High-tolerance UAV Machining: CNC Strategies for Reliable Drone Alignment, Fits, and Repeatability

High-performance drones fail in quiet, expensive ways. Not the dramatic kind—more often it’s the slow drain of “why does this unit vibrate but that unit doesn’t,” “why is the gimbal notchy,” or “why did the payload rail loosen again.” These issues are rarely solved by simply tightening every dimension. They are solved by High-tolerance UAV machining done with a disciplined approach to datums, GD&T, process planning, tool control, workholding, coating allowances, and metrology.

This article is a practical shop-floor and engineering-drawing guide to making UAV parts that assemble consistently and hold alignment under vibration, temperature swings, and service cycles. It is written for UAV design engineers, manufacturing engineers, and sourcing teams who need precision outcomes—not just “nice-looking” CNC parts.

If you need a supplier for precision UAV components, JLYPT supports custom CNC UAV parts here:

https://www.jlypt.com/custom-cnc-uav-parts-manufacturer/

Table of Contents

- What “High Tolerance” Actually Means in UAV Hardware

- Why High-tolerance UAV machining Matters More Than Ever (Performance Drivers)

- Feature Map: Where Tight Tolerances Truly Pay Off in Drones

- Datums and GD&T: The Backbone of High-tolerance UAV Machining

- Tolerance Stack-Up for UAV Assemblies (Motor Axis, Gimbal, Payload)

- Process Selection: 3-Axis, 3+2, 5-Axis, Turning, Mill-Turn, Grinding

- Material Behavior Under Tight Tolerances (7075 vs 6061 vs Titanium, etc.)

- Workholding, Datum Transfer, and Distortion Control

- Tooling, Runout, and Cutting Strategy for Precision Surfaces

- Holes, Bores, Threads: Fits, Reaming, Thread Milling, Inserts

- Surface Finish and Coatings: Anodize/Hardcoat Allowances Without Surprises

- Metrology for High-tolerance UAV Machining: CMM, Roundness, Surface Roughness

- Documentation: FAI, Ballooned Drawings, Control Plans, and Traceability

- Cost & Lead-Time Drivers (and How to Reduce Them Safely)

- DFM Rules for Designers Who Need Tight Tolerances Without Huge Quotes

- Three Case Studies from UAV Precision Machining Programs

- RFQ Checklist and Drawing Notes (Copy/Paste)

- Next Steps with JLYPT + Technical References

1) What “High Tolerance” Actually Means in UAV Hardware

“High tolerance” is often used as shorthand for “small numbers on a drawing.” In reality, High-tolerance UAV machining is about controlling relationships—axis-to-axis alignment, face-to-hole squareness, bolt-circle true position, bore coaxiality, and stable seating faces—so that the assembled drone behaves predictably.

In drones, the parts that look “simple” can be the most sensitive: a motor mounting face that’s slightly out of flat can create clamp-load variation, which turns into micro-slip, which becomes vibration. A bearing bore that is round but not positioned correctly can feel fine on a bench and still generate a gimbal bias under load.

Table 1 — Practical Definition of “High Tolerance” in UAV Parts

| Category | What it means in UAV terms | Typical examples | Risk if uncontrolled |

|---|---|---|---|

| Positional accuracy | features land where assembly expects them | bolt circles, dowel holes, bearing centers | misalignment, uneven thrust vectors |

| Angular control | faces are square/parallel where needed | motor seating face to arm datum | vibration, thrust loss, wear |

| Form control | shape is controlled, not just size | roundness, cylindricity, flatness | binding, runout, sealing issues |

| Surface integrity | finish supports friction, sealing, bearing life | Ra targets on bores/faces | poor bearing feel, leaks |

| Repeatability | part-to-part variation is small | 10–200 pc pilot runs | inconsistent flight behavior |

2) Why High-tolerance UAV machining Matters More Than Ever (Performance Drivers)

Modern UAV platforms pack more capability into lighter structures: higher power density motors, tighter gimbal stabilization, more sensitive IMUs, and payloads that amplify structural resonance. As designs evolve, “average quality” parts start to cap performance.

High-tolerance UAV machining directly affects:

- Vibration behavior and acoustic signature (motor alignment, seating flatness, bolt pattern position)

- Gimbal smoothness and stabilization authority (bearing fits, coaxiality, surface finish)

- Payload pointing accuracy (orthogonality and datum coherence across assemblies)

- Environmental robustness (seal grooves, face flatness, coating compatibility)

- Field maintainability (thread durability, insert strategy, controlled deburr)

3) Feature Map: Where Tight Tolerances Truly Pay Off in Drones

Not every face needs microns. But certain features deserve priority because they define alignment, preload, and repeatability.

Table 2 — UAV Features That Justify High-Tolerance CNC Control

| UAV component | Critical features | Recommended control type | Why it’s critical |

|---|---|---|---|

| Motor mount / hub | seating face flatness, bolt-circle true position, pilot bore | flatness + true position + bore size/form | thrust vector consistency; vibration reduction |

| Arm interface node | datum-to-datum perpendicularity, dowel/locating holes | perpendicularity + position | consistent arm geometry across builds |

| Gimbal yoke/housing | bearing bore size + coaxiality, surface finish | size + coaxiality + Ra | smooth motion, low torque ripple |

| Payload rail | hole spacing, thread durability, sliding fit | position + fit class + insert plan | repeatable payload swaps |

| Sealed avionics enclosure | lid flatness, O-ring groove geometry | flatness + profile | IP rating, pressure equalization |

| Sensor mounts | orthogonality, pattern position | angular + position | calibration stability |

4) Datums and GD&T: The Backbone of High-tolerance UAV machining

If you want precision outcomes, the drawing must describe how the part is supposed to be referenced in assembly. That means datums are not decorative—they’re the manufacturing “north star.”

4.1 Datum strategy that matches real assembly

A workable datum scheme typically uses:

- Datum A: the primary seating face (the face that actually clamps or locates)

- Datum B: a secondary locating feature (edge, bore, or precision slot)

- Datum C: a tertiary feature that removes the last degree of freedom (hole, pin, or side face)

If a drawing does not specify datums clearly, the shop will select them. Different setups can then “make sense” individually while creating stack-up errors in assembly.

4.2 GD&T controls that frequently matter for drones

In High-tolerance UAV machining, GD&T is most valuable when it:

- ties hole patterns to seating faces

- controls axis relationships (coaxiality / position)

- limits face angular drift (perpendicularity / parallelism)

- controls functional surfaces (profile for grooves and sealing faces)

Table 3 — GD&T Controls Commonly Used in High-tolerance UAV Machining

| Functional requirement | Typical GD&T control | What it protects | Notes |

|---|---|---|---|

| Motor seating consistency | flatness on Datum A | uniform clamp load | finish Datum A late |

| Bolt circle alignment | true position to A | B | C |

| Gimbal bore alignment | position or coaxiality | smooth rotation | define inspection method |

| Lid sealing | flatness or profile | leakage prevention | specify surface finish too |

| Sensor orthogonality | perpendicularity | calibration stability | control the right datums |

5) Tolerance Stack-Up for UAV Assemblies (Motor Axis, Gimbal, Payload)

Precision in a drone isn’t a single dimension; it’s the sum of small errors in a chain. Stack-up analysis helps you decide where tolerances are actually needed.

Table 4 — Example Stack-Up Contributors in UAV Subassemblies

| Subassembly | “Bad outcome” | Dominant contributors | Best mitigation |

|---|---|---|---|

| Motor + prop plane | vibration + thrust vector bias | seating flatness, bolt-circle position, perpendicularity | datum-driven machining + CMM position |

| Gimbal rotation axis | notchy feel + drift | bore coaxiality, surface finish, bearing seat geometry | controlled boring + form measurement |

| Payload rail repeatability | payload pointing offset after swap | hole spacing, rail straightness, insert placement | position control + controlled installation |

6) Process Selection for High-tolerance UAV machining

Your tolerance goals should guide the machining route. A “tight” part made with too many re-clamps often becomes a tolerance lottery.

6.1 3-axis milling (precision achievable, but setup-dependent)

Works well for plates, brackets, and parts where key features can be completed in one or two orientations with reliable datum transfer.

6.2 3+2 (positional) machining

A strong choice for multi-face parts when continuous 5-axis is unnecessary. Reduces setups while maintaining strong accessibility.

6.3 5-axis machining (accuracy via fewer setups)

In High-tolerance UAV machining, 5-axis is valuable when:

- hole patterns and bores must remain tightly related across multiple faces

- the part geometry forces multiple orientations

- you want to reduce cumulative re-clamp error

6.4 CNC turning and mill-turn (often the best path for axis parts)

Spacers, shafts, bearing journals, gimbal axles, and precision standoffs benefit from turning because coaxiality and surface finish are naturally strong when done correctly.

6.5 Grinding, honing, lapping (when CNC alone isn’t enough)

Not every UAV program needs grinding, but if you truly need ultra-low runout or extremely tight form requirements, secondary processes may be justified for select features.

Table 5 — Process Capability Map (Typical, Shop-Dependent)

| Process | Best for | Typical strengths | Typical limitations |

|---|---|---|---|

| 3-axis milling | plates, brackets | cost efficiency, speed | multiple setups can accumulate error |

| 3+2 milling | multi-face prismatic parts | fewer setups, good access | still needs good datum definition |

| 5-axis milling | complex housings/nodes | minimal re-clamping, better relationships | programming + probing discipline required |

| CNC turning | shafts, journals | coaxiality, surface finish | secondary milling needed for flats/slots |

| Mill-turn | mixed axis + milled features | concentric + prismatic features | process planning complexity |

| Grinding/honing | bearing seats, ultra-precision | form + finish | higher cost, added handling |

7) Material Behavior Under Tight Tolerances

Material selection isn’t only about strength-to-weight. Under tight tolerances, thermal expansion, stress relief, and coating compatibility can dominate.

Table 6 — Materials Often Used in High-tolerance UAV Machining

| Material | Why UAV teams use it | Precision considerations | Typical applications |

|---|---|---|---|

| 6061-T6 Al | economical, stable | generally forgiving; good for fixtures and brackets | plates, mounts, covers |

| 7075-T6 Al | high stiffness/strength | more sensitive to stress concentration; still machines well | structural nodes, arms, motor mounts |

| Ti-6Al-4V | strength + corrosion | lower thermal conductivity; tool pressure and heat matter | harsh environments, high load points |

| 17-4PH SS | high strength | heat-treat can move geometry; plan sequencing | pins, adapters, wear parts |

| 303/304 SS | corrosion | gummy machining; finish control needed | fasteners, small hardware |

| Engineering plastics | damping, insulation | creep and temperature effects | isolators, covers, fixtures |

Table 7 — Thermal Expansion Snapshot (Why It Matters)

| Material | Relative CTE behavior (qualitative) | What it means for UAV precision |

|---|---|---|

| Aluminum alloys | higher expansion | fits can shift with temperature; consider operating conditions |

| Stainless steels | moderate | stable, but heavier |

| Titanium | moderate | good strength; manage heat during machining |

| Plastics | high + creep | avoid for critical alignment features |

8) Workholding, Datum Transfer, and Distortion Control

Workholding is where precision is won or lost. In High-tolerance UAV machining, the part must be held rigidly without being bent into shape by clamp pressure.

8.1 Fixturing principles that scale to repeatability

- Clamp on robust regions (bosses, thick walls), not thin webs

- Create repeatable datum contact (hard stops, locating pins, precision nests)

- Use probing to verify datum pickup and catch drift early

- Minimize re-clamping steps that re-interpret the datums

8.2 Distortion control for thin-wall UAV parts

- Balanced roughing (leave uniform stock)

- Finish critical faces last

- Avoid removing the “backbone” early in the route

- Consider stress-relieved stock for sensitive geometries

Table 8 — Common Workholding Mistakes vs Fixes

| Mistake | What it causes | Better approach | Benefit |

|---|---|---|---|

| vise clamping thin walls | bowed parts, drifting bores | soft jaws + support pads | geometry stability |

| too many setups | accumulated datum error | 5-axis or 3+2 consolidation | better feature relationships |

| finishing early | later operations distort finished faces | finish critical surfaces last | improved flatness/position |

| no probing | unnoticed setup shift | in-process probing | fewer surprises at inspection |

9) Tooling, Runout, and Cutting Strategy for Precision Surfaces

Precision machining is not only about machines—it’s about controlling the small variables that multiply into measurable error.

Key contributors in High-tolerance UAV machining:

- toolholder quality and runout

- tool deflection (especially on long reach tools)

- chatter and harmonic instability on thin walls

- thermal growth in spindle/part

- consistent finishing stock and toolpath strategy

Table 9 — CNC Parameters That Influence Tolerance (Practical View)

| Parameter | Why it matters | How shops control it |

|---|---|---|

| Tool runout | changes effective diameter; hurts bores | balanced holders, inspection, controlled stick-out |

| Deflection | shifts walls and slots | larger tools where possible; finish passes |

| Heat input | grows part mid-cycle | stable coolant strategy; step sequencing |

| Tool wear | drifts size over batch | tool life tracking; offsets; in-process checks |

| Finish strategy | reduces scallops and taper | consistent step-over; spring passes when needed |

10) Holes, Bores, Threads: Fits That Survive Vibration and Service

A drone is a fastener-driven machine. Holes and threads define assembly repeatability.

10.1 Precision holes: drilling vs reaming vs boring

- Drilling is fast but can wander and leave variable hole quality.

- Reaming improves size and finish but needs good pre-hole control.

- Boring (with a fine boring head or CNC boring cycle) is often the most controllable for critical bores.

10.2 Fits that commonly appear in UAV designs

- slip fits for alignment without binding

- transition fits for controlled location

- press fits for bearing seats or pinned joints

Table 10 — Fit & Feature Guide for High-tolerance UAV Machining

| Feature | Common UAV intent | Preferred method | Inspection tip |

|---|---|---|---|

| bearing seat bore | stable, low-friction rotation | boring + controlled finish | measure size + form (roundness) |

| dowel holes | repeatable assembly | drill undersize + ream | pin gauges + CMM position |

| motor pilot bore | concentric location | boring + chamfer control | CMM + runout check |

| thread in aluminum | repeated service | thread milling + inserts | go/no-go + torque test |

| counterbore/spotface | clamp-load stability | finish pass + deburr | verify depth + burr-free |

11) Surface Finish and Coatings in High-tolerance UAV machining

Coatings are not “cosmetic add-ons” in precision UAV assemblies. They are dimensional changes, friction changes, and sometimes electrical contact changes.

11.1 Anodize / hardcoat considerations

- Thickness can reduce clearance in holes and slots

- Hardcoat improves wear but can change fit feel

- Masking is often the cleanest approach for critical bores

- Post-finish sizing may be necessary for ultra-critical fits

Table 11 — Coating Planning Checklist for Tight Fits

| Item | Why it matters | Recommended note on drawing/RFQ |

|---|---|---|

| Coating type | thickness differs | specify coating class clearly |

| Masking zones | protect precision fits | “mask bore X / datum face A” |

| Allowance strategy | prevent interference | define pre-coat dimensions if needed |

| Electrical contact points | anodize is insulating | specify masked grounding pads |

| Cosmetic zones | avoid needless cost | define “Class A cosmetic” surfaces only |

12) Metrology for High-tolerance UAV machining: CMM, Roundness, Surface Roughness

You cannot “inspect quality into” a part—but metrology prevents you from flying guesses. For high-tolerance UAV assemblies, inspection must measure the same relationships the drone relies on.

12.1 Metrology tools commonly used

- CMM for true position, perpendicularity, profile, and multi-feature relationships

- Surface roughness tester for Ra on sealing faces and bearing seats

- Roundness / cylindricity measurement for critical bores

- Height gauge + granite for fast checks on plates and datums

- Go/No-Go gauges for threads and pins in production-like quantities

Table 12 — Inspection Outputs That Add Real Value

| Output | When it’s worth requesting | What it tells you |

|---|---|---|

| CMM report (GD&T) | bolt patterns, multi-face relationships | whether the part matches assembly intent |

| Surface roughness report | sealing faces, bearing seats | friction/seal performance |

| First Article Inspection (FAI) | new part or major rev | baseline for future lots |

| SPC sampling | pilot production | process stability over time |

| Material certs (if required) | regulated or critical programs | traceability and compliance |

For general standards and metrology references (useful when building an internal spec), see:

- https://www.iso.org/standards.html

- https://www.asme.org/codes-standards

- https://www.nist.gov/

- https://www.astm.org/standards

13) Documentation: FAI, Ballooned Drawings, Control Plans, Traceability

If you want repeatable outcomes from High-tolerance UAV machining, the documentation should match the risk.

Table 13 — Documentation Levels (Match to Your Program Stage)

| Level | Typical deliverables | Best for |

|---|---|---|

| Basic | dimensional spot checks + thread gauges | early engineering builds |

| Standard | full dimension report for critical features | validation builds |

| High-control | ballooned drawing + CMM GD&T + material/finish certs | customer delivery, pilot production |

| Production discipline | control plan + SPC + traceability | scaled manufacturing |

14) Cost & Lead-Time Drivers in High-Tolerance CNC Work

Tight tolerance doesn’t automatically mean high cost. The biggest cost driver is often how many times the part must be reinterpreted—re-clamped, re-datumed, re-measured.

Table 14 — Cost Drivers in High-tolerance UAV Machining (and Safe Optimizations)

| Cost driver | Why it increases cost | How to reduce cost without losing function |

|---|---|---|

| too many critical tolerances | forces slow machining + inspection | tolerance only functional features |

| multiple setups | adds labor and error risk | consolidate via 3+2 or 5-axis |

| deep thin-wall pockets | chatter + scrap | adjust ribs/wall thickness |

| post-coat rework | unpredictable fits | plan masking/allowance early |

| high inspection burden | CMM time is real time | focus CMM on datums + key patterns |

15) DFM Rules for Designers Who Need Tight Tolerances (Without Inflated Quotes)

Designers can make precision cheaper by ensuring machinability supports the tolerance targets.

Table 15 — DFM Moves That Improve Precision and Manufacturability

| Design choice | Why it helps High-tolerance UAV machining | What to avoid |

|---|---|---|

| generous internal radii where possible | stronger tools, less deflection | tiny radii everywhere |

| clear datum features | consistent setup and inspection | ambiguous references |

| avoid ultra-thin floors | reduces warp | “paper floors” under pockets |

| add inspection-friendly features | easier probing and CMM alignment | hidden critical features with no datums |

| standardize fasteners | repeatable assembly | mixing thread standards unnecessarily |

16) Three Case Studies in High-tolerance UAV machining

These examples show how precision problems tend to surface in real UAV programs—and what machining/inspection changes actually fix them.

Case Study 1 — Motor Mount Plate: Bolt Circle True Position + Seating Flatness

Application: high-power multirotor motor mount plate in 7075-T6.

Observed issue:

Two sets of “same design” mounts produced different vibration signatures at mid-throttle. Swapping motors didn’t move the issue; swapping plates did.

Root cause (manufacturing + definition):

- The drawing controlled hole size but did not control true position relative to a functional datum scheme.

- The seating face was within thickness tolerance but not tightly controlled for flatness, and burr control on spotfaces varied.

Precision fix:

- Defined Datum A as the motor seating face; added a flatness control.

- Controlled bolt-circle holes with true position relative to A|B|C.

- Finished the seating face and spotfaces in a final operation; added a mandatory edge-break/deburr note.

- Requested a CMM report for the bolt-circle true position on first articles.

Result:

Assembly became repeatable, clamp load stabilized, and vibration differences between units reduced measurably—without tightening every dimension on the part.

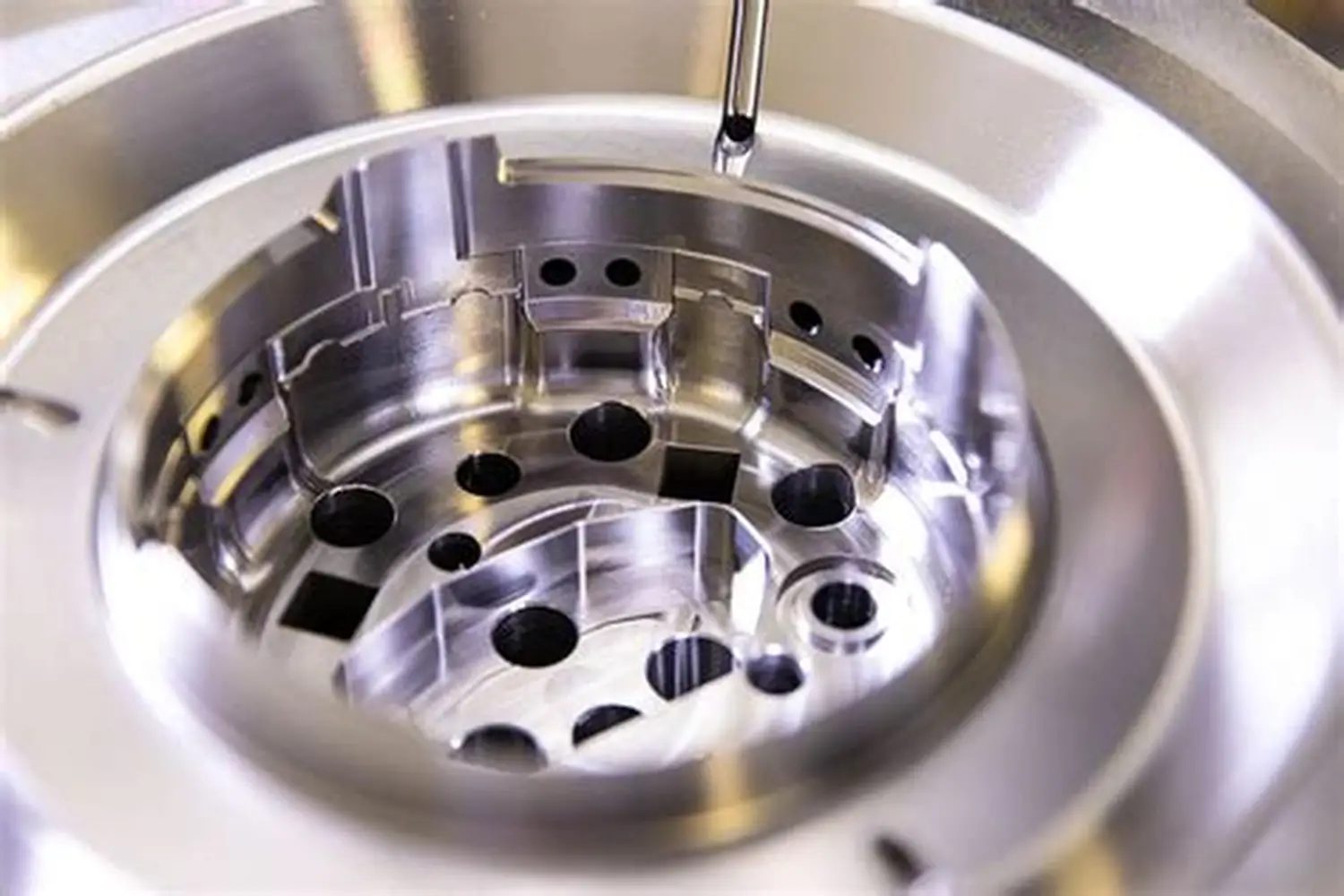

Case Study 2 — Gimbal Bearing Housing: Coaxiality + Surface Finish

Application: compact gimbal bearing cartridge housing (aluminum with anodize).

Observed issue:

Gimbal rotation felt smooth by hand before coating but became slightly notchy after anodize; some housings needed force to seat bearings.

Root cause:

- Bore sizing strategy did not account for coating thickness on functional bearing seats.

- Bores were within diameter tolerance but had inconsistent form and positional relationship across setups.

Precision fix:

- Changed process: bored bearing seats in a single stable orientation and verified with in-process probing.

- Planned coating: masked critical bearing seats (or specified allowance + post-finish sizing when masking wasn’t feasible).

- Added a surface roughness requirement on the bearing seat and verified with a roughness tester.

- Used CMM to confirm bore position relationship to the mounting datums.

Result:

Bearing installation force became consistent, gimbal torque ripple dropped, and coated parts matched the pre-coat assembly behavior.

Case Study 3 — Sealed Avionics Enclosure: Lid Flatness + O-Ring Groove Geometry

Application: UAV avionics enclosure requiring environmental sealing.

Observed issue:

Intermittent sealing failures during thermal cycling and vibration. Lids passed basic dimensional checks, but leak rate varied.

Root cause:

- Lid and enclosure interface relied on flatness and consistent groove geometry, but the inspection plan focused on overall dimensions.

- Machining sequence caused slight distortion after material removal; critical faces were not finished last.

Precision fix:

- Reordered operations so sealing faces were finished at the end of the machining route.

- Added flatness controls on the sealing face and profile control for the O-ring groove.

- Introduced CMM checks on the groove geometry and a surface finish check on the sealing land.

- Standardized deburr requirements to avoid micro-leak paths.

Result:

Seal performance became repeatable across builds, and thermal cycling no longer created “random” leak outcomes.

17) RFQ Checklist and Drawing Notes (Copy/Paste)

If you want faster quoting and fewer engineering back-and-forth cycles, include the information below when sourcing High-tolerance UAV machining.

Table 16 — RFQ Inputs That Improve Precision Outcomes

| Item | Provide | Why it matters |

|---|---|---|

| CAD | STEP (and native if possible) | reduces interpretation error |

| Drawing | PDF with datums + GD&T | defines functional relationships |

| Material | alloy + temper | affects stability and finish |

| Finish | anodize/hardcoat + masking notes | prevents fit surprises |

| Quantity | build qty + possible next lot | influences fixture strategy |

| Critical features list | top 5 features | focuses inspection and process |

| Inspection requirement | CMM/FAI/SPC level | aligns expectations |

| Assembly info | mating parts + fasteners | helps datum strategy |

Practical drawing notes (common in UAV precision parts)

- “Break edges and remove burrs; no sharp edges.”

- “Datum scheme to match assembly; inspect true position of hole pattern relative to A|B|C.”

- “Mask coating on datum faces / bearing bores as noted.”

- “Surface finish requirement on sealing lands/bearing seats where applicable.”

18) Next Steps: JLYPT Support for High-Tolerance UAV Parts

If you’re building UAV hardware where alignment, vibration control, sealing, and repeatability matter, High-tolerance UAV machining should be treated as a system: datums + machining route + inspection plan + finish allowances.

Explore JLYPT’s custom UAV CNC machining support here:

https://www.jlypt.com/custom-cnc-uav-parts-manufacturer/

You can also visit the main site for broader CNC capabilities:

https://www.jlypt.com/