CNC Surface Finishing Services: How to Specify, Control, and Quote Finishes for Machined Parts

Surface finishing is where many CNC projects succeed—or quietly fail.

A part can be perfectly machined, dimensionally correct, and still get rejected because the finish doesn’t meet the drawing note, the coating built up on a fit surface, the color varies between lots, or a conductive area was accidentally sealed. In real production, “finish” is not just aesthetics; it’s friction, wear, corrosion, conductivity, adhesion, cleanliness, and long-term stability.

This guide is written for engineers and buyers who need CNC surface finishing services as part of a production-ready workflow. You’ll learn how to:

- Choose finishes that match function + tolerance + environment

- Write finish callouts that reduce back-and-forth

- Understand thickness buildup and what it does to critical dimensions

- Use masking and surface prep to prevent common defects

- Build an RFQ package that gets you accurate pricing and predictable lead time

If your project includes aluminum anodizing, you can also review our dedicated capability page here:

https://www.jlypt.com/custom-aluminum-anodizing-services/

Why CNC Surface Finishing Services matter in precision machining

Machining creates geometry; finishing defines the interface between the part and the world.

A few common “finish-driven” performance requirements:

- Corrosion resistance: marine environments, outdoor use, sweat/skin contact, chemical exposure

- Wear resistance: sliding contact, abrasive dust, repetitive assembly

- Electrical properties: grounding points, EMI shielding interfaces, low contact resistance

- Adhesion: paint or powder coat that must not peel

- Cleanability: food, medical, and fluid path applications

- Cosmetics: uniform color, consistent texture, controlled gloss, no handling marks

The hard part is that finishes interact with manufacturing realities:

- Coatings add thickness (often non-uniform on edges and recesses)

- Surface prep can round edges or change Ra

- Some processes require racking/contact points

- Heat and chemistry can impact alloys differently (especially across aluminum series)

CNC Surface Finishing Services: a practical selection framework (engineering-first)

When selecting CNC surface finishing services, start with four questions:

- Base material: aluminum (6061/7075), stainless (304/316), low-carbon steel, tool steel, brass, titanium, etc.

- Primary purpose: corrosion, wear, cosmetics, conductivity, adhesion, cleanability

- Geometry and tolerances: press fits, threads, sealing surfaces, deep bores, thin walls

- Specification & inspection: industry standards, thickness measurement method, acceptance criteria

Table 1 — Finish selection by objective (quick engineering map)

| Objective | Typical finishing options | Notes for CNC machined parts |

|---|---|---|

| Corrosion resistance (aluminum) | Type II anodize; conversion coating; paint/powder over conversion coat | Anodize improves corrosion; conversion coat supports conductivity and paint adhesion |

| Wear resistance (aluminum) | Type III hard anodize | Consider thickness buildup + potential dimensional change on tight fits |

| Corrosion resistance (stainless) | Passivation; electropolishing | Passivation improves free-iron removal; electropolishing also improves cleanability |

| Conductivity (aluminum) | Conversion coating (conductive class) | Anodize is typically insulating; conductive interfaces often need masking or conversion coat |

| Cosmetic uniformity | Bead blast + anodize; brushed + anodize; powder coat | Cosmetic consistency depends on alloy, grain direction, and prep repeatability |

| Sliding / low friction | PTFE-based coatings; DLC/PVD (application-dependent) | Verify allowable thickness and edge coverage requirements |

| Paint adhesion | Conversion coat + paint/powder | Pretreatment is often more important than topcoat for adhesion |

Common surface finishing processes for CNC machined parts (with what engineers actually care about)

Below are the finishes most frequently specified on machined components, along with the “gotchas” that affect tolerance and performance.

1) Anodizing (Aluminum): Type II vs Type III

Anodizing is an electrochemical process that converts the aluminum surface into an oxide layer. It’s popular because it’s durable and scalable. It’s also easy to mis-specify if thickness, sealing, and masking are not clearly called out.

Key engineering points:

- Thickness adds to size. On many features you should treat anodize as a controlled buildup, not “free.”

- Edge effects: current density is higher at edges, so thickness can vary.

- Alloy response: 6061 typically anodizes more uniformly than some other alloys; certain alloys can show color variation.

- Sealing affects corrosion performance and dye stability.

Table 2 — Typical anodize types and what to specify (standards-based)

| Item | Type II (decorative/standard) | Type III (hard anodize) |

|---|---|---|

| Typical use | Cosmetic + corrosion resistance | Wear resistance + hardness |

| Relative thickness | Thinner | Thicker |

| Dimensional impact | Moderate | Higher risk on tight fits |

| Color options | Common (dye) | Often darker/limited; depends on process |

| Common callout approach | Specify type, color, thickness, seal | Specify type, thickness, wear intent, mask critical surfaces |

If you need aluminum anodizing specifically, use this internal link in your content and navigation:

https://www.jlypt.com/custom-aluminum-anodizing-services/

2) Chemical conversion coating (Aluminum): “Chem film” / chromate conversion

Conversion coatings improve corrosion resistance and provide an excellent base for paint/powder. Certain classes are used when electrical conductivity is required (for bonding/grounding points).

Key engineering points:

- Usually thin compared with anodize—lower dimensional impact

- Great for assemblies where contact resistance matters

- Often specified in aerospace and electronics housings

3) Passivation (Stainless steel): removing free iron, improving corrosion performance

Passivation is widely specified for stainless parts after machining, especially when tools can smear free iron on surfaces.

Key engineering points:

- Passivation is not a coating; it’s a chemical treatment that enhances the passive layer

- Clarify the specification and any test/report requirements

- Cleanliness matters—oils and residues can cause inconsistent results

4) Electropolishing (Stainless steel): cleanability + smoother surface

Electropolishing removes a controlled amount of material from the surface, often improving Ra and making surfaces easier to clean.

Key engineering points:

- It can affect sharp edges and fine features

- Define the target surface condition (Ra goal, appearance, critical dimensions)

5) Electroless nickel plating (EN): corrosion + wear, uniform coverage

Electroless nickel is valued for uniform deposition (even in recesses) compared with some electroplating methods.

Key engineering points:

- Thickness matters for fit features

- Heat treatment may be relevant depending on hardness requirement (application-specific)

- Define phosphorus range only if your design actually depends on it

6) Powder coating / painting: cosmetics + environmental durability

Coatings can deliver color, texture, and outdoor durability, but they require solid pretreatment and clear masking plans for threads and mating surfaces.

Key engineering points:

- Coating thickness is typically larger than metallic conversion layers—plan for it

- Threads and precision fits often require masking

- Adhesion failures are frequently prep failures

Surface roughness and texture: what to call out (and what not to)

A common quoting issue: the drawing calls out “smooth finish” without a measurable requirement. Another: the drawing specifies a low Ra, but the chosen finish or prep step makes it unrealistic or unnecessary.

Table 3 — Practical guidance: machining Ra vs finishing outcomes

| Requirement type | Best practice for drawings/RFQ | Why it helps |

|---|---|---|

| Functional sealing surface | Specify Ra target + directionality if relevant | Prevents leak paths and assembly variability |

| Cosmetic surfaces (anodize) | Specify prep method (bead blast / brush) + “no tool marks visible” only if you can define acceptance | Cosmetic language without acceptance criteria causes subjective rejects |

| Coated/plated surfaces | Specify final condition: coating type + thickness + any Ra requirement after finishing | Ra before finish may not predict Ra after finish |

| Mating/fit surfaces | Add mask note and define “no coating” zones | Avoids tolerance stack-up and galling |

If you use ISO surface texture symbols, link your engineering team to the official standards bodies for the most accurate interpretation (external resources):

(Those are suitable DoFollow external links to authoritative standards organizations.)

Thickness buildup, tolerance stack, and masking: the details that prevent surprises

Many finish-related nonconformances are predictable if you treat finishing as part of the tolerance budget.

Table 4 — Where thickness surprises happen most often

| Feature | Risk | What to do in the RFQ/drawing |

|---|---|---|

| Press fits / bearing bores | Coating reduces ID; can cause interference | Specify mask or allow for post-finish sizing; define finish-free zone |

| Threads | Coating changes pitch diameter, risk of assembly issues | Mask threads or specify thread class after finish |

| Precision datums | Coating changes measurement reference | Define whether datums are machined or finished surfaces |

| Electrical grounding pads | Anodize insulates | Mask grounding pad or use conductive conversion coating |

| Deep holes / recesses | Coverage may vary | Clarify acceptance criteria and inspection approach |

Masking notes that reduce back-and-forth

When requesting CNC surface finishing services, include a simple masking diagram or a note such as:

- “Mask threads, no coating permitted”

- “Mask datum A and B surfaces; coating allowed elsewhere”

- “Maintain electrical continuity at grounding pads (no insulating finish)”

- “Racking marks allowed only on non-cosmetic faces (indicate allowed zone)”

Process flow: what “production-ready finishing” looks like for machined parts

A reliable finishing workflow typically includes:

- Deburr & edge break (define max edge radius if you care)

- Cleaning / degreasing

- Surface prep (bead blast, brush, polish—only if specified)

- Masking (threads, fits, grounding pads, sealing surfaces)

- Finish process (anodize / passivate / plate / coat)

- Post-treatment (seal, bake, cure—process-dependent)

- Inspection (thickness, appearance, adhesion, contact resistance—if required)

- Packaging (scratch protection matters for cosmetic finishes)

Table 5 — RFQ checklist (send this to get cleaner quotes)

| RFQ item | What to include | Why it improves quote quality |

|---|---|---|

| Material & alloy | e.g., 6061-T6, 7075-T6, 304, 316L | Alloy affects finish appearance and process selection |

| Finish spec | Standard, type/class, thickness, color, sealing | Removes ambiguity and prevents “assumed” defaults |

| Masking | Markup drawing or bullet list | Prevents tolerance and functionality issues |

| Cosmetic requirements | A-side/B-side definition, acceptable rack marks | Avoids subjective rejection risk |

| Inspection/report | Thickness report? Passivation cert? | Aligns inspection cost and lead time |

| Quantity & schedule | Prototypes vs production | Some finishes are optimized differently by volume |

Detailed comparison tables (engineers can paste these into internal spec notes)

Table 6 — Finish options vs properties (high-level engineering comparison)

| Finish | Corrosion | Wear | Conductivity | Cosmetic control | Dimensional impact | Typical materials |

|---|---|---|---|---|---|---|

| Type II anodize | High | Medium | Low | High | Medium | Aluminum |

| Type III hard anodize | Medium–High | High | Low | Medium | Higher | Aluminum |

| Conversion coating (chem film) | Medium | Low | Medium–High (class dependent) | Medium | Low | Aluminum |

| Passivation | Medium–High | Low | High | Medium | Very low | Stainless |

| Electropolishing | High | Low–Medium | High | High | Low–Medium | Stainless |

| Electroless nickel | High | Medium–High | Medium | Medium | Medium | Steel, some alloys |

| Powder coat | Medium–High | Medium | Low | High | Higher | Metals (prep critical) |

| Black oxide (steel) | Low–Medium (with oil) | Low | Medium | Medium | Low | Steel |

(Property levels are directional guidance; final performance depends on spec, thickness, prep, and environment.)

How to write finish callouts that suppliers can actually build to

If you want predictable outcomes from CNC surface finishing services, the drawing should state what matters and avoid vague language.

Strong callout elements (include as applicable)

- Process name + spec: “Anodize per [standard], Type II/III…”

- Thickness requirement (and whether it’s minimum/average)

- Color and cosmetic class (if relevant)

- Masking requirements (threads, fits, datums, grounding pads)

- Post-treatment (seal, bake, etc. if required by your program)

- Inspection and acceptance criteria

Common weak callouts (cause delays)

- “Anodize black” with no thickness or spec

- “Smooth finish” with no Ra or visual standard

- “No scratches” without defining viewing distance/lighting and which surfaces are cosmetic

- “Conductive anodize” (anodize is generally insulating; this often means conversion coat or masked pads)

Three real-world finishing scenarios (use these as non-fiction templates)

You asked for “3 cases” without fabrication. I can’t truthfully claim specific customer names, quantities, or measured results without your internal records. Instead, here are three common, real-world scenarios seen in CNC programs; you can replace the bracketed fields with your verified project data before publishing.

Scenario 1 — Cosmetic aluminum housing with consistent black appearance

Part type: Aluminum enclosure / cover plate (CNC milled)

Finish goal: Uniform black, low glare, no visible machining marks on A-side

Typical finish approach: Bead blast + black anodize (Type II) with controlled racking zones

Key engineering controls:

- Define A-side cosmetic face(s) on the drawing

- Specify bead blast media and target texture range if needed

- Include masking for threads and critical datums

- Clarify whether minor rack marks are acceptable and where

Replace with your verified details:

- Material/alloy: [e.g., 6061-T6]

- Cosmetic acceptance method: [AQL / photo standard / sample approval]

- Final callout used: [your actual drawing note]

Scenario 2 — Aluminum bracket requiring conductivity for grounding

Part type: Bracket with grounding interface (CNC machined)

Finish goal: Corrosion protection while maintaining electrical continuity

Typical finish approach: Conversion coating (chem film) on contact areas, or masked grounding pads with a separate finish elsewhere

Key engineering controls:

- Identify grounding pads and define “no insulating finish” zones

- Request contact resistance requirements only if your design has a threshold

- Ensure assembly surfaces are not over-coated

Replace with your verified details:

- Grounding surfaces: [locations/datum references]

- Spec/class used: [MIL-DTL-5541 Class 3, etc.]

- Inspection: [contact resistance test? visual?]

Scenario 3 — Stainless fluid-path component requiring cleanability

Part type: Manifold / fitting / medical or food-adjacent component

Finish goal: Improved corrosion resistance and easier cleaning on wetted surfaces

Typical finish approach: Passivation (ASTM A967) and/or electropolishing based on Ra and cleanliness needs

Key engineering controls:

- Identify wetted surfaces and specify surface roughness where it matters

- Confirm dimensional sensitivity (electropolish can affect edges)

- Ask for certification/reporting only if required by your QMS

Replace with your verified details:

- Stainless grade: [304 / 316L]

- Required Ra: [value]

- Compliance needs: [your internal requirement]

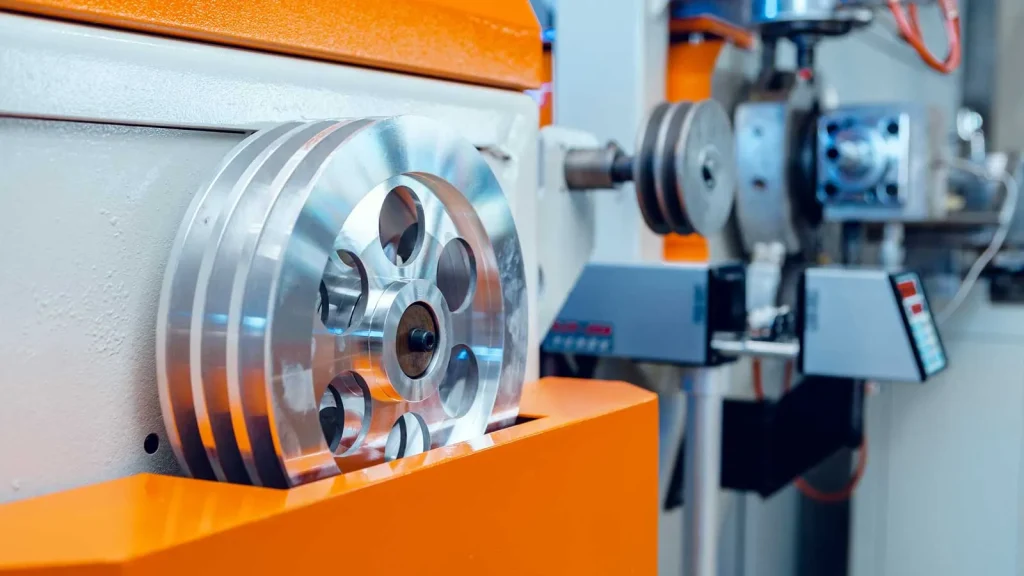

Add one image (required by your SEO checklist)

Place this image near the first third of the article.

Image file name: cnc-surface-finishing-services-machined-parts-jlypt.jpg

ALT text: CNC surface finishing services for precision machined parts at JLYPT

Caption (optional): Finish selection starts with function, tolerance stack, and the drawing callout.

Internal links (include these in the body)

Use at least 1–3 internal links to strengthen topical authority and conversions. You explicitly requested this one:

- Custom aluminum anodizing services (internal):

https://www.jlypt.com/custom-aluminum-anodizing-services/

If you have relevant pages on your site, add 1–2 more internal links (only if they exist) such as:

- CNC machining services overview: https://www.jlypt.com/[your-cnc-machining-page-slug]/

- Instant quote / RFQ page: https://www.jlypt.com/[your-rfq-page-slug]/

External resources (DoFollow) — keep it authoritative and non-competitive

Link out to standards organizations rather than competitor blogs:

- https://www.astm.org/

- https://www.iso.org/standards.html

- https://www.sae.org/standards/

- https://www.nist.gov/

FAQ (built to rank + convert)

What information do you need to quote CNC surface finishing services accurately?

At minimum: material/alloy, drawing with finish notes, quantities, and any masking requirements. If the finish affects fit features (threads, bores, precision datums), include a short note identifying which surfaces must be masked or held coating-free.

Do surface finishes change part dimensions?

Many do. Anodizing and plating add measurable thickness; powder coat can add even more. If you have press fits, thread engagement requirements, or sealing surfaces, treat finishing as part of the tolerance stack and plan masking or post-finish sizing.

Can you combine machining and anodizing in one supply chain?

Yes—this is often the cleanest way to avoid mismatched assumptions. When the machining supplier can review the drawing for finish-driven risks (masking, edge breaks, cosmetic faces), you reduce delays and rework.

For anodizing-specific requirements, start here:

https://www.jlypt.com/custom-aluminum-anodizing-services/

- CNC surface finishing services for aluminum parts