The Science Behind PVD Surface Finishing Technology

1. PVD Technology Process Parameters

StageParameterTypical RangeControl MethodImpact on QualityCleaningPlasma Power200-500WRF GeneratorSurface activationDepositionBase Pressure1×10⁻⁶ mbarTurbomolecular PumpCoating purityCoatingBias Voltage50-200VPulsed DCAdhesion strengthCoolingArgon Flow50-200 sccmMass Flow ControllerStress reduction

2. Industry-Specific PVD Surface Finishing Solutions

Automotive Sector

ComponentPVD CoatingThicknessHardnessKey BenefitPiston RingsCrN3-5μm2200HV60% wear reductionTurbochargerTiAlN5-8μm3200HV800°C stabilityABS SensorsDLC1-2μm3500HVEMI shielding

Medical Applications

DeviceCoatingSpecial PropertyComplianceOrthopedic ImplantsTiO₂Bone integrationISO 13485Surgical ScalpelsZrNAntimicrobialFDA 510(k)Dental ImplantsTaNX-ray visibilityCE Marking

Industrial Tooling

Tool TypePVD SolutionImprovementTesting StandardEnd MillsAlTiN/TiN10x lifespanISO 3685Injection MoldsCrN85% sticking reductionASTM D3359Gear CuttersWC/C55% friction decreaseDIN 50324

3. Case Study Highlights

Case 1: Aerospace Turbine Blade Protection

- Client: European aircraft manufacturer

- Challenge: Needed thermal barrier coating for 900°C operation

- Solution: Graded TiAlN/AlCrN multilayer coating

- Results: Achieved 15,000 flight hours, passed EASA certification

Case 2: Medical Implant Surface Treatment

- Client: US orthopedic company

- Challenge: Required bioactive coating for titanium implants

- Solution: Nanotextured TiO₂ with controlled porosity

- Results: 92% bone integration rate, FDA approval obtained

Case 3: Automotive Transmission Enhancement

- Client: Japanese auto parts supplier

- Challenge: Needed durable coating for CVT components

- Solution: Hybrid CrN+MoS₂ coating system

- Results: 400,000 km durability, 45% friction reduction

4. Our PVD Surface Finishing Process

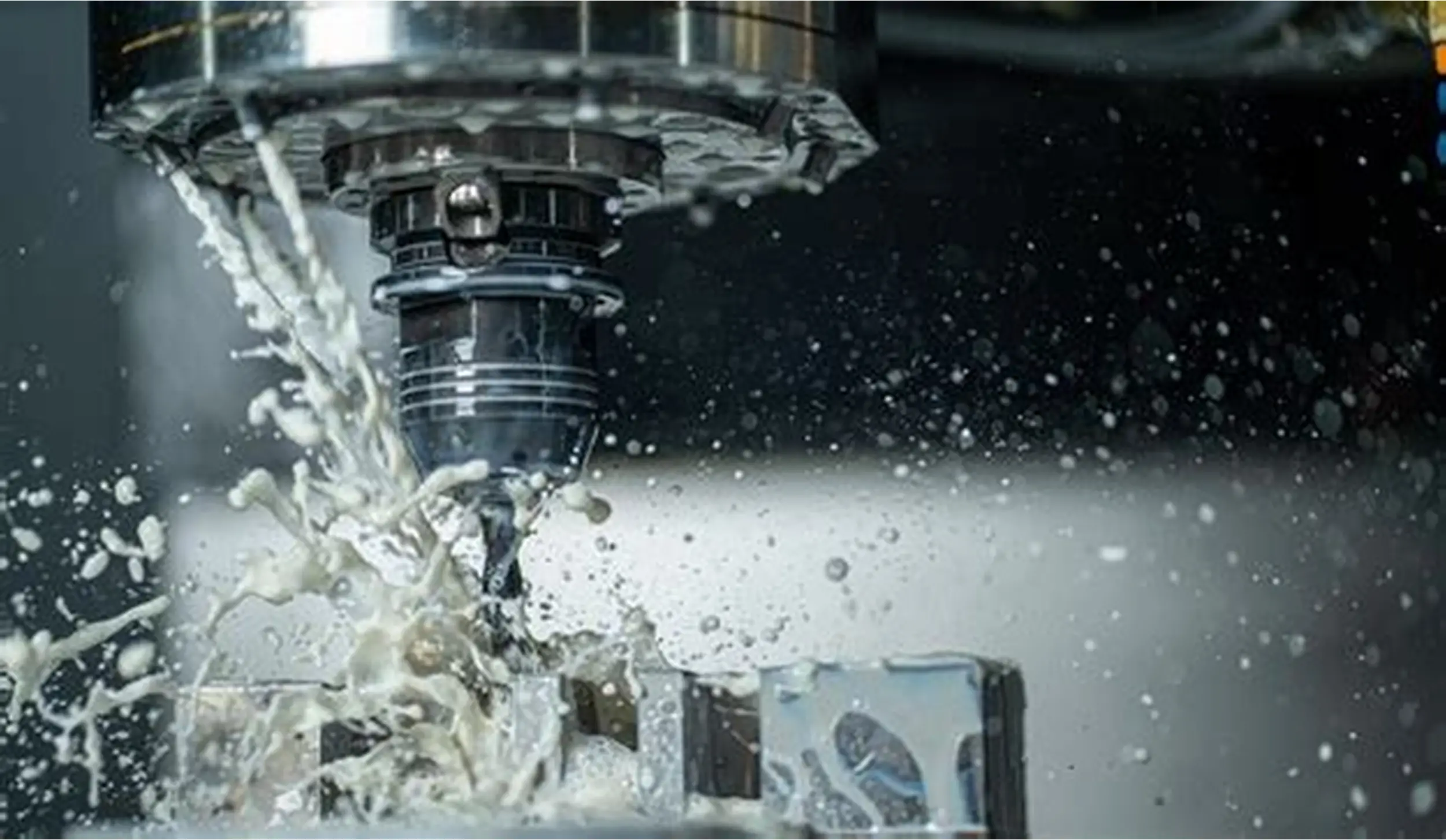

Stage 1: Advanced Substrate Preparation

- 5-axis ultrasonic cleaning (3-stage)

- Argon plasma etching (200-500W)

- Surface roughness optimization (Ra <0.1μm)

Stage 2: Precision Coating Deposition

- HIPIMS technology (High-power impulse magnetron sputtering)

- Computer-controlled layer-by-layer deposition

- Real-time optical emission monitoring

Stage 3: Comprehensive Quality Control

- Scratch testing (ISO 20502)

- XRD phase analysis (Bruker D8 Advance)

- Accelerated aging tests (per ASTM B117)

For custom PVD surface finishing solutions, contact our engineers at [email protected].