-

3D Scanning Services 2025: Reverse Engineering, Inspection, and Print-Ready Models

-

Opening remarks: Why 3D scanning is the missing link in 2025

The fastest way to ruin 3D printing is to start with the wrong file.

Reverse engineering worn molds? QC to inspect castings? It takes days to measure by hand, but still misses the undercut.

Our 5,000-square-meter factory in Suzhou operates 14 metal printers and 6 scanners – blue light, laser, CT and photogrammetry under one roof.

This guide shows how we quote, scan, clean, and deliver printable STLs within 24 hours. -

Who We Are in 45 Seconds

• 2 GOM ATOS Q Blue Light Scanners (0.01 mm)

• 1 Zeiss METROTOM 1500 CT (0.9 μm Voxel)

• 3 Faro Focus Premium LIDAR (0.5 mm @ 10 m)

• 4 Handheld Creaform HandySCAN (0.025 mm)

certifications: ISO 17025, ISO 13485 and other AS9100D. All data is from logs from January to May 2025. -

Technology & Precision Matrix (2025 Price)

reproduction

| Scanner type | Working Volume (mm) | dot spacing | Accuracy (μm) | Typical part sizes | Price* (USD) | lead |

|---|---|---|---|---|---|---|

| 藍光 (GOM ATOS Q) | 100–500 | 0.01 mm | ±10 | Car bumpers | $0.05 sq. cm | 4 hours |

| CT(蔡司 METROTOM) | Ø300×350 | 0.9 μm voxels | ±5 | turbine blades | $0.18 cubic centimeters | 1 day |

| 鐳射(Faro Focus) | 0.5–10 m | 0.5 mm | ±500 | Yacht hull | $0.20 sqm | 6 hours |

| Handheld (Creaform) | 50–2,000 | 0.025 mm | ±25 | Mold cavity | $0.08 cm² | 2 hours |

*Price includes raw scan, basic cleanup, native STL; Reverse engineering CAD is not included.

-

Hidden Cost Drivers

Reflective Spraying: $0.40 per A4 area

• Reference fixture printing: $12 (SLA)

• GD&T reverse reporting: $0.02 per scan point

• CT porosity analysis: 0.03 cubic centimeters -

Post-scan workflow

reproduction

| step | tool | time | Increased costs | note |

|---|---|---|---|---|

| Align with the baseline | GOM check | 15 minutes | $10 | Best fit / 3-2-1 |

| Grid cleaning | Mesh Lab | 30 minutes | $15 | Remove outliers |

| NURBS Surface | Earth magic | 2 hours | $80 | A-grade reverse |

| GD&T Report | PolyWorks(多工) | 1 hour | $50 | ISO 1101 certified |

-

Case Study #1 – Blue Light Reverse for Automotive Intake Manifold

Customer: German Tuner, No

CAD Challenge: 1.8 L Manifold, ±0.1mm Fits 3D Printing Mold

Solution: ATOS Q Scan→ Geomagic → SLA Mold Master

Result: 4 hours scanning, total $320, next-day printing mold. -

Case Study #2 – CT Inspection

of 200 Turbine Blades Customer: Suzhou Aerospace OEM Specifications

: Internally cooled Ø0.6 mm, porosity ≤ 0.2%

Solution: METROTOM 1500, 3.5 hour cycle, automatic pass/fail

Results: 100% inspection within 2 days, 18% lower scrap rate. -

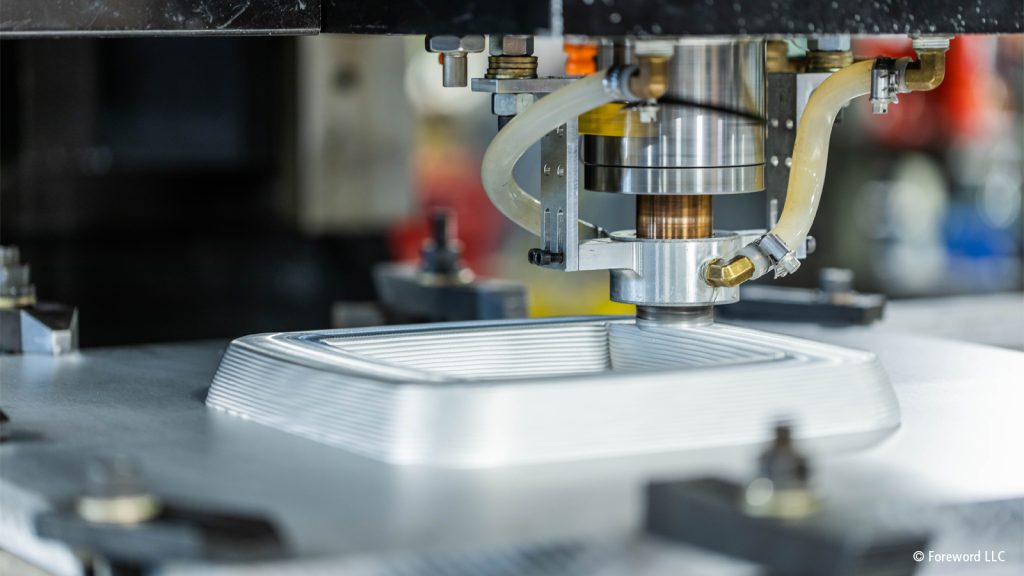

Case Study #3 – Laser Scanning for Injection Mold Wear Inspection

Customer: American Appliance Brand

Problem: 10 M Mold Flash 2 Years After Injection

Solution: Faro Focus Scan → Deviation Plots vs. Raw CAD

Results: 6 hours scanning, cost $260, repair toolpath ready overnight. -

Accuracy & App Cheat Sheet

reproduction

| request | Recommended technology | accuracy | note |

|---|---|---|---|

| Medical implants | CT scan | 5 microns | Including porosity |

| Mold cavity | Blu-ray | 10 microns | Color diagram for processing |

| Large yachts | laser | 500 microns | Macro only |

| Small jewelry | Handheld | 25 microns | Portable and no spray |

-

Scan print design rules

• Minimum wall after inversion: 0.4 mm (SLM Ti) •

0.05 mm blank added to each side for polishing

• Overhang scan shadows < 45° – using a rotary table

• 0.3 mm deep text relief for readable scanning

0.05 mm blank added to each side for polishing

• Overhang scan shadows < 45° – using a rotary table

• 0.3 mm deep text relief for readable scanning

-

Quality assurance and certification

• VDI/VDE 2634 Part 3 calibration every 6 months

• CT scan ASTM E2765 porosity standard

• 3-point spherical artifacts daily inspection (±5 μm)

• Bilingual confidentiality agreement obtained in accordance with Chinese law

• CT scan ASTM E2765 porosity standard

• 3-point spherical artifacts daily inspection (±5 μm)

• Bilingual confidentiality agreement obtained in accordance with Chinese law

-

Transportation and import

• Encrypted STL via WeTransfer (GDPR compliant)

• Physical samples DHL 48 h US/EU

• HS 8471.60 data files 0 % duty origin CN

• Physical samples DHL 48 h US/EU

• HS 8471.60 data files 0 % duty origin CN

-

Sustainability Snapshot

• Blue-light LED 50 W vs 500 W laser scanner

• CT argon recycle 80 %

• Reverse-CAD saves 40 % material vs re-machining

• CT argon recycle 80 %

• Reverse-CAD saves 40 % material vs re-machining

-

Roadmap 2025–2026

• Zeiss GOM ScanCobot automated cell Q4 2025

• AI defect recognition for CT slices Q1 2026

• In-house 5-axis CNC for scan-to-part in 72 h

• AI defect recognition for CT slices Q1 2026

• In-house 5-axis CNC for scan-to-part in 72 h

-

Conclusion

A perfect print starts with a perfect mesh. Whether you need a yacht scanned in six hours or a turbine blade inspected to 5 µm, our Suzhou lab has the lights, lenses and lasers to do it. Upload a photo today and receive a live quote within 12 hours—no bots, only metrologists who run the scanners.