The Strategic Imperative: Your Guide to Choosing a Robot Integrator for CNC Manufacturing Success

Introduction: The Make-or-Break Decision in Automation

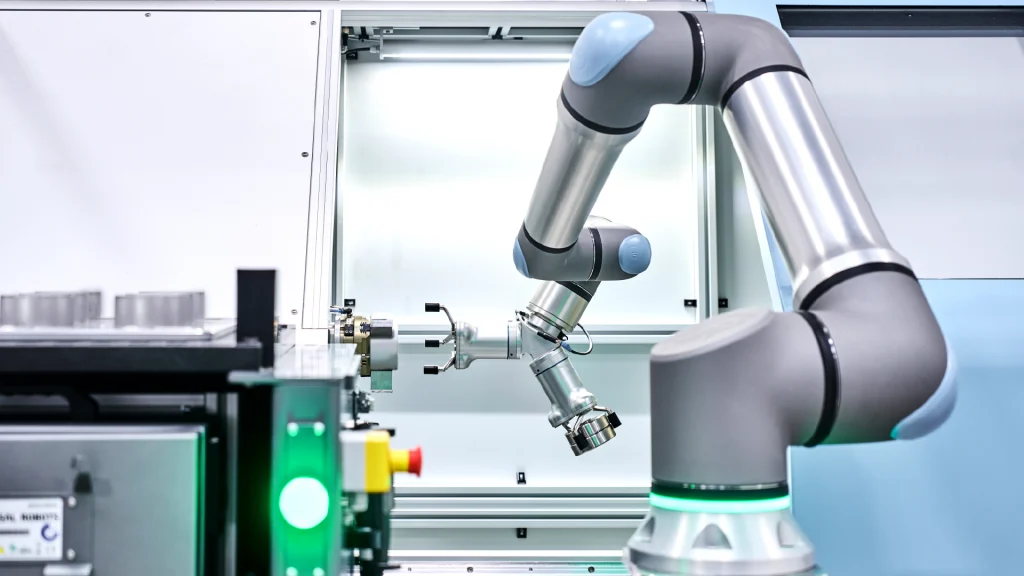

In the precision-driven world of CNC machining, the integration of robotics is no longer a speculative venture into the future; it is a pressing strategic necessity for achieving unparalleled productivity, quality, and agility. A robotic cell, when perfectly harmonized with your machining centers, lathes, and grinders, can transform your operation. However, the path from a conceptual need for automation to a fully operational, high-performing robotic cell is fraught with technical complexity. This journey hinges on one critical decision: choosing a robot integrator. This partner does far more than just “hook up a robot”—they are the architects of your automated future, translating your production challenges into reliable, efficient, and intelligent systems.

Selecting the wrong integrator can lead to a cascade of failures: systems that fail to meet cycle time targets, persistent reliability issues, exorbitant hidden costs, and solutions that cannot adapt to your evolving production needs. The financial and operational setbacks from a failed automation project can be severe. Conversely, the right integrator acts as a force multiplier, becoming a long-term extension of your engineering team. They bring deep domain expertise in both robotics and the unique intricacies of CNC manufacturing processes—from the complexities of high-speed milling and hard turning to the nuances of in-process metrology and lights-out production.

This definitive guide is designed to equip you with a structured, strategic framework for choosing a robot integrator. We will move beyond superficial checklists and delve into the core competencies, evaluation criteria, and collaborative processes that separate true partners from mere vendors. By understanding what to look for and which questions to ask, you can confidently select an integrator who will not only deliver a successful cell but also ensure it becomes a durable, value-generating asset for your business. For leaders at precision manufacturing firms like JLYPT, mastering this selection process is as crucial as selecting the right machine tool itself.

Beyond the Robot Arm: Understanding the Integrator’s True Role

A common misconception is that automation begins with selecting a robot brand. In reality, the robot is just one component—albeit a vital one—within a sophisticated ecosystem. A proficient systems integrator’s role is to design and deliver this complete, functional ecosystem. Their work encompasses the entire lifecycle of the cell:

-

System Architecture & Feasibility: Defining how the robot, CNC machine, material handling systems, safety components, and control software will interact.

-

Mechanical Design & Tooling: Engineering custom end-of-arm tooling (EOAT), grippers, fixtures, and part presenters that handle your specific components with precision and reliability.

-

Software Integration & Programming: Developing the logic that orchestrates the cell. This goes beyond robot path programming to include Programmable Logic Controller (PLC) code, Human-Machine Interface (HMI) design, and seamless communication protocols between the robot controller and the CNC (e.g., via PROFINET, EtherCAT, or MTConnect).

-

Safety System Design: Implementing comprehensive safeguards—from physical fencing and light curtains to safety-rated monitored stops (SRMS)—that comply with stringent standards like ISO 10218 and ANSI/RIA R15.06.

-

Commissioning & Validation: Meticulously testing the integrated system against performance metrics like cycle time, part quality, and Overall Equipment Effectiveness (OEE) before handover.

-

Training & Long-Term Support: Ensuring your team can operate, maintain, and troubleshoot the system, backed by accessible technical support and clear documentation.

An integrator’s value is measured by their ability to synthesize these disciplines into a cohesive, robust solution tailored to your unique application. They sell not a robot, but a guaranteed production outcome.

The Strategic Framework: Four Pillars for Choosing a Robot Integrator

Evaluating potential partners requires a multi-faceted approach. The following framework, supported by key industry insights, provides a structured methodology for assessment.

Pillar 1: Technical Expertise and Process Comprehension

This is the non-negotiable foundation. The integrator must demonstrate a profound understanding of both robotics and your specific CNC machining processes.

-

Depth of CNC Knowledge: Do they speak the language of machining? Can they discuss chip load calculations, tool wear monitoring, fixture repeatability, and thermal compensation? Their engineers should understand how robotic movements interact with cutting forces and machine dynamics.

-

Application-Specific Portfolio: Request detailed case studies of past projects involving similar processes—be it high-volume automotive component milling, complex 5-axis aerospace part tending, or delicate medical implant finishing. A history in welding, for example, does not directly translate to the precision demands of machining.

-

Simulation and Digital Twin Capability: A leading indicator of technical maturity is the use of advanced offline simulation software. As noted by industry experts, simulation using actual 3D models is critical for proving robot sizing, validating reach, preventing collisions, and optimizing cycle times before any metal is cut. This de-risks the project significantly.

Pillar 2: Proven Methodology and Project Management

Even the best ideas fail with poor execution. The integrator must have a disciplined, transparent process for taking your project from concept to production.

-

Structured Project Lifecycle: They should outline a clear phase-gate process: Initial Consultation & Feasibility Study > Detailed Design & Simulation > Fabrication & Factory Acceptance Testing (FAT) > Installation & Site Acceptance Testing (SAT) > Final Documentation & Training.

-

Clear Communication and Defined Roles: Who is your single point of contact—the Project Manager? This individual should have a manufacturing background and understand how the robotic system integrates into your broader production goals. Regular, structured updates are essential.

-

Risk Management and Change Control: How do they handle scope changes? A professional integrator will have a formal process for Engineering Change Orders (ECOs) to manage adjustments without derailing the project budget or timeline.

Pillar 3: Business Alignment and Partnership Potential

View this as forming a strategic alliance, not just executing a transaction. The integrator should be invested in your long-term success.

-

Financial Stability and Honesty: Are they transparent about costs? Beware of low initial bids that may hide expenses for training, spare parts, or future modifications. A trustworthy partner will help you model the Return on Investment (ROI) and Total Cost of Ownership (TCO), considering not just purchase price but also operational savings in labor, scrap reduction, and increased throughput.

-

Accessibility and Support Structure: Where is their support team located? For rapid response, a partner within a day’s drive is often ideal. What is their protocol for remote diagnostics and on-site service? Do they maintain an inventory of critical spare parts?

-

Cultural Fit: Do their values of quality, communication, and innovation align with yours? The project will require close collaboration; a good working relationship is paramount.

Pillar 4: Commitment to Safety and Standards

In a machining environment with high-speed spindles, sharp tools, and heavy workpieces, safety cannot be an afterthought.

-

Safety-by-Design Philosophy: Safety systems should be integral to the initial cell design, not added later. The integrator must be fluent in risk assessment methodologies and the application of relevant safety standards.

-

Comprehensive Documentation: Upon project completion, you should receive complete documentation: electrical schematics, pneumatic diagrams, safety validation reports, and detailed maintenance manuals. This is a mark of professionalism and is crucial for your team’s safety and for future troubleshooting.

The following table consolidates these pillars into a practical evaluation checklist.

Table 1: Comprehensive Checklist for Choosing a Robot Integrator

| Evaluation Category | Key Questions to Ask | What to Look For (Evidence) |

|---|---|---|

| Technical & Process Expertise | 1. Can you show me case studies for CNC machining/tending projects similar to mine? 2. How do you approach process validation and cycle time verification before build? 3. What is your experience with integrating [Your CNC Controller Brand] with [Robot Brand]? |

Detailed project portfolios with customer testimonials. Use of offline simulation/digital twin software. Engineers who ask insightful questions about your process. |

| Project Execution & Management | 1. Walk me through your standard project lifecycle and milestones. 2. Who will be my dedicated Project Manager, and what is their background? 3. What is your protocol for handling scope changes or unforeseen challenges? |

A defined, documented project management methodology. An experienced PM assigned to your project. A clear ECO process. |

| Business & Partnership | 1. Can you provide a transparent, line-item cost breakdown and ROI projection? 2. What does your post-installation support and service agreement include? 3. What is your company’s policy on training our personnel? |

Detailed, understandable proposals. Robust service level agreements (SLAs) with defined response times. Comprehensive training curricula and materials. |

| Safety & Standards | 1. How do you incorporate safety into the initial design phase? 2. Can you provide examples of safety documentation from past projects? 3. Are your systems compliant with ISO 10218 and local regulations? |

Safety schematics and risk assessment templates in proposals. Discussion of functional safety (PL/SIL) concepts. Commitment to final safety validation and sign-off. |

Case Studies in Strategic Integration

The following hypothetical scenarios illustrate how the principles of choosing a robot integrator play out in real-world CNC manufacturing challenges.

Case Study 1: The High-Mix, Low-Volume (HMLV) Aerospace Machine Shop

-

Challenge: A shop specializing in complex, low-batch aerospace components needed to automate the tending of three different 5-axis machining centers. The system had to handle over 50 unique part families with minimal changeover time, requiring exceptional flexibility and precision.

-

Integrator Selection & Solution: The shop prioritized integrators with proven experience in flexible manufacturing systems (FMS) and advanced vision guidance. The chosen partner utilized 3D simulation to design a multi-skilled robotic cell with a dual-gripper EOAT and an integrated 3D vision system for random bin picking. A standardized, quick-change fixturing pallet system was designed, and the robot programs were structured for easy recall by part number.

-

Outcome: Changeover time between part families was reduced from 45 minutes to under 5 minutes. The cell enabled lights-out production for first and second operations, increasing overall machine utilization by 35%. The integrator’s deep understanding of both precision robotics and aerospace machining tolerances was critical to success.

Case Study 2: The High-Volume Automotive Tier 1 Supplier

-

Challenge: A supplier of transmission cases faced labor shortages and consistency issues in a manual deburring and washing station following machining. The process was ergonomically challenging and produced variable results.

-

Integrator Selection & Solution: The supplier needed an integrator with specific expertise in force-controlled finishing and integration with secondary processes. The selected partner designed a cell featuring a robot equipped with a force-torque sensor for adaptive deburring, followed by an automated transit through a custom wash station. The integrator’s strong project management ensured the line was installed during a scheduled plant shutdown.

-

Outcome: The automated cell provided a consistent, high-quality finish 24/7, eliminating a bottleneck and reducing part rejection rates by 90%. The integrator’s turnkey approach and robust safety design for a wet environment delivered a system that met both quality and production rate targets from day one.

Case Study 3: The Medical Device Manufacturer Scaling Production

-

Challenge: A manufacturer of orthopedic implants needed to scale production of a newly approved device. The multi-step process involved precision milling, laser marking, and 100% vision inspection. Manual handling risked contamination and introduced variability.

-

Integrator Selection & Solution: Paramount concerns were cleanliness, traceability, and ultra-high precision. The manufacturer chose an integrator with a cleanroom design pedigree and expertise in medical-grade automation. The solution was a fully enclosed cell with a collaborative robot (cobot) for gentle part handling, integrated laser marker, and high-resolution vision inspection. All components were designed for easy sterilization and validation.

-

Outcome: The cell ensured an aseptic production flow, with every part’s machining data, laser mark, and inspection results linked in a Manufacturing Execution System (MES) for full traceability. Production throughput increased by 50% while achieving a zero-defect quality standard for the critical product launch.

Conclusion: Your Partner in Precision Automation

The journey of choosing a robot integrator is a strategic investment in your company’s future competitiveness. It requires moving beyond price comparisons and focusing on the partner who possesses the technical depth, methodological rigor, and collaborative spirit to understand your unique world of precision metal cutting. The right integrator doesn’t just deliver a machine; they deliver a solution that enhances your capabilities, safeguards your quality, and provides a clear path to a strong return on investment.

At JLYPT, we view automation through the lens of precision and partnership. While we excel in delivering world-class CNC Machining Services, we understand that the future of manufacturing lies in intelligent, integrated systems. We encourage you to apply the rigorous framework outlined in this guide to find an integrator who will become a true partner in your growth.

Ready to explore how integrated automation can elevate your precision manufacturing? Begin the conversation about your next project by visiting JLYPT CNC Machining Services to learn more about our commitment to engineering excellence.