What is a Collaborative Robot? The Definitive Guide for Modern CNC Machining

Introduction: Redefining Automation on the Factory Floor

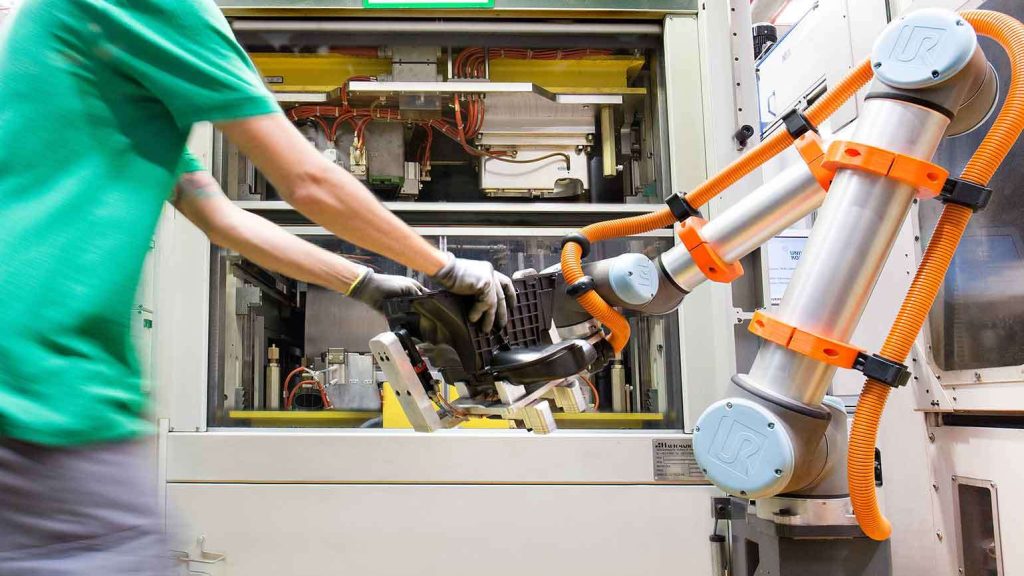

The landscape of industrial automation is undergoing a profound and necessary evolution. For decades, the prevailing image of robotics in manufacturing has been one of immense, caged giants—powerful, precise, but isolated from human workers behind barriers of steel mesh and light curtains. This paradigm, while effective for high-volume, repetitive tasks, created a stark divide: fully automated, inflexible cells versus entirely manual, skill-dependent workstations. In the dynamic, high-mix, low-volume (HMLV) world of precision CNC machining, this binary model often falls short. It is within this gap that a transformative technology has emerged: the collaborative robot, or cobot.

So, what is a collaborative robot? At its core, a collaborative robot is a specifically designed robotic arm engineered to work safely alongside human operators in a shared workspace. Unlike traditional industrial robots that operate in strict isolation, cobots are built with inherent safety features, intuitive programmability, and a flexibility that makes them an ideal force multiplier for skilled machinists and technicians. For a precision-focused service provider like JLYPT, understanding and leveraging cobots is not about replacing human expertise; it is about augmenting it, creating hybrid work cells where human ingenuity and robotic consistency combine to achieve new levels of productivity, quality, and agility.

This comprehensive guide will dissect the anatomy of a collaborative robot, explore the international safety standards that define its operation, and detail its practical, transformative applications within a CNC machining environment. We will move beyond marketing buzzwords to provide a clear, technical, and actionable understanding of how cobots are reshaping the future of precision manufacturing.

Deconstructing the Cobot: Key Characteristics and Design Philosophy

A collaborative robot is distinguished from its traditional industrial counterpart by a suite of integrated design features. These features are not add-ons but fundamental engineering principles that enable safe and effective human-robot interaction (HRI).

1. Inherent Safety through Power and Force Limiting (PFL)

The most critical design principle is Power and Force Limiting (PFL). Cobots are constructed with lightweight materials, rounded edges, and compliant joints or actuators. Their motors are inherently limited in the power they can output, and they are equipped with sophisticated force/torque sensors at each joint and sometimes at the wrist. These sensors continuously monitor for unexpected contact. If a collision with a human operator is detected, the robot can stop almost instantaneously. The biomechanical limits for safe contact—defined in the technical specification ISO/TS 15066—ensure that any transient contact will not cause injury. This is a radical departure from traditional robots, whose immense kinetic energy makes physical guarding an absolute necessity.

2. User-Friendly Programming and Deployment

Traditional industrial robots often require specialized knowledge of proprietary programming languages (e.g., KRL, RAPID). Cobots, in contrast, are designed for rapid deployment by the existing workforce, not robotics PhDs.

-

Hand-Guiding/Lead-Through Teaching: An operator can physically grab the robot arm and manually move it through the desired task sequence. The robot records these points and movements, creating a program in real-time. This is intuitive and eliminates the need for complex code.

-

Intuitive Graphical Interfaces: Programming is often done via simple tablet or pendant interfaces with drag-and-drop logic, waypoint teaching, and familiar icons. This drastically reduces training time and allows machinists and cell operators to become robot programmers.

3. Flexibility and Mobility

Cobots are typically lighter and more compact than industrial robots. They can be easily mounted on mobile carts, benchtops, or even directly onto machine tools. This mobility allows a single cobot to be deployed for multiple tasks throughout a shift—performing machine tending at a CNC mill in the morning, deburring parts at a workstation in the afternoon, and assisting with kitting or inspection in the evening. This flexibility is a game-changer for job shops and HMLV producers where dedicating a fixed, expensive automation cell to a single task is not economically viable.

4. Advanced Sensing and Perception

While not universal, many cobots can be easily integrated with vision systems (2D/3D cameras) and other sensors. This allows for adaptive behaviors, such as identifying a part’s precise location on a table, picking randomly oriented components from a bin (bin picking), or verifying a part’s features after machining. This sensory intelligence transforms the cobot from a simple repeater of movements into a responsive assistant.

The Framework of Safety: ISO/TS 15066 and the Four Collaborative Modes

The safe operation of a cobot is not just about its hardware; it is governed by a rigorous international framework. ISO/TS 15066:2016 supplements the broader machinery safety standards (ISO 10218-1 & -2) by providing detailed guidelines for collaborative robot systems. It defines four distinct types of collaborative operation, each with its own safety requirements. Understanding these modes is essential for proper cell design and risk assessment.

Table 1: The Four Collaborative Operation Modes per ISO/TS 15066

| Collaborative Mode | Operating Principle | Key Safety Technologies | Typical CNC Machining Application |

|---|---|---|---|

| Safety-Rated Monitored Stop | The robot operates autonomously. When a human enters a defined collaborative workspace, the robot stops completely. It only resumes once the human has left the area. | Safety-rated area scanners, light curtains, or pressure mats. Robot stop functions must meet Performance Level d (PL d). | A cobot performing a long, unsupervised deburring cycle. An operator can safely enter the cell to retrieve finished parts or perform quality checks, pausing the robot automatically. |

| Hand Guiding | The human operator physically directs the robot’s motion by hand. The robot only moves when directly guided. | Enabling device (deadman switch), force sensors to detect guiding direction. | A machinist guides a cobot to demonstrate a complex loading path into a 5-axis vise or to teach a precise inspection point on a new prototype part. |

| Speed and Separation Monitoring (SSM) | The robot and human can move simultaneously. Safety systems ensure a protective separation distance is always maintained. If the human approaches too closely, the robot slows down or stops. | Safety-rated vision systems (e.g., 3D time-of-flight cameras), laser scanners that dynamically map the operator’s position. | A cobot tending a CNC lathe while an operator works at an adjacent bench. The system monitors the operator’s location and adjusts the robot’s speed to maintain a safe bubble of space. |

| Power and Force Limiting (PFL) | The robot and human can work in direct contact. The robot’s inherent design limits the forces and pressures it can exert to biomechanically safe levels. | Compliant joint design, integrated force/torque sensing, software that limits power output. | A cobot handing a sharp, freshly machined part directly to an operator for visual inspection, or light sanding/polishing where contact is expected and safe. |

Crucial Note: A true collaborative application often uses a combination of these modes. Furthermore, compliance is not optional. A proper risk assessment must be conducted for every cobot application to select the appropriate modes and validate that all safety functions meet the required Performance Level (PL).

Transformative Applications in CNC Machining

The unique attributes of cobots make them exceptionally well-suited to solve persistent challenges in precision machining environments. Here are the most impactful applications:

1. Machine Tending and Part Loading/Unloading

This is the most common entry point for cobot integration. A cobot can reliably load raw material (blanks, castings) and unload finished parts from CNC mills, lathes, and grinders.

-

Value Proposition: Frees the machinist from repetitive, ergonomically taxing loading tasks, allowing them to focus on programming, inspection, and process optimization. It enables lights-out machining for portions of a shift, increasing machine tool utilization (OEE).

-

Technical Nuance: Integration involves interfacing with the CNC’s I/O to receive “door open” and “cycle complete” signals. Adaptive grippers (often pneumatic or electric) and machine vision may be used to handle part families with slight variations.

2. Secondary and Finishing Operations

Many parts require manual work after primary machining: deburring sharp edges, polishing surfaces, chamfering holes, or applying identification marks.

-

Value Proposition: Cobots bring relentless consistency to these tasks. A force-controlled spindle or tool mounted on the cobot can apply the exact same pressure and follow the same path every time, eliminating the variability of manual finishing.

-

Technical Nuance: This requires path programming (often via hand-guiding) and the integration of force/torque sensing for adaptive control. The cobot compensates for tool wear or part dimensional variation by maintaining constant force.

3. In-Process Inspection and Metrology

Skilled machinists spend considerable time performing first-article inspection and in-process checks using hand tools or CMMs.

-

Value Proposition: A cobot equipped with a touch probe or laser scanner can be programmed to automatically measure critical dimensions after a machining cycle. This data can be fed back to the CNC for automatic tool offset compensation, creating a closed-loop quality system.

-

Technical Nuance: This demands high positional repeatability from the cobot and seamless data communication between the probe, robot controller, and CNC control (e.g., Fanuc, Siemens, Heidenhain).

4. Flexible Assembly and Kitting

For shops that also perform assembly, cobots excel at tasks like inserting bearings, applying threadlocker, screwing fasteners, or kitting all components for a final assembly.

-

Value Proposition: Increases throughput and reduces assembly errors. The cobot’s force sensitivity allows it to perform delicate insertion tasks without damaging components.

-

Technical Nuance: Often relies heavily on vision guidance to locate parts and tool changers to switch between screwdrivers, dispensers, and grippers for a multi-step process.

Table 2: Cobot vs. Traditional Industrial Robot for CNC Tasks

| Aspect | Collaborative Robot (Cobot) | Traditional Industrial Robot | Implication for CNC Shops |

|---|---|---|---|

| Safety Integration | Inherent safety (PFL) allows shared workspace without extensive fixed guarding. | Requires complete physical separation (fences, light curtains) from humans. | Cobot: Lower integration cost, faster deployment, flexible layout. Industrial: Higher safety system cost, dedicated space. |

| Programming | Intuitive; hand-guiding and graphical interfaces. Can be done by machinists. | Complex; requires specialized knowledge of proprietary languages. | Cobot: Rapid redeployment for new tasks, empowers existing staff. Industrial: Requires specialist programmer, less agile for changeovers. |

| Payload & Speed | Typically lower (<20 kg), slower speeds due to force-limiting design. | Very high (up to 1000s of kg), very high speeds. | Cobot: Ideal for small-to-medium parts, secondary ops. Industrial: Necessary for heavy raw stock, high-speed palletizing. |

| Flexibility & ROI | High flexibility, mobile, faster ROI for varied, low-volume tasks. | Lower flexibility, fixed, ROI justified by high-volume, single-task duty. | Cobot: Perfect for HMLV, job shops, and pilot automation projects. Industrial: Best for dedicated, high-volume production lines. |

| Accuracy | Good repeatability (often ±0.1mm), sufficient for many tasks. | Very high repeatability and absolute accuracy. | Cobot: Excellent for loading, finishing, many inspections. Industrial: Required for ultra-high-precision assembly or machining. |

Case Studies: Cobots in Action at Precision Machine Shops

Case Study 1: The High-Mix Job Shop – Doubling Lathe Productivity

-

Challenge: A precision job shop running multiple CNC lathes struggled with operator fatigue and bottlenecking. One operator could only tend one or two machines efficiently, and part changeovers were manual and time-consuming.

-

Solution: They deployed a Universal Robots UR10e cobot on a mobile cart. The cobot was equipped with a dual gripper—one side for raw bar stock, the other for finished parts. Using simple hand-guiding, the shop programmed the cobot to open the lathe door, remove the finished part, load new stock, close the door, and signal the lathe to start. The mobile cart allowed the single cobot to service multiple lathes in sequence.

-

Outcome: The setup enabled lights-out operation for one full shift. A single operator could now oversee 4-5 machines, effectively doubling spindle utilization and overall shop throughput. The cobot’s intuitive programming allowed machinists to set up new part programs in under 30 minutes.

Case Study 2: The Aerospace Supplier – Eliminating Manual Deburring

-

Challenge: An aerospace manufacturer machining complex aluminum structural components faced a quality bottleneck. Manual deburring of hundreds of small pockets and edges was slow, inconsistent, and led to repetitive strain injuries.

-

Solution: A stationary FANUC CRX-10iA cobot was integrated into a dedicated finishing cell. The cobot was fitted with a spindle and a ball-nose deburring tool. Using a force-torque sensor, the cobot was programmed to apply a constant 5N force while following the contoured paths extracted from the part’s CAD model.

-

Outcome: The cobot achieved a perfect, consistent edge break on every part, completely eliminating rework due to incomplete or uneven deburring. The cycle time was predictable, and the dangerous manual task was removed, improving both quality and worker safety. The cell paid for itself in under 12 months through labor savings and scrap reduction.

Case Study 3: The Medical Device Maker – Ensuring 100% Inspection

-

Challenge: A manufacturer of titanium orthopedic implants required 100% inspection of critical bore diameters and thread quality after CNC machining. Manual inspection with plug gauges was slow and created a data-logging burden.

-

Solution: A Techman TM Robot cobot with integrated vision was installed at the end of the machining line. The cobot picks each finished implant and presents it to a high-resolution vision camera and a keyence laser micrometer. It measures all critical features, compares them to tolerances stored in the system, and logs the results directly to a database.

-

Outcome: Inspection time per part was reduced by 70%. The digital record provided full traceability for FDA audits. The cobot’s gentle handling and precise positioning ensured no damage to the delicate, high-value implants. The system also automatically segregated any out-of-spec parts.

Implementing Cobots: A Strategic Roadmap

Successfully integrating a cobot requires more than just purchasing hardware. Follow this strategic approach:

-

Identify the Right Process: Start with a task that is repetitive, ergonomically challenging, and a known bottleneck. Machine tending and finishing are excellent first projects.

-

Conduct a Formal Risk Assessment (ISO/TS 15066): This is a legal and ethical imperative. Document all hazards and define the collaborative modes and safety functions required. This may involve an external consultant.

-

Select the Ecosystem, Not Just the Arm: Choose a cobot brand with strong support, easy-to-use programming, and a wide range of certified end-of-arm tooling (EOAT) and peripherals (vision, force sensors).

-

Plan for Integration: Consider how the cobot will interface with your CNC machines (I/O, communication protocols), the fixturing needed, and the workflow changes for your staff.

-

Invest in Training: While easier than traditional robots, proper training for your machinists on programming, operation, and basic troubleshooting is key to long-term success and acceptance.

-

Start Small and Scale: Begin with a single, well-scoped application. Use the lessons learned and the confidence gained to expand cobot usage to other areas of your shop.

Conclusion: The Collaborative Future is Now

The question “what is a collaborative robot?” is ultimately answered not by its technical specifications, but by the new manufacturing paradigm it enables. Cobots represent a pragmatic, accessible, and powerful form of automation that aligns perfectly with the needs of modern, agile, precision-focused machine shops. They are tools that amplify human skill, ensure consistent quality, and provide the flexibility to thrive in a market demanding both customization and efficiency.

At JLYPT, we see cobots not as a replacement for the master machinist, but as their ultimate apprentice—a tireless, precise, and adaptable partner. By understanding their capabilities, safety frameworks, and ideal applications, forward-thinking manufacturers can seamlessly integrate this technology to build a more resilient, productive, and competitive operation.

Ready to explore how a collaborative robot can become a strategic asset in your machining cell? Contact JLYPT today to discuss a feasibility assessment for your specific application. Discover how our expertise in precision machining and intelligent automation can guide your collaborative future. Visit our service page to learn more: JLYPT CNC Machining Services.