Integration of 3D printing with CNC machining for enhanced geometric freedom and further compression of manufacturing timelines

-

Advanced Materials: Development and implementation of new alloys and engineered materials with enhanced properties for specific performance requirements

-

Sustainable Manufacturing: Implementation of energy-efficient processes, material recycling, and waste reduction strategies without compromising speed or quality

Conclusion: Strategic Partnership for Accelerated Innovation

In today’s competitive manufacturing environment, speed, precision, and responsiveness are not merely advantages – they are necessities. The capabilities offered by advanced quick-turn CNC machining service in the USA provide companies across industries with the manufacturing agility needed to navigate dynamic markets, accelerate innovation, and maintain competitive advantage.

At JLYPT Precision, our comprehensive approach to quick-turn CNC machining service in the USA combines state-of-the-art equipment, deep technical expertise, and optimized workflows to deliver exceptional components with accelerated lead times. Whether supporting rapid prototyping, bridge manufacturing, or emergency production requirements, our capabilities and commitment to excellence ensure that our customers can move with confidence and speed from concept to reality.

Ready to accelerate your next project with precision quick-turn machining? Contact JLYPT Precision today to discover how our expertise in quick-turn CNC machining service in the USA can help you achieve your development and production goals with unprecedented speed, quality, and technical excellence. Visit our CNC Machining Services page to learn more about our comprehensive capabilities and request your instant quote.