Industrial Drone Parts Supplier: How to Qualify a CNC Machining Partner for Reliable UAV Production (Materials, GD&T, QA, Lead Times + 3 Case Studies)

Industrial drones are not “hobby aircraft with bigger motors.” They’re tools—flying assets expected to perform under schedule pressure, vibration, dust, moisture, temperature cycling, and repeated maintenance. When a platform fails in the field, the root cause often traces back to a detail that looked minor during design: a datum that wasn’t stable across setups, a thread that wore early, a coating that changed a fit, or a housing that distorted after deep pocketing.

That reality changes what buyers should look for in an Industrial drone parts supplier. Price matters, but it’s rarely the decisive factor over a program’s lifetime. The decisive factor is whether the supplier can produce parts that assemble the same way every time, in batches, with predictable lead times—and whether they can control the boring (but mission-critical) details: process routing, GD&T interpretation, fixturing strategy, inspection plans, traceability, and change control.

This long-form guide is written for engineering and sourcing teams who need a practical, CNC-machining-centered framework for selecting and managing an industrial drone parts supplier. It focuses on what affects real production outcomes: yield, field reliability, serviceability, and cost per flight hour.

If you’re evaluating a CNC machining partner for custom UAV components, you can review JLYPT’s dedicated manufacturing page here:

https://www.jlypt.com/custom-cnc-uav-parts-manufacturer/

Table of Contents

- What “Industrial Drone Parts Supplier” Really Means (Beyond a Quote)

- Industrial Drone Parts: Categories and the Manufacturing Implications

- CNC Machining Processes Used in Industrial UAV Programs (Milling, Turning, Multi-Axis)

- Materials for Industrial Drone Parts: How to Choose for Strength, Weight, and Stability

- Finishes & Coatings: Anodize, Chem Film, Passivation, Paint—And the Tolerance Traps

- GD&T and Datum Strategy: The Hidden Driver of Assembly Yield

- Production Workholding & Fixturing: Repeatability Beats Raw Clamping Force

- Quality Systems: FAI, Control Plans, CMM, Gage R&R Thinking, Traceability

- DFM for Industrial Drones: Design Decisions That Cut Cost Without Cutting Reliability

- Lead Times, Scaling, and Inventory Approaches for Spares

- Supplier Qualification Checklist (Detailed Tables)

- Three Case Studies (Prototype → Pilot → Production)

- Working with JLYPT as Your Industrial Drone Parts Supplier

- External Engineering References (DoFollow Links)

1) What “Industrial Drone Parts Supplier” Really Means (Beyond a Quote)

An Industrial drone parts supplier is not simply a machine shop that can “make drone parts.” Industrial UAV programs require a supplier that can deliver:

- Dimensional repeatability over time (not just one successful prototype)

- Process repeatability (same routing, same datum approach, controlled changes)

- Risk management (spotting tolerance traps, coating impacts, thin-wall distortion)

- Documentation and inspection discipline appropriate to your product risk level

- Production support (fixtures, batch planning, spare parts continuity)

A fast quote is easy. A stable supply chain is hard.

The industrial difference

Industrial drone fleets see:

- repeated field disassembly (fasteners and threads matter)

- environmental exposure (corrosion, sealing, coating compatibility)

- vibration and impact (fatigue, loosening, fretting, stress risers)

- sensor alignment sensitivity (positional tolerances, flatness, perpendicularity)

From a manufacturing perspective, that means your supplier must think like a production engineer, not only like a programmer.

2) Industrial Drone Parts: Categories and the Manufacturing Implications

Industrial UAV platforms combine structural, electromechanical, thermal, and sealing requirements. Below is a practical classification of CNC-relevant parts.

Table 1 — Industrial Drone Parts Categories vs Manufacturing Priorities

| Part category | Examples | Typical CNC process | Primary CTQs (Critical-to-Quality) | Common failure mode if done poorly |

|---|---|---|---|---|

| Structural frame parts | center plates, arm junctions, brackets | 3/4/5-axis milling | flatness, parallelism, hole position | vibration, misalignment, crack initiation |

| Housings & enclosures | avionics box, RF module body, payload shell | milling + secondary ops | sealing face flatness, pocket depth, connector cutouts | leaks, connector mismatch, warped lids |

| Motor & drivetrain mounts | motor plates, adapters, gearbox mounts | milling, drilling, reaming | perpendicularity, bore position, thread quality | motor tilt, bearing wear, noise, loosening |

| Precision rotating assemblies | gimbal yokes, bearing carriers, hubs | 4/5-axis + boring | coaxiality/position, surface finish | stiction, vibration, poor stabilization |

| Thermal management parts | heat spreaders, finned sinks | milling | interface flatness, fin geometry | overheating, throttling, reduced service life |

| Small turned parts | shafts, spacers, bushings, pins | CNC turning | diameter tolerance, runout, surface finish | wobble, wear, inconsistent fit |

| Field-service parts | latches, covers, clamps | milling/turning | durability, edge condition | stripped threads, poor ergonomics |

Industrial drone programs often combine many of these into one build. That’s why choosing an Industrial drone parts supplier is really choosing a manufacturing system that can handle mixed part families without sacrificing quality.

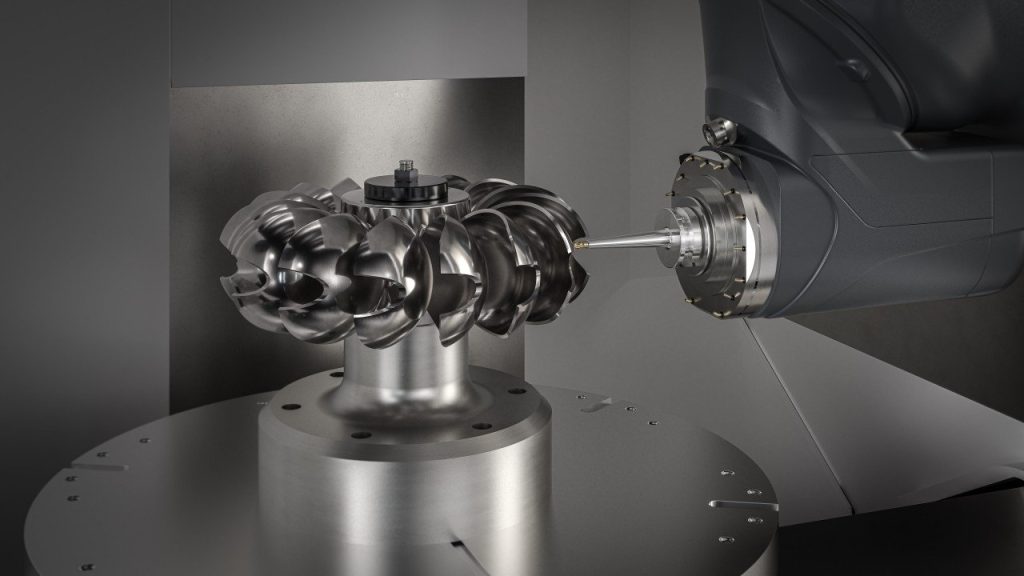

3) CNC Machining Processes Used in Industrial UAV Programs

Industrial drone components frequently require both milling and turning, sometimes with multi-axis access to reduce setups and improve positional accuracy.

3.1 CNC milling: 3-axis, 4-axis indexing, and 5-axis

- 3-axis milling: efficient for plates, brackets, and two-sided housings

- 4-axis indexing: ideal for parts with perimeter features (connector windows, side drilling)

- 5-axis milling: reduces setup count for complex geometry, angled features, and tight datum relationships

3.2 CNC turning: shafts, spacers, bushings, threaded components

Turned components often appear “simple” but drive precision in rotating systems. Runout, surface finish, and diameter control determine bearing life and vibration behavior.

3.3 Secondary operations and assembly support

Industrial drone parts often require:

- deburring and edge breaks (critical for sealing and cable protection)

- thread inserts (serviceability)

- reaming (repeatable dowel alignment)

- bead blasting (cosmetic uniformity pre-anodize)

- laser marking (serialization/traceability)

Table 2 — Process Selection Matrix for an Industrial Drone Parts Supplier

| Requirement | Best-fit process | Why it’s selected | Notes |

|---|---|---|---|

| tight hole pattern position | 4/5-axis milling + probing | fewer re-clamps, stable datum | pairs well with CMM verification |

| angled interfaces | 5-axis or 3+2 | reduces custom fixtures | improves consistency of compound angles |

| high-volume bracket families | 3-axis with dedicated fixture | fast cycle time | fixture discipline matters more than axis count |

| precision bores | boring/reaming in controlled setup | geometry control | inspect with bore gages/CMM |

| shafts and pins | CNC turning + ground stock if needed | diameter and finish control | consider heat treat and post-process |

An Industrial drone parts supplier should be comfortable recommending process routes instead of blindly following a model that was optimized only for appearance.

4) Materials for Industrial Drone Parts: Strength, Weight, and Stability

Material choice is one of the biggest levers for performance, cost, and manufacturing stability. Drones are weight-sensitive, but industrial drones are also duty-cycle-sensitive. You can’t chase grams at the expense of fatigue behavior or thread durability.

Common CNC materials for industrial drones

- 6061‑T6 aluminum: strong baseline, cost-effective, stable, great for general structures

- 7075‑T6 aluminum: higher strength, good for compact high-load mounts

- 2024 aluminum: fatigue strength, corrosion management required

- Stainless steels (304/316): corrosion resistance, heavier; used where wear/chemicals matter

- Titanium alloys: premium strength-to-weight, difficult machining, higher cost

- Engineering plastics (PEEK, acetal): RF transparency, chemical resistance, creep/thermal expansion considerations

Table 3 — Material Tradeoffs (CNC + Field Use)

| Material | Best use in industrial drones | CNC machining behavior | Finishing compatibility | Watch-outs |

|---|---|---|---|---|

| 6061‑T6 | frames, housings, brackets | very machinable | anodize, chem film | lower strength than 7075 |

| 7075‑T6 | motor mounts, high-stress joints | machines well | anodize (manage corrosion) | stress corrosion considerations in some environments |

| 2024 | fatigue-driven structures | good | anodize/paint (planned) | corrosion sensitivity |

| 316 stainless | corrosive/sea exposure parts | slower machining | passivation | weight penalty |

| Ti alloys | premium mounts, high-temp areas | challenging | passivation/controlled finishes | tool wear, cycle time |

| PEEK | covers, isolators, RF windows | good with correct tooling | typically no anodize | creep under load, expensive |

If you’re sourcing, an Industrial drone parts supplier should help you avoid “material mismatch” situations—for example, using a soft aluminum thread in a high-service panel without inserts, or using a heavy stainless part where a coated aluminum solution would meet requirements.

5) Finishes & Coatings: Where Industrial Programs Win or Lose

Finishes are frequently treated as cosmetic choices, but in industrial drone parts they are functional:

- corrosion resistance

- wear resistance

- electrical conductivity (or insulation)

- dimensional change affecting fits and sealing

Table 4 — Finish Options and CNC Planning Implications

| Finish | Typical purpose | Dimensional impact | CNC planning note |

|---|---|---|---|

| Type II anodize | corrosion + appearance | low to moderate | define masking zones for grounding and tight fits |

| Type III hard anodize | wear resistance | moderate to high | tolerance strategy must account for growth |

| chem film (conversion coating) | conductive corrosion protection | minimal | good for bonding/grounding surfaces |

| passivation (stainless) | corrosion protection | negligible | keep surfaces clean; avoid contamination |

| paint/powder coat | aggressive environments, branding | variable | avoid on sealing lands and precision fits |

| bead blast (prep) | uniform appearance | none (but changes texture) | can affect sealing surface finish expectations |

A capable Industrial drone parts supplier treats coating as part of the manufacturing route, not an afterthought. That means designing masking and defining which surfaces are “functional finishes” vs “cosmetic finishes.”

6) GD&T and Datum Strategy: The Hidden Driver of Assembly Yield

When industrial drone assemblies don’t fit, the cause is often not “bad machining”—it’s unclear datum selection or inconsistent setup logic. CNC machining is only as good as the datum scheme you ask it to follow.

Practical datum strategy for drone parts

- Choose functional datums: surfaces that actually locate the part in the assembly

- Avoid using thin walls as primary references

- Place critical hole patterns relative to stable planes or dowel features

- Use reamed dowel holes where repeatable alignment is required (especially for multi-part stacks)

Table 5 — GD&T Controls Commonly Critical in Industrial Drone Parts

| Feature | GD&T control often used | Why it matters in drones |

|---|---|---|

| mounting face | flatness | affects stiffness, vibration, sealing compression |

| parallel planes | parallelism | prevents twist and stress during assembly |

| bolt patterns | position | prevents assembly forcing and fastener cross-load |

| connector openings | profile of surface | ensures connector alignment and gasket function |

| bores for bearings | position / coaxiality as required | affects smoothness, wear, vibration |

| side faces | perpendicularity | controls orthogonality of attached modules |

A strong print makes it easier for an Industrial drone parts supplier to build a stable inspection plan and avoid “interpretation drift” between shifts or batches.

7) Production Workholding & Fixturing: Repeatability Beats Force

Drone parts are often pocketed and thin. If you clamp too hard, you bend the part and machine the “bent shape”—which springs back out of tolerance after unclamping. If you clamp inconsistently, you get variation across a batch.

Typical fixtures used for industrial drone parts

- custom soft jaws (machined to the part’s profile)

- zero-point workholding systems for repeatable re-clamping

- modular fixture plates with dowels and stops

- vacuum fixtures for lids/plates (when cutting loads are manageable)

Table 6 — Fixturing Approaches an Industrial Drone Parts Supplier Should Offer

| Workholding method | Best for | Advantage | Risk to manage |

|---|---|---|---|

| soft jaws | irregular housings, brackets | repeatable location | jaw wear and clamp distortion |

| zero-point pallets | multi-op routing | fast setups, repeatability | requires disciplined setup standards |

| modular dowel plates | prototypes and small batches | flexible | operator consistency is key |

| vacuum | flat lids/panels | minimal distortion | limited cutting forces, leakage |

If your supplier can’t clearly explain how they will fixture your part, you don’t have a process—you have a gamble.

8) Quality Systems: What to Ask an Industrial Drone Parts Supplier

Industrial drones are operational assets. That typically requires a quality level beyond “it looks good.” You don’t need bureaucracy for its own sake, but you do need controls that prevent surprises.

Quality elements that matter in CNC UAV production

- FAI (First Article Inspection) aligned to your datums and CTQs

- CMM inspection for position, profiles, and multi-feature relationships

- In-process probing to control setup offsets and detect drift

- Material certificates and lot control for critical parts

- Change control: revision tracking, controlled program updates

- Sampling plans that match risk (100% for CTQs, sampling elsewhere)

Table 7 — Inspection Methods vs Drone-Relevant CTQs

| CTQ | Typical inspection tool | Why it’s the right tool |

|---|---|---|

| hole pattern position | CMM, functional gage | validates datums and stackups |

| sealing face flatness | surface plate/CMM plane | leak prevention |

| bore size and roundness | bore gage, CMM | bearing life and vibration |

| thread quality | go/no-go gages | field service reliability |

| coating thickness (when critical) | coating thickness meter | fit control after finishing |

Table 8 — Traceability Levels (Choose Based on Program Risk)

| Traceability level | What’s tracked | Suitable for |

|---|---|---|

| basic | material + job traveler | prototypes, internal testing |

| intermediate | lot traceability + inspection records | pilot builds, limited fleets |

| advanced | serialization per part + linked inspection data | regulated/mission-critical fleets |

A strong Industrial drone parts supplier will ask you which level you actually need—then implement it without burying you in unnecessary cost.

9) DFM for Industrial Drones: Cut Cost Without Cutting Reliability

Design-for-manufacturability is not only about making machining cheaper; it’s about making results more consistent across batches. Consistency is what reduces field failure and rework.

High-impact DFM moves for CNC drone parts

- Avoid deep, narrow pockets that force long tool stick-out

- Use internal radii that match standard end mills

- Add access for deburring and tool approach

- Avoid stacking too many tight tolerances that don’t affect function

- Prefer reamed dowels for repeatable alignment rather than relying on bolt clearance holes

- Define cosmetic zones separately from functional zones

Table 9 — DFM Issues That Inflate Cost in Drone Parts

| DFM issue | Why it increases cost | Better alternative |

|---|---|---|

| extremely sharp internal corners | requires small tools, slow feeds | add radii consistent with tooling |

| tight tolerance everywhere | increases inspection time and scrap risk | apply tight tolerances only on CTQs |

| thin walls with heavy pocketing | distortion, chatter, rework | add ribs, stage roughing, adjust wall thickness |

| mixed finishes on same surface | masking complexity | define finish zones cleanly |

A practical Industrial drone parts supplier will propose DFM edits that preserve function while improving manufacturability and yield.

10) Lead Times, Scaling, and Spare Parts Strategy

Industrial fleets need spares. The manufacturing strategy should address:

- ramp from prototype to pilot to production

- controlled revision transitions

- stocking of high-wear parts (motor mounts, clamps, latches)

- packaging that protects sealing faces and cosmetic surfaces

Table 10 — Program Phase vs Supplier Expectations

| Program phase | Typical volumes | What you should require from an industrial drone parts supplier |

|---|---|---|

| prototype | 1–10 | speed, DFM feedback, basic inspection |

| pilot | 10–200 | fixture planning, stable routing, FAI + documented CTQs |

| production | 200+ | capacity planning, SPC-minded controls on CTQs, revision discipline |

| sustainment/spares | ongoing | repeatability over time, controlled materials and finishes |

11) Supplier Qualification Checklist (Detailed Tables)

Use the following checklists to qualify an Industrial drone parts supplier based on CNC reality—not marketing.

Table 11 — Capability Checklist (CNC and Supporting Operations)

| Category | What to confirm | Why it matters |

|---|---|---|

| milling | 3/4/5-axis availability | setup reduction, positional accuracy |

| turning | CNC lathe capability | shafts/spacers are common CTQ parts |

| work envelope | max part size | avoids awkward outsourcing |

| fixturing | soft jaws, modular, zero-point | repeatability and throughput |

| probing | in-process probing routines | reduces setup drift and scrap |

| deburr process | controlled edge break | cable protection, sealing integrity |

| inserts | helicoil/key-locking install | serviceability for field maintenance |

| marking | laser marking options | traceability and assembly control |

Table 12 — Engineering & Communication Checklist

| Topic | What “good” looks like | Red flags |

|---|---|---|

| DFM feedback | specific changes tied to cost/yield | vague “should be fine” responses |

| datum alignment | supplier explains how datums map to fixtures | no mention of datums or probing |

| tolerance review | identifies CTQs and inspection approach | promises tight tolerances everywhere without plan |

| coating planning | masking strategy, fit impacts discussed | “coating later” with no fit strategy |

| revision control | clear handling of ECO/ECN updates | mixed revisions in the same batch |

Table 13 — Quality Documentation Checklist

| Document / record | When to request it | Why |

|---|---|---|

| FAI report | first build of a revision | establishes baseline conformance |

| CMM report | tight position/profile features | confirms multi-feature geometry |

| material certificate | critical parts | ensures alloy/temper traceability |

| process routing | pilot and production | ensures repeatability |

| inspection plan | production | aligns sampling with CTQs |

| nonconformance handling | always | prevents silent rework and drift |

12) Three Case Studies (Prototype → Pilot → Production)

The examples below are presented as real manufacturing scenarios (not generic “success stories”), focusing on decisions that an Industrial drone parts supplier must get right: datums, setups, coatings, inspection, and field service behavior.

Case Study 1 — Rugged Motor Mount Bracket for a Heavy-Lift Industrial Drone

Part function: Holds motor and aligns thrust axis to frame; high vibration exposure; periodic motor replacement

Material/finish: 7075‑T6 aluminum, anodized

Primary CTQs:

- perpendicularity of motor face to mounting datum

- bolt pattern positional accuracy

- thread durability under repeated service cycles

Manufacturing risks

- re-clamp drift causing motor tilt across batches

- anodize growth affecting fit and fastener seating

- thread wear in aluminum during maintenance

Process strategy

- machine critical datums and bolt patterns in a controlled setup (reduce re-clamps)

- use probing to establish datum plane repeatably

- specify inserts (or controlled thread engagement and thread milling) for high-service fasteners

- define masking or tolerance strategy for anodized mating surfaces

Inspection strategy

- CMM verification for bolt pattern position relative to datums

- surface flatness/perpendicularity checks on the motor interface face

- thread gaging for service-critical holes

Result Motor axis alignment became consistent across batches, reducing vibration-related complaints and improving bearing life—exactly the kind of reliability expectation that drives teams to select an experienced Industrial drone parts supplier.

Case Study 2 — Avionics Module Enclosure with Controlled Sealing Lands (Field Replaceable)

Part function: Protects flight-control electronics in dust and humidity; must be opened for service

Material/finish: 6061‑T6 aluminum, conversion coating or anodize depending on grounding requirements

Primary CTQs:

- sealing land flatness and surface condition

- connector window geometry and location

- pocket depth and standoff pattern for PCB clearance

Manufacturing risks

- sealing face distortion after deep pocketing

- burrs at connector cutouts (risk to harnesses and gaskets)

- mixed requirements: corrosion protection vs electrical grounding

Process strategy

- rough internal pockets in stages, leaving stock for finishing

- finish sealing lands late in the routing to minimize distortion

- apply a controlled deburr/edge break standard, especially on connector windows

- define grounding pads as masked surfaces when using anodize (or use a conductive coating strategy)

Inspection strategy

- surface plate or CMM plane evaluation of sealing land

- CMM or functional gage for connector window relationship to datums

- depth measurement for PCB pockets and standoffs

Result Service reassembly became faster and more consistent because lids seated without rocking and connectors lined up without forcing—an outcome that depends on manufacturing discipline, not luck, and a core reason to select a capable Industrial drone parts supplier.

Case Study 3 — Precision Turned Shaft + Milled Bearing Carrier for a Stabilized Payload System

Part function: Supports smooth rotation; alignment affects stabilization performance and image quality

Material/finish: stainless shaft (passivated) + aluminum bearing carrier (anodized)

Primary CTQs:

- shaft diameter and surface finish

- bearing carrier bore geometry and positional relationship to mounting features

- controlled stack-up between turned and milled components

Manufacturing risks

- runout variation on turned shafts causing vibration

- bore position drift if carrier is machined across too many setups

- coating affecting press fit or slip fit behavior

Process strategy

- CNC turning with tight process control for diameter and finish; verify with calibrated micrometers and runout checks

- machine bearing carrier bores in a stable setup (4/5-axis where it reduces re-clamps)

- plan fits accounting for coating growth (mask bores or adjust tolerances)

Inspection strategy

- runout measurement on shafts

- bore gaging and CMM position checks for carriers

- functional assembly check using a controlled gauge shaft

Result Stabilization performance improved because mechanical runout and axis misalignment were reduced at the part level—proof that the right Industrial drone parts supplier can influence system performance, not just part appearance.

13) Working with JLYPT as Your Industrial Drone Parts Supplier

Choosing an Industrial drone parts supplier is ultimately about production confidence: the ability to move from a working prototype to reliable batches, with controlled costs, stable geometry, and inspection discipline that matches your real risks.

JLYPT CNC Machining supports custom UAV component manufacturing with CNC-focused engineering collaboration—covering milling/turning strategies, fixture planning, coating-aware tolerance thinking, and inspection approaches suitable for industrial programs.

Primary internal link (requested):

https://www.jlypt.com/custom-cnc-uav-parts-manufacturer/

Additional internal link:

https://www.jlypt.com/

To speed up quoting and reduce back-and-forth, send:

- STEP model + 2D drawing with datums/GD&T

- material and finish requirements (including masking notes if applicable)

- target quantities (prototype + pilot + production forecast if available)

- CTQ list (what must be controlled tightly, and why)

- any mating part info (critical stackups, dowels, connectors, sealing approach)

14) External Engineering References (DoFollow Links)

These references are useful for standard terminology and measurement alignment (no content is copied from them):

- ISO standards overview: https://www.iso.org/standards.html

- ASME standards (GD&T context): https://www.asme.org/codes-standards

- ASTM material standards: https://www.astm.org/standards

- NIST measurement fundamentals: https://www.nist.gov/