Introduction: The Critical Role of Precision Manufacturing in Robotic Evolution

In the landscape of modern industrial automation, the performance ceiling of any robotic system is determined long before software optimization or sensor integration—it is fundamentally established during the manufacturing of its mechanical components. Robotic Parts Machining represents a specialized discipline at the intersection of precision engineering, advanced materials science, and multi-axis manufacturing, where tolerances are measured in microns, structural dynamics are engineered into the material, and geometric complexity must serve functional imperatives. At JLYPT, we operate within this critical niche, transforming engineering specifications for robotic arms, end effectors, and motion systems into physical components that deliver deterministic performance across millions of operational cycles.

The distinction between conventional machining and precision robotic parts machining manifests in measurable system-level outcomes: a 0.005mm improvement in bearing seat concentricity can reduce transmission backlash by 40%; a strategically engineered internal lattice can increase structural stiffness by 60% while reducing mass; and a surface finish improvement from Ra 0.8µm to Ra 0.2µm can extend harmonic drive service life by 300%. These are not incremental gains but transformative improvements that enable robots to perform delicate assembly tasks, execute high-speed pick-and-place operations with micron-level repeatability, and operate continuously in demanding industrial environments without degradation. This manufacturing discipline requires understanding not just how to remove material efficiently, but how to engineer the resulting component’s interaction with forces, motions, and environmental factors unique to robotic operation.

This comprehensive examination details the technical methodologies, material strategies, and validation protocols that define modern robotic component manufacturing. We will analyze why specialized aluminum alloys and vacuum-treated steels are specified for different robotic subsystems, how 5-axis simultaneous machining enables consolidated joint assemblies, and what metrological approaches verify that kinematic performance matches computational models. For engineers developing collaborative robots for sensitive human interaction, high-speed delta robots for packaging, or specialized robotic systems for surgical applications, this knowledge forms the essential bridge between theoretical design and reliable operation. Discover how our specialized capabilities in precision robotic parts machining provide the mechanical foundation upon which advanced automation systems are built.

The Mechanical Imperatives: Unique Requirements for Robotic Components

Robotic systems impose a distinct set of mechanical requirements that differentiate them from conventional machinery components. These requirements drive every aspect of the manufacturing process from initial material selection through final quality validation.

Kinematic Accuracy and Error Stack-Up Mitigation

Robotic systems function as kinematic chains where the position and orientation of the end-effector result from the cumulative positioning of each joint in the serial linkage. This creates a critical manufacturing challenge: error stack-up. A minute angular deviation at the base joint or a tiny parallelism error in a link translates to magnified positional inaccuracy at the end of the arm. Consequently, robotic parts demand exceptional geometric tolerances:

-

Bearing seat concentricity and perpendicularity typically within 0.008mm (0.0003″)

-

Bore true position tolerances often held to 0.01mm (0.0004″)

-

Flatness of mounting surfaces frequently specified at 0.01mm per 100mm

-

Pitch circle accuracy for gear and timing pulley mounts within 0.005mm

Dynamic Performance and Vibration Control

High-speed robotic operation generates significant dynamic forces that challenge structural integrity and precision. Components must be engineered for:

-

High natural frequencies to avoid resonance with operational vibration spectra (typically requiring first structural mode > 150Hz for industrial arms)

-

Optimal damping characteristics to dissipate vibrational energy without adding excessive mass

-

Balanced rotating assemblies to minimize induced vibrations from motors and transmissions

-

Controlled stiffness-to-weight ratios that maximize acceleration capabilities while maintaining precision under load

Cyclic Loading and Fatigue Life

Industrial robots routinely execute millions of motion cycles, creating demanding fatigue environments:

-

High-cycle fatigue resistance exceeding 10⁷ cycles at operational stress levels

-

Surface integrity that minimizes stress concentration points that initiate cracks

-

Material homogeneity that prevents inclusion-initiated failure in highly stressed areas

-

Residual stress management from manufacturing processes that could accelerate fatigue

Thermal Stability in Precision Systems

Robotic accuracy must be maintained across operational temperature ranges as heat generates from:

-

Servo motor operation (particularly in compact joint designs)

-

Transmission inefficiencies in gearboxes and reducers

-

Environmental fluctuations in manufacturing facilities

-

Friction in linear motion components

This necessitates materials with low coefficients of thermal expansion, designs that accommodate thermal growth, and manufacturing processes that ensure dimensional stability across temperature ranges.

Table 1: Robotic Component Performance Requirements vs. Manufacturing Solutions

| Performance Parameter | Robotic System Requirement | Conventional Machining Limitation | Precision Robotic Parts Solution |

|---|---|---|---|

| Positional Accuracy | End-effector repeatability ≤ 0.02mm | Tolerance stack-up from multiple setups | Single-setup 5-axis machining; In-process verification |

| Dynamic Stiffness | High natural frequency (>150Hz); Minimal vibration | Limited thin-wall capability; Isotropic material properties | Topologically optimized structures; Directional reinforcement |

| Cyclic Durability | >10⁷ cycle operational life without degradation | Surface imperfections acting as stress concentrators | Superfinished surfaces (Ra ≤ 0.2µm); Controlled residual stresses |

| Thermal Stability | ≤ 0.01mm drift across 20°C temperature range | Uncontrolled thermal expansion; Inhomogeneous materials | Low-CTE alloys; Symmetrical thermal design; Stress-relieving processes |

| Backlash Minimization | ≤ 0.005mm transmission backlash for precision tasks | Conventional bearing fits; Assembly-induced misalignment | H6/g5 or tighter bearing fits; Integrated preload mechanisms |

| Mass Optimization | Maximum acceleration with given actuator capabilities | Prismatic designs with high safety factors | Generative design algorithms; Thin-wall machining (≥0.5mm walls) |

Material Science for Robotic Applications

The selection of engineering materials for robotic components represents a critical decision point that balances mechanical properties, manufacturability, environmental factors, and economic considerations.

Aluminum Alloys for Structural Components

-

7075-T6 Aluminum: The premier choice for high-performance robotic structures requiring maximum strength-to-weight ratios. With tensile strength approaching 570 MPa and excellent machinability, this alloy enables thin-wall construction that maintains stiffness while minimizing moving mass. Applications include robot arm links, joint housings, and end-effector structures where dynamic performance is paramount.

-

6061-T6 Aluminum: Provides excellent all-around properties for less critically loaded components, offering good machinability, weldability, and corrosion resistance at lower cost. Typical applications include protective covers, mounting brackets, and enclosures where extreme strength is not required.

-

Cast Aluminum Alloys (A356-T6): Used for complex housings where near-net-shape casting reduces machining requirements. Typically requires precision CNC machining for critical interfaces and bearing surfaces to achieve required tolerances.

Steel Alloys for High-Strength Applications

-

4140/4340 Alloy Steel (Heat Treated): Delivers exceptional strength (up to 1,380 MPa yield) for gears, shafts, and high-stress connections in heavy-payload robots. Requires careful heat treatment management to minimize distortion, with final machining often performed after hardening using grinding or hard turning processes.

-

Stainless Steel (304, 316, 17-4PH): Essential for food-grade, medical, and corrosive environment robotics. 17-4PH (precipitation hardening stainless) offers the unique advantage of being machined in a soft condition then age-hardened to approximately 44 HRC with minimal dimensional change.

-

Tool Steels (D2, A2, M2): Used for wear surfaces, cutting tool interfaces, and high-abrasion components in specialized robotic applications. These materials require specialized machining approaches and typically undergo heat treatment to achieve working hardness levels.

Specialized Alloys for Demanding Applications

-

Titanium (Ti-6Al-4V): Provides exceptional strength-to-weight ratio and corrosion resistance for aerospace and medical robotic applications. Despite challenging machinability and higher cost, its performance justifies use in critical components.

-

Invar (Fe-Ni36%): Offers extremely low coefficient of thermal expansion (CTE ≈ 1.2 × 10⁻⁶/°C) for metrology frames and precision reference structures where thermal stability is paramount.

-

Magnesium Alloys: While less common due to corrosion and flammability concerns, magnesium provides the highest strength-to-weight ratio of commonly machined metals for applications where minimal mass is critical.

Engineering Polymers and Composites

-

PEEK (Polyetheretherketone): High-performance thermoplastic offering excellent strength, chemical resistance, and thermal stability for insulating components, low-friction bushings, and vacuum-compatible parts.

-

VESPEL (Polyimide): Used in extreme temperature applications where conventional polymers fail, with continuous service up to 260°C (500°F).

-

Carbon Fiber Reinforced Composites: Provide exceptional stiffness-to-weight ratios and damping characteristics for long robot arms and high-speed components where minimizing deflection and vibration is critical.

Table 2: Material Selection Matrix for Robotic Components

| Component Type | Primary Requirements | Optimal Materials | Alternative Options | Key Manufacturing Considerations |

|---|---|---|---|---|

| Robot Arm Links | High stiffness/weight; Fatigue resistance; Damping | 7075-T6 Aluminum; Carbon Fiber Composites | 6061-T6; Titanium (premium) | Thin-wall machining; Topological optimization; Vibration damping features |

| Joint Housings | Bearing seat precision; High strength; Thermal stability | 7075-T6 Aluminum; Ductile Iron (large) | 6061-T6; Steel castings | Bore concentricity (≤0.008mm); Preload management; Heat dissipation |

| Gears & Transmission | Wear resistance; High strength; Precision tooth form | 4140 Steel (hardened); Powdered metals | 8620 Steel; Bronze (wear surfaces) | Post-hardening grinding; Tooth profile accuracy; Surface finishing |

| Linear Guide Components | Wear resistance; Dimensional stability; Smooth motion | 1045 Steel (hardened & ground); Aluminum with inserts | Stainless steel; Engineering polymers | Grinding to precision tolerances; Straightness control; Surface finish (Ra ≤ 0.4µm) |

| End-Effector Jaws | Gripping force; Wear resistance; Low inertia | Tool steel (D2, A2); Aluminum with hard coating | Titanium; Engineering polymers | Hardening after machining; Surface treatments; Mass optimization |

| Sensor Mounts | Vibration isolation; Dimensional stability; Low CTE | Invar; 6061-T6 with isolation | Magnesium; Engineering polymers | Micro-machining for alignment features; Vibration damping integration |

| Base Structure | Rigidity; Vibration damping; Mass | Granite composite; Welded steel with stress relief | Cast iron; Concrete-filled steel | In-situ machining of mounting surfaces; Vibration damping design |

Advanced Machining Technologies for Robotic Components

Meeting the stringent requirements of robotic parts necessitates specialized machining technologies beyond conventional 3-axis milling.

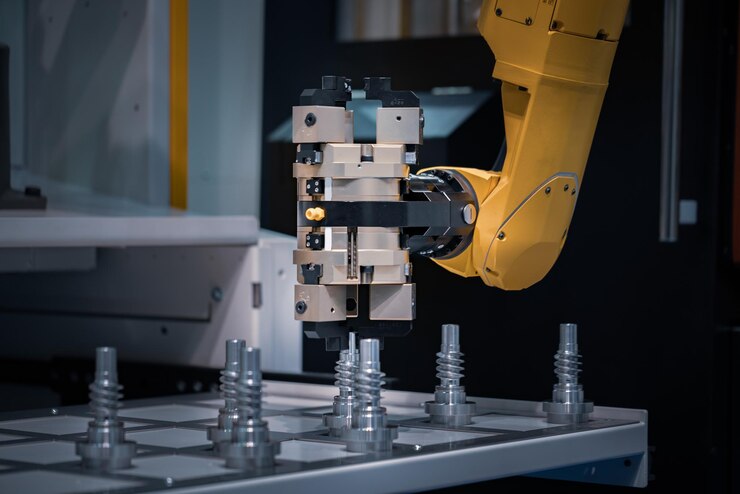

5-Axis Simultaneous Machining

This technology enables machining of complex robotic components from multiple angles in a single setup, providing critical advantages:

-

Complex geometry capability for consolidated joint assemblies and optimized structural shapes

-

Improved accuracy by eliminating multiple setups that introduce tolerance stack-up

-

Superior surface finish through optimal tool orientation and continuous tool engagement

-

Reduced lead times by completing parts in fewer operations

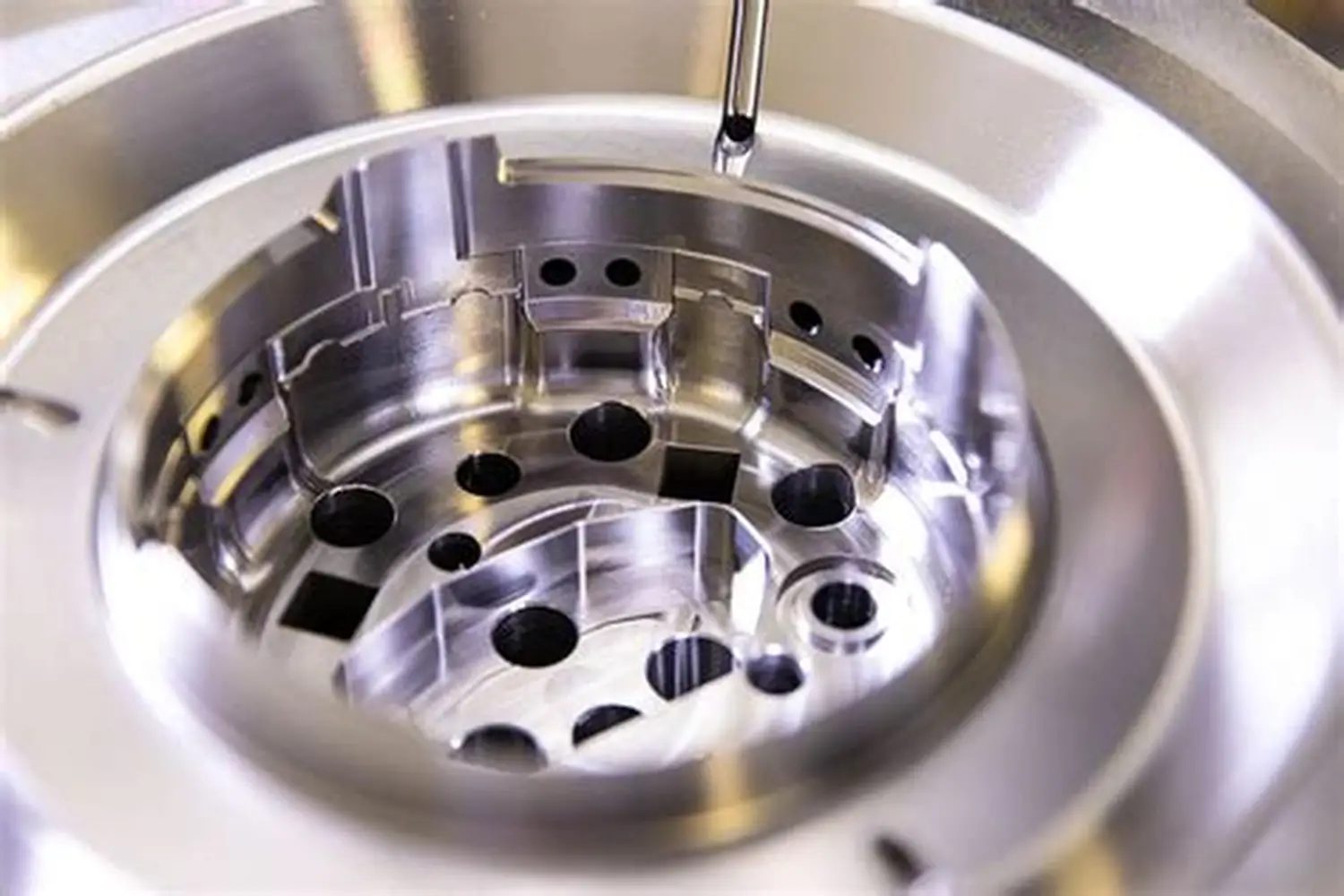

Micromachining for Precision Features

Many robotic components require exceptionally fine features that demand specialized micromachining capabilities:

-

Small diameter tools (down to 0.1mm/0.004″) for intricate channels and fine details

-

High spindle speeds (up to 60,000 RPM) for proper cutting speeds with micro-tools

-

Advanced toolpath strategies to prevent tool deflection and breakage

-

Sub-micron positioning for feature accuracy and surface finish

Hard Turning and Grinding

For components requiring exceptional hardness and precision after heat treatment:

-

Hard turning of materials up to 62 HRC using cubic boron nitride (CBN) or polycrystalline cubic boron nitride (PCBN) inserts

-

Precision grinding for the highest accuracy surfaces, achieving tolerances to 0.001mm (0.00004″) and surface finishes to Ra 0.1µm

-

Centerless grinding for high-volume production of shafts and pins with exceptional roundness and diameter control

Ultrasonic Assisted Machining

Applying ultrasonic vibration during cutting processes provides significant benefits for challenging robotic materials:

-

Reduced cutting forces (30-70% reduction) enabling thinner walls and more delicate features

-

Improved surface finish through altered chip formation mechanisms

-

Extended tool life particularly with difficult-to-machine alloys like titanium and Inconel

-

Minimized workpiece distortion through reduced cutting forces and temperatures

Quality Assurance and Metrology for Robotic Parts

The precision requirements of robotic components demand comprehensive quality assurance methodologies throughout the manufacturing process.

First Article Inspection (FAI)

Complete dimensional validation against design specifications using:

-

Coordinate Measuring Machines (CMM) with volumetric accuracy ≤ 0.001mm + L/350µm

-

Laser scanning for complex surface verification

-

Optical comparators for profile verification

-

Surface roughness measurement with profilometers

In-Process Verification

Real-time quality assurance during manufacturing:

-

On-machine probing for feature verification between operations

-

Tool condition monitoring to ensure cutting edge integrity

-

Adaptive control systems that adjust parameters based on real-time feedback

-

Statistical process control (SPC) tracking critical dimensions through production runs

Non-Destructive Testing (NDT)

Ensuring material integrity without compromising components:

-

Dye penetrant inspection (DPI) for surface-breaking defect detection

-

X-ray inspection for internal void and inclusion detection

-

Ultrasonic testing for bond integrity and material consistency

-

Eddy current testing for surface and near-surface defect detection

Functional Testing

Validating performance under simulated operating conditions:

-

Runout and concentricity testing for rotating assemblies

-

Backlash measurement in gear trains and transmission systems

-

Stiffness testing under simulated operational loads

-

Vibration testing to verify dynamic characteristics

Table 3: Robotic Component Quality Standards and Validation Methods

| Component Category | Critical Quality Parameters | Measurement Methods | Acceptance Standards |

|---|---|---|---|

| Bearing Housings | Bore diameter (H6/H7); Concentricity; Surface finish | CMM; Air gaging; Surface profilometer | ISO 286 H6/H7; Concentricity ≤ 0.008mm; Ra ≤ 0.4µm |

| Precision Shafts | Diameter (g5/g6); Straightness; Surface finish | Micrometer; Laser micrometer; Roundness tester | ISO 286 g5/g6; Straightness ≤ 0.005mm/100mm; Ra ≤ 0.2µm |

| Gear Components | Tooth profile; Pitch accuracy; Surface finish | Gear analyzer; CMM with gear software; Surface profilometer | AGMA 2000-A88 Class 10+; Pitch error ≤ 0.005mm; Ra ≤ 0.4µm |

| Structural Frames | Flatness; Hole pattern accuracy; Squareness | CMM; Laser tracker; Precision level | Flatness ≤ 0.01mm/100mm; Position tolerance ≤ 0.02mm; Squareness ≤ 0.005mm/100mm |

| Linear Guide Rails | Straightness; Parallelism; Surface finish | Autocollimator; Precision level; Surface profilometer | Straightness ≤ 0.003mm/100mm; Parallelism ≤ 0.005mm; Ra ≤ 0.2µm |

| Rotary Unions | Concentricity; Face runout; Surface finish | CMM; Dial indicator; Surface profilometer | Concentricity ≤ 0.005mm; Face runout ≤ 0.003mm; Ra ≤ 0.2µm |

Case Studies: Precision Manufacturing Solutions for Robotic Applications

Case Study 1: Collaborative Robot (Cobot) Forearm Assembly

Challenge: A cobot manufacturer required a forearm assembly that maximized payload capacity while maintaining the stiffness necessary for precision tasks and providing integrated cable routing for power and data transmission.

Solution: We designed and manufactured a monolithic forearm housing from 7075-T6 aluminum using 5-axis simultaneous machining:

-

Topologically optimized structure achieving 40% weight reduction while increasing torsional stiffness by 25%

-

Integrated cable channels with smooth radii to prevent cable wear during articulation

-

Precision bearing seats with 0.006mm concentricity for smooth joint operation

-

Hardcoat anodized surfaces at wear points for extended service life

Results: The forearm assembly enabled a 15% increase in maximum payload capacity while maintaining 0.02mm end-effector repeatability. Integrated cable routing eliminated external cabling, improving safety and reliability in collaborative environments.

Case Study 2: High-Speed Delta Robot Central Platform

Challenge: A packaging automation company needed a central moving platform for a high-speed delta robot capable of 300 picks per minute with 0.01mm repeatability.

Solution: We precision-machined the platform from solid 7075-T6 aluminum using single-setup 5-axis machining:

-

Three pairs of bearing seats machined in one setup ensuring perfect mutual parallelism (≤0.005mm) and angular position

-

Kinematic coupling features for precise, repeatable end-effector mounting

-

Dynamic balancing to 0.1g·mm residual imbalance at operating speed

-

Mass optimization removing 30% material while maintaining structural integrity

Results: The platform achieved 0.008mm measured repeatability at 300 picks/minute, exceeding design requirements. Dynamic balancing eliminated high-frequency vibration that had previously limited operational speed in earlier designs.

Case Study 3: Surgical Robot Wrist Mechanism

Challenge: A medical device company required a miniature robotic wrist mechanism providing two degrees of freedom within a 10mm diameter envelope for minimally invasive surgical applications.

Solution: We employed micro-machining techniques with specialized equipment:

-

Titanium (Ti-6Al-4V ELI) components for biocompatibility and strength

-

Micro-gears with module 0.15 and precision bearing surfaces

-

Single-micron tolerances on critical features

-

Electropolished surfaces for biocompatibility and cleanability

Results: The wrist mechanism provided smooth, backlash-free motion through ±90° articulation with 0.01° repeatability. The complete assembly met sterilization requirements and performed successfully in preclinical trials.

Future Directions in Robotic Parts Manufacturing

The field of robotic component manufacturing continues to evolve with several emerging trends:

Additive Manufacturing Integration

-

Complex internal channels for cooling, lubrication, and cable routing

-

Customized lattice structures for optimized stiffness-to-weight ratios

-

Multi-material components with localized property optimization

-

Reduced assembly through consolidated part design

Smart Manufacturing and Industry 4.0

-

Digital twins of manufacturing processes for predictive optimization

-

AI-driven process control adapting to material variations

-

Blockchain-enabled traceability for quality assurance documentation

-

Predictive maintenance based on manufacturing equipment monitoring

Sustainable Manufacturing Practices

-

Material efficiency optimization through advanced nesting algorithms

-

Energy consumption reduction through process optimization

-

Closed-loop material systems for recycling machining waste

-

Low-impact manufacturing processes minimizing environmental footprint

Conclusion: Manufacturing as the Foundation of Robotic Performance

The advancement of robotic technology is fundamentally constrained by the precision, reliability, and performance of its mechanical components. Robotic Parts Machining has evolved from a commodity manufacturing service to a specialized engineering discipline that directly determines the capabilities of automation systems. From material science through advanced processing to comprehensive validation, each aspect of the manufacturing process contributes to the ultimate performance of the robotic system.

At JLYPT, we recognize that robotic components are not merely mechanical parts but integral elements of sophisticated motion systems. Our approach combines deep technical expertise in precision manufacturing with understanding of robotic operational requirements, creating synergistic relationships between design intent and manufacturing execution.

Ready to advance your robotic system with precision manufacturing partnerships that understand your technical challenges? Contact our engineering team to discuss how our specialized machining services can transform your designs into reliable, high-performance robotic components. From prototype development through production manufacturing, we provide the precision foundation for advanced automation systems. Begin your project at JLYPT Precision Robotic Parts Machining.