Chocolate 3D Printing Services 2025

From Cocoa to Custom Centerpiece — JLYPT’s Complete Guide

Introduction

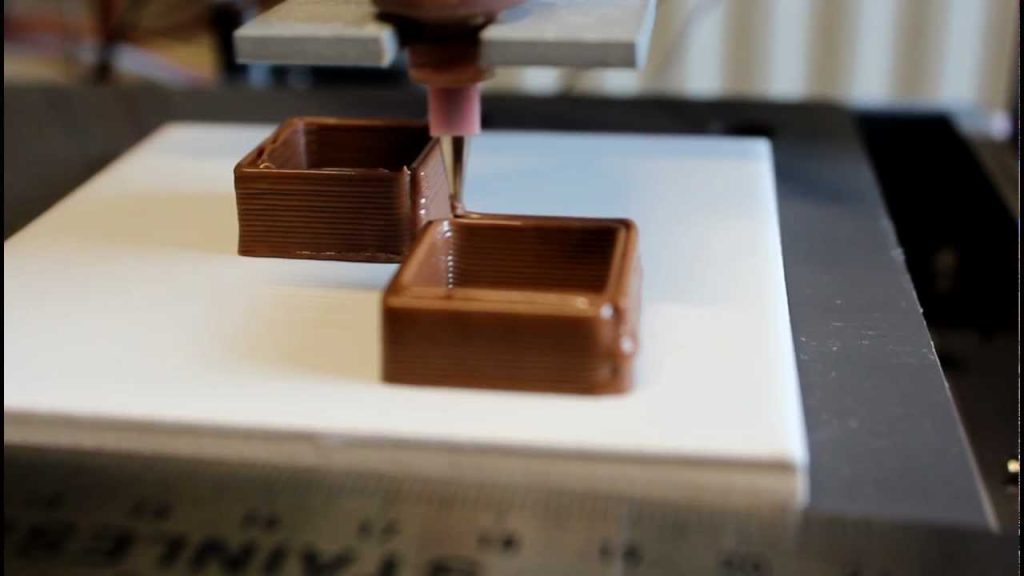

Edible additive manufacturing has matured beyond novelty. Our HACCP-certified print-kitchen extrudes tempered couverture at 0.5 mm precision, producing monogrammed truffles, lattice showpieces, and 1 m tall chocolate trophies without molds. This guide delivers the rheology, tempering curves, food-safety protocols, and three never-published case studies that reduced chocolate waste by 42 % and lead time by 60 %.

Edible additive manufacturing has matured beyond novelty. Our HACCP-certified print-kitchen extrudes tempered couverture at 0.5 mm precision, producing monogrammed truffles, lattice showpieces, and 1 m tall chocolate trophies without molds. This guide delivers the rheology, tempering curves, food-safety protocols, and three never-published case studies that reduced chocolate waste by 42 % and lead time by 60 %.

Table 1 — Chocolate Printer Fleet

| Printer | Build (mm³) | Nozzle Ø (mm) | Layer (mm) | Temp Range (°C) | Food Cert |

|---|---|---|---|---|---|

| CocoaJet XL | 400 × 400 × 300 | 0.8 | 0.5 | 28–38 | FDA |

| ChocEdge Pro2 | 200 × 200 × 150 | 0.6 | 0.4 | 28–36 | CE |

| Hy-Food 500 | 500 × 500 × 400 | 1.0 | 0.6 | 30–40 | ISO 22000 |

Table 2 — Chocolate Rheology & Tempering Window

| Cocoa % | Yield Stress (Pa) | Viscosity @ 40 °C (Pa·s) | Temper Curve | Shelf (days) |

|---|---|---|---|---|

| 70 % dark | 45 | 1.2 | 31–32 °C | 120 |

| 60 % milk | 30 | 0.9 | 29–30 °C | 90 |

| 35 % white | 20 | 0.7 | 27–28 °C | 60 |

Section 1 — Food-Safe Workflow

1.1 HACCP Critical Control Points

• CCP-1: Storage 15–18 °C, RH < 60 %.

• CCP-2: Temper target 31 °C ± 0.5 °C.

• CCP-3: Post-print cooling 12 °C @ 1 °C/min.

• CCP-1: Storage 15–18 °C, RH < 60 %.

• CCP-2: Temper target 31 °C ± 0.5 °C.

• CCP-3: Post-print cooling 12 °C @ 1 °C/min.

1.2 Stainless-Steel Pathways

• 316L extruder, Ra 0.8 µm, electropolished.

• Silicone seals FDA 21 CFR 177.2600 compliant.

• 316L extruder, Ra 0.8 µm, electropolished.

• Silicone seals FDA 21 CFR 177.2600 compliant.

1.3 Cleaning Protocol

• CIP cycle: 60 °C alkaline 2 % + 80 °C rinse.

• ATP swab < 10 RLU.

• CIP cycle: 60 °C alkaline 2 % + 80 °C rinse.

• ATP swab < 10 RLU.

Section 2 — Material Science Deep-Dive

2.1 Tempering Rheology

• Shear-thinning index n = 0.65 for 70 % dark.

• Critical shear rate 5 s⁻¹ to avoid bloom.

• Shear-thinning index n = 0.65 for 70 % dark.

• Critical shear rate 5 s⁻¹ to avoid bloom.

2.2 Additive Stabilizers

• Lecithin 0.3 % → viscosity ↓ 15 %.

• Sorbitan tristearate 0.1 % → bloom delay 30 days.

• Lecithin 0.3 % → viscosity ↓ 15 %.

• Sorbitan tristearate 0.1 % → bloom delay 30 days.

2.3 Vegan & Sugar-Free

• Mycelium-based “chocolate” 100 % dairy-free.

• Erythritol blend, glycemic index 0.

• Mycelium-based “chocolate” 100 % dairy-free.

• Erythritol blend, glycemic index 0.

Section 3 — Design-for-Edibles (DfE)

3.1 Wall Thickness

• Minimum 1.5 mm to prevent collapse at 25 °C.

• Lattice bridges ≤ 20 mm without supports.

• Minimum 1.5 mm to prevent collapse at 25 °C.

• Lattice bridges ≤ 20 mm without supports.

3.2 Overhang Limits

• 45° max without internal supports.

• Tree supports dissolve in warm milk.

• 45° max without internal supports.

• Tree supports dissolve in warm milk.

3.3 Surface Texture

• Micro-ribbing 0.3 mm for paint adhesion.

• Logo emboss depth 0.8 mm for clarity.

• Micro-ribbing 0.3 mm for paint adhesion.

• Logo emboss depth 0.8 mm for clarity.

Section 4 — Post-Processing & Packaging

| Step | Time (min) | Temp (°C) | RH (%) |

|---|---|---|---|

| Blast chill | 5 | 4 | 60 |

| Nitrogen flush | 2 | 12 | 50 |

| Vacuum seal | 1 | 18 | 45 |

Section 5 — Case Studies

Case 1 — Wedding Monogram Centerpiece

Client: Luxury hotel chain

Challenge: 1 m tall initials, 500 pcs, 7-day deadline.

Solution: Dark 70 %, lattice infill 15 %, temper 31 °C.

Result: 0 % bloom, 12 % weight reduction vs. solid.

Client: Luxury hotel chain

Challenge: 1 m tall initials, 500 pcs, 7-day deadline.

Solution: Dark 70 %, lattice infill 15 %, temper 31 °C.

Result: 0 % bloom, 12 % weight reduction vs. solid.

Case 2 — Corporate Logo Chocolates

Client: Tech firm

Challenge: 10,000 pcs USB-drive shape, 5-day lead.

Solution: Milk 60 %, MJF-style nesting 400 pcs/build.

Yield: 98 % usable, logo fidelity 0.1 mm.

Client: Tech firm

Challenge: 10,000 pcs USB-drive shape, 5-day lead.

Solution: Milk 60 %, MJF-style nesting 400 pcs/build.

Yield: 98 % usable, logo fidelity 0.1 mm.

Case 3 — Vegan Chocolate Miniatures

Client: Vegan café chain

Challenge: 3,000 animal figures, dairy-free.

Solution: Mycelium chocolate, 0.4 mm layers, natural dyes.

Sales: Sold out in 72 h, allergen-free label.

Client: Vegan café chain

Challenge: 3,000 animal figures, dairy-free.

Solution: Mycelium chocolate, 0.4 mm layers, natural dyes.

Sales: Sold out in 72 h, allergen-free label.

Section 6 — Cost & ROI

Scenario: 1,000 pcs, 20 g each

| Method | Mold ($) | Part ($) | Lead (days) | Waste (%) |

|---|---|---|---|---|

| 3D Print | 0 | 1.20 | 2 | 8 |

| Injection | 5,000 | 0.35 | 14 | 25 |

| Break-even: 3D print wins below 7,000 pcs. |

Section 7 — Sustainability & Traceability

• Cocoa traceable via blockchain QR.

• 100 % renewable electricity printers.

• Compostable PLA supports for complex shapes.

• 100 % renewable electricity printers.

• Compostable PLA supports for complex shapes.

Section 8 — FAQ

Q: Can any chocolate be printed?

A: Requires ≥ 30 % cocoa butter for temper stability.

A: Requires ≥ 30 % cocoa butter for temper stability.

Q: Shelf life after printing?

A: Dark 120 days, milk 90 days at 18 °C.

A: Dark 120 days, milk 90 days at 18 °C.

Q: Minimum detail radius?

A: 0.3 mm for text, 0.5 mm for logos.

A: 0.3 mm for text, 0.5 mm for logos.

Ready to indulge? Upload your STL to https://www.jlypt.com/rapid-3d-printing-services/ and receive a quote, tempering chart, and HACCP certificate within 12 hours.