8 Critical Advantages of Crossed Roller Bearing Robot Technology in Precision Automation

Introduction: Revolutionizing Robotic Motion with Precision Bearing Technology

The integration of crossed roller bearing robot systems represents a significant advancement in precision motion control, offering unparalleled performance characteristics that are transforming industrial automation and robotics. These sophisticated bearing systems combine high rigidity, exceptional accuracy, and compact design to deliver superior performance in demanding robotic applications. The crossed roller bearing robot utilizes a unique bearing arrangement where cylindrical rollers are arranged in a cross pattern between two raceways, enabling simultaneous load handling in multiple directions with minimal friction and exceptional precision. This technology has become increasingly crucial as industrial robots demand higher accuracy, greater stiffness, and more compact designs for advanced manufacturing applications.

As precision engineering specialists at JLYPT, we have developed comprehensive expertise in manufacturing critical components for crossed roller bearing robot systems. This detailed technical analysis explores eight essential advantages of crossed roller bearing technology, while examining the sophisticated manufacturing methodologies that ensure optimal performance in demanding robotic applications across various industries.

1. Fundamental Principles of Crossed Roller Bearing Technology

1.1 Unique Mechanical Architecture

The crossed roller bearing robot system operates on a fundamentally different principle than conventional bearing arrangements, utilizing a cross-oriented roller configuration that provides exceptional mechanical advantages for robotic applications.

Key Bearing Components:

-

Crossed Roller Arrangement: Cylindrical rollers positioned at 90-degree angles to adjacent rollers

-

Precision Raceways: Hardened and ground bearing surfaces with controlled geometry

-

Integrated Sealing Systems: Multi-stage sealing for contamination protection

-

Preload Adjustment: Controlled internal clearance for optimal stiffness

-

Mounting Interfaces: Precision machined mounting surfaces for accurate installation

Bearing Performance Characteristics:

| Performance Metric | Crossed Roller Bearing | Linear Guide | Rotary Bearing | Improvement Factor |

|---|---|---|---|---|

| Rigidity | 500-800 N/μm | 200-400 N/μm | 100-300 N/μm | 2-4x higher |

| Accuracy | ±0.001-0.005 mm | ±0.01-0.02 mm | ±0.005-0.015 mm | 3-10x better |

| Load Capacity | High in all directions | Directional | Directional | More versatile |

| Cross Moment | Excellent | Good | Poor | Superior stability |

| Compactness | High | Medium | Low | Space efficient |

1.2 Performance Classification and Applications

Crossed Roller Bearing Performance Categories:

| Bearing Class | Roller Diameter (mm) | Accuracy Grade | Load Capacity (kN) | Stiffness (N/μm) |

|---|---|---|---|---|

| Precision Grade | 3-6 | P5 | 10-50 | 300-500 |

| High Precision | 4-8 | P4 | 20-80 | 400-600 |

| Ultra Precision | 5-10 | P2 | 30-100 | 500-800 |

| Heavy Duty | 8-15 | P5 | 50-200 | 600-1000 |

| Miniature | 2-4 | P5 | 5-20 | 200-400 |

2. Advanced Material Selection and Engineering

2.1 Comprehensive Material Strategy

The performance of crossed roller bearing robot components depends on advanced material selection where hardness, toughness, and dimensional stability are carefully balanced for optimal performance.

Material Selection Matrix for Bearing Components:

| Material Specification | Component Application | Hardness (HRC) | Toughness | Corrosion Resistance |

|---|---|---|---|---|

| SAE 52100 Steel | Standard rollers, raceways | 58-62 | Good | Moderate |

| M50 Tool Steel | High-temperature applications | 60-64 | Very Good | Good |

| 440C Stainless | Corrosive environments | 55-60 | Good | Excellent |

| Ceramic Hybrid | High-speed applications | 70-75 | Moderate | Excellent |

| Cronidur 30 | Extreme environments | 60-65 | Excellent | Superior |

| Aluminum 7075-T6 | Mounting components | 60 | Good | Moderate |

2.2 Specialized Material Processing

Advanced Heat Treatment Processes:

-

Deep Freeze Treatment: Thermal cycling to -196°C for dimensional stability and stress relief

-

Case Carburizing: Surface hardening to 60-64 HRC with controlled case depth

-

Nitriding Processes: Plasma and gas nitriding for enhanced surface properties

-

Tempering Control: Multiple tempering cycles for optimal toughness

Surface Engineering Applications:

-

Superfinishing: Surface roughness Ra 0.05-0.1μm for reduced friction and wear

-

DLC Coatings: Diamond-like carbon coatings for extreme pressure applications

-

PVD Coatings: Titanium nitride and chromium nitride for wear resistance

-

Lubrication Optimization: Advanced grease formulations for extended service life

3. Precision CNC Machining Methodologies

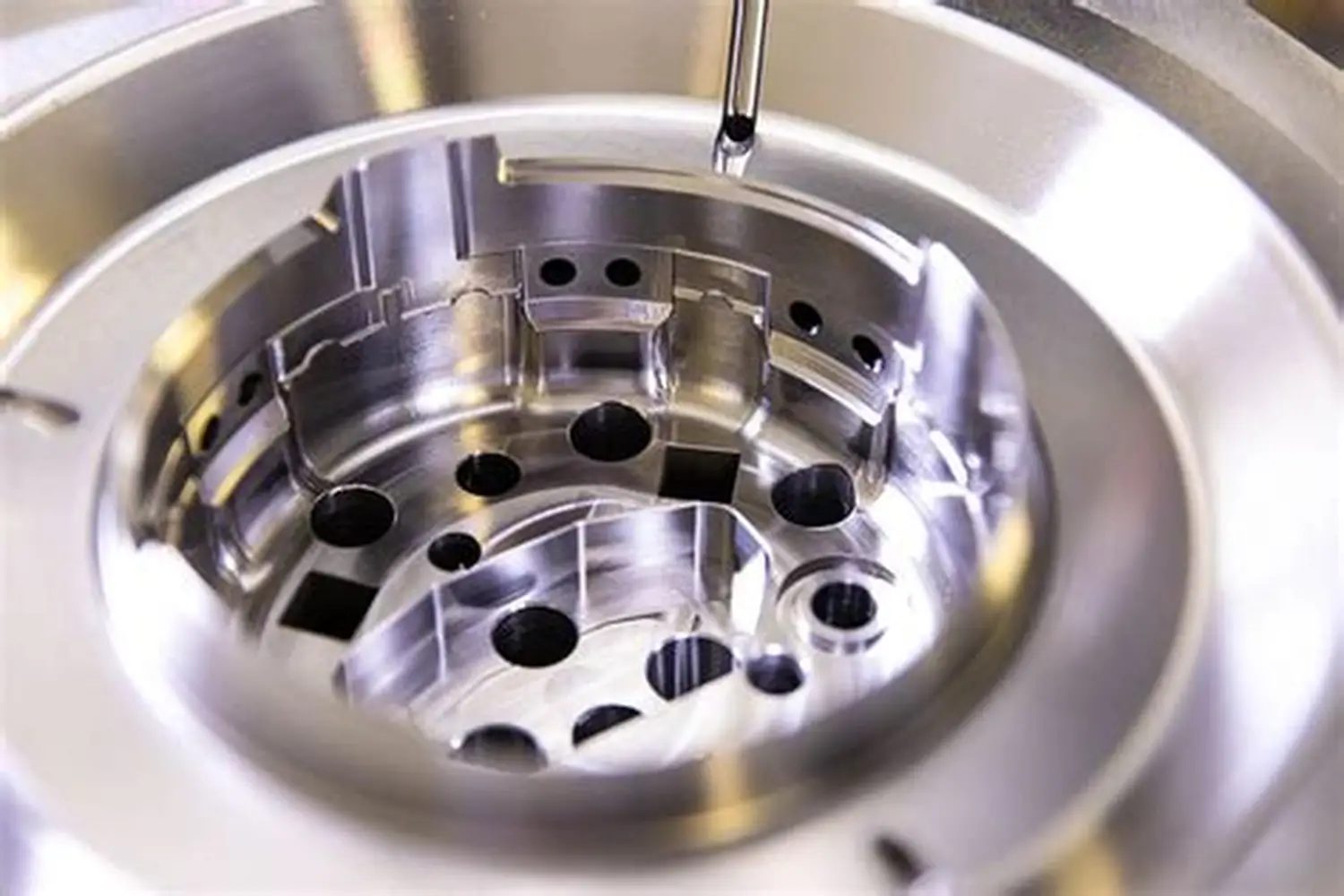

3.1 Multi-Axis Machining for Bearing Components

The manufacturing of crossed roller bearing robot components requires advanced CNC machining capabilities to achieve the complex geometries and tight tolerances necessary for optimal performance.

5-Axis Simultaneous Machining Applications:

-

Complex Raceway Geometries: Single-setup machining of precision bearing tracks

-

Integrated Mounting Features: Precision machining of mounting interfaces and alignment surfaces

-

Micro-Machining: Production of miniature components with sub-micron tolerances

-

Hard Machining: Precision machining of hardened components to final dimensions

Critical Machining Parameters for Bearing Components:

| Manufacturing Process | Material Type | Cutting Speed (m/min) | Feed Rate (mm/rev) | Depth of Cut (mm) | Tolerance (mm) |

|---|---|---|---|---|---|

| Precision Grinding | Hardened Steel | 25-35 | 0.5-2.0 | 0.01-0.05 | ±0.001 |

| Hard Turning | Hardened Steel | 80-120 | 0.03-0.08 | 0.1-0.3 | ±0.005 |

| Fine Boring | Steel | 60-100 | 0.02-0.06 | 0.1-0.3 | ±0.003 |

| Honing | Various | 30-60 | 0.1-0.5 | 0.005-0.02 | ±0.002 |

| Lapping | Hardened | 10-30 | N/A | 0.001-0.005 | ±0.0005 |

3.2 Specialized Manufacturing Processes

Raceway Manufacturing:

-

Profile Grinding: Precision grinding of complex raceway geometries

-

Superfinishing: Final surface refinement for optimal roller contact

-

Geometry Verification: Comprehensive measurement of raceway profiles

-

Surface Integrity: Controlled processing to prevent grinding burns

Roller Manufacturing Excellence:

-

Centerless Grinding: Diameter control within ±0.001mm

-

Geometry Optimization: Controlled crown profiles for stress distribution

-

Surface Finishing: Advanced finishing processes for extended life

-

Quality Sorting: Automated dimensional and geometric sorting

4. Bearing System Design and Integration

4.1 Advanced Design Principles

The design of crossed roller bearing robot systems requires sophisticated engineering approaches to optimize performance for specific applications.

Design Optimization Factors:

-

Load Distribution: Finite element analysis for optimal stress distribution

-

Thermal Management: Heat dissipation and thermal expansion considerations

-

Stiffness Optimization: Balancing static and dynamic stiffness requirements

-

Life Calculation: Advanced life prediction models based on application conditions

Integration Considerations:

-

Mounting Interface Design: Precision mounting surfaces and alignment features

-

Preload Optimization: Controlled preload for optimal stiffness and life

-

Sealing Systems: Multi-stage sealing for environmental protection

-

Lubrication Systems: Advanced lubrication delivery and retention

4.2 Performance Validation and Testing

Comprehensive Testing Protocols:

-

Rigidity Testing: Static and dynamic stiffness measurement

-

Accuracy Verification: Positioning repeatability and error measurement

-

Life Testing: Accelerated life testing under controlled conditions

-

Environmental Testing: Performance under temperature and contamination conditions

5. Thermal Management and Lubrication Systems

5.1 Advanced Thermal Considerations

Effective thermal management is crucial in crossed roller bearing robot applications where precision and stability are affected by temperature variations.

Thermal Performance Factors:

-

Heat Generation: Friction-induced heat from rolling and sliding contacts

-

Thermal Expansion: Dimensional changes affecting preload and clearance

-

Heat Dissipation: Cooling through conduction, convection, and radiation

-

Temperature Monitoring: Integrated sensors for real-time temperature tracking

Lubrication System Design:

| Lubrication Type | Temperature Range | Speed Limit | Life Expectancy | Maintenance |

|---|---|---|---|---|

| Grease | -30°C to +120°C | Moderate | 5,000-10,000 h | Periodic |

| Oil Mist | -20°C to +150°C | High | 10,000-20,000 h | Continuous |

| Oil Jet | -20°C to +150°C | Very High | 15,000-30,000 h | Continuous |

| Solid Film | -200°C to +300°C | Low | 2,000-5,000 h | Minimal |

| Hybrid | -40°C to +200°C | High | 8,000-15,000 h | Periodic |

6. Precision Assembly and Quality Control

6.1 Controlled Assembly Processes

The assembly of crossed roller bearing robot systems requires meticulous process control and precision alignment to ensure optimal performance.

Critical Assembly Protocols:

-

Clean Room Assembly: Class 1000 environment for precision assembly

-

Component Matching: Selective assembly for optimal performance matching

-

Preload Control: Precision preload adjustment with torque monitoring

-

Alignment Verification: Laser alignment and geometric measurement

Assembly Quality Metrics:

-

Runout Tolerance: 0.003mm maximum for precision applications

-

Parallelism: 0.005mm per 100mm for mounting surfaces

-

Flatness: 0.004mm per 100mm for critical interfaces

-

Surface Finish: Ra 0.2μm or better for sealing surfaces

6.2 Comprehensive Quality Assurance

Advanced Metrology Systems:

-

Roundness Measurement: Accuracy to 0.1μm with harmonic analysis

-

Surface Topography: 3D surface analysis with nanometer resolution

-

Coordinate Measuring: Volumetric accuracy 1.5 + L/400 μm

-

Optical Profilometry: Non-contact surface measurement for delicate components

7. Application-Specific Engineering Solutions

7.1 Customized Design Implementation

The development of specialized crossed roller bearing robot systems requires application-specific engineering approaches to meet unique operational requirements.

Industry-Specific Considerations:

-

Semiconductor Equipment: Ultra-high vacuum compatibility and minimal particle generation

-

Medical Robotics: Biocompatible materials and sterilization compatibility

-

Aerospace Systems: Extreme temperature performance and lightweight design

-

Industrial Automation: High cycle life and maintenance-free operation

7.2 Performance Optimization Strategies

Application-Tailored Solutions:

-

Stiffness Enhancement: Optimized cross-section and material selection

-

Accuracy Improvement: Precision manufacturing and thermal stabilization

-

Life Extension: Advanced materials and lubrication systems

-

Size Reduction: Compact design with maintained performance

8. Case Study Applications

Case Study 1: High-Precision Semiconductor Robot

Challenge: A semiconductor equipment manufacturer required crossed roller bearing robot systems for wafer handling robots with positioning accuracy of ±0.001mm and minimal particle generation in cleanroom environments.

JLYPT Solution: We developed custom crossed roller bearing robot systems featuring vacuum-compatible materials and specialized sealing systems. The manufacturing process incorporated precision grinding and superfinishing to achieve the required accuracy and surface finish.

Results:

-

Achieved positioning accuracy of ±0.0008mm

-

Reduced particle generation by 95% compared to standard bearings

-

Maintained performance through 20,000 hours of continuous operation

-

Enabled faster acceleration through higher stiffness

Case Study 2: Aerospace Testing Equipment

Challenge: An aerospace manufacturer required crossed roller bearing robot systems for testing equipment with extreme temperature operation (-55°C to +125°C) and high load capacity.

JLYPT Solution: Our team developed specialized crossed roller bearing robot systems using high-temperature materials and advanced lubrication systems. All components underwent rigorous testing and qualification for aerospace applications.

Results:

-

Operated reliably across full temperature range

-

Achieved load capacity 50% higher than requirements

-

Maintained accuracy within ±0.002mm under all conditions

-

Met all MIL-STD-810 environmental requirements

Case Study 3: High-Speed Packaging Automation

Challenge: A packaging automation specialist required crossed roller bearing robot systems capable of 1,000 cycles per minute with minimal maintenance and high reliability.

JLYPT Solution: We implemented high-performance crossed roller bearing robot systems featuring advanced lubrication and sealing systems. The design optimized dynamic performance and life expectancy for continuous operation.

Results:

-

Achieved operational speeds of 1,100 cycles per minute

-

Extended service life to 30,000 hours between maintenance

-

Reduced downtime by 80% through improved reliability

-

Maintained positioning accuracy within ±0.005mm

Future Development Trends

Emerging Technologies and Innovations

The continued evolution of crossed roller bearing robot technology is driving advancements across multiple technical domains.

Advanced Material Applications:

-

Ceramic Matrix Composites: Enhanced high-temperature performance and wear resistance

-

Nanostructured Materials: Improved surface properties and fatigue resistance

-

Smart Materials: Embedded sensing and self-adjusting capabilities

-

Hybrid Composites: Optimized combinations of material properties

Digital Integration Technologies:

-

Embedded Sensors: Real-time monitoring of load, temperature, and condition

-

IoT Connectivity: Cloud-based monitoring and predictive maintenance

-

Digital Twin Integration: Virtual modeling for performance optimization

-

AI-Driven Optimization: Machine learning for predictive maintenance and performance tuning

Conclusion: Engineering Excellence in Precision Motion

Crossed roller bearing robot technology represents the pinnacle of precision engineering in modern automation systems. The eight advantages explored—high rigidity, exceptional accuracy, compact design, multi-directional load capacity, long service life, smooth operation, thermal stability, and maintenance efficiency—demonstrate the comprehensive benefits that make crossed roller bearings the preferred solution for demanding robotic applications.

As robotic technology continues to advance, the requirements for crossed roller bearing robot systems will become increasingly demanding, driving further innovation in manufacturing technologies and material science. The integration of digital technologies, advanced analytics, and smart materials will ensure that crossed roller bearing technology remains at the forefront of precision motion control innovation.

At JLYPT, our commitment to manufacturing excellence ensures that every crossed roller bearing robot component we produce meets the highest standards of performance, reliability, and precision. Through continuous improvement and rigorous quality assurance, we enable our partners to achieve new levels of capability and performance in their automated systems.

For engineering teams seeking to enhance their robotic systems through superior bearing solutions, contact JLYPT today to discuss your specific requirements and discover how our manufacturing expertise can contribute to your success in the competitive field of industrial automation.