Optimizing Production with Used Industrial Robots for CNC Machining: A Strategic Technical Guide

Introduction: The Strategic Advantage of Used Industrial Robots for CNC Machining

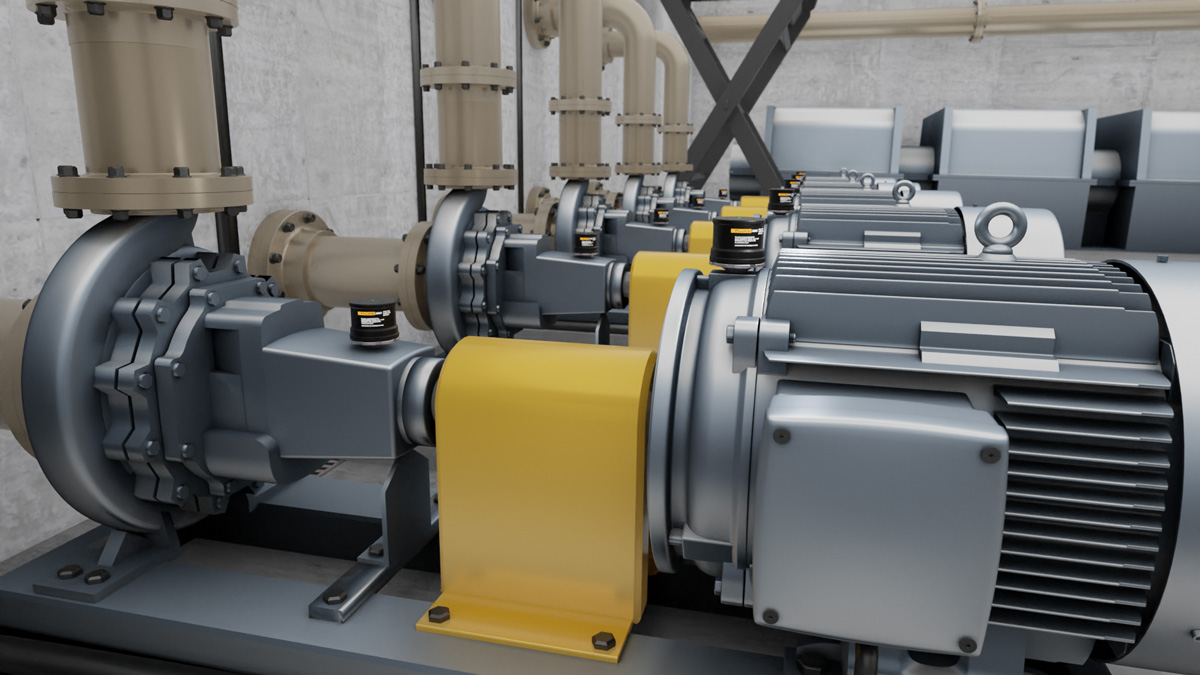

In the relentless pursuit of manufacturing excellence, the integration of automation has transitioned from a luxury to a necessity. For precision-driven sectors served by CNC machining, such as aerospace, automotive, and medical device manufacturing, the constant pressure to enhance throughput, ensure micron-level accuracy, and control operational costs is paramount. While new robotic automation solutions offer cutting-edge features, they often come with a prohibitive capital expenditure. This is where a strategic, optimized approach to used industrial robots for CNC machining presents a transformative opportunity.

At JLYPT, our expertise in high-precision CNC machining services is complemented by a deep understanding of manufacturing systems. We recognize that used industrial robots for CNC machining are not merely cost-saving tools but potent assets that, when properly selected, refurbished, and integrated, can elevate a machining cell’s performance to rival that of fully new installations. This comprehensive guide is engineered for manufacturing engineers, operations managers, and business owners seeking to harness the power of automation without the steep initial investment. We will dissect the technical considerations, outline a meticulous optimization framework, and present detailed case studies to demonstrate how used industrial robots for CNC machining can become the cornerstone of a more efficient, reliable, and profitable manufacturing operation.

Section 1: The Synergistic Role of Robots in Modern CNC Ecosystems

CNC machining, by its nature, is a subtractive manufacturing process defined by programmed toolpaths, precise spindle control, and rigid workholding. The introduction of industrial robots into this environment creates a synergistic system where each component’s capabilities are multiplied.

1.1 Core Applications in the Machining Cell

Robots transcend simple material handling in advanced CNC setups. Their primary applications include:

-

Automated Part Loading/Unloading (Pick-and-Place): The most common application, where robots interface with conveyors, pallet systems, or CNC machine doors to manage raw blanks and finished parts, enabling lights-out manufacturing.

-

Machine Tending: This involves more complex interaction, where a robot may open the machine door, unclamp a finished part, remove it, clean the fixture (via air blast or brushing), load a new blank, and initiate the next cycle—all synchronized with the CNC’s M-codes.

-

Secondary Operations: Robots can be equipped with tools to perform in-cell deburring, polishing, washing, or laser marking after the primary CNC operation is complete, consolidating process steps.

-

Complex Positioning for Multi-Axis Machining: In advanced 5-axis or mill-turn applications, a robot can act as a “repositioner,” holding and dynamically orienting a workpiece to allow the CNC machine to access all required angles in a single setup, dramatically reducing cycle times and improving accuracy.

1.2 Technical Imperatives for Robotic Integration

Not every robot is suited for the harsh, precise world of CNC machining. Key technical specifications must be evaluated:

-

Payload Capacity: Must account for the weight of the heaviest workpiece plus the end-of-arm tooling (EOAT). A safety margin of 25-30% is recommended.

-

Repeatability vs. Accuracy: For machining tending, repeatability (the robot’s ability to return to the same point) is often more critical than absolute accuracy. Modern used robots from reputable brands typically offer repeatability well within ±0.1mm, sufficient for most loading tasks.

-

Stiffness and Vibration Damping: The robot’s structural rigidity directly impacts its ability to handle machining forces during part repositioning and its resistance to vibration, which can affect long-term reliability.

-

IP Rating: Ingress Protection rating is crucial. Machining environments contain coolants, oils, and metallic particulates. A minimum of IP54 is often required, with IP67 being ideal for wash-down or harsh conditions.

Section 2: The Compelling Economics and Selection of Used Industrial Robots

The decision to invest in used industrial robots for CNC machining is fundamentally strategic. The following table breaks down the key comparative factors.

Table 1: Financial and Operational Analysis: New vs. Used Industrial Robots

| Parameter | New Industrial Robots | Used Industrial Robots (Optimized) | Strategic Implication for CNC |

|---|---|---|---|

| Capital Expenditure (CAPEX) | Very High ($70,000 – $250,000+) | Moderate to High ($20,000 – $80,000) | Faster ROI. Lower upfront cost allows capital allocation to other critical areas like tooling or inspection. |

| Depreciation | Highest in first 3 years. | Majority of depreciation already absorbed. | Improved asset ledger value and reduced financial risk. |

| Lead Time to Deployment | Long (12-36 weeks) | Short (2-8 weeks with reputable dealer) | Rapid implementation to address immediate production bottlenecks. |

| Performance Baseline | State-of-the-art speed, precision, and connectivity. | Dependent on model age, wear, and refurbishment level. Can be upgraded to near-new specs. | Requires thorough inspection and a proactive optimization plan (see Section 3). |

| Warranty & Support | Full OEM warranty (1-3 years). | Typically 90-day to 1-year warranty from dealer. Service contracts available. | Emphasizes the importance of choosing a reputable dealer and establishing a maintenance plan. |

| Technology Features | Latest controllers, software, and safety systems. | May lack the latest software features but core mechanical performance remains robust. | Retrofitting (controller upgrades, new EOAT, sensors) can bridge the technology gap effectively. |

| Sustainability Impact | New resource consumption, higher embedded carbon. | Promotes circular economy. Extends product lifecycle, reduces electronic waste. | Aligns with corporate ESG (Environmental, Social, and Governance) goals. |

2.2 Sourcing and Due Diligence Checklist

Selecting the right used unit is critical. A comprehensive pre-purchase assessment should include:

-

Service History & Hour Meter: Verify total operational hours (akin to mileage on a car). Robots are often rated for 80,000+ hours.

-

Mechanical Inspection: Check for excessive play in gears, condition of cables and hoses, and signs of collision damage.

-

Controller and Software: Power on the controller, check for error logs, verify the software version, and test all axes through their full range of motion.

-

Brand and Model Reputation: Prioritize models known for durability and widespread use (e.g., Fanuc, ABB, KUKA, Yaskawa/Motoman). This ensures spare parts and community knowledge are readily available.

-

Dealer Reputation: Source from established dealers who offer refurbishment services, warranty, and technical support.

Section 3: A Technical Framework for Optimizing Used Robots in CNC Applications

Simply installing a used robot is insufficient. Optimization is a multi-stage process to ensure reliability, precision, and seamless integration.

H3: Stage 1: Foundational Reconditioning and Calibration

-

Preventive Maintenance Replacement: Proactively replace wear-prone components: grease in all reducers and joints, replace internal batteries on the controller and absolute encoders, and inspect/change filters.

-

Mastering/Calibration: Over time, a robot can lose its “home” position. Mastering (recalibrating each axis to its zero point) is essential. For high-precision applications, laser tracker calibration can be employed to create an error map of the robot’s entire envelope, with compensation values uploaded to the controller, significantly enhancing absolute accuracy.

H3: Stage 2: Mechanical and Control System Retrofitting

-

End-of-Arm Tooling (EOAT) Design: This is the critical interface. Design must consider grip force, part geometry variation, and quick-change functionality. Incorporating compliance (via passive or active mechanisms) can compensate for minor misalignment during part loading.

-

Controller Upgrades: Older controllers may be upgraded to newer versions for better processing speed, connectivity (Ethernet/IP, PROFINET, OPC UA), and safety features like Safe Move (ABB) or Dual Check Safety (Fanuc).

-

Sensor Integration: Adding vision guidance (2D or 3D) allows the robot to locate parts on a conveyor or in a bin, adapting to positional variance. Force-Torque sensors enable delicate insertion, contact detection, and adaptive processes like compliant deburring.

H3: Stage 3: Process-Specific Programming and Simulation

-

Offline Programming (OLP): Using software like RobotStudio (ABB), RoboGuide (Fanuc), or DELMIA, programmers can develop, simulate, and optimize robot paths within a digital twin of the cell. This minimizes costly production downtime for teaching.

-

Synchronization with CNC: Integration goes beyond I/O signals. Using MTConnect or direct bus communication, the robot and CNC can share real-time data (cycle status, tool life, alarms), enabling truly coordinated and intelligent cell management.

-

Path Optimization: Fine-tuning movement trajectories, approach/departure angles, and acceleration profiles minimizes cycle time and reduces wear on both the robot and the CNC machine’s components.

Table 2: Optimization Parameters and Their Impact on CNC Machining Quality

| Optimization Parameter | Target for CNC Integration | Method for Used Robots | Direct Impact on Machining Process |

|---|---|---|---|

| Positional Repeatability | < ±0.1 mm | Laser calibration; backlash compensation; thermal drift compensation. | Ensures consistent part seating in the fixture, critical for holding tight tolerances. |

| Path Accuracy | Minimize deviation from programmed path. | Dynamic model-based error compensation in controller. | Vital for complex repositioning moves in 5-axis or robotic milling applications. |

| Cycle Time | Minimize non-cut time. | Optimize robot trajectories via OLP; implement overlapping motions. | Increases overall equipment effectiveness (OEE) by reducing idle time of the expensive CNC machine. |

| Communication Latency | Near real-time (<50ms). | Upgrade to industrial Ethernet protocols (EtherCAT, PROFINET IRT). | Enables precise synchronized motion between robot and CNC, such as on-the-fly part rotation. |

| System Stiffness | Maximize to reduce vibration. | Ensure proper mechanical pre-load; retrofit stiffened EOAT. | Prevents “chatter” during robot-held machining or fine finishing operations. |

Section 4: In-Depth Case Studies: From Theory to Shop Floor Reality

Case Study 1: High-Mix, Low-Volume Aerospace Component Manufacturer

-

Challenge: A manufacturer of bespoke satellite components needed to automate the tending of 5-axis CNC mills but faced extreme part variety and low batch sizes, making dedicated automation uneconomical.

-

Solution: Integration of a used Fanuc M-20iB robot with a 6-axis force sensor and a tool-changer equipped with multiple custom grippers. A 3D vision system was mounted above the input rack.

-

Optimization Process: The robot was laser-calibrated. The OLP system was used to pre-program paths for hundreds of part families. The vision system identified the part, and the robot selected the correct gripper. The force sensor ensured delicate, precise placement into a zero-point clamping system.

-

Outcome: Setup time between different parts reduced by 85%. The cell enabled 16 hours of unattended operation daily. The total investment in the used robot and integration was 40% of a new cell, with ROI achieved in 14 months. Learn more about JLYPT’s approach to complex component machining.

Case Study 2: Automotive Tier-1 Supplier – High-Volume Turning Cell

-

Challenge: A producer of transmission shafts required a reliable, cost-effective solution to load/unload two CNC lathes in a high-volume, three-shift operation.

-

Solution: Deployment of a used KUKA KR 60-3 robot on a linear track (seventh axis) between the two lathes. A robust, dual-gripper EOAT was designed to handle the raw forgings and finished shafts.

-

Optimization Process: The robot’s mechanical drive units were inspected and regreased. The controller was upgraded to KRC4 for better reliability. The programming maximized overlapping motion: while one lathe was machining, the robot was servicing the other. Palletizing logic was added for finished parts.

-

Outcome: The system achieved a 99% uptime rate. Labor for the cell was reduced from 3 operators per shift to 1 monitor. The used robot system paid for itself in under 11 months through labor savings and reduced scrappage from manual handling errors.

Case Study 3: Medical Implant Manufacturer – Cleanroom Machining Cell

-

Challenge: Machining of titanium orthopedic implants required not only precision but also strict contamination control and traceability in an ISO Class 7 cleanroom.

-

Solution: A used ABB IRB 6700 robot with a cleanroom-specific variant (sealed joints, low outgassing paints) was sourced and refurbished. It was integrated with a 5-axis machining center and an in-line vision measurement system.

-

Optimization Process: All lubricants were replaced with cleanroom-grade equivalents. The EOAT was designed with smooth surfaces for easy cleaning. The robot was programmed to present each finished implant to the vision system for automated first-article inspection. Data was logged directly to the MES.

-

Outcome: The automated cell improved consistency, eliminated human contamination vectors, and provided full digital traceability for each part. The use of a certified used robot saved over $100,000 compared to a new cleanroom model, allowing the project to proceed within budget.

Conclusion: Building Your Competitive Edge with Optimized Automation

The journey to implement used industrial robots for CNC machining is a testament to smart, resilient engineering. It moves beyond simple cost-cutting to a philosophy of strategic asset utilization, sustainability, and technological empowerment. As demonstrated, the “used” designation is not a limitation but a starting point for a comprehensive optimization process encompassing mechanical refurbishment, calibration, system integration, and intelligent programming.

For manufacturers looking to navigate this complex but rewarding path, partnering with experts who understand both the intricacies of high-performance CNC machining and robotic systems is invaluable. At JLYPT, we bring this dual-perspective to every project, ensuring that automation solutions—whether built on new or expertly optimized used platforms—are seamlessly aligned with your core manufacturing objectives for quality, efficiency, and growth.

Ready to explore how optimized robotic automation can transform your CNC machining operations? Contact JLYPT today to discuss your next project. Visit our service page at JLYPT CNC Machining Services to learn more about our capabilities.