Streamlining Material Flow: A Comprehensive Guide to AGV (Automated Guided Vehicle) Systems in Modern CNC Machining Workshops

Introduction: The Logistical Imperative – AGV (Automated Guided Vehicle) Systems as the Circulatory System of Smart CNC Shops

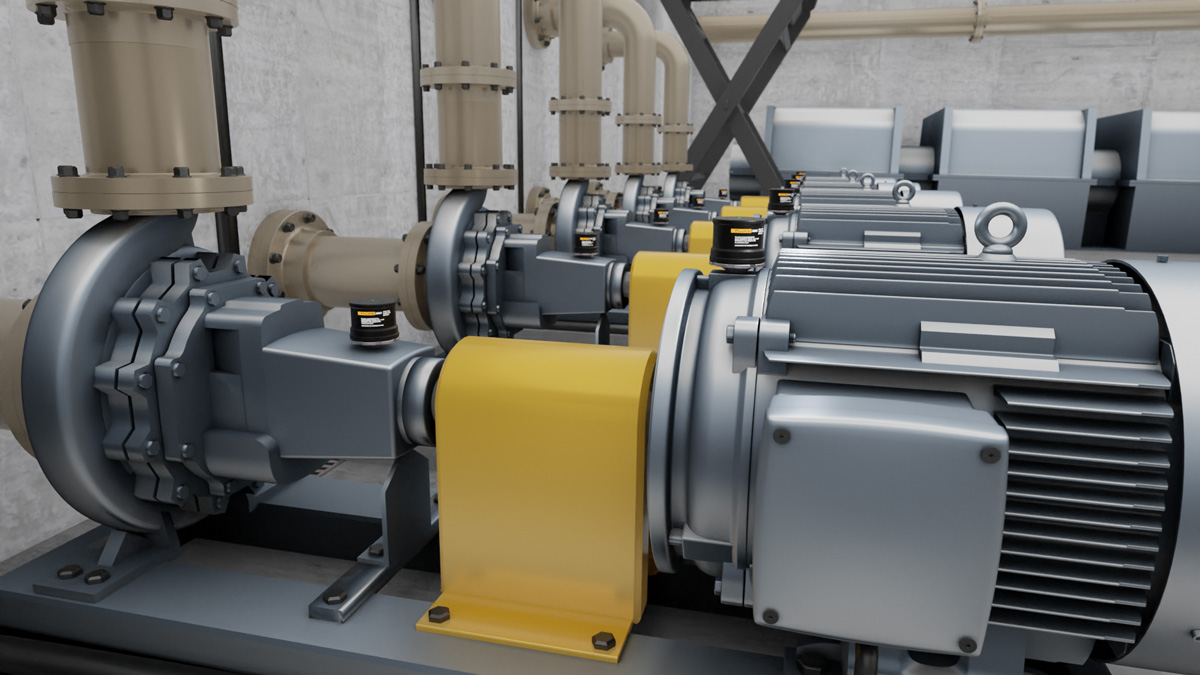

In the precision-driven ecosystem of a CNC machining workshop, where the focus is rightly placed on spindle accuracy, toolpath optimization, and micron-level tolerances, the critical element of material logistics is often an afterthought. Yet, the flow of raw billets, fixtures, work-in-progress (WIP), and finished components between storage, machines, and inspection stations represents a significant source of hidden costs, bottlenecks, and potential quality risks. As shops evolve from isolated islands of automation into connected, flexible manufacturing cells, the need for an intelligent, reliable, and seamless material handling solution becomes paramount. This is where the strategic implementation of AGV (Automated Guided Vehicle) systems transitions from a futuristic concept to a foundational operational necessity.

At JLYPT, our perspective is shaped by the intersection of high-precision component manufacturing and the systemic efficiency required to deliver it consistently. We view AGV (Automated Guided Vehicle) systems not as standalone gadgets but as the vital circulatory system of a modern workshop. These driverless vehicles form the connective tissue that links CNC machining centers, coordinate measuring machines (CMMs), wash stations, and storage racks into a cohesive, synchronized production organism. This guide is crafted for machining cell designers, plant managers, and operations leaders who recognize that the next frontier of productivity lies not just in faster metal removal, but in eliminating non-value-added movement and wait times. We will delve into the core technologies of AGV (Automated Guided Vehicle) systems, provide a detailed framework for selection and integration specific to machining environments, and analyze the tangible return on investment through real-world application studies.

Section 1: Foundational Technologies – Navigating the Landscape of AGV (Automated Guided Vehicle) Systems

Understanding the technological underpinnings is essential for selecting the right AGV (Automated Guided Vehicle) systems for a CNC environment, which presents unique challenges like coolant mist, metallic debris, and the need for high-positioning accuracy at machine interfaces.

1.1 Core Navigation and Guidance Technologies

The “guidance” in AGV defines its intelligence and flexibility. The evolution here is from fixed-path to free-navigation systems.

-

Traditional Wire-Guided AGVs: These follow a passive wire embedded in the factory floor, generating a magnetic field. They are highly reliable on fixed routes and were the industry standard for decades. However, they are inflexible; any change in workflow or machine layout requires expensive and disruptive floor cutting and rewiring. This makes them less suitable for dynamic CNC shops adapting to changing product mixes.

-

Laser Target Navigation (LGV): A significant advancement, where the vehicle uses an onboard rotating laser scanner to detect fixed reflective targets mounted on walls, columns, or posts. By triangulating its position relative to these targets, the LGV can navigate with high precision (±10mm). Paths are changed via software, offering excellent flexibility. This technology is highly robust in the typically well-structured, if sometimes cluttered, environment of a machining workshop.

-

Natural Feature Navigation (or SLAM-based AMRs): The cutting edge for AGV (Automated Guided Vehicle) systems is embodied in Autonomous Mobile Robots (AMRs). Using Simultaneous Localization and Mapping (SLAM) algorithms, combined with data from lidar, cameras, and often inertial measurement units, these vehicles build and continuously update a map of their environment. They navigate by recognizing natural features—racks, machine tools, walls—and can dynamically plan and replan paths around obstacles like pallets or personnel. This offers maximum flexibility for shops with frequent layout changes or dense, shared aisles.

1.2 Vehicle Types and Payload Interfaces for Machining

The physical form of the AGV (Automated Guided Vehicle) systems must match the load.

-

Unit Load Carriers/Tow Vehicles: Designed to move individual pallets, tote bins, or custom fixtures. They often incorporate lift mechanisms (roller decks, lift tables) to facilitate automatic transfer at pickup/drop-off (P&D) stations. Ideal for moving standardized pallets of raw material or finished parts between a warehouse and a machining cell buffer.

-

Forklift-Type AGVs: Automate the classic forklift function for handling standard euro-pallets or skids. Crucial for shops that receive raw materials on pallets and need to move them to breakdown saws or first-operation machines.

-

Assembly Line Vehicles: Typically smaller, used for moving kits of components or sub-assemblies between cells in a lean production flow.

-

Custom Engineered Vehicles: For specialized applications, such as transporting massive turned shaft fixtures between a lathe and a gear hobber, or moving an entire multi-pallet machining cube. The payload interface is critical and often requires custom engineering, an area where JLYPT’s design-for-manufacture expertise is frequently applied to create robust, precision lifting and locating features.

Table 1: Comparative Analysis of AGV (Automated Guided Vehicle) Systems Guidance Technologies for CNC Workshops

| Guidance Technology | How It Works | Pros for CNC Machining | Cons for CNC Machining | Ideal Workshop Scenario |

|---|---|---|---|---|

| Wire Guidance | Follows a low-frequency magnetic field from a floor-embedded wire. | High reliability on fixed path; immune to ambient light/dust; lower initial vehicle cost. | Zero layout flexibility; high installation disruption; path blockage stops all traffic. | High-volume, single-product line with a permanent, simple material flow path. |

| Laser Target Navigation (LGV) | Onboard laser scanner triangulates position using wall-mounted reflective targets. | High precision (±5-10mm); flexible paths changed in software; reliable in industrial lighting. | Targets require clear line-of-sight; initial site survey and mapping required; reflective surfaces can cause interference. | Most CNC machining workshops with defined aisles and stable infrastructure. Excellent for machine-to-machine transport. |

| Natural Feature / SLAM (AMR) | Creates a map using lidar/cameras and navigates via real-time feature recognition. | Ultimate flexibility; no infrastructure needed; dynamic obstacle avoidance; easy to redeploy. | Higher unit cost; path planning can be less predictable in ultra-dense traffic; requires more sophisticated fleet management software. | Dynamic, high-mix shops; environments shared with humans; frequently changing floor layouts or production flows. |

| Magnetic Tape / Optical | Follows a visible or magnetic tape on the floor surface. | Very low cost, simple to install and modify. | Tape is prone to wear, damage from chips/coolant, and obsurescence; low positioning accuracy; poor for heavy loads. | Extremely lightweight, simple, and temporary material movement tasks. Rarely suitable for core production. |

Section 2: The Integration Framework – Deploying AGV (Automated Guided Vehicle) Systems in a CNC Ecosystem

Successful implementation of AGV (Automated Guided Vehicle) systems is a systemic engineering challenge, not just a procurement exercise.

H2: Phase 1: Process Mapping and Traffic Design

Before selecting hardware, map the complete material journey.

-

Identify Nodes: Define all pickup and drop-off points: raw material rack, saw, CNC Machine #1 (load station), CMM, wash station, deburr cell, finished goods staging.

-

Quantify Flow: Determine the volume, weight, and dimensions of loads between each node. Calculate required trip frequency per shift.

-

Design the Roadway: Plan paths, junctions, charging zones, and buffer areas. Consider aisle width (vehicle width + safety margin), turning radii, and floor condition (levelness, cracks). A key decision is implementing unidirectional vs. bidirectional traffic lanes, which impacts complexity and cost.

-

Interface Definition: Precisely specify the load transfer mechanism at each node. Will the AGV lift a pallet onto a fixed roller conveyor? Will it position itself under a raised pallet at a machine’s shuttle table? This interface design is critical for unattended operation.

H2: Phase 2: Technology Selection and Fleet Sizing

Using the process map, select the appropriate technology from Table 1.

-

Fleet Sizing: This is a balance of capital cost and system responsiveness. Use simulation software or queuing theory to model traffic. Factors include: travel distances, transfer times at nodes, required throughput, and vehicle charging strategy (opportunity charging at idle points vs. scheduled battery swaps). An under-sized fleet creates delays; an over-sized fleet wastes capital and congests pathways.

-

The Charging Question: Modern AGV (automated guided vehicle) systems often use opportunity charging. The vehicle automatically docks at a wireless or contact-based charging station during natural waiting periods (e.g., while a machine completes a cycle), enabling 24/7 operation without manual battery management.

H2: Phase 3: Control System Integration – The Brain of the Operation

The true power of AGV (automated guided vehicle) systems is unlocked through software integration.

-

Fleet Management Software (FMS): This is the dispatching brain. It assigns tasks to the most suitable vehicle, optimizes traffic to prevent deadlocks, manages battery states, and provides a dashboard for monitoring. Advanced FMS can integrate with…

-

Manufacturing Execution System (MES) / Warehouse Management System (WMS): This is the strategic layer. The MES, knowing the production schedule, can issue a transport order: “Move Pallet P-1234, containing Titanium Blanks for Job J-567, from Raw Store to CNC Mill 5.” The FMS executes it. The AGV becomes an executing agent of the digital production plan.

-

Machine and Station PLCs: At the tactical level, the AGV must communicate with the machine’s PLC. A typical handshake: AGV arrives at station, sends “I am here” signal. PLC confirms fixture is ready and triggers unlock/transfer. AGV completes transfer, sends “task complete” signal, and receives its next order from the FMS.

Section 3: Addressing the Machining Workshop Environment – Specialized Considerations

CNC shops are not cleanrooms. Successful integration of AGV (automated guided vehicle) systems must account for harsh conditions.

H3: Contamination and Durability

-

Sealed Design: Vehicles must have a high Ingress Protection (IP) rating (e.g., IP54) to resist coolant mist, oil, and fine aluminum or cast iron dust.

-

Tire Selection: Polyurethane or rubber tires must be resistant to common workshop fluids and capable of traversing minor floor imperfections without losing traction or damaging the floor.

-

Sensor Protection: LiDAR windows and cameras need regular cleaning schedules or automated air-blast cleaners to maintain functionality.

H3: Precision and Repeatability at the Interface

While an AGV navigates the aisle with ±10mm accuracy, loading a part into a CNC machine may require ±0.5mm accuracy. This is solved at the transfer point.

-

Mechanical Alignment: Use conical pins, V-guides, or hardened steel locating features on both the AGV’s lift table and the machine’s receiver to ensure precise final positioning through “chamfer and lead-in” design.

-

Secondary Actuation: In high-precision applications, the AGV delivers the pallet to a “buffer station” with its own high-accuracy positioning slides. The AGV leaves, and the buffer station makes the final micron-accurate alignment with the machine.

-

This design of precision interfaces and custom fixturing is a core competency at JLYPT, ensuring that automated material handling enhances, rather than compromises, part quality.

Table 2: Cost-Benefit and ROI Analysis for AGV (Automated Guided Vehicle) Systems in CNC Machining

| Investment & Operational Factor | Traditional Manual Cart/Forklift | Integrated AGV System | Impact & Justification |

|---|---|---|---|

| Upfront Capital Cost | Low (Vehicle + Operator cost is operational). | High (Vehicle(s), FMS software, installation, site prep, interfaces). | Major capital project requiring detailed ROI analysis. |

| Direct Labor Cost | High. Requires dedicated or shared operator time. | Eliminated or drastically reduced. Frees skilled labor for value-added tasks like programming, setup, inspection. | Primary driver of hard cost savings. Justifies project on labor reduction alone in many cases. |

| Utilization of Capital Equipment (CNC Machines) | Low to Moderate. Machines idle during load/unload wait times. | Maximized. AGVs provide just-in-time material delivery, reducing machine idle time. Enables lights-out machining shifts. | Significant productivity gain. Increases effective capacity of existing multi-million dollar machine tools. |

| Material Traceability | Prone to error. Manual logging or barcode scans can be missed. | Automatic and inherent. Each transport is a digital transaction logged in MES/FMS. Links pallet ID to location and process step. | Reduces quality risks and improves lot control. Critical for aerospace, medical, and automotive compliance. |

| Work-in-Progress (WIP) & Floor Space | High. Parts wait in carts or on floor near machines. | Reduced and organized. AGVs deliver on demand, promoting a pull-based flow. Frees floor space for more machines or better organization. | Supports Lean Manufacturing principles. Reduces inventory carrying costs and lead times. |

| Safety & Damage | Higher risk of collisions, part drops, and ergonomic injuries. | Enhanced. AGVs follow strict safety protocols (sensors, speed limits). Eliminates manual handling of heavy, sharp, or valuable parts. | Reduces insurance costs and liability. Protects both personnel and high-value components. |

| Flexibility & Scalability | High (human adaptability) but unstructured. | Programmable and scalable. Adding a new machine or process node involves software mapping, not physical reorganization of labor. | Future-proofs the operation. Supports business growth and product mix changes efficiently. |

Section 4: Case Studies – AGV (Automated Guided Vehicle) Systems Driving CNC Workshop Transformation

Case Study 1: High-Volume Automotive Component Producer

-

Challenge: A manufacturer of engine blocks and cylinder heads operated 15 large CNC machining lines. Material movement between bulk storage, washing, machining, and leak testing was done with a fleet of forklifts and manual carts, causing traffic congestion, scheduling delays, and occasional part damage.

-

Solution: Implementation of a fleet of 8 laser-guided unit load carrier AGV (automated guided vehicle) systems. Each line was equipped with standardized pallet conveyors as P&D stations. The AGVs were integrated with the plant’s MES. Raw castings on pallets were automatically dispatched from central storage to line buffers. Finished assemblies were collected and delivered to the test department.

-

Outcome: A 22% reduction in direct material handling labor. A 15% increase in machine utilization due to consistent and timely part delivery. Elimination of part damage from manual handling, saving an estimated €80,000 annually in scrap. The AGV system provided a predictable, trackable material flow that became the backbone of their lean production system.

Case Study 2: High-Mix, Low-Volume Aerospace Machine Shop

-

Challenge: A shop machining complex titanium and Inconel parts for aerospace had a chaotic, high-WIP floor. Parts spent 80% of their time waiting or moving between 5-axis mills, CMMs, and EDM machines. Traceability was manual and error-prone.

-

Solution: Deployment of two SLAM-navigating AMRs. Instead of moving heavy pallets, these robots were fitted with custom-designed fixtures to carry individual part-specific holding pallets (often machined in-house by JLYPT for critical clients). The shop floor was digitally mapped. The MES, containing the job traveler, would dispatch an AMR to pick up a completed part from Mill A and deliver it to the CMM queue, then later to EDM.

-

Outcome: Part throughput time (dock-to-dock) was reduced by 35%. WIP inventory visibly dropped by 50%. Digital traceability became 100% accurate, providing flawless documentation for aviation authorities. The flexibility of the AMRs allowed the shop to rearrange machine locations twice a year for process optimization without any change to the AGV system infrastructure.

Case Study 3: Integrated Flexible Manufacturing System (FMS) for Die & Mold Making

-

Challenge: A mold manufacturer using multiple large 5-axis machining centers wanted to achieve 24/7 unmanned operation for roughing and semi-finishing cycles on large steel mold blocks.

-

Solution: A custom-engineered, high-precision forklift-type AGV (automated guided vehicle) system was integrated into a pallet pool system. The AGV’s role was to service a central pallet storage rack, retrieving pre-set pallets with raw blocks and delivering them to an available machine’s automatic pallet changer (APC), and vice-versa for completed pallets.

-

Outcome: The cell achieved true lights-out production for over 16 hours per day. Machine utilization soared above 85%. The AGV worked in tandem with the machine APCs and a central tool presetter, creating a fully automated machining cell. The high initial investment was recouped in under 3 years through the ability to take on more work without adding expensive machine tools or skilled night-shift operators.

Conclusion: From Islands of Automation to a Connected Continent

The integration of AGV (Automated Guided Vehicle) systems represents a paradigm shift for CNC machining workshops. It marks the transition from viewing material handling as a necessary, low-skill overhead to recognizing it as a strategic, data-rich process that can be optimized, automated, and fully integrated into the digital thread of manufacturing. The journey involves careful technological selection, meticulous process engineering, and deep software integration.

The payoff, however, is substantial: not merely labor savings, but a fundamental enhancement in the productivity of your most valuable assets—your CNC machine tools. You gain predictability, traceability, safety, and the agility to adapt to changing market demands. In today’s competitive landscape, the efficiency of the material flow between machines can be as great a differentiator as the machining capability within them.

Implementing such a system requires a partner who understands both the logistical challenges and the precision demands of a machining environment. At JLYPT, we combine our expertise in precision component manufacturing with a systems-thinking approach to help clients design and realize these integrated production ecosystems.

Ready to explore how intelligent material flow with AGV (Automated Guided Vehicle) systems can unlock the next level of efficiency in your workshop? Contact JLYPT to begin a strategic discussion. Discover our holistic approach to manufacturing solutions at JLYPT CNC Machining Services.