Precision Engineered: Mastering Bespoke Parts Machining for the Luxury Automotive Sector

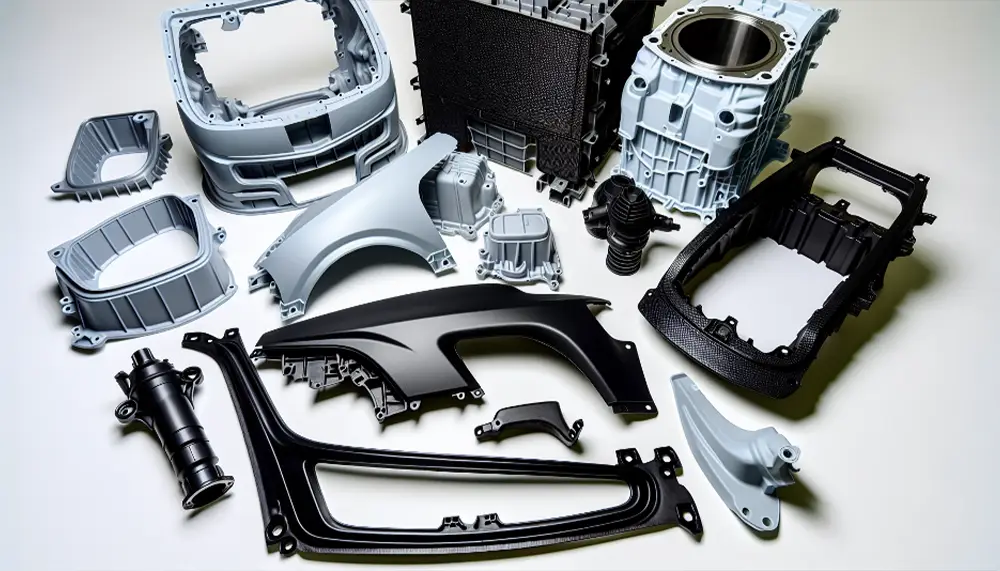

The luxury automotive sector represents the pinnacle of automotive engineering, where exceptional performance, exclusive design, and uncompromising quality converge. In this rarefied environment, standard components fall short of meeting the exacting standards demanded by discerning manufacturers and their clientele. At JLYPT CNC Machining, we have positioned ourselves at the forefront of bespoke parts machining for luxury automotive sector applications, combining artisanal craftsmanship with state-of-the-art manufacturing technologies to create components that embody automotive excellence.

This comprehensive analysis explores the sophisticated engineering methodologies, advanced manufacturing technologies, and uncompromising quality standards that define world-class bespoke parts machining for luxury automotive sector applications. We examine how the strategic implementation of multi-axis CNC technologies, coupled with material science expertise and rigorous validation protocols, enables the creation of automotive components that meet the extraordinary demands of luxury vehicle manufacturers.

The Engineering Imperatives of Luxury Automotive Manufacturing

Luxury automotive components must satisfy performance parameters that far exceed conventional automotive standards. Successful bespoke parts machining for luxury automotive sector applications requires addressing multiple critical challenges simultaneously:

Performance Under Extreme Conditions

Luxury vehicle components must deliver flawless performance across diverse operating environments:

-

Structural Integrity: Components must maintain dimensional stability and mechanical properties under extreme loads, temperatures, and vibration conditions encountered in high-performance driving

-

Thermal Management: Precision thermal characteristics for components operating in engine compartments, exhaust systems, and high-performance braking applications where temperatures can exceed 800°C

-

Acoustic Performance: Specific material selections and manufacturing techniques to achieve desired acoustic properties and vibration damping characteristics for superior cabin refinement

-

Long-Term Reliability: Exceptional durability and wear resistance to maintain performance throughout vehicle lifespan under demanding conditions while preserving aesthetic qualities

Aesthetic and Functional Excellence

Beyond mechanical performance, luxury components must satisfy stringent aesthetic requirements:

-

Surface Perfection: Mirror finishes, precise textures, and flawless visual surfaces for both visible and tactile components with surface roughness values below Ra 0.4 μm

-

Geometric Perfection: Complex curvature compliance and seamless integration with surrounding components with gap and flushness tolerances within ±0.1mm

-

Material Harmony: Strategic material selection to complement adjacent components and overall vehicle aesthetics while maintaining functional performance

-

Functional Elegance: Seamless integration of aesthetic appeal with operational functionality in controls, interfaces, and mechanical systems

Advanced Manufacturing Technologies for Luxury Applications

The extraordinary requirements of luxury automotive components demand specialized manufacturing approaches and equipment capabilities that define superior bespoke parts machining for luxury automotive sector production:

Multi-Axis CNC Machining Capabilities

Our advanced CNC infrastructure provides the foundation for precision manufacturing of luxury components:

-

5-Axis Simultaneous Machining: Complex 3D contouring and uninterrupted machining of sophisticated aerodynamic surfaces, structural elements, and architectural components with continuous toolpath optimization and minimal setup interventions

-

High-Speed Machining Strategies: Optimized toolpaths, cutting parameters, and advanced tooling for superior surface finishes, reduced machining times, and enhanced dimensional stability with spindle speeds exceeding 30,000 RPM

-

Precision Micro-Machining Expertise: Advanced manufacturing of small features, intricate details, and miniature components with tolerances within ±5 microns using specialized tooling applications and advanced CAM programming

-

Adaptive Machining Techniques: Dynamic adjustment of machining parameters based on real-time conditions, tool wear monitoring, and process optimization for consistent, high-quality results across production batches

Specialized Processes for Luxury Applications

Certain luxury components require highly specialized manufacturing approaches that elevate bespoke parts machining for luxury automotive sector to an art form:

-

Hard Material Machining: Precision processing of hardened steels (45-65 HRC), titanium alloys, and advanced composites while maintaining tight tolerances and superior surface finishes through specialized tooling and cooling strategies

-

Mirror Finishing Capabilities: Advanced polishing and surface treatment techniques to achieve exceptional visual and tactile surface quality with roughness values below Ra 0.1 μm for visible components

-

Non-Conventional Machining: Application of EDM, laser processing, and other advanced technologies for complex geometries and challenging materials that defy conventional machining approaches

-

Hybrid Manufacturing: Integration of additive and subtractive processes to create complex internal structures and optimized material distribution in performance-critical components

Material Selection for Luxury Automotive Applications

The performance, aesthetics, and longevity of luxury automotive components are profoundly influenced by appropriate material selection in bespoke parts machining for luxury automotive sector projects:

Advanced Metallic Materials

-

Aerospace-Grade Aluminum Alloys: Exceptional strength-to-weight ratios with superior thermal and electrical conductivity for structural and architectural components, with 7075-T651 and 6061-T6 being predominant choices

-

Titanium Alloys: Outstanding strength-to-weight characteristics, corrosion resistance, and premium aesthetic appeal for critical and visible components, particularly Ti-6Al-4V for its balanced properties

-

High-Performance Stainless Steels: Superior corrosion resistance, mechanical properties, and surface quality for functional and decorative applications, with 316L and 17-4PH being frequently specified

-

Specialty Alloys: Custom-engineered materials with specific mechanical, thermal, and aesthetic properties for specialized applications including Inconel for extreme temperature applications

Advanced Non-Metallic Materials

-

Engineering Composites: Carbon fiber and advanced composite materials offering exceptional stiffness-to-weight ratios and design flexibility for structural and aesthetic applications

-

High-Performance Polymers: Advanced engineering plastics with specific thermal, mechanical, and aesthetic properties including PEEK and PEI for underhood and interior applications

-

Exotic Materials: Implementation of rare and specialized materials for unique applications and extreme performance requirements including magnesium alloys and advanced ceramics

Technical Specifications for Luxury Automotive Applications

The table below details technical considerations for various luxury automotive component applications in bespoke parts machining for luxury automotive sector projects:

| Application Category | Critical Technical Requirements | Material Selection | Manufacturing Approach |

|---|---|---|---|

| Architectural Components | Structural integrity, aesthetic perfection, precise interfaces, weight optimization | Titanium alloys, Aluminum alloys, Composites | 5-axis machining of complex surfaces, micro-machining of details, specialized finishing processes |

| Performance Elements | Extreme temperature stability, wear resistance, dimensional precision under load | High-performance steels, Titanium, Special alloys | High-speed machining, thermal management, precision grinding, specialized heat treatments |

| Aesthetic Features | Surface perfection, complex geometries, material harmony, tactile quality | Aluminum, Stainless steel, Composites, Plastics | Mirror finishing, precision contouring, specialized coatings, texture matching |

| Functional Systems | Reliability under load, precise operation, longevity, maintenance of tolerances | Engineering alloys, Composites, Polymers | Precision machining, integrated assembly, rigorous testing, validation protocols |

For comprehensive understanding of automotive manufacturing standards and technical specifications in bespoke parts machining for luxury automotive sector, we regularly consult resources from ASME Automotive Engineering Standards to ensure compliance with industry requirements and technical excellence.

Comprehensive Case Studies: Luxury Automotive Manufacturing Solutions

Case Study 1: Architectural Console Component for Luxury SUV

-

Challenge: A luxury automotive manufacturer required a complex architectural console component integrating multiple functions with exceptional aesthetic appeal. The component needed to seamlessly integrate with surrounding elements while providing precise mounting for advanced electronic systems and maintaining structural integrity under daily use.

-

Technical Solution: We engineered the component from precision-machined aluminum with integrated titanium reinforcements. The design incorporated complex organic geometries with precise mounting features and cable management systems concealed within the architectural form, achieving perfect harmony between aesthetics and functionality.

-

Manufacturing Approach: The component was manufactured using 5-axis simultaneous machining strategies with adaptive toolpaths to maintain optimal surface finish across complex contours. Critical interfaces underwent precision micro-machining to ensure perfect integration with adjacent components, while specialized finishing processes achieved the required tactile and visual qualities.

-

Technical Outcomes: The component achieved perfect integration with surrounding elements while providing exceptional functionality. The surface finish exceeded automotive standards for visible components with Ra values below 0.3 μm, and the precise mounting features ensured flawless operation of integrated electronic systems throughout the vehicle’s lifespan.

Case Study 2: Performance Exhaust Component for High-Performance Vehicle

-

Challenge: A manufacturer of high-performance luxury vehicles required an exhaust component with exceptional thermal properties, structural integrity under vibration, and aesthetic appeal. The component needed to withstand extreme temperatures while maintaining precise dimensional stability and contributing to the vehicle’s acoustic signature.

-

Technical Solution: We developed the component using high-performance stainless steel with strategic titanium elements for thermal management and weight optimization. The design incorporated advanced thermal expansion compensation features and precision mounting interfaces, while computational fluid dynamics optimized exhaust flow characteristics.

-

Manufacturing Approach: The component was manufactured using specialized high-temperature machining strategies with integrated thermal stress management during processing. Critical sealing surfaces underwent precision grinding to ensure perfect sealing under thermal cycling conditions, while specialized welding techniques maintained material integrity in high-stress areas.

-

Technical Outcomes: The component demonstrated exceptional durability under extreme thermal cycling with zero failures in accelerated life testing exceeding 1000 hours. The precision manufacturing ensured perfect sealing and mounting integrity, while the aesthetic execution met the vehicle’s premium positioning and contributed to the desired exhaust note.

Case Study 3: Bespoke Interior Element for Limited Edition Vehicle

-

Challenge: A manufacturer creating a limited edition luxury vehicle required a signature interior element combining multiple exotic materials with perfect integration and exceptional tactile quality. The component needed to reflect the vehicle’s exclusive nature while providing precise functionality and maintaining durability under regular use.

-

Technical Solution: We engineered a complex assembly integrating machined aluminum, titanium accents, and composite elements. The design incorporated precise transitions between materials and hidden fixation elements to maintain clean visual lines, while ergonomic considerations ensured perfect human-machine interface characteristics.

-

Manufacturing Approach: Each material was processed using specialized techniques optimized for its specific characteristics. Precision machining ensured perfect interfaces between dissimilar materials, while specialized finishing techniques created harmonious surfaces across all elements. Advanced joining technologies maintained integrity across material boundaries without visible fasteners.

-

Technical Outcomes: The component achieved exceptional visual and tactile quality with perfect integration of diverse materials. The precision manufacturing resulted in seamless operation and enduring quality that reflected the vehicle’s exclusive character, with all interfaces maintaining perfection through validation testing equivalent to 10 years of use.

Quality Assurance for Luxury Automotive Applications

The development of luxury automotive components through bespoke parts machining for luxury automotive sector demands uncompromising validation methodologies:

-

Comprehensive Metrology: Advanced coordinate measurement, surface analysis, and form verification using state-of-the-art measurement technologies including 3D scanning and white light interferometry

-

Material Verification: Complete material certification, microstructure analysis, and mechanical properties validation to ensure compliance with automotive standards and specific performance requirements

-

Performance Testing: Functional testing under simulated operating conditions, including thermal cycling, vibration, and load testing to validate durability and performance under real-world conditions

-

Aesthetic Validation: Precise evaluation of surface quality, visual appeal, and tactile characteristics against stringent standards using both instrumental analysis and expert assessment

The Future of Luxury Automotive Manufacturing

The field of bespoke parts machining for luxury automotive sector continues to evolve with emerging technologies and methodologies:

-

Advanced Digital Integration: Comprehensive digital twin implementation and virtual validation of components and systems reducing development time and enhancing first-time quality

-

Sustainable Manufacturing: Implementation of environmentally conscious manufacturing approaches without compromising quality or performance, including energy-efficient processes and recyclable materials

-

Smart Manufacturing: Integration of advanced monitoring and optimization systems throughout the manufacturing process enabling real-time quality assurance and process optimization

-

Material Science Advancements: Development and implementation of new materials with enhanced properties and capabilities including smart materials and advanced composites

Conclusion: Excellence in Luxury Automotive Manufacturing

The creation of bespoke components for luxury automotive applications represents one of the most demanding domains of precision manufacturing. Success requires comprehensive expertise in engineering, materials science, manufacturing technologies, and quality assurance, combined with deep understanding of the unique requirements of luxury vehicles.

At JLYPT CNC Machining, our approach to bespoke parts machining for luxury automotive sector applications combines technical excellence with practical automotive manufacturing experience. We understand that luxury vehicles demand exceptional levels of performance, quality, and aesthetic appeal, and we have developed our capabilities and processes to meet these extraordinary demands. Our commitment to excellence in bespoke parts machining for luxury automotive sector ensures that every component we produce meets the highest standards of quality and performance.

Ready to enhance your luxury vehicle with precision-engineered components? Contact JLYPT CNC Machining today to discover how our expertise in bespoke parts machining for luxury automotive sector can help you achieve your performance, quality, and aesthetic objectives with components manufactured to the highest standards of excellence. Visit our CNC Machining Services page to learn more about our comprehensive capabilities.