Maximizing CNC Uptime: The Definitive Guide to Machine Tending Robots

Introduction: The Imperative for Automation in Modern CNC Machining

In the world of precision manufacturing, the capabilities of advanced CNC machine tools have reached astonishing levels. Machines offering 5-axis simultaneous milling and ±0.005 mm tolerances can produce components of breathtaking complexity from materials like aerospace-grade titanium and Inconel 718. Yet, for many machine shops, this monumental investment in subtractive technology is hamstrung by a persistent, inefficient, and costly bottleneck: the manual loading and unloading of workpieces. This repetitive, non-value-added task leads to significant machine idle time, limits production to a single shift, exposes skilled operators to potential injury, and introduces variability in cycle times. For manufacturers seeking to achieve true lights-out manufacturing and maximize the return on their capital equipment, the integration of machine tending robots is not merely an upgrade—it is a strategic necessity.

This comprehensive guide explores the critical role of machine tending robots in unlocking the full potential of a CNC machining operation. We will dissect the technology, evaluate integration pathways, and quantify the transformative return on investment (ROI) that automated tending delivers. For a precision partner like JLYPT, which provides the foundational components for complex systems, understanding this automation layer is key to helping our clients build more resilient, efficient, and competitive manufacturing ecosystems.

The Core of Automation: What Are Machine Tending Robots?

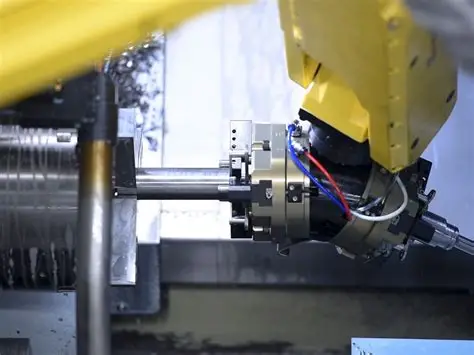

At its essence, a machine tending robot is an automated system designed to service a CNC machine tool by handling raw material, work-in-process, and finished parts. While loading and unloading is the primary function, modern systems are sophisticated enough to perform a suite of secondary operations within the same work cycle.

Key Functions of a Machine Tending System:

-

Primary Material Handling: Automatically picks a raw blank from a conveyor, pallet, or storage rack and loads it precisely into the CNC machine’s vise or fixture. Upon cycle completion, it unloads the finished part and places it in a designated output location.

-

Secondary Process Integration: Advanced cells integrate processes like part inspection (using touch probes or vision systems), deburring, blow-off (to remove chips and coolant), washing, and even laser marking or packaging. This consolidates multiple post-processing steps into a single, automated flow.

-

Process Monitoring & Data Collection: Integrated sensors can provide real-time feedback, enabling predictive maintenance and closed-loop quality control.

The Tangible Benefits: Why Automate?

The advantages of implementing machine tending robots are well-documented and impactful:

-

Dramatically Increased Productivity & Throughput: By eliminating manual intervention, robots enable CNC machines to run continuously through breaks, shift changes, and overnight. This can effectively triple the output of a single machine, as demonstrated in real-world implementations.

-

Unwavering Consistency and Improved Quality: Robots perform the same task with identical precision every cycle. This eliminates human error in part placement (which can cause crashes) and ensures consistent clamping forces, leading to higher part quality and dramatically reduced scrap.

-

Optimized Labor and Enhanced Safety: Automation frees highly skilled machinists from monotonous, physically demanding tasks. They can be redeployed to higher-value work like programming, quality assurance, and process optimization. It also removes personnel from potential hazards near heavy machinery and sharp metal parts.

-

Operational Flexibility and Lights-Out Manufacturing: With proper fixturing and programming, a single robotic cell can tend multiple part numbers. This makes it ideal for high-mix, low-volume (HMLV) production. Furthermore, it is the cornerstone of unattended “lights-out” production runs, maximizing asset utilization.

Navigating the Technology Landscape: Types of Machine Tending Solutions

Selecting the right robotic solution is a critical multi-criteria decision that depends on payload, reach, flexibility, and budget. The market offers a spectrum of options, from collaborative to fully industrial systems.

Table 1: Comparison of Primary Machine Tending Robot Technologies

| Robot Type | Typical Configuration | Key Advantages | Best Suited For | Integration Consideration |

|---|---|---|---|---|

| Collaborative Robot (Cobot) | 6-axis arm, often on a mobile base. Force-limited and designed for safe interaction. | Easiest to program and deploy; requires minimal safety fencing; portable between machines; lower upfront cost. Ideal for high-mix, low-volume shops. | Small to medium parts (<10kg). Prototyping, job shops, environments where human-robot collaboration is needed. | Often sold as pre-engineered, plug-and-play cells (e.g., ABB’s OmniVance). Installation can take as little as one day. |

| Articulated Industrial Robot | 6-axis arm mounted on a pedestal or linear track (7th axis). | High speed, heavy payload capacity (10kg+), large work envelope. Superior repeatability (±0.02mm). Robust for 24/7 duty. | Medium to large parts. High-volume production, heavy materials (steel, Inconel). Tending multiple machines on a rail. | Requires comprehensive safety guarding (per RIA/ISO standards). Needs more involved programming and integration. |

| Gantry (Cartesian) Robot | XYZ linear axes mounted on a rigid overhead frame. | Extremely high rigidity and positional accuracy over a very large area. Can service multiple machines in a line. | Very large, heavy, or long parts. Large-scale production cells and Flexible Manufacturing Systems (FMS). | Significant space and structural requirements. Higher initial cost but unparalleled stability for precision tasks. |

The Critical Role of Precision Components: Regardless of the robot type, its performance is ultimately dependent on the accuracy of its end-of-arm tooling (EOAT) and workholding fixtures. A robot with ±0.02mm repeatability cannot achieve reliable part placement if its custom gripper jaws or fixture locators are machined to a lower standard. This is where the partnership with a precision machinist like JLYPT becomes vital, ensuring the mechanical interface between robot and workpiece is engineered and manufactured to exacting tolerances.

From Concept to Cell: A Framework for Successful Integration

Implementing a machine tending robot is an engineering project that extends beyond purchasing hardware. A systematic approach is key to success.

Phase 1: Evaluation and Planning

-

Process Analysis: Identify the target CNC process and catalog all parts. Key factors include dimensions, weight, material, cycle time, and annual volume.

-

ROI Justification: Calculate the business case. Key metrics include: increased machine uptime (e.g., from 40% to 85%), labor cost savings, reduced scrap, and shorter lead times. A clear ROI target (often 12-24 months) guides the project scope.

-

Partner Selection: Choosing the right systems integrator is as crucial as choosing the robot. Look for partners with proven experience in CNC automation, strong post-installation support, and a commitment to understanding your specific production goals.

Phase 2: Design and Simulation

-

Cell Layout & Digital Twin: Using offline programming (OLP) software, integrators create a 3D simulation of the entire work cell. This validates robot reach, prevents collisions, and optimizes cycle time before any metal is cut.

-

Design for Automation (DfA): Review part designs for features that facilitate robotic handling, such as consistent locating surfaces or strategic grooves for gripper access.

Phase 3: Implementation and Commissioning

-

Fixture and EOAT Fabrication: High-precision custom fixtures and grippers are machined. This step relies heavily on the capabilities of a precision CNC partner.

-

Installation & Programming: The cell is installed, and the robot, CNC, and peripherals are programmed to work in harmony. Modern solutions emphasize user-friendly, code-free interfaces to empower existing staff.

-

Site Acceptance Test (SAT): The system must prove it can run a complete production cycle meeting all throughput, quality, and safety requirements.

Case Studies: Machine Tending Robots in Action

Case Study 1: Job Shop Scalability with Plug-and-Play Automation

Challenge: TL Aerotek, a small milling job shop, faced a surge in orders that outstripped its manual operating capacity. Labor constraints limited them to a single shift, capping their growth potential.

Solution: The shop implemented Mitsubishi Electric’s LoadMate Plus, a plug-and-play robotic tending cell connected to their existing CNC. The system featured a 6-axis robot and was integrated via a simple Ethernet connection.

Outcome: The solution enabled unattended 24-hour production. The shop tripled its normal output without adding manual labor. The pre-engineered nature of the system allowed for quick deployment, providing an immediate competitive advantage and the ability to scale business on demand.

Case Study 2: High-Mix Flexibility with Advanced Vision

Challenge: Renold Australia, a manufacturer of industrial chains, needed to automate the tending of a machine producing a wide variety of components. Parts arrived in stacks with random orientation, making automation with traditional methods difficult.

Solution: Automated Solutions Australia (ASA) integrated a FANUC M10iD robot equipped with 2D vision guidance and dual grippers. The vision system allowed the robot to identify and locate randomly stacked parts, while the dual gripper enabled efficient handling of different part geometries.

Outcome: The system transformed an 8-hour operation into a 24/7 production cell. The installation was completed in half the allotted time (7 days), minimizing downtime. Critically, the user-friendly system allowed Renold’s existing staff to learn programming quickly, expanding the cell’s use to over 50 different parts.

Case Study 3: Enterprise-Grade Integration for Unmanned Production

Challenge: A large automotive component supplier needed to maximize the output of a bank of high-value CNC horizontal machining centers (HMCs) to meet just-in-time delivery schedules. Manual tending was a bottleneck and a significant labor cost.

Solution: A fully enclosed, safety-certified cell was built using a heavy-duty articulated robot on a linear rail. The cell included an automated pallet system for raw forgings and finished parts, integrated in-process probing, and chip/coolant management.

Outcome: The cell achieved true lights-out manufacturing for multiple shifts. Overall Equipment Effectiveness (OEE) for the HMCs increased from below 50% to over 90%. The system provided a predictable, high-volume output with full traceability, paying for itself in under 18 months through labor savings and increased capacity.

Conclusion: Building Your Automated Future

The integration of machine tending robots represents the most direct and impactful step a CNC machining operation can take toward Industry 4.0. It is a transformation that yields hard returns in productivity, quality, and cost savings while building a more agile and resilient business. The technology is no longer the exclusive domain of large OEMs; with the advent of collaborative robots and pre-engineered cells, automation is now accessible and justifiable for job shops and large enterprises alike.

The journey begins with a clear assessment of your processes and goals. By partnering with experienced integrators and precision manufacturing experts, you can design a system that not only automates a task but elevates your entire manufacturing capability.

Ready to explore how machine tending automation can transform your CNC operations? The journey toward lights-out manufacturing starts with a conversation about your unique challenges and ambitions. Contact JLYPT today to discuss how our expertise in precision component manufacturing supports the foundation of reliable, high-performance automation cells.