Strategic Manufacturing Partnerships: Comprehensive OEM Services for Robotics Innovation and Production

The robotics industry’s explosive growth has fundamentally transformed manufacturing paradigms, creating unprecedented demand for specialized OEM services for robotics companies that combine engineering expertise with scalable production capabilities. As robotics systems evolve from standardized platforms to highly specialized solutions, Original Equipment Manufacturer partnerships have become essential strategic relationships that determine market success. At JLYPT, our comprehensive OEM services for robotics companies encompass the complete product lifecycle—from initial concept development through volume production and aftermarket support—enabling robotics innovators to focus on core competencies while we manage the complex challenges of precision manufacturing and supply chain optimization.

The Evolution of OEM Partnerships in Robotics Manufacturing

The traditional OEM model has undergone significant transformation in the robotics sector, driven by several industry-specific factors:

Technical Complexity Integration

Modern robotic systems require OEM services for robotics companies that can manage increasingly complex technical integrations:

-

Multi-Disciplinary Engineering: Successful robotics OEM partnerships must bridge mechanical, electrical, software, and control engineering disciplines

-

Material Science Advancement: Implementation of advanced materials including composites, specialized alloys, and engineered polymers

-

Precision Requirements: Component tolerances now routinely reach ±0.005mm, with surface finishes demanding Ra 0.2μm or better for optimal performance

-

Regulatory Compliance: Navigating complex regulatory landscapes including ISO 10218, ISO/TS 15066, and industry-specific certifications

Supply Chain Optimization Challenges

Effective OEM services for robotics companies must address unique supply chain considerations:

-

Component Specialization: Many robotic components have no commercial equivalents, requiring custom manufacturing solutions

-

Quality Consistency: Maintaining consistent quality across production runs despite complex manufacturing processes

-

Lead Time Management: Balancing production efficiency with the rapid iteration cycles common in robotics development

-

Cost Engineering: Implementing value engineering without compromising performance or reliability

Comprehensive OEM Service Framework

Our OEM services for robotics companies are structured around a comprehensive framework designed to address every aspect of robotic product development and manufacturing:

Design and Engineering Services

-

Design for Manufacturing Analysis: Early-stage optimization of designs for efficient production while maintaining performance requirements

-

Tolerance Stack Analysis: Comprehensive evaluation of cumulative tolerances across complex assemblies

-

Finite Element Analysis: Structural, thermal, and dynamic analysis ensuring design robustness

-

Prototype Development: Rapid prototyping using multiple technologies including CNC machining, 3D printing, and vacuum casting

Advanced Manufacturing Capabilities

-

Multi-Axis CNC Machining: 5-axis simultaneous machining for complex geometries with accuracies to ±0.005mm

-

Precision Grinding: Surface, cylindrical, and profile grinding achieving surface finishes to Ra 0.1μm

-

Swiss-Type Machining: For small, complex components requiring high precision and volume production

-

Additive Manufacturing: Metal and polymer 3D printing for complex internal structures and lightweight components

Assembly and Integration Services

-

Cleanroom Assembly: Class 1000 cleanroom facilities for precision assembly operations

-

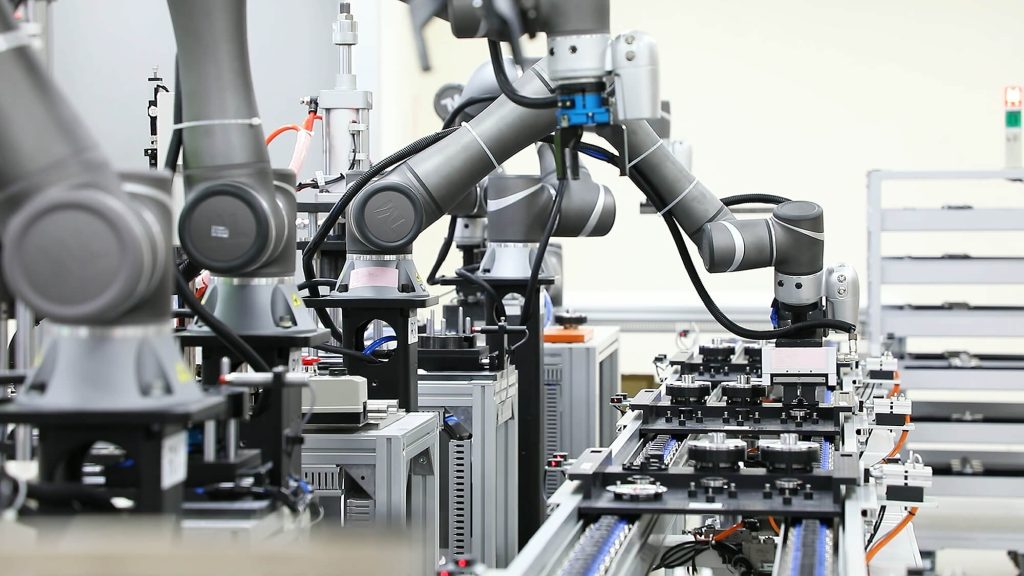

Automated Assembly Lines: Robotic workcells for high-volume production with consistent quality

-

Testing and Validation: Comprehensive functional testing, including motion accuracy, repeatability, and cycle testing

-

Packaging and Logistics: Custom packaging solutions and global logistics management

Technical Capability Matrix

Table 1: Comprehensive OEM Services Capability Matrix

| Service Category | Standard OEM | Advanced OEM | Full-Service OEM | Turnkey Solutions |

|---|---|---|---|---|

| Design Services | Basic DFM | Full engineering support | Complete design ownership | Innovation partnership |

| Prototyping | Limited iterations | Multiple iterations | Unlimited iterations | Accelerated development |

| Volume Capacity | 100-10,000 units | 1,000-100,000 units | 10,000-1M units | Scalable to any volume |

| Tolerance Capability | ±0.05mm | ±0.02mm | ±0.005mm | ±0.002mm |

| Material Options | Standard metals | Extended material range | Full material portfolio | Custom material development |

| Quality Systems | ISO 9001 | ISO 13485/AS9100 | IATF 16949 | Customer-specific systems |

| Supply Chain | Basic management | Full visibility | Complete management | Strategic optimization |

| Testing Services | Basic functional | Comprehensive testing | Full validation suite | Certification support |

| Lead Time | 8-12 weeks | 6-10 weeks | 4-8 weeks | 2-6 weeks |

| IP Protection | Standard NDA | Enhanced protection | Full security systems | Co-development agreements |

Precision Manufacturing Technologies

Our OEM services for robotics companies leverage advanced manufacturing technologies specifically optimized for robotic components:

Multi-Axis CNC Machining Specialization

-

5-Axis Simultaneous Machining: Complex contour machining for robotic arm segments and end-effector components

-

High-Speed Machining: Spindle speeds to 30,000 RPM with optimized toolpaths for aluminum and composite materials

-

Micro-Machining: Capabilities for miniature components with features as small as 0.1mm

-

Turn-Mill Centers: Complete processing of complex components in single setups

Advanced Material Processing

-

Titanium Machining: Specialized techniques for Ti-6Al-4V and other aerospace-grade alloys

-

Composite Manufacturing: Precision machining of carbon fiber and other advanced composites

-

Hard Material Processing: Machining of hardened steels (up to 65 HRC) and ceramics

-

Exotic Alloys: Experience with Inconel, Hastelloy, and other specialized materials

Surface Enhancement Technologies

-

Electropolishing: Precision surface finishing for stainless steel components

-

Anodizing: Type II and Type III anodizing for aluminum components

-

Plating Services: Nickel, chrome, and specialty plating for enhanced wear resistance

-

Heat Treatment: Vacuum heat treating, nitriding, and case hardening services

Quality Assurance and Regulatory Compliance

Our OEM services for robotics companies include comprehensive quality systems designed for the robotics industry:

Quality Management Systems

-

ISO 9001:2015 Certification: Fundamental quality management system

-

AS9100D Compliance: Aerospace quality standards applicable to high-reliability robotics

-

ISO 13485 Certification: Medical device quality management for surgical and medical robotics

-

IATF 16949: Automotive quality standards for automotive robotics applications

Metrology and Inspection Capabilities

-

Coordinate Measuring Machines: Multi-sensor CMMs with volumetric accuracy to 1.8 + L/350 μm

-

Optical Measurement Systems: White light scanners and vision measurement systems

-

Surface Analysis: Profilometers and interferometers for nano-scale surface characterization

-

Material Testing: Complete in-house material verification and testing

Documentation and Traceability

-

Full Material Traceability: Documentation from raw material to finished assembly

-

First Article Inspection: Comprehensive FAIR reports per AS9102 standards

-

Statistical Process Control: Real-time process monitoring and control

-

Electronic Traveler Systems: Complete digital record of manufacturing processes

Case Study Applications

Case Study 1: Collaborative Robot Manufacturer

-

Challenge: A startup developing collaborative robots needed to scale from prototype to volume production while maintaining the precision and quality required for safe human-robot interaction. They lacked manufacturing infrastructure and expertise in production scaling.

-

Solution: JLYPT provided complete OEM services for robotics companies, including redesign for manufacturability, supply chain establishment, and implementation of automated assembly lines. We developed specialized fixtures for precision alignment and implemented 100% functional testing of all units.

-

Result: Enabled production scaling from 10 units/month to 500 units/month within 9 months. Achieved consistent quality with positional repeatability of ±0.02mm across all production units. Reduced manufacturing costs by 40% through value engineering and process optimization.

Case Study 2: Surgical Robotics System

-

Challenge: A medical device company developing a minimally invasive surgical robot required OEM services that could meet FDA regulatory requirements while achieving extreme precision and reliability. Components required biocompatible materials and cleanroom manufacturing.

-

Solution: We established a dedicated cleanroom manufacturing cell (Class 1000) and implemented medical-grade manufacturing processes. Our OEM services for robotics companies included complete documentation systems for FDA 510(k) submission and rigorous validation testing.

-

Result: Successfully achieved FDA clearance with zero manufacturing-related issues. Components maintained sterile barrier integrity and met all precision requirements (±0.01mm positional accuracy). Established sustainable production capacity of 200 systems annually.

Case Study 3: Autonomous Mobile Robot Fleet

-

Challenge: A logistics automation company needed to manufacture 5,000 autonomous mobile robots for warehouse deployment within 18 months. The challenge included complex supply chain management, quality consistency, and field service support.

-

Solution: JLYPT implemented a turnkey OEM services for robotics companies solution, including supply chain management, automated assembly lines, and comprehensive testing. We established regional service centers and developed a modular design allowing field upgrades and repairs.

-

Result: Delivered 5,200 units within 16 months, achieving 99.7% first-pass yield. Established field service network supporting 98% uptime across deployed fleet. Implemented continuous improvement process reducing manufacturing costs by 15% annually.

Supply Chain Integration and Management

Effective OEM services for robotics companies require sophisticated supply chain management:

Supplier Development and Management

-

Strategic Sourcing: Development of supply base for specialized robotic components

-

Supplier Qualification: Rigorous qualification processes for all suppliers

-

Performance Monitoring: Continuous monitoring of supplier quality and delivery performance

-

Risk Management: Multi-sourcing strategies and inventory buffer management

Inventory and Logistics Optimization

-

Just-in-Time Delivery: Synchronized delivery of components to production lines

-

Kanban Systems: Visual management systems for production supply

-

Warehouse Management: Efficient storage and retrieval of components and finished goods

-

Global Logistics: Coordination of international shipping and customs clearance

Cost Management and Value Engineering

-

Should-Cost Analysis: Detailed analysis of component manufacturing costs

-

Value Engineering: Continuous identification of cost reduction opportunities

-

Total Cost of Ownership: Comprehensive evaluation of all cost factors

-

Lifecycle Costing: Analysis of costs across the entire product lifecycle

Technology and Innovation Integration

Our OEM services for robotics companies actively incorporate emerging technologies:

Digital Manufacturing Technologies

-

Industrial IoT Integration: Connected manufacturing equipment providing real-time production data

-

Digital Twin Technology: Virtual models of manufacturing processes for optimization

-

Augmented Reality: AR-assisted assembly and quality inspection

-

Predictive Analytics: Data analytics for predictive maintenance and quality prediction

Sustainable Manufacturing Initiatives

-

Energy Efficiency: Optimization of manufacturing processes for reduced energy consumption

-

Material Optimization: Reduction of material waste through advanced nesting and optimization

-

Circular Economy: Design for disassembly and material recovery

-

Environmental Compliance: Adherence to environmental regulations and standards

Advanced Automation Integration

-

Collaborative Robotics: Implementation of cobots in manufacturing processes

-

Automated Quality Inspection: Vision systems and automated measurement

-

Smart Factory Integration: Integration of manufacturing systems with enterprise systems

-

Adaptive Manufacturing: Flexible manufacturing systems responding to changing requirements

Strategic Partnership Advantages

Choosing JLYPT for OEM services for robotics companies provides significant strategic advantages:

Risk Mitigation

-

Manufacturing Risk Transfer: Transfer of manufacturing risks to experienced partner

-

Capital Preservation: Avoidance of capital investment in manufacturing infrastructure

-

Scalability Flexibility: Ability to scale production up or down based on market demand

-

Technology Risk Management: Access to latest manufacturing technologies without investment

Time-to-Market Acceleration

-

Parallel Development: Concurrent engineering and manufacturing preparation

-

Ramp-Up Optimization: Efficient transition from prototype to volume production

-

Regulatory Navigation: Expertise in regulatory requirements and certification processes

-

Market Responsiveness: Ability to respond quickly to market changes and opportunities

Cost Optimization

-

Economies of Scale: Leveraging volume across multiple customers

-

Manufacturing Expertise: Optimization of processes for cost efficiency

-

Supply Chain Leverage: Volume purchasing power with suppliers

-

Overhead Distribution: Spreading fixed costs across multiple customers

Future Trends in Robotics OEM Services

The landscape of OEM services for robotics companies continues to evolve:

Technology Integration Trends

-

AI-Enhanced Manufacturing: Artificial intelligence optimizing manufacturing processes

-

Additive Manufacturing Growth: Increasing use of 3D printing for complex components

-

Advanced Materials: Implementation of new materials with enhanced properties

-

Digital Thread Integration: Complete digital record from design through retirement

Business Model Evolution

-

Servitization: Shift from product sales to service-based models

-

Platform Strategies: Development of platform-based approaches to robotics

-

Ecosystem Development: Creation of ecosystems around robotic platforms

-

Global Localization: Balancing global scale with local customization

Sustainability Focus

-

Carbon Neutral Manufacturing: Implementation of carbon-neutral manufacturing processes

-

Extended Producer Responsibility: Taking responsibility for products throughout lifecycle

-

Sustainable Materials: Increasing use of recycled and sustainable materials

-

Energy-Efficient Designs: Optimization of products for energy efficiency

Conclusion: Strategic Manufacturing Partnerships for Robotics Success

The selection of OEM services for robotics companies represents one of the most critical strategic decisions in robotics product development and commercialization. In an industry characterized by rapid technological advancement and intense competition, effective manufacturing partnerships can determine market success or failure. The right OEM partner provides not just manufacturing capacity, but strategic advantage through engineering expertise, supply chain management, and quality assurance.

At JLYPT, our comprehensive approach to OEM services for robotics companies encompasses every aspect of product realization, from initial concept through volume production and aftermarket support. We combine advanced manufacturing technologies with deep robotics expertise to deliver solutions that accelerate time-to-market, optimize costs, and ensure quality. Our partnership model is designed to evolve with your needs, providing scalable solutions that support growth and adaptation in dynamic markets.

Ready to accelerate your robotics product development with comprehensive OEM services? Contact JLYPT today to discuss how our OEM services for robotics companies can transform your manufacturing strategy. Our team stands ready to partner with you in creating innovative robotic solutions that define the future of automation.