The Ultimate Guide to Aerospace-Grade Titanium Coating Services: Enhancing Performance and Safety in Aviation

Introduction to Aerospace-Grade Titanium Coating Services

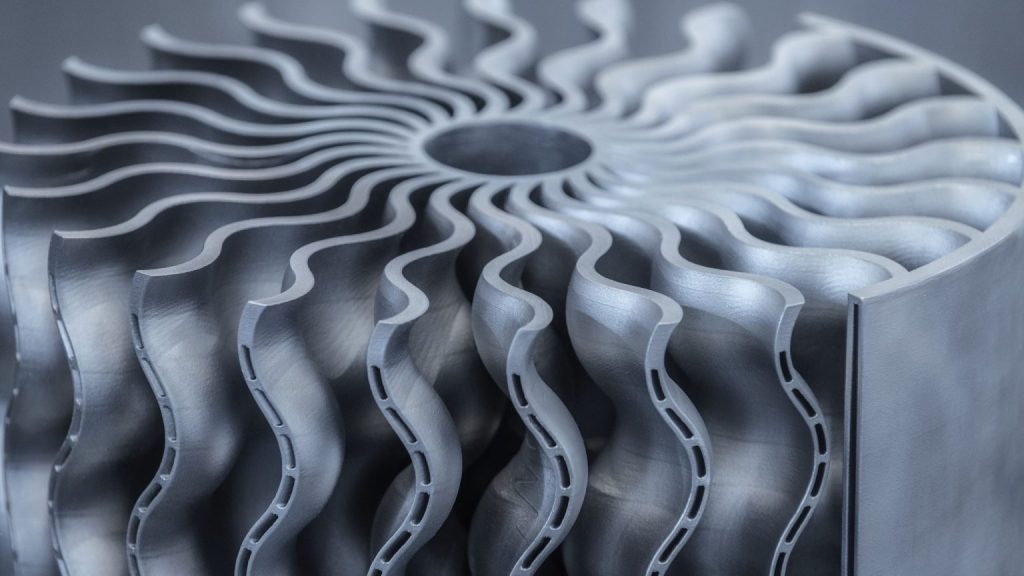

Aerospace-grade titanium coating services represent the pinnacle of surface engineering technology, combining advanced materials science with precision application processes to enhance the performance, durability, and safety of critical aviation components. These specialized coatings have become indispensable in modern aerospace manufacturing, where extreme operational conditions demand exceptional material performance and reliability. The global aerospace coating service market continues to expand significantly, driven by increasing demands for fuel-efficient aircraft, enhanced component longevity, and superior corrosion resistance in challenging operational environments.

Titanium’s exceptional strength-to-weight ratio and inherent corrosion resistance make it an ideal material for aerospace applications. However, even this advanced material requires specialized surface treatments to meet the rigorous demands of modern aviation. Aerospace-grade coatings enhance titanium components by providing improved wear resistance, thermal barrier properties, enhanced lubrication, and superior environmental protection against extreme atmospheric conditions encountered during flight operations.

The Critical Importance of Surface Treatment in Aerospace Applications

Surface treatment represents a fundamental manufacturing process that significantly impacts component performance, safety, and service life in aerospace applications. For titanium components, specialized coatings provide essential enhancements that transcend mere cosmetic improvement, delivering measurable improvements in operational performance and reliability.

Why Aerospace Components Require Specialized Coatings

Table: Operational Challenges Addressed by Aerospace-Grade Titanium Coatings

| Operational Challenge | Impact on Components | Coating Solution | Performance Benefit |

|---|---|---|---|

| High-Temperature Exposure | Oxidation, thermal fatigue, creep | Thermal barrier coatings | 300-500°C increased temperature capability |

| Corrosive Environments | Pitting, stress corrosion cracking | Corrosion-resistant coatings | 5-10x improvement in corrosion resistance |

| Wear and Erosion | Dimensional loss, surface degradation | Hard coatings, DLC | 3-8x improvement in wear resistance |

| Friction and Galling | Seizure, increased energy consumption | Low-friction coatings | 40-70% friction reduction |

| Foreign Object Damage | Impact damage, surface pitting | Impact-resistant coatings | Improved damage tolerance |

Regulatory and Certification Requirements

Aerospace coatings must comply with stringent international standards and certification requirements:

-

FAA Regulations: Federal Aviation Administration requirements for aircraft components

-

EASA Standards: European Union Aviation Safety Agency certification

-

OEM Specifications: Original Equipment Manufacturer technical standards

-

Military Standards: MIL-SPEC requirements for defense applications

-

Quality Management Systems: AS9100 certification for aerospace suppliers

Advanced Titanium Coating Technologies for Aerospace Applications

1. Physical Vapor Deposition (PVD) Coatings

PVD processes create ultra-thin, extremely hard coatings through vapor deposition techniques:

Table: PVD Coating Technologies for Aerospace Titanium Components

| Coating Type | Hardness (HV) | Maximum Service Temperature | Key Properties | Aerospace Applications |

|---|---|---|---|---|

| TiN (Titanium Nitride) | 2300-2400 | 600°C | Good wear resistance, golden color | Fasteners, cutting tools, bearings |

| TiCN (Titanium Carbonitride) | 3000-3200 | 750°C | High hardness, good lubricity | Actuator components, valve parts |

| TiAlN (Titanium Aluminum Nitride) | 3200-3500 | 900°C | Excellent thermal stability | Turbine components, high-temperature parts |

| CrN (Chromium Nitride) | 1800-2200 | 700°C | Superior corrosion resistance | Marine aircraft components, exterior parts |

| DLC (Diamond-Like Carbon) | 2000-4000 | 300-600°C | Extreme hardness, low friction | Fuel system components, sliding surfaces |

2. Plasma Electrolytic Oxidation (PEO)

PEO processes create thick, hard ceramic coatings on titanium surfaces through electrochemical conversion:

-

Coating Thickness: 20-100 μm

-

Hardness: 400-1500 HV

-

Adhesion Strength: Excellent metallurgical bonding

-

Thermal Stability: Withstands temperatures up to 2000°C

-

Applications: Thermal protection systems, engine components, wear surfaces

3. Thermal Spray Coatings

Thermal spray technologies deposit molten or semi-molten materials onto titanium substrates:

-

High-Velocity Oxygen Fuel (HVOF): Dense, well-bonded coatings for wear resistance

-

Plasma Spray: Thermal barrier coatings and abradable seals

-

Cold Spray: Solid-state deposition for sensitive components

-

Detonation Gun: Extremely hard, dense coatings for severe wear applications

4. Electrochemical Processes

Specialized electrochemical treatments enhance titanium surface properties:

-

Anodizing: Creates decorative and protective oxide layers

-

Electropolishing: Produces ultra-smooth, microfinished surfaces

-

Plasma Nitriding: Diffuses nitrogen into surface for improved hardness

-

Ion Implantation: Modifies surface chemistry without dimensional changes

Material Properties and Performance Enhancements

Titanium Alloy Considerations

Different titanium alloys require specific coating approaches:

Table: Coating Compatibility with Aerospace Titanium Alloys

| Titanium Alloy | Common Applications | Recommended Coating Processes | Special Considerations |

|---|---|---|---|

| Ti-6Al-4V (Grade 5) | Structural components, engine parts | PVD, PEO, Thermal Spray | Most common aerospace alloy |

| Ti-6Al-2Sn-4Zr-2Mo | High-temperature engine components | PVD, Thermal Barrier Coatings | Excellent creep resistance |

| Ti-5Al-2.5Sn | Cryogenic components, airframe parts | Anodizing, E-coating | Good weldability and toughness |

| Ti-3Al-2.5V | Hydraulic systems, tubing | Electroless Nickel, PVD | Excellent corrosion resistance |

| Beta Titanium Alloys | Springs, fasteners | PVD, DLC coatings | High strength, fatigue resistance |

Performance Metrics and Testing

Rigorous testing ensures coating performance meets aerospace requirements:

-

Salt Spray Testing: ASTM B117 corrosion resistance evaluation

-

Taber Abrasion: ASTM D4060 wear resistance measurement

-

Thermal Cycling: MIL-STD-810 thermal shock resistance

-

Adhesion Testing: ASTM D4541 pull-off adhesion strength

-

Hardness Testing: Microindentation and nanoindentation analysis

-

Fatigue Testing: Improved fatigue life performance verification

Quality Assurance and Certification

Aerospace Quality Standards

Aerospace coating services must adhere to stringent quality standards:

-

AS9100: Aerospace Quality Management System

-

NADCAP: Special Process Accreditation for Aerospace

-

ISO 9001: Quality Management Systems

-

MIL-SPEC: Military specifications for defense applications

-

OEM Approvals: Manufacturer-specific qualifications and approvals

Inspection and Testing Protocols

Comprehensive quality assurance includes:

-

First Article Inspection: Detailed verification of initial production parts

-

Statistical Process Control: Monitoring of critical process parameters

-

Non-Destructive Testing: X-ray, ultrasonic, and dye penetrant inspection

-

Metallurgical Analysis: Cross-section analysis and microstructure evaluation

-

Surface Metrology: 3D surface profiling and roughness measurement

Applications in Aerospace Systems

Gas Turbine Engine Components

Titanium coatings provide critical protection in turbine engines:

-

Compressor Blades and Vanes: Wear-resistant coatings for erosion protection

-

Turbine Sections: Thermal barrier coatings for high-temperature components

-

Combustion Chambers: Oxidation-resistant coatings for extended service life

-

Shafts and Bearings: Low-friction coatings for improved efficiency

Airframe Structures

Structural components benefit from specialized coatings:

-

Fastening Systems: Corrosion-resistant coatings for joints and fasteners

-

Landing Gear Components: Wear-resistant coatings for high-load applications

-

Hydraulic System Components: Low-friction coatings for moving parts

-

Exterior Surfaces: Environmental protection coatings for airframe structures

Avionics and Electronic Systems

Specialized coatings protect sensitive electronic systems:

-

EMI/RFI Shielding: Conductive coatings for electromagnetic protection

-

Corrosion Protection: Protective coatings for circuit boards and connectors

-

Thermal Management: Thermally conductive coatings for heat dissipation

-

Space Applications: Radiation-resistant coatings for satellite components

Case Studies: Aerospace Coating Success Stories

Case Study 1: Turbine Blade Coating for Extended Service Life

Challenge: Improve high-temperature oxidation resistance and erosion performance of titanium turbine blades in business jet engines, extending service intervals from 1,000 to 2,000 hours while maintaining dimensional stability and aerodynamic performance.

Solution: Implemented multi-layer PVD coating system incorporating TiAlN base layer with proprietary topcoat formulation. The process included specialized masking to protect critical dimensional features and aerodynamic surfaces while ensuring complete coverage in high-wear areas.

Results: Achieved 125% improvement in service life with 2,250 hours between overhauls. Coated blades demonstrated 80% reduction in oxidation-related degradation and 60% improvement in erosion resistance. The solution received OEM approval and has been implemented across the engine fleet.

Case Study 2: Aircraft Fastener Coating for Corrosion Protection

Challenge: Solve recurring corrosion issues in titanium structural fasteners on commercial aircraft operating in marine environments, where saltwater exposure caused premature failure and required frequent replacement.

Solution: Developed specialized electroless nickel-PTFE composite coating with enhanced corrosion resistance and lubricity. The process included precision control of coating thickness to maintain fastener tolerances and ensure proper clamping force in critical structural joints.

Results: Eliminated corrosion-related failures with 0% failure rate after 24 months of service. Coated fasteners demonstrated 500% improvement in salt spray resistance per ASTM B117 and reduced installation torque values by 25%, improving assembly efficiency and reducing labor costs.

Case Study 3: Space Component Coating for Thermal Management

Challenge: Provide extreme temperature protection for titanium satellite components experiencing temperature fluctuations from -150°C to +200°C while maintaining electrical properties and preventing outgassing in vacuum conditions.

Solution: Applied plasma electrolytic oxidation coating with customized electrolyte chemistry to create a thick, stable ceramic layer with tailored thermal emissivity and electrical insulation properties. The process included extensive vacuum testing to ensure compliance with space environment requirements.

Results: Achieved excellent thermal stability with less than 1% dimensional change after thermal cycling. Coated components demonstrated superior thermal management with 40% improved heat dissipation and zero outgassing in vacuum testing. The solution met all NASA and ESA requirements for space applications.

Implementing Aerospace Coating Services: Technical Considerations

Design for Coating

Successful implementation requires early consideration of coating requirements:

-

Geometry Limitations: Some processes have line-of-sight limitations or require specific geometries

-

Masking Requirements: Areas requiring protection from coating must be designed for effective masking

-

Stress Relief: Thermal processes may require stress relief cycles to prevent distortion

-

Dimensional Allowances: Coatings adding significant thickness require dimensional compensation

Process Selection Methodology

Systematic approach to selecting appropriate coating processes:

-

Performance Requirements Analysis: Define specific functional needs (temperature, wear, corrosion, etc.)

-

Material Compatibility Assessment: Evaluate base material constraints and interactions

-

Geometric Feasibility Study: Determine technical feasibility for component geometry

-

Economic Viability Analysis: Balance performance benefits against cost implications

-

Validation Testing Planning: Develop appropriate test protocols to verify performance

Environmental and Safety Considerations

Aerospace coating facilities must address environmental requirements:

-

VOC Emissions Control: Compliance with air quality regulations

-

Hazardous Material Handling: Proper management of chemicals and materials

-

Waste Treatment: Treatment and disposal of process wastes

-

Worker Safety: Protection against chemical and physical hazards

-

Environmental Compliance: Meeting all regulatory requirements

Future Trends in Aerospace Titanium Coating Technology

Emerging Technologies

Several advanced technologies show promise for future aerospace applications:

-

Nanostructured Coatings: Engineered nanoscale structures for enhanced properties

-

Smart Coatings: Materials that respond to environmental conditions or damage

-

Multifunctional Coatings: Integrated solutions combining multiple properties

-

Digital Twin Technology: Virtual process optimization and prediction

-

AI-Optimized Coating Design: Machine learning algorithms for coating development

Sustainability Developments

Environmental considerations driving process innovations:

-

Green Chemistry Approaches: Reduced environmental impact of coating processes

-

Energy-Efficient Technologies: Lower energy consumption in coating applications

-

Waste Reduction Strategies: Closed-loop systems and reduced consumable usage

-

Longer Service Life: Reduced replacement frequency through enhanced durability

Industry 4.0 Integration

Digitalization of coating processes:

-

IoT-Enabled Equipment: Real-time monitoring and adjustment of process parameters

-

Predictive Maintenance: AI-driven equipment maintenance scheduling

-

Digital Process Documentation: Complete digital records of coating parameters

-

Automated Quality Control: Machine vision and AI for defect detection

Conclusion: The Strategic Value of Aerospace-Grade Titanium Coating Services

Aerospace-grade titanium coating services have evolved from a secondary manufacturing consideration to a critical technology that fundamentally enhances component performance, safety, and reliability. The selection and implementation of appropriate coating processes require sophisticated understanding of materials science, surface engineering, and aerospace requirements.

As aerospace technology continues to advance toward ever-higher levels of performance and efficiency, coating technologies will play an increasingly vital role in enabling these advancements. The future will see greater integration between design, manufacturing, and coating processes, with digital technologies enabling unprecedented levels of optimization and control.

For aerospace manufacturers seeking competitive advantage through enhanced product performance, partnering with experts in aerospace coating services provides access to specialized knowledge and technologies that can significantly impact product success in the marketplace.

By understanding the technologies, applications, and considerations outlined in this guide, engineers and manufacturers can make informed decisions about aerospace coatings for their specific applications, ensuring optimal results and maximum value from their manufacturing investments.

For specific applications or to discuss your aerospace coating requirements, please contact our technical team for personalized assistance and process recommendations: https://www.jlypt.com/anodizing-near-me-surface-finishing-services/