Aerospace Component Manufacturing Supplier: Precision CNC Machining for the Sky and Beyond

Introduction: The Critical Role of Precision Manufacturing in Aerospace

The aerospace industry represents one of the most demanding sectors for component manufacturing, where exceptional precision and uncompromising quality are non-negotiable requirements. As a specialized CNC machining service provider, we understand that aircraft and spacecraft components must perform flawlessly under extreme conditions, including dramatic temperature fluctuations, intense vibration, and significant mechanical stress. This comprehensive guide explores the technical capabilities, quality standards, and specialized approaches that define world-class aerospace component manufacturing.

In an industry where a single component failure can have catastrophic consequences, aerospace manufacturers rely on suppliers who demonstrate consistent excellence across every aspect of their operations—from material selection and machining processes to quality verification and documentation. The global market for aviation parts on-demand manufacturing services, valued at approximately $4.55 billion in 2024, continues to grow at a steady pace, driven by both commercial and defense aerospace sectors . This growth underscores the increasing importance of reliable, precision-focused manufacturing partners in the aerospace supply chain.

Aerospace Manufacturing Standards and Certification Requirements

Stringent Quality Management Systems

Aerospace component manufacturing operates within a rigorous regulatory framework designed to ensure absolute reliability and safety. Suppliers must maintain comprehensive quality management systems that address every aspect of the manufacturing process, with particular emphasis on traceability, documentation, and process control.

Table 1: Key Aerospace Quality Standards and Certifications

| Standard/Certification | Focus Area | Importance for Aerospace Manufacturing |

|---|---|---|

| AS9100D | Quality Management System for Aviation, Space, and Defense | Defines the quality system requirements for aerospace suppliers, emphasizing risk management and product safety |

| NADCAP | Special Process Accreditation (e.g., heat treating, welding, NDT) | Provides industry-wide accreditation of special processes, often required for aircraft OEM suppliers |

| ITAR | International Traffic in Arms Regulations | Controls export of defense-related articles and services on the United States Munitions List |

| FAA PMA | Parts Manufacturer Approval | Authorization from FAA to produce replacement parts for aircraft without need for approval from original type certificate holder |

| ISO 13485 | Medical Devices Quality Management | Relevant for aerospace components with medical applications or cabin environments |

Leading aerospace component manufacturers like Acutec Precision Aerospace maintain multiple certifications including AS9100D, ITAR, and NADCAP to serve diverse markets including commercial aircraft, defense, aerospace, and power generation . These certifications provide the foundation for manufacturing everything from vibration and rotor components to engine parts, fuel systems, air controls, avionics, landing gear, and braking systems.

Material Traceability and Documentation

Complete material traceability is essential throughout the aerospace supply chain. From raw material procurement to final part delivery, manufacturers must maintain detailed records documenting material composition, heat treatment, testing results, and processing history. This meticulous documentation ensures that any potential issues can be quickly traced to their source and addressed appropriately, minimizing safety risks and supply chain disruptions.

Advanced CNC Technologies for Aerospace Components

Multi-Axis Machining Capabilities

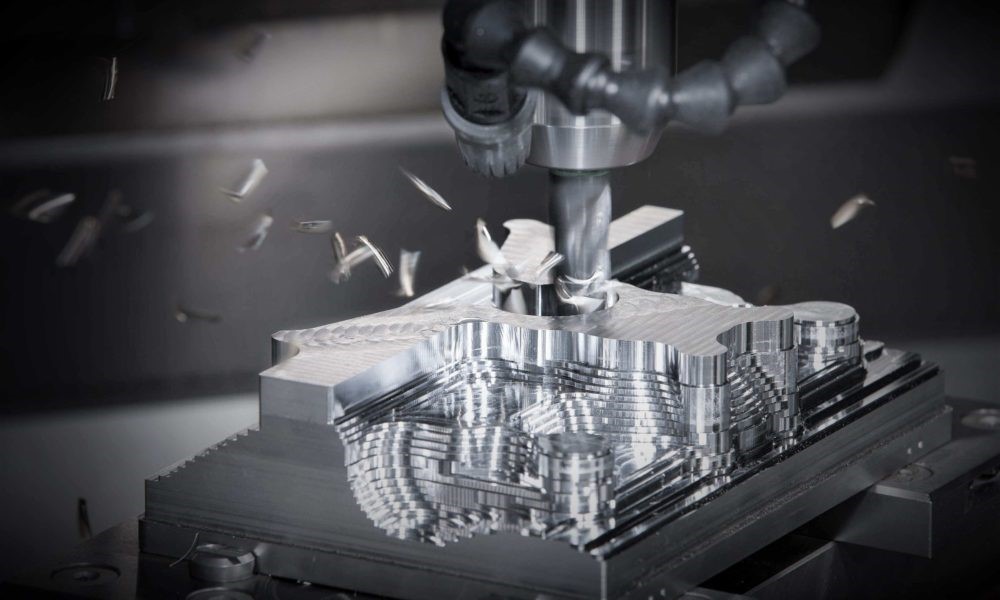

Five-axis CNC machining has revolutionized aerospace component manufacturing by enabling complete processing of complex geometries in single setups. This technology eliminates cumulative errors associated with multiple repositioning operations and significantly reduces lead times while improving dimensional accuracy .

The experience of Dunlop Aerospace Braking Systems demonstrates the value of advanced CNC capabilities. The company invested £2 million in three key CNC machines between 1998 and 2000, including a multi-axis Mazak Integrex with C-axis and powered tools for milling-turn operations, a Mazak HV800 five-axis horizontal machining center, and a Mori Seiki MT4000 . This investment enabled them to handle diverse production requirements from high-volume orders to small batches and even one-off projects like remanufacturing components for 1950s Canberra aircraft.

Integrated Measurement and Process Control

In-process verification using touch probes and laser measurement technologies has become standard practice in aerospace manufacturing. These systems identify workpiece position and material condition, update offsets, and monitor variations in raw material forgings to ensure machining begins from precisely located surfaces .

As Andrew Cartledge of Dunlop Aerospace noted, “We have now been using probe systems on this cell for over six years, and they have provided cost and time savings as well as massive improvements in process control and consistency” . The implementation of probe systems at Dunlop significantly reduced machining cycle times and overall setup time per component, crucial benefits for their new product introduction process.

Aerospace Materials and Their Machining Considerations

Advanced Metallic Alloys

Aerospace components demand materials that offer exceptional strength-to-weight ratios, corrosion resistance, and performance across extreme temperature ranges. The selection of appropriate materials directly impacts aircraft performance, fuel efficiency, and safety.

Table 2: Common Aerospace Materials and Their Applications

| Material | Key Properties | Aerospace Applications | Machining Considerations |

|---|---|---|---|

| Aluminum Alloys | Excellent strength-to-weight ratio, good corrosion resistance, high machinability | Wing skins, fuselage frames, aircraft structure, brackets, housings | High cutting speeds possible, requires sharp tools to prevent material adhesion |

| Titanium Alloys | High strength-to-weight ratio, excellent corrosion resistance, withstands extreme temperatures | Engine components, fasteners, landing gear, hydraulic systems | Low thermal conductivity requires specialized tooling and cooling strategies |

| Stainless Steel | High strength, good corrosion resistance, durability | Engine mounts, exhaust components, landing gear components, critical joints | Work-hardening tendency demands consistent feed rates and sharp tooling |

| High-Temperature Alloys | Maintain strength at elevated temperatures, corrosion resistant | Turbine blades, engine components, exhaust systems, heat shields | Extremely abrasive nature requires advanced tool materials like PCBN |

| Carbon Fiber Composites | Exceptional strength-to-weight ratio, fatigue resistant, corrosion resistant | Control surfaces, wing boxes, fuselage sections, fairings | Specialized tool geometries needed to prevent delamination and fraying |

Aluminum’s incredible strength-to-weight ratio makes it ideal for high-load applications like aircraft brackets and housings, while its light weight benefits aerospace structural applications including wing skins and fuselage sections . Titanium offers exceptional properties including resistance to corrosion, chemicals, and extreme temperatures, making it perfect for demanding applications in spacecraft and aircraft engines .

Material Selection for Specific Applications

The operating environment dictates material selection in aerospace manufacturing. For instance, engine components require materials that maintain structural integrity at high temperatures, while landing gear demands exceptional fatigue resistance and strength. As described by RapidDirect, “CNC machining aircraft parts, including bushings, hinges, fixtures, or other custom parts, all require the use of quality materials” to ensure proper functioning without risks .

R&D Manco’s experience highlights the importance of material knowledge in aerospace manufacturing. The company successfully transitioned many parts from casting to hogout (complete machining from solid block), achieving 60% shorter lead times and approximately 20% cost reductions by selecting appropriate materials and employing advanced five-axis machining techniques .

Specialized Machining Processes for Aerospace Components

Five-Axis Machining for Complex Geometries

Five-axis simultaneous machining enables the production of aerospace components with complex, organic shapes that would be impossible to create using conventional three-axis equipment. This capability is particularly valuable for parts with deep pockets, complex contours, or multiple compound angles.

The importance of five-axis technology is evident in R&D Manco’s approach to aerospace manufacturing. Company president John Bloom and general manager Kevin Beach identified five-axis machining as the most important technology for their transition from cast to hogout parts . This technology allowed them to machine complex shapes that previously required casting, significantly reducing lead times and costs while improving quality.

High-Speed Machining for Efficiency and Surface Finish

Advanced toolpath strategies like trochoidal milling and dynamic milling enable higher material removal rates while protecting tooling and maintaining dimensional accuracy. These techniques maintain constant tool engagement, reducing heat generation and extending tool life.

The competitive culture at R&D Manco exemplifies the pursuit of machining efficiency. Their engineers successfully reduced machining time for a complex aluminum part nicknamed “Three Ball” from over eight hours to just two hours and forty-three minutes by optimizing feed rates and cutting depths . Such improvements directly impact manufacturing costs and delivery times for aerospace customers.

Quality Assurance and Metrology in Aerospace Manufacturing

Comprehensive Inspection methodologies

Rigorous inspection protocols ensure every aerospace component meets precise dimensional and quality requirements before delivery. Advanced measurement technologies including coordinate measuring machines (CMM), optical comparators, and laser scanners verify critical dimensions on complex components.

Dunlop Aerospace implemented a “Manufacturing Process Approval” (MPA) step in their new product introduction process. For any machining process that could affect wheel stress and component strength, they conducted rigorous analysis before launching production . This systematic approach to quality assurance is essential in aerospace manufacturing, where component failure is not an option.

First Article Inspection and Process Validation

First article inspection represents a critical step in aerospace manufacturing, particularly for new components or process changes. R&D Manco identified waiting for first article inspection as one of their most significant production bottlenecks and addressed it by adding a CMM and dedicated technician specifically for first-piece inspection .

Additionally, they explored performing first article inspection without removing parts from the machine using Renishaw’s Productivity+ software, which enables automated comparison of measured part features against original CAD data . Such innovations streamline the quality assurance process while maintaining rigorous standards.

Case Studies: Aerospace Manufacturing Excellence

Case Study 1: Dunlop Aerospace Braking Systems

Challenge: Dunlop Aerospace, part of Meggitt PLC, needed to produce wheel and brake units for commercial and military aircraft with high consistency and reduced production times while maintaining stringent quality standards.

Solution: The company invested in three advanced multi-axis CNC machines between 1998 and 2000, specifically specifying Renishaw probe systems for each machine. These probe systems identified workpiece position and material condition, updated offsets, and monitored variations in wheel forgings.

Results: The implementation achieved significant improvements in machining cycle times and setup times. The probe systems provided cost and time savings while delivering massive improvements in process control and consistency over six years of operation .

Case Study 2: R&D Manco’s Transition to Hogout Manufacturing

Challenge: R&D Manco, a machining subcontractor serving aerospace industry leaders, sought to reduce lead times and costs by transitioning parts from traditional casting to complete machining from solid billet (hogout).

Solution: The company employed advanced five-axis machining capabilities combined with a competitive company culture that encouraged process improvements and innovation. They implemented machine tool monitoring to identify production bottlenecks and optimize utilization.

Results: R&D Manco achieved 60% shorter lead times and approximately 20% cost reductions compared to cast parts. They successfully transitioned half of their common parts previously made via casting to hogout manufacturing, significantly streamlining their customers’ supply chains .

Case Study 3: Acutec Precision Aerospace’s Tooling Innovation

Challenge: Acutec Precision Aerospace faced bottlenecks in their cutting tool supply chain, with external suppliers requiring 6-10 weeks for delivery of small batch tools, disrupting production schedules.

Solution: The company invested in ANCA CNC tool grinding machines for internal production of short-batch tools, implementing the MX7 and FX5 Linear models with AR300 robot automation and laser measurement systems.

Results: Acutec reduced their tooling costs by 75% compared to external suppliers and slashed delivery time from 6-10 weeks to same-day or next-day production. The $200,000 annual savings yielded a return on investment of less than three years while providing greater control over quality and delivery .

The Future of Aerospace Component Manufacturing

Digital Integration and Industry 4.0

The adoption of Industry 4.0 principles is transforming aerospace manufacturing through enhanced connectivity, data analytics, and digital workflow integration. These technologies support the creation of “digital twins” that simulate both manufacturing processes and component performance, reducing physical iteration requirements.

Machine tool monitoring, as implemented at R&D Manco, provides valuable insights into production efficiency and bottlenecks. By collecting and analyzing machine status data, manufacturers can identify areas for improvement and optimize overall equipment effectiveness .

Additive and Hybrid Manufacturing

Combining additive and subtractive technologies represents an emerging trend in aerospace manufacturing. While 3D printing enables complex internal geometries and lightweight structures, CNC machining provides superior surface finishes and tight tolerances on critical features.

The global market for aviation parts on-demand manufacturing services includes 3D printing alongside CNC machining and injection molding services, reflecting the growing importance of hybrid approaches in aerospace manufacturing .

Conclusion: Partnering for Aerospace Manufacturing Success

Aerospace component manufacturing demands specialized expertise, advanced equipment, and rigorous quality systems. As the industry continues to evolve with increasing demands for performance, efficiency, and reliability, manufacturers must invest in both technology and expertise to remain competitive.

The case studies presented demonstrate that success in aerospace manufacturing requires more than advanced equipment—it demands strategic implementation, continuous improvement, and deep technical knowledge. From five-axis machining and integrated measurement systems to innovative approaches like hogout manufacturing and in-house tool production, leading manufacturers leverage every available advantage to deliver exceptional value to their aerospace customers.

For your next aerospace component project, partner with a manufacturing supplier that understands both the technical complexities and quality requirements of the aerospace industry. Contact us today to discuss how our aerospace component manufacturing capabilities can address your specific application requirements.