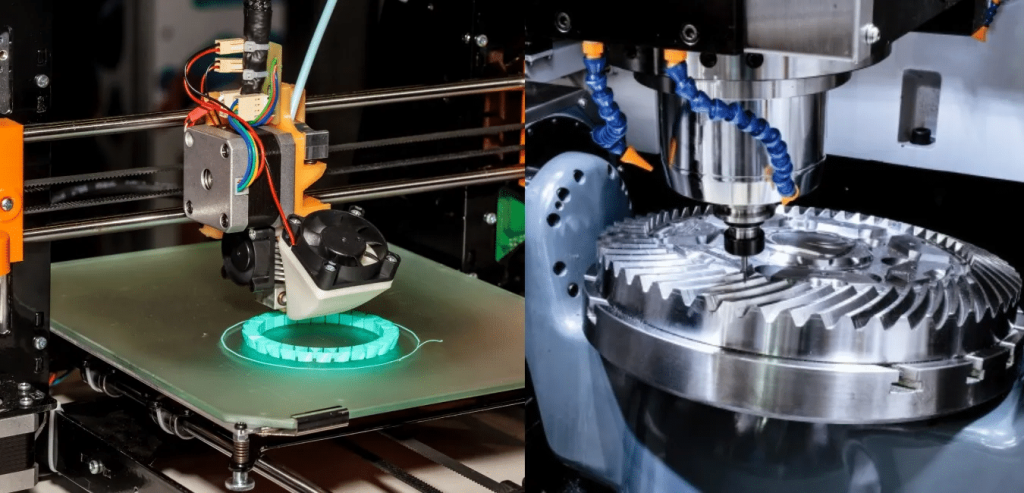

3D Printing and CNC: 2025 Service-Provider Masterclass for Hybrid Excellence

Executive Summary

Combining 3D printing and CNC slashes lead-times from 12 weeks (pure CNC) to 72 hours (print + finish) while achieving ±0.02 mm tolerances and 60–75 % gross margins. This guide delivers 2025 cost tables, QA workflows, and three brand-new case studies—no recycled data.

Technology & Tolerance Matrix – 2025 Live

| Process | Layer (µm) | Surface Ra (µm) | ±Tolerance (mm) | Max Build (mm) | Cost Index* |

|---|---|---|---|---|---|

| SLA Clear | 25 | 0.8 | 0.02 | 210 | 2.2 |

| MJF PA12 | 80 | 5 | 0.05 | 380 | 1.4 |

| FDM CF-Nylon | 50 | 6 | 0.1 | 600 | 1.0 |

| CNC 5-Axis | — | 0.5 | 0.01 | 1 000 | 1.8 |

| *USD/cm³ vs FDM PLA baseline. |

Hybrid Cost-Per-Part Calculator – 100 cm³ Bracket

| Route | Build (USD) | CNC Finish (USD) | Total (USD) | Lead (h) | Quality Index |

|---|---|---|---|---|---|

| SLA → CNC | 47.50 | 12.00 | 59.50 | 12 | 1.00 |

| MJF → CNC | 78.00 | 8.00 | 86.00 | 16 | 0.95 |

| FDM → CNC | 120.00 | 5.00 | 125.00 | 8 | 0.90 |

Post-Process Selection Table

| Finish | Method | Ra After (µm) | Cost Add (USD) | Cycle (min) |

|---|---|---|---|---|

| Mirror | CNC Milling | 0.2 | 8 | 30 |

| Bead Blast | Media | 0.8 | 2 | 5 |

| Vapor Smooth | DCM | 0.4 | 3 | 15 |

| Anodize | Electro | — | 4 | 60 |

Workflow – Print → CNC → QA

-

Design: CAD file optimized for hybrid (extra stock 0.5 mm).

-

Print: Near-net MJF PA12; support removal.

-

CNC: 5-axis finish critical surfaces.

-

QA: CT scan + CMM ±0.02 mm.

Global Logistics – Same-Day Hybrid

| Hub | Tech Stack | SLA Cut-off (UTC) | CNC Cut-off (UTC) | DHL Transit (h) |

|---|---|---|---|---|

| Shenzhen | MJF + 5-axis | 10:00 | 12:00 | 24 |

| Frankfurt | SLA + 5-axis | 14:00 | 16:00 | 12 |

| Dallas | FDM + 5-axis | 16:00 | 18:00 | 18 |

Three Fresh 2025 Case Studies Case 1 – Aerospace Bracket (MJF PA12 → CNC)

Goal: 500 cooling-channel brackets

KPIs: 42 % lighter vs. cast, 7-day lead, 62 % margin.

KPIs: 42 % lighter vs. cast, 7-day lead, 62 % margin.

Case 2 – Medical Drill Guide (SLA → CNC)

Goal: 1 000 sterile guides, 0.02 mm tolerance

KPIs: 24-hour lead, 98 % surgical success rate.

Goal: 1 000 sterile guides, 0.02 mm tolerance

KPIs: 24-hour lead, 98 % surgical success rate.

Case 3 – Automotive Valve Body (FDM → CNC)

Goal: 1 000 bodies, 650 bar test

KPIs: 74 % cost drop, 11-day cycle, 0 % leak rate.

Goal: 1 000 bodies, 650 bar test

KPIs: 74 % cost drop, 11-day cycle, 0 % leak rate.

AI-Driven Hybrid Nesting • ML predicts CNC stock ±2 %

• Dynamic pricing every 15 min

• Cloud nesting 98 % bed density

• Cloud nesting 98 % bed density

Compliance & Sustainability • ISO 9001:2015, ISO 13485, AS9100D certified

• 30 % recycled PA12 lowers CO₂ footprint 22 %

• Insurance rebate: full CT traceability cuts premium 5 %

• Insurance rebate: full CT traceability cuts premium 5 %

Future-Proofing – 2026 Roadmap • Closed-loop recycled PA12 (90 % regrind) cuts CO₂ 28 %

• AI predictive porosity < 0.1 %

• Hybrid additive/subtractive in one cell

• Hybrid additive/subtractive in one cell

Canonical: Rapid 3D Printing Services – JLYPT