Engineering Precision: The Complete Guide to Custom Robot Joint Manufacturing

Introduction: The Critical Nexus of Robotic Motion

In the intricate ecosystem of industrial automation, collaborative robotics, and specialized robotic systems, the custom robot joint represents the fundamental mechanical nexus where power transmission, precision motion, and structural integrity converge. Unlike standardized, off-the-shelf robotic components, custom robot joint manufacturing enables engineers to transcend the limitations of modular designs, creating optimized kinematic solutions for specific payloads, workspaces, and dynamic performance requirements. At JLYPT, we specialize in the precision engineering and manufacture of these critical subsystems, transforming conceptual kinematic models into durable, high-performance mechanical reality through advanced CNC machining and integrated systems engineering.

The distinction between a standard and a custom-manufactured robot joint manifests in quantifiable performance metrics: a custom harmonic drive housing can exhibit 40% higher torsional stiffness than its catalog counterpart; a bespoke rotary union can integrate fluid and electrical pass-throughs, reducing external cabling by 70%; and a tailored joint assembly can achieve positional repeatability of under ±0.005mm, a tolerance unattainable with assembled commercial units. The modern robotic joint is not merely a pivot point but a sophisticated electromechanical system housing bearings, sensors, seals, and often the reduction gearing itself. Its design and manufacture dictate the ultimate performance ceiling of the entire robotic arm in terms of precision, speed, durability, and reliability.

This comprehensive technical guide explores the multi-disciplinary engineering behind custom robot joint manufacturing. We will analyze the critical design trade-offs between stiffness and weight, delve into the material science required for components experiencing extreme cyclic stresses, and detail the advanced multi-axis CNC machining strategies necessary to produce monolithic, high-tolerance housings. For engineers developing next-generation collaborative robots, high-speed delta pickers, or specialized robotic arms for surgical or aerospace applications, mastering the principles of custom joint fabrication is essential. Discover how our integrated approach at JLYPT Precision Robotic Parts Machining provides the foundational mechanical intelligence for advanced robotic motion.

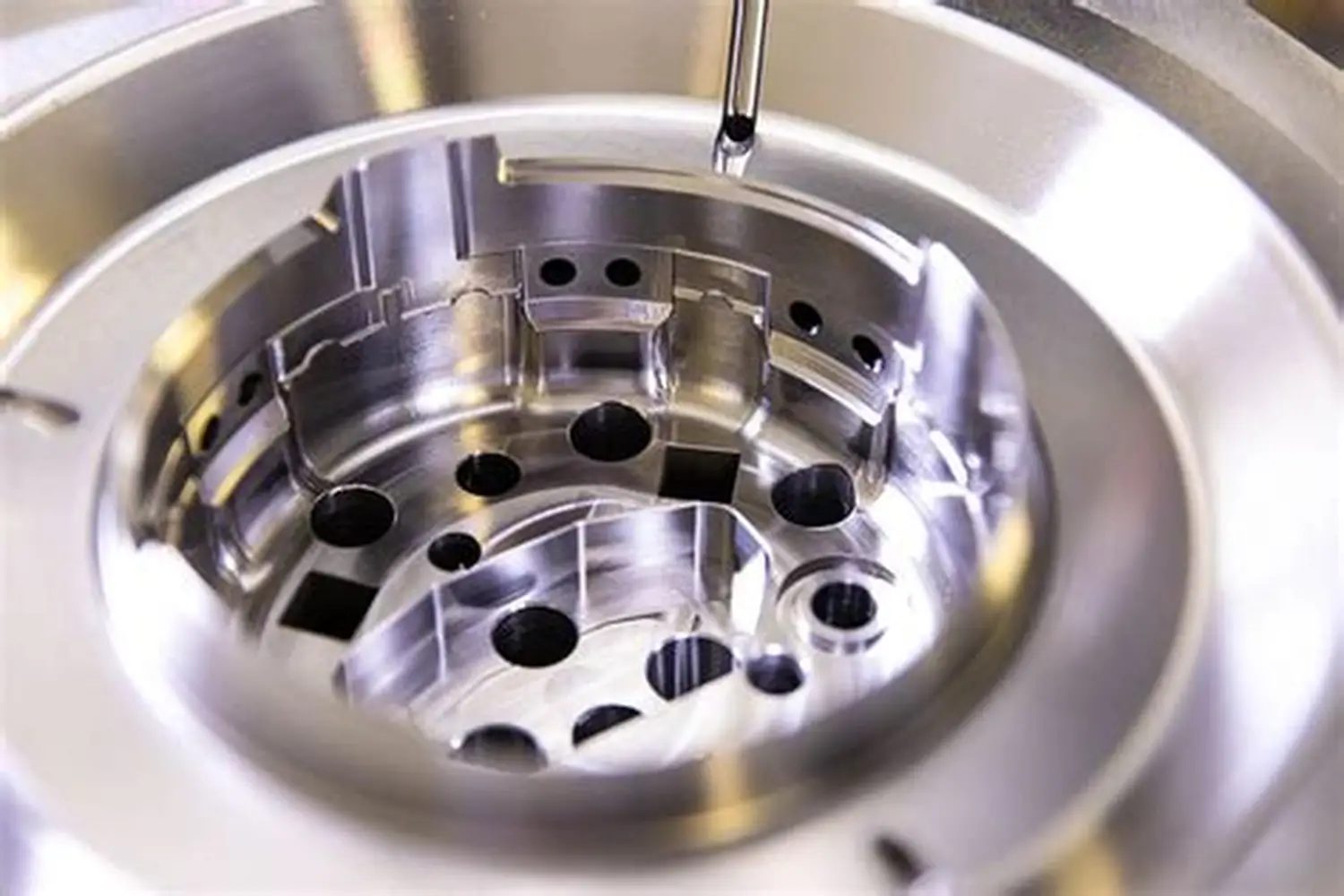

The Anatomy of a Robotic Joint: Core Subsystems and Functions

A robotic joint is a complex assembly of interdependent subsystems, each demanding precise engineering and manufacturing.

1. The Structural Housing: The Foundation of Rigidity

This component forms the joint’s exoskeleton, transmitting loads between connected links and providing mounting interfaces for all internal components.

-

Primary Loads: Bending moments, torsional forces, and bearing reaction loads.

-

Key Manufacturing Tolerances: Bearing seat diameters (typically H6/H7), true position of multiple bores (< 0.015 mm), perpendicularity of mounting faces (< 0.01 mm/100mm), and surface finish for seals (Ra < 0.4 µm).

-

Manufacturing Challenge: Achieving the required geometric accuracy and surface integrity across often complex, asymmetric geometries. 5-axis simultaneous machining is frequently essential to machine all critical features in a single setup, eliminating error stack-up.

2. Bearing and Preload System: Ensuring Smooth, Precise Rotation

This subsystem constrains motion to a single rotational degree of freedom with minimal friction and backlash.

-

Bearing Types: Commonly crossed roller bearings for their high moment load capacity and compactness, or angular contact ball bearings in duplex pairs for high-speed applications.

-

Preload Mechanism: Critical for eliminating axial and radial play. This often involves machining precise spacer dimensions or designing integral preload adjustment features (e.g., threaded caps) into the housing. Preload must be calculated to balance stiffness against excessive rolling resistance and heat generation.

-

Sealing: Integrated labyrinth seals or grooves for rotary lip seals are machined directly into the housing to protect bearings from contaminants.

3. Torque Transmission & Reduction: The Joint’s “Muscle”

Most joints incorporate a reduction system to multiply motor torque.

-

Harmonic Drive Integration: The most common solution for compact, high-ratio, zero-backlash reduction. Manufacturing involves precision machining of the wave generator bearing seats, circular spline interfaces, and flexspline mounting features, all with extreme concentricity requirements.

-

Planetary Gearboxes: Used for very high torque. Requires precision machining of gear pockets and bearing journals.

-

Direct Drive Interfaces: For applications requiring exceptionally low backlash and high stiffness, the joint housing may interface directly with a torque motor’s rotor and stator.

4. Integrated Sensor Mounting: The Joint’s “Proprioception”

Modern joints embed sensors for position, torque, and temperature feedback.

-

Encoder Mounting: Surfaces for mounting high-resolution absolute or incremental encoders must be machined with exceptional face runout and bore concentricity tolerances (often < 0.005 mm TIR) to ensure accurate signal generation.

-

Strain Gauge Integration: Areas may be specifically thinned or shaped to act as a torsion beam for in-line torque sensors, requiring precise control of local wall thickness and surface finish.

Table 1: Core Components of a Custom Robotic Joint & Their Manufacturing Imperatives

| Joint Subsystem | Primary Function | Critical Material Properties | Key CNC Machining Processes | Post-Processing |

|---|---|---|---|---|

| Structural Housing | Transmit load, align components, provide sealing surfaces. | High specific stiffness, good damping, fatigue resistance. | 5-axis contour milling, precision boring, deep-hole drilling, thread milling. | Stress relieving, hardcoat anodizing, vibratory finishing. |

| Bearing Seat & Preload Assembly | Provide precise, stiff, low-friction rotation axis. | High hardness & wear resistance at bearing interface. | Micro-finishing boring, face grooving, precision turning. | Superfinishing (Ra < 0.1 µm), surface hardening (nitriding). |

| Gearbox/Harmonic Drive Interface | Transmit and reduce motor torque with minimal backlash. | High contact fatigue strength, dimensional stability. | Hobbling/skiving (gears), EDM (complex splines), precision broaching. | Black oxide/phosphating, precision grinding, DLC coating. |

| Shafts & Adapters | Connect drive elements (motor, encoder) to reduction system. | High torsional strength, good surface fatigue life. | CNC turning between centers, spline/serration milling, keyway cutting. | Induction hardening, chrome plating, dynamic balancing. |

| Covers & Sealing Plates | Protect internal components, manage cables. | Light weight, corrosion resistance. | Sheet metal fabrication (CNC punch/press brake), milling. | Powder coating, silk screening, EMI/RFI shielding. |

Design Philosophy & Engineering Trade-offs

The design of a custom joint is an exercise in balancing conflicting requirements. The optimal design is always application-specific.

Stiffness vs. Weight: The Fundamental Trade-off

Robotic dynamic performance is governed by the stiffness-to-weight ratio. A stiffer joint improves positional accuracy under load and raises the system’s natural frequency, reducing vibration. However, adding material for stiffness increases weight and inertia, reducing maximum acceleration.

-

Solution: Utilize topology optimization (TO) software. Starting with the maximum design envelope and applied load cases, TO algorithmically removes material from low-stress areas, resulting in complex, organic-looking structures that are both light and stiff. These shapes are ideal for 5-axis CNC machining.

-

Material Choice: Aluminum 7075-T6 is the default for an excellent strength-to-weight ratio. For extreme stiffness requirements, beryllium-free copper alloys (e.g., C17200) or carbon fiber composites with machined metal inserts are used.

Precision vs. Cost: Managing Tolerance Stack-up

Tighter tolerances improve performance but exponentially increase manufacturing cost and time.

-

Strategy: Apply tight tolerances (ISO IT4-IT6) only to critical functional features (bearing seats, gear meshes, encoder mounts). Use more relaxed tolerances (ISO IT8-IT10) for non-critical structural elements.

-

Design for Assembly (DFA): Incorporate self-locating features (dowel pins, tapered fits) and adjustment mechanisms (eccentric bushings, shim gaps) to compensate for the accumulated variance of looser tolerances, achieving high precision at the system level without requiring every part to be perfect.

Thermal Management: Stability Under Power

Joints generate heat from motor losses, bearing friction, and gear meshing. Uneven thermal expansion causes drift in precision.

-

Solution: Design for thermal symmetry. Use finite element analysis (FEA) to model heat flow and expansion. Strategic placement of cooling channels (machined or via additive manufacturing) and use of materials with matched coefficients of thermal expansion (CTE) for adjacent components are critical.

Lubrication & Sealing: Ensuring Long-Term Reliability

A joint must retain lubrication and exclude contaminants over millions of cycles.

-

Integrated Lubrication: Design includes machined lubricant reservoirs, distribution galleries, and grease fittings.

-

Seal Selection: Machine grooves for specific seal types (O-ring, lip, labyrinth). Surface finish in the seal groove and on the dynamic sealing surface is paramount.

Table 2: Design Decision Matrix for Custom Robotic Joints

| Performance Priority | Recommended Joint Architecture | Optimal Material Selection | Key Manufacturing Focus | Primary Trade-off |

|---|---|---|---|---|

| Maximum Precision & Stiffness | Direct-drive or high-grade harmonic drive; Crossed roller bearings. | AISI 52100 steel (bearings), 7075-T6 Al (housing), Invar (metrology frames). | Sub-micron geometric tolerances; Super-finished bearing races; Thermal growth compensation. | High cost, increased mass, potential lower speed. |

| High Speed & Acceleration | Low-inertia design; Planetary or strain wave gear; Angular contact bearings. | 7075-T6 or 6061-T6 Al (lightweight), titanium (shafts), PEEK (covers). | Dynamic balancing of rotating assemblies; Thin-wall machining; Optimized mass distribution. | Reduced maximum torque and stiffness. |

| Heavy Payload & Durability | Robust housing; High-torque gearbox (cycloidal/planetary); Large diameter bearings. | 4340 or 4140 steel (QT) for housing, case-hardened steels for gears. | Deep-hardening heat treatment; Shot peening for fatigue life; Robust sealing systems. | Significant weight, lower maximum speed. |

| Compact Size & Light Weight | Integrated motor design; Harmonic drive; Needle bearings. | 7075-T6 Al, magnesium alloys, titanium for critical shafts. | 5-axis machining of complex internal cavities; Micro-machining; Hybrid manufacturing (AM+CNC). | Limited heat dissipation, potential for reduced stiffness. |

| Corrosion Resistance / Cleanroom | Stainless steel construction; Encapsulated seals; Smooth external surfaces. | Stainless Steel (316L, 17-4PH), anodized aluminum, PEEK. | Electropolishing; Deburring to sharp edges; Passivation. | Lower strength-to-weight ratio compared to high-strength steels. |

Advanced Manufacturing Methodologies

Producing the complex geometries and tight tolerances of custom joints demands a suite of advanced CNC capabilities.

Multi-Axis Machining (5-Axis Simultaneous): This is not a luxury but a necessity. It allows for:

-

Complex Contours: Machining the organic shapes from topology optimization.

-

Single-Setup Accuracy: Machining bearing seats, mounting faces, and bolt patterns in one clamping, ensuring perfect mutual alignment.

-

Deep Feature Access: Using shorter, stiffer tools to machine deep internal cavities for integrated electronics or cable routing.

Precision Boring & Turning: For achieving the perfect bore. Fine-boring heads with micrometer adjustment can achieve tolerances of H6 (a few microns) and surface finishes below Ra 0.4 µm. CNC turning centers with live tooling are ideal for complex shafts, allowing turning, milling, and drilling in one setup.

Gear & Spline Manufacturing: For joints incorporating custom gears.

-

Gear Hobbing: The standard for producing spur and helical gears.

-

Gear Shaping: Used for internal gears and gears close to shoulders.

-

Spline Broaching or Milling: For creating involute or straight-sided splines on shafts and hubs.

Additive Manufacturing (AM) Hybrid Approach: Metal 3D printing (DMLS/SLM) is used to create near-net-shape housings with impossible-to-machine internal features like conformal cooling channels or integrated lattice structures for weight reduction. The printed part is then precision machined on CNC equipment to create the critical functional surfaces (bearing seats, sealing faces), marrying geometric freedom with micron-level accuracy.

Heat Treatment & Surface Engineering: Critical for performance.

-

Through-hardening (Quench & Temper): For high-strength steel housings (e.g., 4140 to ~40 HRC).

-

Case Hardening (Carburizing/Nitriding): For gears and bearing surfaces needing a hard wear surface over a tough core.

-

Precipitation Hardening: For stainless steels like 17-4PH, machined in the “solution annealed” state then aged to high strength.

-

PVD Coatings: Applying TiN, CrN, or DLC coatings to gear teeth or bearing surfaces to drastically reduce friction and wear.

Quality Assurance & Metrology

The performance of a custom joint is only as good as its verification.

First Article Inspection (FAI): A complete dimensional validation using a Coordinate Measuring Machine (CMM) to verify every feature against the CAD model.

In-Process Verification:

-

On-machine probing: Checking critical dimensions between operations to allow for tool wear compensation.

-

Surface finish analysis: Using profilometers to ensure Ra values are met, especially on sealing and bearing surfaces.

Functional & Performance Testing:

-

Runout and Backlash Measurement: Using dial indicators and specialized fixtures to measure rotational play.

-

Stiffness Testing: Applying a known torque and measuring angular deflection.

-

Cycle Testing: Running the joint through millions of motion cycles to validate durability and seal integrity.

-

Thermal Testing: Monitoring performance and accuracy across a defined temperature range.

Case Studies: Custom Joints Solving Real-World Challenges

Case Study 1: High-Speed Delta Robot Wrist Joint

-

Challenge: A manufacturer of packaging robots needed to increase the speed of their delta robot’s central wrist from 150 to 250 picks per minute. The existing wrist, using commercial bearings and a fabricated housing, exhibited excessive vibration and wear at the target speed.

-

JLYPT Solution: We designed and manufactured a monolithic titanium (Ti-6Al-4V) wrist housing.

-

Design: Used modal analysis to shape the housing, pushing its first natural frequency above 800 Hz, well above the excitation frequency of the motors.

-

Integration: The housing incorporated preloaded angular contact bearings and a direct-mount interface for a frameless torque motor, eliminating adapter parts.

-

Machining: Entire housing was produced via 5-axis machining in two setups. Critical bearing seats were held to H5 tolerance with better than 0.008 mm concentricity.

-

Balancing: The complete assembly was dynamically balanced to G2.5 at the operational speed.

-

-

Result: The new wrist assembly achieved the 250 picks/min target with a 75% reduction in measured vibration. Bearing life increased by over 400%, and positional repeatability at the end-effector improved to ±0.01 mm.

Case Study 2: Collaborative Robot (Cobot) Elbow Joint with Integrated Safety

-

Challenge: A cobot developer needed a compact, lightweight elbow joint that could integrate a collision detection system without increasing the joint’s external profile. The joint also needed to be back-drivable for safe human interaction.

-

JLYPT Solution: We engineered a joint using a custom strain wave gear (harmonic drive) with a monolithic aluminum housing.

-

Housing Design: The housing was designed as a structural “cage” with openings that reduced weight by 30% while maintaining stiffness. These openings also served as access points for internal wiring.

-

Integrated Sensing: We machined precise mounting locations on the flexspline for a full-bridge strain gauge array to directly measure joint torque for collision detection.

-

Sealing: A custom labyrinth seal path was machined directly into the housing and cover to protect the strain gauges and gearing.

-

-

Result: The joint met all size and weight targets while providing direct, high-fidelity torque feedback for sensitive collision detection. The integrated design eliminated several external brackets and connectors, improving reliability and simplifying assembly.

Case Study 3: Underwater Remotely Operated Vehicle (ROV) Manipulator Shoulder Joint

-

Challenge: An oceanographic ROV needed a shoulder joint capable of operating at 3000m depth (30 MPa pressure), resisting corrosion, and providing high torque for sediment sampling.

-

JLYPT Solution: We manufactured the joint from Grade 5 Titanium (Ti-6Al-4V) and 316L Stainless Steel.

-

Pressure Housing: The main structural element was a titanium pressure vessel with hemispherical ends, machined from a solid forging. All penetrations for shafts used conical pressure seals.

-

Corrosion Management: All stainless steel components (shafts, fasteners) were electropolished and passivated. Dissimilar metal contact points used insulating sleeves and washers to prevent galvanic corrosion.

-

Gearing: Incorporated a custom planetary gearset made from corrosion-resistant maraging steel, coated with PVD CrN for wear protection in sandy conditions.

-

-

Result: The joint successfully passed pressure chamber testing to 45 MPa. It has performed reliably on multiple deep-sea expeditions, demonstrating zero corrosion and maintaining its torque output specification in the harsh marine environment.

Conclusion: The Joint as a System, Not Just a Component

The development of a custom robot joint is a systems engineering endeavor that integrates mechanical design, material science, precision manufacturing, and rigorous validation. It moves beyond selecting parts from a catalog to engineering a complete motion subsystem optimized for a specific set of performance parameters. The benefits—enhanced precision, improved reliability, reduced size and weight, and unique functional integrations—justify the investment for applications where robotic performance is critical to success.

At JLYPT, we approach custom robot joint manufacturing as a collaborative partnership. We provide not just machining services, but the engineering insight to translate performance requirements into manufacturable, reliable designs. From initial concept through FEA analysis, material selection, precision machining, and final validation, we ensure that the joint forms a solid foundation for the entire robotic system’s performance.

Are you designing a robotic system where off-the-shelf joints limit your potential? Partner with us to engineer the precise motion foundation your innovation requires. Contact our engineering team to discuss your custom joint application at JLYPT Precision Robotic Parts Machining.