Unlocking Productivity: The Ultimate Guide to Turnkey Robotics Solutions for CNC Machining

Introduction: The Path to Autonomous Manufacturing – Why Turnkey Robotics Solutions Are the Strategic Accelerant

The journey toward automating a CNC machining operation is fraught with technical complexity, integration challenges, and organizational risk. While the end goal—unmanned production, consistent quality, and maximized asset utilization—is universally understood, the path to achieving it often resembles a labyrinth of component sourcing, software compatibility issues, and multi-vendor coordination. This is where the paradigm of turnkey robotics solutions emerges not merely as a purchasing option, but as a strategic methodology for de-risking and accelerating the automation journey. A turnkey robotics solution represents more than the sum of its mechanical parts; it is a complete, fully integrated production system delivered ready for operation at the push of a button. For manufacturing executives and plant managers navigating the pressures of labor shortages and global competition, opting for turnkey robotics solutions is the decisive step that transforms automation from a complex engineering project into a predictable, accountable business investment with a clear path to return.

At JLYPT, our experience at the intersection of precision machining and systemic process optimization gives us a unique appreciation for the turnkey robotics solutions approach. We understand that our clients’ core competency is manufacturing excellence, not systems integration. A turnkey robotics solution effectively outsources the complexity—the mechanical design, the electrical panel build, the software programming, and the safety validation—to a single accountable partner. This guide is engineered for business leaders, operations directors, and financial decision-makers who need automation to work on day one, not after months of debugging. We will dissect the anatomy of a true turnkey robotics solution, contrast it with alternative approaches, provide a definitive framework for evaluating providers, and present detailed case studies that demonstrate the transformative impact of a properly executed turnkey project. The focus is on delivering certainty in an uncertain process.

Section 1: Deconstructing the Turnkey Robotics Solution – Beyond the Buzzword

The term “turnkey” is often misapplied. A genuine turnkey robotics solution is defined by its completeness and single-point accountability.

1.1 The Core Components of a True Turnkey System

A comprehensive turnkey robotics solution encompasses every element required for the automated process to function, from the physical infrastructure to the digital thread. It includes:

-

Robotic Manipulator & Controller: The selected industrial robot (articulated, SCARA, gantry) with its teach pendant and processing unit, pre-configured for the application.

-

Application-Specific End-Effector: Not an off-the-shelf gripper, but a custom-engineered tool designed and validated for your specific parts. This includes mechanical grippers, vacuum systems, or specialized welding torches.

-

Peripheral Process Equipment: All necessary supporting hardware. For a machining cell: part conveyors, precision fixtures, chip management systems, coolant mist collectors. For a welding cell: welding power source, wire feeder, torch cleaning station, fume extraction.

-

Safety System & Enclosure: A complete, code-compliant safety system. This includes the physical fencing (with interlocked access gates), safety-rated PLC, light curtains, emergency stops, and all necessary risk assessment documentation (per ISO 10218/ISO 13849).

-

Control System Integration: A centralized control panel housing the PLC, motor drives, communication gateways, and power distribution. This panel is pre-wired and pre-programmed to orchestrate the robot, CNC machine, and all peripherals as a single unit.

-

Software & Programming: Fully developed and tested application software. This includes the robot programs, PLC logic, HMI screens, and any necessary communication protocols (Profinet, Ethernet/IP) to interface with your existing plant systems (MES, ERP).

-

Installation, Commissioning, and Training: Physical installation at your facility, full system commissioning and runoff (producing good parts), and comprehensive training for your operators and maintenance staff.

-

Documentation & Ongoing Support: Complete documentation pack (electrical schematics, mechanical drawings, software backups, maintenance manuals) and a defined support agreement (warranty, phone support, spare parts).

1.2 The Project Lifecycle of a Turnkey Solution

Unlike a piecemeal approach, a turnkey robotics solution follows a managed, phase-gated project plan led by the integrator:

-

Discovery & Feasibility: Detailed analysis of your parts, processes, and goals.

-

Conceptual Design & Proposal: Layouts, simulations, and a fixed-price, fixed-scope proposal.

-

Detailed Design & Fabrication: All components are engineered and built off-site.

-

Factory Acceptance Test (FAT): You witness the complete system running at the integrator’s facility before it ships.

-

Installation & Site Acceptance Test (SAT): Installation at your plant and final validation against agreed performance metrics.

-

Training & Handover: Knowledge transfer and formal system handover.

Table 1: Comparative Analysis: Turnkey Solution vs. DIY/Best-of-Breed Integration

| Aspect | Turnkey Robotics Solution | DIY / Multi-Vendor Integration |

|---|---|---|

| Project Management | Single point of accountability. The integrator manages all vendors and timelines. | Internal team must manage multiple vendors, schedules, and blame assignment for delays. |

| Technical Risk | Borne by the integrator. System performance is guaranteed in the contract. | Borne entirely by the buyer. Compatibility and performance issues are your problem to solve. |

| Upfront Cost | Typically higher due to comprehensive engineering and project management. | Appears lower initially, but hidden costs (engineering time, integration delays, troubleshooting) often exceed turnkey price. |

| Time to Production | Predictable. Based on a defined project schedule from contract to SAT. | Unpredictable. Dependent on internal resources and multiple vendor coordination, often leading to significant delays. |

| System Integration | Seamless by design. All components are selected and programmed to work together from the start. | Fragmented. Potential for communication protocols, mechanical interfaces, and software to be incompatible. |

| Performance Warranty | Single, comprehensive warranty covering the entire system’s performance. | Multiple, component-level warranties. Diagnosing a system failure across different vendors is complex. |

| Ongoing Support | One phone call for any issue. The integrator owns the resolution. | Must diagnose which vendor is at fault and manage separate support calls for robot, gripper, PLC, etc. |

| Ideal For | Companies seeking a guaranteed outcome, predictable ROI, and minimal drain on internal engineering resources. | Companies with deep in-house automation engineering teams and the desire for maximum customization control. |

Section 2: Key Application Areas for Turnkey Robotics Solutions in CNC-Centric Operations

Turnkey robotics solutions are tailored to specific, high-value processes where automation delivers clear and rapid returns.

H2: Application 1: Turnkey Machine Tending & Load/Unload Cells

This is the most common entry point for CNC automation.

-

The Challenge: CNC machines sit idle during manual part changes. Labor is tied to repetitive, low-value tasks.

-

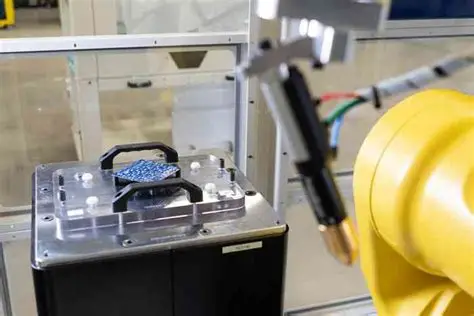

The Turnkey Solution: A fully enclosed cell with a robot, part presentation system (conveyor, pallet stack), custom gripper, and integrated safety. The system is delivered pre-programmed to open the machine door, unload the finished part, load a raw blank, and start the cycle. It includes error recovery routines (e.g., for a dropped part) and production counting.

-

Value Proposition: Transforms a stand-alone CNC machine into an automated production unit capable of lights-out operation. Directly attacks machine idle time to boost OEE.

H2: Application 2: Turnkey Robotic Welding Cells for Fabricated Assemblies

Where CNC-machined components become sub-assemblies.

-

The Challenge: Welding fabricated structures (frames, enclosures, manifolds) is skill-intensive, slow, and quality can vary.

-

The Turnkey Solution: A complete welding cell featuring a robot, welding power source, wire feeder, positioner (turntable or headstock/tailstock), and custom fixturing. The system arrives with optimized weld programs for your specific assemblies, often developed using offline programming from your CAD models.

-

Value Proposition: Delivers consistent, high-quality welds at a pace unmatched by manual welders. Dramatically reduces dependence on scarce welding talent and minimizes post-weld rework.

H2: Application 3: Turnkey Palletizing & Packaging Solutions

Automating the final step in the value chain.

-

Challenge: Manual packing is physically demanding, prone to errors in count or orientation, and a significant labor cost.

-

The Turnkey Solution: A cell comprising a robot, vision guidance system (for random part orientation), specialized end-of-arm tooling, and integrated pallet handling (conveyor, stretch wrapper). The system is programmed to build stable, dense pallet patterns according to your shipping specifications.

-

Value Proposition: Eliminates a major ergonomic concern, ensures shipment accuracy, optimizes shipping cube utilization, and provides digital tracking of finished goods.

Section 3: The Strategic Framework for Selecting a Turnkey Robotics Solutions Partner

Choosing the right integrator is the most critical decision. The following framework ensures you select a partner capable of delivering a true turnkey outcome.

H3: Phase 1: Evaluate Technical Capability & Domain Expertise

-

Application Experience: Do they have a proven track record with your specific application (milling, turning, welding)? Ask for case studies and customer references.

-

Engineering Depth: Do they have in-house mechanical, electrical, and software engineering teams? Or are they merely assemblers?

-

Simulation & Validation: Do they use offline simulation software (RoboDK, DELMIA) to validate cell layout and cycle time before build? This is a hallmark of a professional integrator.

-

Quality of Past Work: Request to see examples of their control panel builds and mechanical fabrications. Clean, organized work reflects a disciplined engineering process.

H3: Phase 2: Scrutinize the Project Methodology & Commercial Terms

-

Fixed-Price, Fixed-Scope Proposal: The proposal must clearly define what is included (Bill of Materials) and, just as importantly, what is excluded. Ambiguity here leads to change orders.

-

Performance Guarantees: The contract should specify measurable performance criteria (cycle time, part quality, uptime) that will be validated during the Site Acceptance Test (SAT).

-

Phased Payments: Payments should be tied to project milestones (e.g., design approval, FAT completion, SAT completion), not arbitrary dates.

-

Comprehensive Documentation: Requirement for full as-built documentation should be non-negotiable.

H3: Phase 3: Assess Long-Term Support & Strategic Alignment

-

Warranty & Support Structure: What is covered under warranty and for how long? What is the process for post-warranty support?

-

Training Program: Is operator and maintenance training comprehensive and hands-on?

-

Cultural Fit: Do they communicate clearly and proactively? Do they understand your business goals, not just the technical task?

Table 2: Total Cost of Ownership (TCO) Analysis: Turnkey vs. Incremental Automation

| Cost Category | Turnkey Robotics Solution | Incremental / DIY Automation | Long-Term Impact & Rationale |

|---|---|---|---|

| Initial Capital Outlay | Higher, but known and fixed. | Appears lower, but is variable and often escalates. | Turnkey provides budget certainty. DIY often experiences 20-50% cost overruns. |

| Internal Engineering & Project Management | Minimal. The integrator’s team does the work. | Very High. Internal engineers are pulled from revenue-generating projects for months. | Hidden cost of DIY is immense. Calculate the fully burdened cost of your engineering staff’s time. |

| Installation & Commissioning Downtime | Short and scheduled. Integrator works efficiently on-site. | Long and disruptive. Multiple vendors and internal teams cause extended machine downtime. | Turnkey minimizes production disruption. Faster time-to-production means faster ROI. |

| System Debugging & Optimization | Included. The system is fully tested and optimized before arrival. | Buyer’s responsibility. Can take weeks or months of frustrating troubleshooting. | Turnkey delivers a working system on day one. DIY can lead to “shelfware” – automation that never works properly. |

| Ongoing Maintenance Complexity | Simplified. One source for support and standardized spare parts. | Complex. Must maintain expertise on multiple different vendor systems and inventories. | Turnkey reduces long-term operational overhead. One manual, one point of contact. |

| System Scalability & Future Upgrades | Can be designed in from the start. The integrator understands the full architecture. | Difficult. Future upgrades may be incompatible with the original DIY design. | A professional turnkey design considers future state, making expansion more straightforward. |

| Risk of Project Failure | Very Low. The integrator’s reputation depends on success. | High. Lack of experience can lead to abandoned projects or severely underperforming systems. | Turnkey transfers the performance risk to the expert. This is its core value proposition. |

Section 4: Case Studies – Turnkey Robotics Solutions Delivering Transformative Results

Case Study 1: Mid-Sized Job Shop – 24/7 Machining of Valve Bodies

-

Challenge: A family-owned machine shop won a large contract to machine stainless steel valve bodies but lacked the labor to run a third shift. Manual operation limited them to 16 hours/day.

-

Solution: They partnered with an integrator for a turnkey robotics solution. The solution was a dual-station cell: a 6-axis robot on a linear rail tending two identical CNC lathes. The integrator provided everything: the robot, custom jaw grippers, a central conveyor for raw/finished parts, full safety enclosure, and complete programming. The system was built, tested at the integrator’s facility (FAT), and installed over a weekend.

-

Outcome: The shop achieved immediate 24/7 production capability. Machine utilization jumped from 55% to over 90%. They fulfilled the contract without hiring new machinists and reduced part-to-part variation by eliminating manual handling inconsistencies. The turnkey robotics solution paid for itself in 14 months and allowed the shop to competitively bid on other high-volume work.

Case Study 2: Fabrication House – Automated Welding of Equipment Frames

-

Challenge: A manufacturer of custom industrial machinery struggled with welding lead times and quality variance across their welders. Each frame was unique, making traditional hard automation impossible.

-

Solution: A turnkey robotic welding cell was implemented. The cell featured a large-format positioner and a robot with through-arc seam tracking. The integrator’s key innovation was creating a library of parametric weld programs. The shop’s engineers would define the frame dimensions in a simple form, and the software would automatically generate the robot path. The turnkey package included the robot, welding equipment, fume extraction, and extensive programmer training.

-

Outcome: Weld time on standard frames was reduced by 60%. Weld quality became consistently excellent, eliminating rework. The flexible programming system allowed them to robotically weld over 80% of their product line. The turnkey robotics solution transformed welding from a bottleneck into a competitive advantage.

Case Study 3: Medical Device Contract Manufacturer – Sterile Packaging Automation

-

Challenge: After machining and cleaning, implantable components required meticulous, gloved-hand placement into sterile packaging trays. The process was slow and introduced a contamination risk.

-

Solution: A cleanroom-certified turnkey robotics solution was deployed. A collaborative robot (cobot) with a vision system and a soft, sanitary gripper was integrated into a laminar flow bench. The integrator designed the entire cleanroom module, including HEPA filtration and material pass-throughs. The system was validated to ISO 14644 cleanroom standards.

-

Outcome: Packaging throughput increased by 300% while eliminating the risk of human-borne contamination. The gentle, precise robot handled the delicate parts without damage. The turnkey robotics solution provided the necessary documentation and validation reports for the client’s FDA audits, a value far beyond the labor savings.

Conclusion: From Capital Expenditure to Strategic Capability

Investing in a turnkey robotics solution represents a fundamental shift in how companies approach automation. It moves the conversation from a technical discussion about components to a strategic discussion about business outcomes: increased capacity, guaranteed quality, and operational resilience. By transferring the integration risk and complexity to a specialized partner, manufacturers can focus on their core competency—making products—while gaining the benefits of world-class automation.

The value of a true turnkey robotics solution is ultimately measured in certainty: certainty of cost, certainty of timeline, and certainty of performance. In an era defined by supply chain volatility and skilled labor shortages, this certainty is itself a formidable competitive asset.

For manufacturers ready to take the definitive step toward autonomous production without the traditional pitfalls, the path is clear: partner with an expert who can deliver a complete, accountable turnkey robotics solution. This partnership allows you to harness the full power of automation to drive growth, quality, and profitability.

Ready to explore a guaranteed path to automation with a comprehensive turnkey robotics solution? Contact JLYPT to begin a discovery conversation about your production challenges and goals. Learn how our precision-focused approach extends to system-level solutions at JLYPT CNC Machining Services.