Automotive Prototyping and Testing: Accelerating Innovation Through Precision CNC Machining

The Critical Role of Prototyping in Automotive Development

The automotive industry faces unprecedented transformation as electrification, autonomous driving, and lightweighting initiatives demand faster development cycles and more sophisticated components. In this rapidly evolving landscape, precision prototyping has emerged as a critical bridge between conceptual design and mass production, enabling manufacturers to validate designs, assess functionality, and accelerate time-to-market. As a specialized CNC machining service provider, we’ve witnessed firsthand how advanced prototyping methodologies are reshaping automotive development timelines and outcomes.

The traditional approach to automotive prototyping often involved lengthy processes with high costs and limited flexibility. Today, forward-thinking manufacturers leverage integrated prototyping strategies that combine multiple technologies and expertise to create high-fidelity prototypes that accurately represent final production parts in form, fit, and function. This comprehensive guide explores the technical considerations, methodologies, and practical applications of automotive prototyping and testing, providing engineering professionals with actionable insights for their next development project.

Advanced CNC Technologies for Automotive Prototyping

Multi-Axis Machining Capabilities

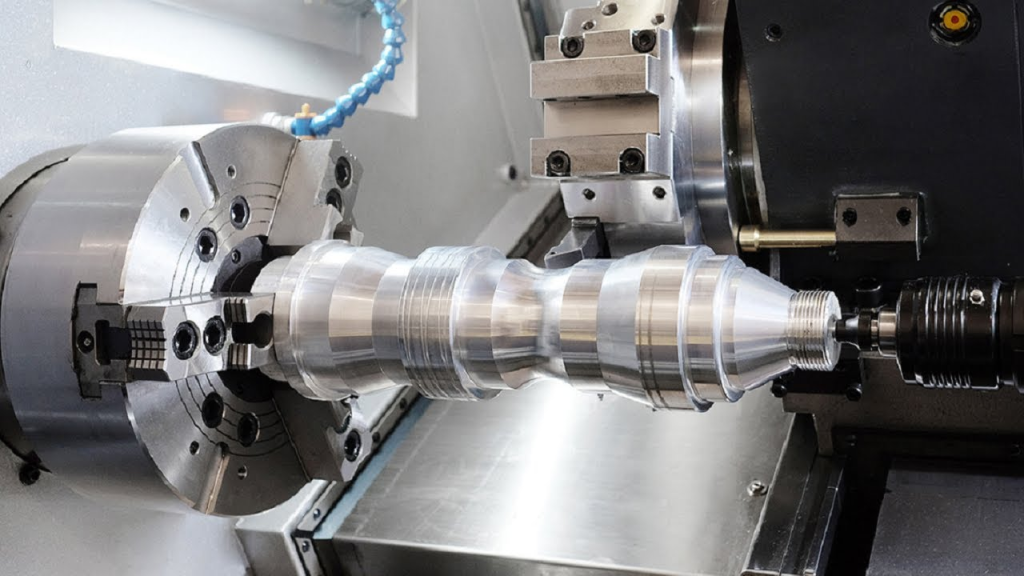

The evolution of multi-axis CNC systems has dramatically expanded possibilities for automotive component prototyping. Five-axis machining technology enables complete processing of complex geometries in single setups, eliminating cumulative errors associated with multiple repositioning operations and significantly reducing lead times.

As demonstrated by industry leaders, 5-axis CNC machining facilitates the production of complex components with tight tolerances and superior surface finishes . This capability is particularly valuable for automotive components with organic shapes, complex contours, or multiple compound angles that would be impractical to produce with conventional three-axis equipment. The technology has proven essential for everything from engine components and transmission parts to custom automotive accessories.

High-Speed Machining Strategies

Advanced toolpath strategies like dynamic milling and trochoidal machining have revolutionized the processing of both metallic and non-metallic automotive materials. These algorithms maintain constant tool engagement, reducing heat generation and extending tool life while enabling significantly higher material removal rates.

The implementation of high-speed machining strategies directly impacts prototyping efficiency. As noted by manufacturing specialists, “Our flexible approach allows us to adopt integrated manufacturing technologies and advanced facilities to manufacture on-demand automotive parts” . This acceleration in prototyping throughput directly translates to shorter development cycles and faster iteration—critical advantages in the competitive automotive landscape.

Materials Selection for Automotive Prototyping

Engineering-Grade Materials

Selecting appropriate materials is crucial for creating functional prototypes that accurately simulate production part performance. Automotive prototypes must often demonstrate similar mechanical properties, environmental resistance, and manufacturing characteristics as their production counterparts.

Table: Common Automotive Prototyping Materials and Applications

| Material Category | Specific Materials | Automotive Applications | Key Considerations |

|---|---|---|---|

| Aluminum Alloys | 6061, 7075 | Engine components, brackets, structural elements | Excellent strength-to-weight ratio, good machinability |

| Stainless Steels | 304, 316, 17-4PH | Exhaust components, fasteners, decorative trim | Corrosion resistance, strength, durability |

| Tool Steels | P20, H13 | Mold making for injection molding | Hardness, thermal stability, wear resistance |

| Engineering Plastics | ABS, Nylon, PEEK | Interior components, connectors, housings | Impact resistance, thermal properties, chemical resistance |

| High-Performance Alloys | Titanium, Inconel | High-stress engine components, exhaust systems | Extreme temperature performance, strength-to-weight ratio |

Leading prototyping providers offer extensive material options, with some supporting 120+ materials and 60+ surface finishing options to meet diverse needs from functionality to aesthetics . This material diversity ensures that prototypes can accurately replicate the performance characteristics of production components across various automotive systems.

Material Certification and Traceability

For safety-critical automotive components, material traceability is essential throughout the prototyping process. Reputable manufacturers provide comprehensive documentation including material certifications, test reports, and processing records that create a complete chain of custody from raw material to finished prototype.

As emphasized by quality-focused providers, “Our quality control process ensures that you obtain parts that meet your quality requirements at a low cost” . This documentation becomes increasingly important as prototypes progress through validation testing and approach production readiness.

Quality Assurance in Automotive Prototyping

Precision Measurement and Validation

Rigorous inspection protocols ensure automotive prototypes meet precise dimensional and quality requirements before testing begins. Advanced measurement technologies including coordinate measuring machines (CMM), optical comparators, and laser scanners verify critical dimensions on complex components.

Specialized automotive prototyping suppliers employ comprehensive inspection methodologies, with one noting they “use multiple quality documentation options to verify part geometry” . This commitment to measurement precision ensures that test results accurately reflect design performance rather than manufacturing variations.

Rapid Iteration Based on Test Results

The true value of functional prototyping emerges when test results inform rapid design improvements. Advanced CNC machining services support this iterative process by enabling quick modifications based on performance data, reducing overall development time and mitigating downstream production risks.

The advantage of rapid iteration is highlighted by providers who note their ability to complete prototyping within 1-3 days, particularly valuable for customers who need to “quickly verify designs and shorten R&D cycles” . This accelerated feedback loop enables automotive engineers to explore more design alternatives and optimize performance before committing to production tooling.

Automotive Prototyping Applications

Powertrain Components

Engine and transmission development represents one of the most demanding applications for automotive prototyping. These components typically require high-temperature materials, precise geometries, and exceptional durability under extreme operating conditions.

CNC machining enables the creation of functional powertrain prototypes that can undergo rigorous testing, including engine blocks, cylinder heads, transmission cases, and specialized components for electric vehicle powertrains. The ability to produce these parts from production-grade materials ensures accurate performance validation.

Chassis and Structural Components

Vehicle architecture components demand precise mechanical properties and structural integrity. Prototyping these elements requires careful material selection and manufacturing approaches that replicate production characteristics.

Suspension components, frame elements, and mounting systems all benefit from precision prototyping that validates not only dimensional accuracy but also mechanical performance under load. Advanced prototyping services leverage capabilities including 5-axis machining and high-speed milling to produce these structurally critical elements .

Interior and Exterior Systems

Automotive styling and ergonomics require prototypes that accurately represent both aesthetic and functional attributes. From interior control interfaces to exterior body components, these prototypes must demonstrate proper fit, finish, and usability.

The importance of aesthetic prototyping is demonstrated by companies specializing in automotive accessories, where development teams create prototypes to “verify model size and appearance” before production . This application highlights how prototyping bridges technical performance and user experience.

Case Studies: Automotive Prototyping Success Stories

Case Study 1: Electric Vehicle Battery Enclosure Development

Challenge: An electric vehicle manufacturer needed to develop and validate a new battery enclosure design with complex thermal management channels and stringent sealing requirements. The component required validation under various environmental and impact scenarios.

Solution: Implementation of a multi-stage prototyping approach utilizing 5-axis CNC machining to create the complex geometry from aluminum alloy. The process included:

-

Initial prototype for form and fit verification

-

Secondary iteration with functional cooling channels for thermal testing

-

Final pre-production prototypes for crash testing validation

Results: The prototyping process identified several design improvements that enhanced thermal performance and sealing reliability. The rapid iteration capability enabled the manufacturer to accelerate their development timeline by approximately 40% compared to traditional methods.

Case Study 2: Performance Braking System Component

Challenge: A automotive braking supplier required functional prototypes of a new caliper design for performance vehicles. The components needed to withstand extreme temperatures and pressures while maintaining precise dimensional stability.

Solution: Utilization of high-performance aluminum alloy and specialized CNC machining techniques to produce functional brake caliper prototypes. The approach included:

-

Precision machining of critical sealing surfaces

-

Implementation of strict process controls to ensure material integrity

-

Comprehensive measurement and documentation of all critical features

Results: The prototypes successfully underwent rigorous testing, validating the design’s thermal performance and structural integrity. The components met all performance requirements, allowing the customer to proceed directly to production tooling without design modifications.

Case Study 3: Advanced Driver Assistance Systems Housing

Challenge: An automotive technology company needed to develop protective housings for new sensor technology with precise mounting features and specific electromagnetic compatibility requirements.

Solution: Development of a rapid prototyping methodology that combined multiple manufacturing technologies. The process included:

-

CNC machining of primary housing components from engineered plastics

-

Integration of specialized shielding elements

-

Rapid iteration based on sensor performance testing

Results: The prototyping approach enabled quick refinement of the housing design to optimize sensor performance. The iterative process reduced development time by approximately 60% compared to traditional methods, accelerating the technology’s market introduction.

The Future of Automotive Prototyping

Digital Integration and Industry 4.0

The adoption of Industry 4.0 principles is transforming automotive prototyping through enhanced connectivity, data analytics, and digital workflow integration. These technologies support the creation of “digital twins” that simulate both manufacturing processes and component performance, reducing physical iteration requirements.

Advanced prototyping providers are implementing increasingly digital workflows, with some offering “online monitoring” of production status and “instant manufacturability feedback” that accelerates the design-to-part process . This digital transformation continues to reduce prototyping timelines while improving outcomes.

Hybrid Manufacturing Approaches

Combining additive and subtractive technologies represents an emerging trend in automotive prototyping, leveraging the strengths of each approach. While 3D printing enables complex internal geometries and lightweight structures, CNC machining provides superior surface finishes and tight tolerances on critical features.

The growing acceptance of hybrid approaches is reflected in the service offerings of leading providers, with many maintaining capabilities across multiple manufacturing technologies including CNC machining, 3D printing, and injection molding . This integrated approach allows optimal technology selection based on specific prototype requirements.

Conclusion: Strategic Advantages of Professional Automotive Prototyping

Automotive prototyping has evolved from a simple validation step to a strategic development tool that significantly impacts product quality, performance, and time-to-market. The integration of advanced CNC technologies with comprehensive testing methodologies creates a powerful framework for innovation across all automotive systems.

The case studies presented demonstrate that successful automotive prototyping requires more than advanced equipment—it demands technical expertise, material knowledge, and a systematic approach to validation. By partnering with experienced prototyping specialists, automotive engineers can accelerate development cycles, reduce program risks, and deliver superior products to market.

For your next automotive component project, consider how professional prototyping services can enhance your development process. The investment in high-fidelity prototypes typically returns significant value through optimized designs, reduced production issues, and accelerated commercialization.