Premium Aluminum Anodizing Services: Type II & Type III Hard Coat

Transform your machined aluminum parts with JLYPT’s professional anodizing services. Whether you need the vibrant aesthetics of Type II decorative anodizing or the extreme wear resistance of Type III hard coat anodizing, we deliver consistent, high-quality finishes. Our process meets strict industry standards (including MIL-A-8625 compliance), making our parts ideal for aerospace, medical, and robotics applications.

JLY Precision Tech is an industry leader in the application of decorative surface finishes.We offer a wide range of process capabilities, including PVD coating, electroplating, and trivalent chrome, for both plastic and metal substrates.

Our expertise extends to mechanical highlighting, vibratory finishing, powder coating, and lacquer technologies. At JLY Precision Tech, we demonstrate that “Quality is More than Decorative” by consistently delivering advanced finishes with exceptional performance and aesthetic appeal.

Different Surface Finishing Types We Offer

In different machining process, surface finish refers to the texture, smoothness, and appearance of a part’s surface after it has been machined. Different types of surface finishes are applied to improve the aesthetic, functional, and protective qualities of the part. These finishes can affect the part’s performance, wear resistance, and suitability for certain environments.

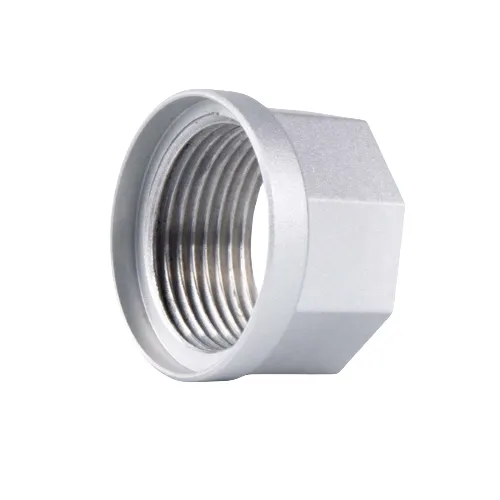

| Image | Finishing | Description | Application |

| As-Machined | Description: This is the default surface finish directly from the CNC machine without any additional processing. It exhibits visible tool marks, and the roughness is usually defined by the cutting tool and the machining parameters. Surface Roughness: Typically Ra 1.6-3.2 µm. | Prototypes, functional parts where aesthetics aren’t critical. |

| Smooth | Description: Smoothing involves using abrasive tools or media to gently remove the top layer of material, reducing roughness and imperfections. This process can be done manually or with automated equipment depending on the complexity of the part. Surface Roughness: Typically Ra ≤ 0.4 µm, though it can vary depending on the material and the desired finish. | Used for parts that need a refined appearance or smoother contact surfaces, such as consumer goods, mechanical components, and medical devices. |

| Bead Blasting | Description: This process involves blasting the surface with fine glass beads or other media to achieve a smooth, matte, or satin finish. It helps remove tool marks and surface imperfections. Surface Roughness: Ra 2.8-3.8 µm (depending on the material and blast media used). | Used to achieve an even texture for aesthetic purposes, typically in consumer products or decorative parts. |

| Anodizing | Description: An electrochemical process that increases the thickness of the natural oxide layer on the surface of aluminum parts. It can be either clear (natural) or dyed in various colors. Benefits: Adds corrosion resistance, improves appearance, and can create an electrically insulating surface. Surface Roughness: Anodizing typically doesn’t significantly change surface roughness. | Commonly used in aerospace, electronics, and automotive industries for aluminum parts. |

| Polishing | Description: A finishing process that makes the surface smooth and glossy by mechanically removing surface material. Polishing can be done to different degrees, from basic smoothing to achieving a mirror-like finish. Surface Roughness: Can achieve extremely low surface roughness, Ra ≤ 0.1 µm. | Used for aesthetic parts, reflective surfaces, or parts requiring low friction. |

| Powder Coating | Description: A dry finishing process where powdered paint is electrostatically applied to the surface and then cured under heat to form a durable, uniform coating. It creates a protective layer resistant to wear, corrosion, and environmental factors. Surface Roughness: Typically smooth but varies depending on the powder type. | Used in automotive, industrial equipment, consumer products, and outdoor applications. |

| Brushing | Description: This finish is created by brushing the surface with abrasive belts or brushes to give it a uniform, directional texture. It provides a satin or matte look while reducing surface imperfections. Surface Roughness: Ra 0.4-2.5 µm, depending on the type of brush and material. | Common in decorative and aesthetic applications, especially for stainless steel or aluminum products. |

| Electroplating | Description: This process involves blasting the surface with fine glass beads or other media to achieve a smooth, matte, or satin finish. It helps remove tool marks and surface imperfections. Surface Roughness: Ra 2.8-3.8 µm (depending on the material and blast media used). | Used to achieve an even texture for aesthetic purposes, typically in consumer products or decorative parts. |

| Passivation | Description: A chemical treatment applied to stainless steel and other metals to remove free iron from the surface, enhancing corrosion resistance by forming a passive oxide layer. Surface Roughness: Passivation doesn’t change the surface roughness. | Commonly used in medical, food, and aerospace industries where corrosion resistance is critical. |

| Heat Treating | Description: A process that involves heating and cooling metal parts to change their hardness, strength, or toughness. While not primarily a surface finish, it affects the surface properties by hardening the outer layer. Surface Roughness: Not specified. | Used for parts that need wear resistance or improved mechanical properties, like gears and cutting tools. |

| Electropolishing | Description: An electrochemical process that removes materialfrom the part’s surface, smoothing and brightening it to achieve ahigh-gloss, reflective finish. lt also improves corrosion resistanceand reduces surface roughness. Surface Roughness: Can reduce surface roughness significantly,up to Ra 0.1 um. | Used in medical, pharmaceutical,and food processing equipment forcleanability and corrosionresistance. |

| Chromating | Description: A chemical process that converts the surface ofmetals, particularly aluminum, into a protective layer. Chromateconversion coatings provide corrosion resistance and serve as aprimer for paint or powder coating. Surface Roughness: Typically does not alter surface roughnesssignificantly. | Used in aerospace and electronics industries where corrosion resistance and conductivity are important. |

| Sandblasting | Description: Similar to bead blasting, sandblasting uses abrasive materials (such as silica, sand, or aluminum oxide) to clean or texture the surface. It creates a rougher surface than bead blasting.Surface Roughness: Ra 2.5-10 µm, depending on the abrasive used. | Prepares surfaces for coating, removes old paint, or creates a rough texture for improved adhesion of coatings. |

| Tumbling | Description: A finishing process that uses abrasive media and vibrations to polish, deburr, or smooth the surface of parts. It’s ideal for small components or complex shapes that need uniform finishing. Surface Roughness: Varies, but generally produces a smoother finish than raw machined surfaces. | Used for mass finishing in industries like automotive and aerospace for deburring and surface smoothing. |

| Laser Engraving | Description: A process that uses a laser beam to etch or mark the surface of the part with precise, permanent markings. It doesn’t alter the overall finish of the part but adds logos, text, or serial numbers. | Common for branding, labeling, and creating unique part identifiers. |

| Black Oxide | Description: A chemical coating applied to steel to create a black matte finish, which provides moderate corrosion resistance and reduces light reflection. Surface Roughness: Does not significantly change surface roughness. | Used for aesthetic purposes, to reduce glare, and to provide corrosion protection on machine components and tools. |

Hard Anodizing Type Comparison

A detailed comparison between Type II (Standard/Decorative) and Type III (Hard Coat) anodizing processes for aluminum

Black, Blue, Red, Gold, etc.

60-70 Rockwell C

Dark Grey to Black

| Feature |

Type II (Standard/Decorative)

|

Type III (Hard Coat)

|

|---|---|---|

| Thickness | 5 - 25 microns | 25 - 50+ microns |

| Hardness | Moderate | Extremely Hard (60-70 Rockwell C) |

| Primary Use | Aesthetics, Corrosion Resistance | Wear Resistance, Industrial Parts |

| Color Options |

Wide range Black, Blue, Red, Gold, etc. |

Limited Dark Grey to Black |

| Cost | Lower | Higher |

Type II Best For:

- Decorative applications

- Consumer products

- Architectural components

- Moderate wear environments

- Corrosion resistance with aesthetics

- Budget-conscious projects

Type III Best For:

- Industrial equipment

- High wear applications

- Aerospace components

- Military hardware

- Extreme environments

- Long-term durability needs

Common Applications

Type II Applications

Consumer electronics, architectural trim, automotive trim, furniture, decorative hardware, signage, and consumer goods.

Type III Applications

Hydraulic pistons, firearm components, aerospace parts, military equipment, industrial machinery, and high-wear mechanical parts.

Selection Guideline

Choose Type II when aesthetics and corrosion resistance are priorities. Choose Type III when extreme wear resistance and durability are required, regardless of appearance.

Note: Type III creates a thicker, harder layer but has limited color options and higher cost.

A Variety of Process Offerings

Electroplating

Delivers a flawless metallic finish, enhancing durability and beauty for every component

Anodizing

Provides a durable, corrosion-resistant finish, adding both strength and style to every component.

Chemical Plating

Ensures a uniform, high-quality coating, enhancing wear resistance and surface protection for every part.

Shot Blasting

Delivers a smooth, clean surface finish, preparing each component for optimal coating and durability

Phosphating

Enhances surface protection, providing a strong, corrosion-resistant base for improved coating adhesion

Hot Dip Plating

Creates a tough, protective coating, ensuring superior corrosion resistance and longevity for each component.

Blackening Treatment

enhance corrosion resistance and appearance for metal components.

Polishing

Offer polishing services to achieve a high-gloss finish on metal components. Our precision polishing enhances surface smoothness and aesthetic appeal, while also improving corrosion resistance.

Our Facilities