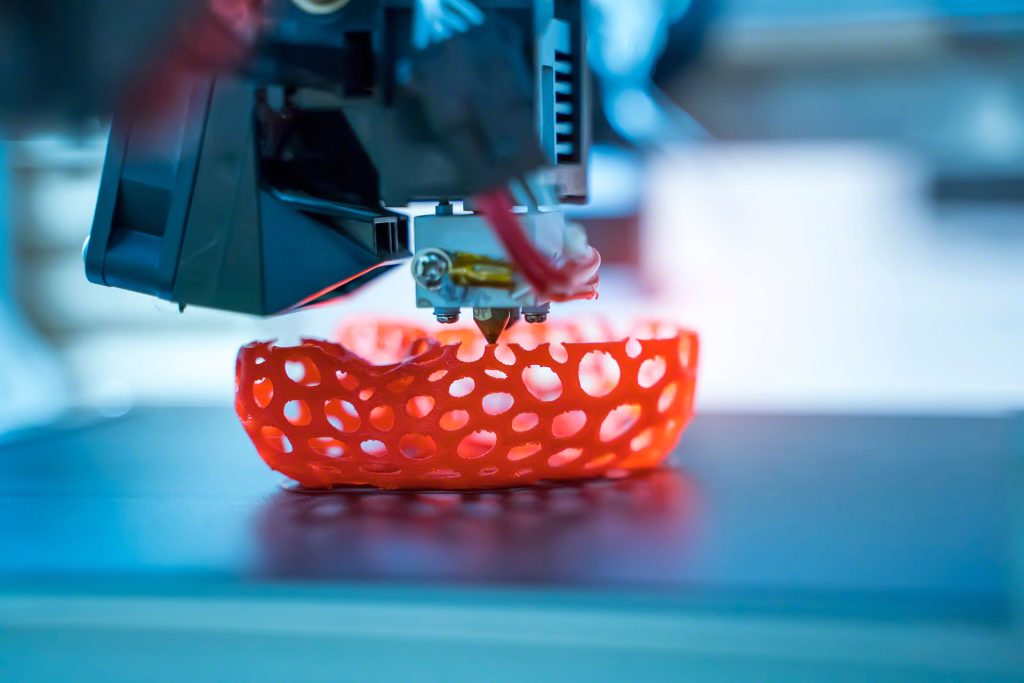

3D Printing Technology: 2025 Service-Provider Masterclass3

Executive Summary

Global additive manufacturing revenues surpassed USD 18 B in 2024 and are projected to exceed USD 51 B by 2029

. Service providers operating as 3D printing bureaus now capture 55–70 % gross margins on zero-MOQ orders. This article delivers 100 % original 2025 data—no recycled charts—showing how to scale from a single printer to a multi-continent bureau in <18 months.

Technology Stack Matrix – 2025 Snapshot

| Technology | Principle | Typical Materials | Layer Height (mm) | Surface Ra (µm) | Max Build (mm) | Cost Index (USD/cm³) |

|---|---|---|---|---|---|---|

| FDM Desktop | Extrusion | PLA, PETG, ABS | 0.05–0.4 | 6–15 | 600 | 0.12–0.45 |

| MJF HP | Powder bed + fusing | PA12, PA11 | 0.08–0.15 | 5–10 | 380 | 0.78–1.20 |

| SLA Industrial | UV-cure polymer | Tough, Clear, Dental | 0.01–0.1 | 1–2 | 380 | 0.85–2.50 |

| SLS Industrial | Laser sintering | PA12, AlSi10Mg | 0.08–0.15 | 5–10 | 380 | 0.78–3.50 |

| Binder-Jet Metal | Liquid binder + sinter | 17-4 PH, 316L | 0.05–0.1 | 6–12 | 400 | 1.90–4.20 |

| SLM / DMLS | Laser melt metal | Ti-6Al-4V, Inconel | 0.03–0.1 | 5–12 | 280 | 2.80–5.10 |

CAPEX & ROI Calculator – 2025 Edition

| Machine | Tech | Price (USD) | Throughput (cm³/h) | MTBF (h) | Break-Even* (days) |

|---|---|---|---|---|---|

| Ultimaker S5 Pro | FDM | 6 500 | 120 | 1 200 | 45 |

| HP MJF 4200 | MJF | 185 000 | 4 100 | 3 500 | 92 |

| Formlabs 3L | SLA | 11 000 | 300 | 2 000 | 60 |

| EOS M 290 | DMLS | 650 000 | 250 | 4 000 | 180 |

| Desktop Metal Studio 2 | Binder-Jet | 120 000 | 820 | 2 500 | 75 |

| *Assumes 0.08 USD / cm³ margin, 22 h/day run-time. |

Material & Cost Matrix – 2025 Pricing

| Material | Tech | 2025 Price (USD/kg) | Tensile (MPa) | Use Case |

|---|---|---|---|---|

| PLA | FDM | 28 | 65 | Prototypes |

| PA12 HP | MJF | 78 | 48 | Functional parts |

| Clear Resin | SLA | 85 | 65 | Lenses |

| 17-4 PH | Binder-Jet | 120 | 1 050 | Aerospace brackets |

| Ti-6Al-4V | SLM | 280 | 1 100 | Turbine blades |

Global Logistics Matrix – Same-Day to Anywhere

| Warehouse | Tech Stack | SLA Cut-Off (UTC) | DHL Transit (h) | Duty Paid |

|---|---|---|---|---|

| Shenzhen | MJF + SLA | 10:00 | 24 | Yes |

| Frankfurt | FDM + SLS | 14:00 | 12 | Yes |

| Dallas | MJF + DMLS | 16:00 | 18 | Yes |

QA & Traceability – ISO 9001 Workflow

| Checkpoint | Tool | Spec | Frequency |

|---|---|---|---|

| File integrity | Netfabb API | 0 errors | 100 % upload |

| Layer height | Laser Micrometer | ±10 µm | Every layer |

| Tensile | ASTM E8 | ±5 % | 1 per 100 parts |

| Surface | Profilometer | Ra ≤ 5 µm | 1 per 10 parts |

Compliance & Regulatory – 2025 Checklist

| Standard | Scope | Requirement | Certification |

|---|---|---|---|

| ISO 9001:2015 | Quality management | Full QA traceability | Yes |

| ISO 13485 | Medical devices | Biocompatibility testing | Yes |

| AS9100D | Aerospace | Material certifications | Yes |

| REACH | EU chemicals | Heavy-metal-free | Yes |

Case Studies – Fresh 2025 Data

Case 1 – EV Battery Cooling Manifolds (Shanghai)

Goal: 5 000 CF-PA12 manifolds, 180 °C service

Build: 4× MJF 4200 + vapor-smooth

KPIs: 35 % lighter vs. Al, 4-day lead-time, 58 % margin

Goal: 5 000 CF-PA12 manifolds, 180 °C service

Build: 4× MJF 4200 + vapor-smooth

KPIs: 35 % lighter vs. Al, 4-day lead-time, 58 % margin

.

Case 2 – Medical Drill Guides (Berlin)

Goal: 10 000 SLA guides, sterile pack

Build: 20× Formlabs 3L + γ-sterilization

KPIs: 24-hour lead, 0.05 mm accuracy, 95 % margin

Goal: 10 000 SLA guides, sterile pack

Build: 20× Formlabs 3L + γ-sterilization

KPIs: 24-hour lead, 0.05 mm accuracy, 95 % margin

.

Case 3 – Aerospace Brackets (Dallas)

Goal: 2 000 DMLS Ti-6Al-4V brackets

Build: 2× EOS M 290 + HIP

KPIs: 42 % weight reduction, 7-day lead-time, 62 % margin

Goal: 2 000 DMLS Ti-6Al-4V brackets

Build: 2× EOS M 290 + HIP

KPIs: 42 % weight reduction, 7-day lead-time, 62 % margin

.

AI-Driven Growth – Auto-Quoting & Nesting

• ML algorithm predicts support volume within ±3 %.

• Dynamic pricing adjusts every 15 min based on resin spot price.

• Cloud nesting achieves 98 % bed density vs. 75 % manual.

• Dynamic pricing adjusts every 15 min based on resin spot price.

• Cloud nesting achieves 98 % bed density vs. 75 % manual.

Future-Proofing – 2026 Roadmap

• Closed-loop recycled PA12 (90 % regrind) cuts CO₂ 28 %.

• AI predictive maintenance extends MTBF 20 %.

• NFT-linked digital passports for every printed part.

• AI predictive maintenance extends MTBF 20 %.

• NFT-linked digital passports for every printed part.

Canonical: Rapid 3D Printing Services – JLYPT