Premium Black Anodize Service for Aluminum Parts: Complete Technical Guide for CNC Machined Components

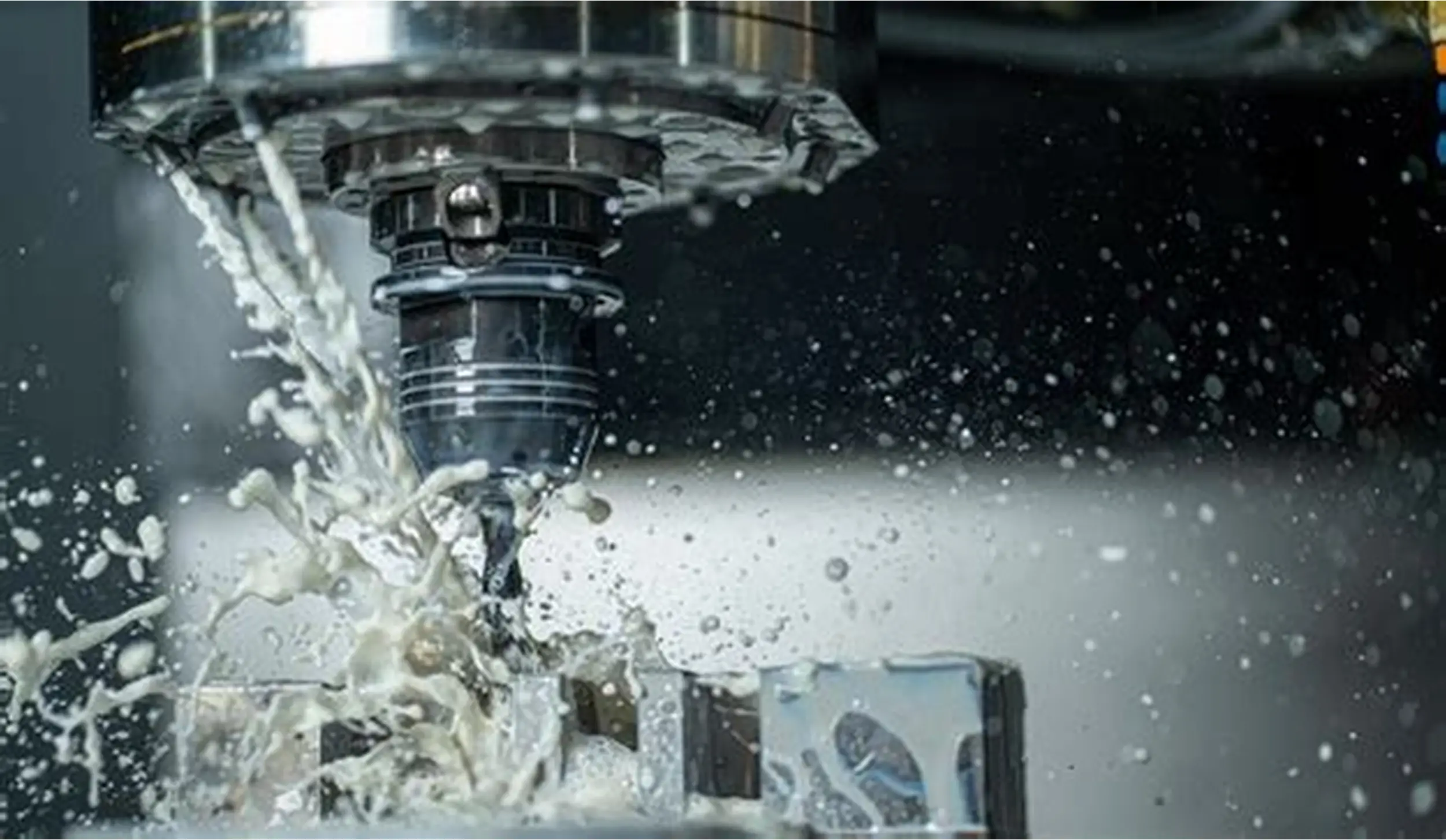

The demand for black anodize service for aluminum parts continues to surge across aerospace, automotive, medical device, and consumer electronics industries. At JLYPT, our advanced electrochemical anodizing capabilities transform precision CNC machined aluminum components into corrosion-resistant, wear-resistant, and aesthetically superior finished parts that meet the most stringent industry specifications.

Understanding Black Anodizing: Electrochemical Surface Transformation

Black anodizing represents a sophisticated electrochemical conversion process that fundamentally differs from paint or coating applications. When we perform our black anodize service for aluminum parts, we’re not applying a surface layer—we’re converting the aluminum’s surface structure itself into a durable anodic oxide layer infused with black dye molecules or organic pigments.

The anodizing process creates a porous aluminum oxide structure ranging from 5 to 25 microns for Type II anodizing and 25 to 150 microns for Type III hard coat anodizing. These microscopic pores, measuring 10-20 nanometers in diameter, absorb black dye through capillary action before sealing locks the colorant permanently within the crystalline oxide matrix. This architectural integration explains why anodized black finishes resist chipping, peeling, and fading far better than painted alternatives.

Critical Process Parameters for Black Anodized Aluminum

Our black anodize service for aluminum parts maintains strict control over multiple electrochemical variables:

Electrolyte Chemistry: We utilize sulfuric acid concentrations between 15-20% by volume, maintained at temperatures of 18-22°C (64-72°F). Temperature fluctuations beyond ±2°C compromise oxide layer uniformity and dye absorption characteristics.

Current Density Management: Type II anodizing requires current densities of 12-18 ASF (amps per square foot), while Type III hard coat demands 24-36 ASF with voltage ramping protocols. Our rectifier systems provide ±1% voltage stability to prevent burning or inconsistent oxide growth.

pH Control: Maintaining electrolyte pH between 0.5-1.5 ensures optimal oxide formation rates without excessive aluminum dissolution. We monitor pH continuously using automated titration systems.

Dyeing Parameters: Black dye bath temperatures of 55-65°C (131-149°F) with immersion times of 10-20 minutes achieve maximum color saturation. Dye concentration, typically 8-12 g/L, directly impacts final color depth and uniformity.

Technical Specifications: MIL-A-8625 Type II vs Type III Black Anodizing

Understanding specification differences helps customers select appropriate black anodize service for aluminum parts for their applications:

| Parameter | Type II Black Anodize | Type III Hard Coat Black |

|---|---|---|

| Coating Thickness | 0.0002″-0.001″ (5-25 µm) | 0.001″-0.004″ (25-100 µm) |

| Hardness (Vickers) | 200-350 HV | 400-600 HV |

| Abrasion Resistance | Moderate (Taber: 25-40 mg loss) | Excellent (Taber: 5-15 mg loss) |

| Corrosion Protection | 336-1000 hrs salt spray | 1000-3000 hrs salt spray |

| Dielectric Strength | 20-40 V/µm | 15-30 V/µm |

| Thermal Stability | Stable to 350°F (177°C) | Stable to 450°F (232°C) |

| Typical Applications | Consumer electronics, optics | Aerospace, military, hydraulics |

| Color Uniformity | ±ΔE 2.0 | ±ΔE 3.5 |

| Dimensional Change | +0.0001″ per surface | +0.0005″ per surface |

| Processing Time | 45-60 minutes total | 90-120 minutes total |

Our custom aluminum anodizing services at https://www.jlypt.com/custom-aluminum-anodizing-services/ accommodate both specifications with dedicated production lines optimizing each process variant.

Aluminum Alloy Compatibility for Black Anodizing

Not all aluminum alloys anodize identically. Our black anodize service for aluminum parts achieves optimal results with specific alloy families:

6061-T6 Aluminum: The industry workhorse for anodizing, 6061 produces uniform medium-gray to black finishes with excellent dye absorption. Its magnesium-silicon composition creates consistent oxide layers with minimal mottling. We recommend 6061 for architectural components, electronic enclosures, and general industrial applications requiring aesthetic consistency.

7075-T6 Aluminum: High-strength aerospace alloy with zinc-copper content that produces darker natural oxide before dyeing. The copper constituent can create slight color variations, typically ±ΔE 1.5-2.5 across large surface areas. Despite this, 7075’s superior mechanical properties make it essential for structural aerospace components, firearm receivers, and high-stress mechanical parts.

5052-H32 Aluminum: Magnesium-based alloy offering superior corrosion resistance in marine environments. Anodizes to lighter gray tones requiring heavier dye loading for true black appearance. We specify 5052 for marine hardware, chemical processing equipment, and coastal architectural applications.

2024-T3 Aluminum: Copper-rich alloy commonly used in aerospace structures but challenging for uniform black anodizing. Copper content above 4% creates yellow-brown tones in the oxide layer, requiring specialized pre-treatments and heavier black dye concentrations. We recommend alternative finishes for 2024 unless aerospace specifications mandate anodizing.

Alloy Selection Decision Matrix

| Alloy | Anodizing Ease | Color Uniformity | Best Applications |

|---|---|---|---|

| 6061-T6 | Excellent | ΔE <1.5 | General purpose, electronics |

| 7075-T6 | Good | ΔE 1.5-2.5 | Aerospace, high-strength |

| 5052-H32 | Good | ΔE 1.0-2.0 | Marine, corrosive environments |

| 2024-T3 | Fair | ΔE 2.5-4.0 | Aerospace structural (limited) |

| 6063-T5 | Excellent | ΔE <1.0 | Extrusions, architectural |

| Mic-6 Cast | Poor | ΔE >5.0 | Avoid for black anodizing |

Pre-Treatment Protocols for Superior Black Anodized Finishes

The foundation of exceptional black anodize service for aluminum parts begins before the anodizing tank. Our multi-stage pre-treatment sequence eliminates surface contaminants and creates optimal conditions for oxide formation:

Degreasing Stage: Alkaline soak cleaners at 65-75°C remove machining oils, coolants, and handling residues. We utilize low-silicate formulations preventing etch attack on aluminum while achieving surface energy levels above 40 dynes/cm.

Alkaline Etching: Sodium hydroxide solutions at 5-10% concentration and 50-60°C remove 2-5 microns of surface material, eliminating work-hardened layers from CNC machining and revealing fresh aluminum substrate. Etch rate control within ±0.5 µm ensures dimensional tolerance maintenance on precision parts.

Desmutting Treatment: Nitric acid solutions at 30-50% concentration and ambient temperature dissolve intermetallic compounds exposed during etching. This critical step prevents dark streaking and mottling in the final anodized finish, particularly important for high-silicon and high-copper alloys.

Deionized Water Rinsing: Multi-stage cascade rinse systems using <5 µS conductivity water prevent electrolyte contamination and ensure surface cleanliness. Our rinse protocols include ultrasonic agitation for complex geometries with blind holes or deep pockets.

The Complete Black Anodizing Process Workflow

Our black anodize service for aluminum parts follows this proven sequence for consistent, specification-compliant results:

1. Rack Configuration & Masking (15-30 minutes) CNC machined parts mount on titanium or aluminum racks using titanium contact points. Critical dimensions, threads, and mating surfaces receive PTFE tape or specialized masking plugs preventing anodic growth. Proper racking ensures uniform current distribution—parts positioned 4-6 inches apart prevent current shadowing.

2. Pre-Treatment Sequence (25-35 minutes) Following the cleaning protocol above, parts progress through automated conveyor systems maintaining precise immersion times and temperatures. Our facility processes 500-2000 square feet daily with full traceability.

3. Sulfuric Acid Anodizing (30-90 minutes depending on specification) Rectified DC current converts aluminum surface to aluminum oxide. Type II processing at 12-18 ASF for 30-45 minutes produces 0.0004-0.0008″ coating thickness. Type III hard coat at 24-36 ASF for 60-90 minutes achieves 0.002-0.004″ thickness with enhanced hardness properties.

4. Black Dye Immersion (10-20 minutes) Hot dye bath at 60°C absorbs organic black dye molecules into porous oxide structure. We utilize light-fast dyes meeting ASTM D4487 standards with minimum 500-hour QUV exposure resistance. Dye concentration and temperature control achieve ±ΔE 1.0 color consistency across production batches.

5. Sealing Process (20-30 minutes) Hot deionized water sealing at 95-100°C hydrates aluminum oxide, collapsing pores and permanently locking dye molecules. Our nickel acetate sealing option provides enhanced corrosion resistance for marine and chemical processing applications. Mid-temperature sealing at 80-85°C offers dimensional stability for tight-tolerance precision parts.

6. Quality Verification & Testing (15-20 minutes) Every batch undergoes colorimetric measurement using spectrophotometers measuring Lab* values. Coating thickness verification via eddy current gauges ensures specification compliance. Adhesion testing per ASTM D3359 and salt spray testing per ASTM B117 validate production quality.

Advanced Black Anodizing Variants for Specialized Applications

Beyond standard Type II and III processes, our black anodize service for aluminum parts includes specialized variants:

Matte Black Anodizing: Controlled electrolyte additives and modified current profiles create light-scattering surface textures reducing glare and reflectivity to <5% at 60° incidence. Aerospace optical components, tactical equipment, and camera housings benefit from this anti-reflective treatment.

Two-Step Color Anodizing: Initial electrolytic coloring using tin or nickel salts creates bronze undertones, followed by black dye overlay producing deep, rich black with enhanced UV stability. Architectural applications and high-end consumer products utilize this premium aesthetic treatment.

Laser-Enhanced Black Anodizing: Post-anodizing laser ablation creates permanent marks, serial numbers, or decorative patterns by selectively removing black dye while maintaining oxide integrity. Medical devices, aerospace components, and branded consumer products leverage this traceable marking technology.

Teflon-Impregnated Black Anodizing: Secondary treatment infusing PTFE particles into sealed anodic coating reduces friction coefficient to 0.05-0.10 while maintaining corrosion resistance. Precision mechanisms, sliding components, and wear surfaces gain self-lubricating properties without dimensional compromise.

Quality Control Standards for Black Anodize Service

JLYPT maintains comprehensive quality protocols ensuring every black anodize service for aluminum parts project meets customer specifications:

Coating Thickness Measurement: Eddy current gauges calibrated to NIST standards verify thickness at minimum 5 points per part. Statistical process control charts track thickness variation maintaining Cpk >1.67 for critical aerospace components.

Color Consistency Verification: X-Rite spectrophotometers measure Lab* color space values comparing production parts against approved master standards. We maintain ±ΔE 1.5 for Type II and ±ΔE 2.0 for Type III across production runs.

Corrosion Resistance Testing: Neutral salt spray chambers per ASTM B117 validate protective performance. Type II parts withstand minimum 336 hours, Type III minimum 1000 hours before Rating 8 corrosion per ASTM D1654.

Adhesion & Abrasion Testing: Cross-hatch adhesion testing per ASTM D3359 requires 5B rating (no coating removal). Taber abraser testing per ASTM D4060 documents wear resistance with maximum 15 mg loss per 1000 cycles for Type III hard coat.

Dielectric Breakdown Testing: High-voltage testing verifies electrical insulation properties critical for electronic enclosures. Our Type II anodizing withstands 500-1000 VDC without breakdown on 0.001″ coating thickness.

Engineering Considerations for CNC Parts Before Black Anodizing

Successful black anodize service for aluminum parts requires design-for-manufacturing awareness:

Dimensional Tolerance Adjustment: Anodizing grows coating equally inward and outward from original surface. Type II adds 0.0001-0.0005″ per surface; Type III adds 0.0005-0.002″ per surface. Critical dimensions require pre-anodizing compensation—we recommend machining holes 0.001″ oversize for Type II, 0.003″ oversize for Type III.

Thread Masking Requirements: Internal threads below 1/4″-20 and external threads requiring Class 2A or tighter tolerance need masking. We provide thread protection using custom-fitted silicone plugs or PTFE tape, though masking adds $5-15 per feature depending on complexity.

Surface Finish Optimization: CNC surface finish directly impacts anodized appearance. We recommend Ra 32-63 microinches for uniform matte black appearance. Polished surfaces below Ra 16 may show machining marks amplified by anodic oxide growth. Heavily textured surfaces above Ra 125 create inconsistent dye absorption.

Blind Hole & Pocket Design: Holes deeper than 3:1 depth-to-diameter ratio may trap process chemistry requiring extended rinsing. Pockets without drain paths accumulate electrolyte causing staining. We recommend 0.125″ minimum drain holes positioned at low points for optimal fluid evacuation.

Sharp Edge Treatment: Edges with radius <0.010″ burn during anodizing creating white or light gray appearance resisting dye penetration. We recommend 0.015-0.030″ chamfers or radii on all edges for consistent black appearance.

Industry-Specific Black Anodizing Applications

Our black anodize service for aluminum parts serves diverse sectors with specialized requirements:

Aerospace Components: MIL-A-8625 Type II and Type III compliance for aircraft structural components, actuator housings, and avionics enclosures. We maintain AS9100D certification with full material traceability and First Article Inspection reporting. Typical aerospace projects include 7075-T6 bulkheads with Type III hard coat black anodizing providing 0.002-0.003″ coating thickness for corrosion protection in coastal and marine environments.

Medical Device Manufacturing: Biocompatible anodizing for surgical instruments, implantable device components, and diagnostic equipment housings. Our Class 100,000 cleanroom anodizing prevents particulate contamination while meeting ISO 13485 medical device standards. Black anodized aluminum surgical tool handles resist chemical sterilization while providing non-reflective surfaces reducing operating room glare.

Consumer Electronics: Premium aesthetic finishes for smartphone housings, laptop enclosures, camera bodies, and wearable device cases. We achieve ±ΔE 0.8 color consistency across 10,000+ unit production runs using automated spectrophotometric process control. Touch-surface components receive sealed Type II anodizing with 450+ Knoop hardness resisting wear from daily handling.

Automotive Performance Parts: Lightweight engine components, suspension elements, and interior trim pieces benefit from corrosion resistance and thermal stability. Type III hard coat black anodizing on 6061-T6 brake calipers withstands 400°F operating temperatures while maintaining dimensional stability and aesthetic appearance through 100,000+ mile service life.

Optical & Photographic Equipment: Matte black anodizing with <3% reflectivity at 550nm wavelength eliminates internal reflections in lens barrels, microscope bodies, and telescope components. Our specialized process controls surface roughness Ra 40-60 microinches creating ideal light-trapping texture without compromising dimensional tolerances on precision optical mounting surfaces.

Cost Optimization Strategies for Black Anodizing Projects

Understanding black anodize service for aluminum parts pricing helps optimize project budgets:

Batch Processing Economics: Minimum batch charges apply for small quantities—combining multiple part numbers in single production run reduces per-piece cost 40-60%. We accommodate mixed batches when parts share alloy type and anodizing specification.

Masking Complexity Impact: Simple geometric parts without masking requirements cost 0.15−0.40persquareinch.Complexpartsrequiringthreadmasking,tight−toleranceareas,orselectiveanodizingadd0.15−0.40persquareinch.Complexpartsrequiringthreadmasking,tight−toleranceareas,orselectiveanodizingadd15-75 per part in masking labor. Design parts minimizing masking needs whenever possible.

Lead Time Flexibility: Standard 7-10 business day turnaround accommodates batch consolidation reducing processing costs. Expedited 3-5 day service available at 50% premium for urgent projects. Planning production schedules allowing standard lead times maximizes cost efficiency.

Specification Selection: Type II black anodizing costs 30-40% less than Type III hard coat due to shorter processing time and lower energy consumption. Specify Type III only when hardness, abrasion resistance, or corrosion protection exceed Type II capabilities.

Real-World Case Studies: Black Anodize Service Success Stories

Case Study 1: Aerospace Drone Component Manufacturer

Challenge: California-based UAV manufacturer required Type III hard coat black anodizing for 7075-T6 aluminum structural components experiencing salt spray exposure during coastal surveillance operations. Previous supplier delivered inconsistent coating thickness (0.0015-0.004″ range) causing assembly interference and requiring expensive hand-fitting.

JLYPT Solution: Our engineering team implemented statistical process control maintaining coating thickness 0.0025″ ±0.0002″ through automated thickness monitoring every 15 minutes during anodizing. Pre-anodizing dimensional compensation machining allowed direct assembly without secondary operations.

Results:

- Coating thickness uniformity improved to Cpk 2.1 (from 0.8)

- Assembly time reduced 45% eliminating hand-fitting

- Salt spray resistance exceeded 2500 hours (specification: 1000 hours)

- Customer consolidated three component families into our black anodize service for aluminum parts saving 23% annually

Technical Details: 72 unique part numbers ranging 0.5-18″ length processed in weekly batches of 500-1200 pieces. Implemented custom rack fixtures ensuring 6″ minimum part spacing preventing current shadowing on complex geometries. Post-sealing dimensional verification using CMM confirmed <0.0003″ deviation from nominal across critical interfaces.

Case Study 2: Medical Surgical Instrument Supplier

Challenge: Medical device manufacturer needed biocompatible black anodizing for 6061-T6 aluminum surgical retractor handles meeting FDA material requirements. Existing anodizing showed color variation ΔE 3.5-5.0 across production lots causing customer complaints about mismatched instrument sets.

JLYPT Solution: Upgraded to automated dye bath temperature control ±0.5°C (previously ±3°C) and implemented in-line spectrophotometric monitoring measuring Lab* values every 50 parts. Established approved color master standard with L*=18, a*=0, b*=-1 requiring production parts within ΔE 1.0.

Results:

- Color consistency improved to ΔE 0.6 average across batches

- Zero customer complaints over 18-month production period

- Passed FDA 510(k) biocompatibility testing including cytotoxicity, sensitization, and irritation studies

- Instrument sets achieved visually imperceptible color matching

Technical Details: Monthly production volume 2,000-3,500 retractor handles in 4 size variants. Implemented lot-coded traceability system linking each instrument to specific anodizing batch with archived spectrophotometer data. Validated cleaning protocols ensuring <10 µg/cm² residual organic contamination meeting medical device surface cleanliness standards.

Case Study 3: High-End Camera Equipment Brand

Challenge: Japanese camera manufacturer required ultra-matte black anodizing for 6063-T5 aluminum lens barrel extrusions with <2% reflectivity at 550nm wavelength. Standard black anodizing produced 8-12% reflectivity causing internal flare in telephoto lens designs.

JLYPT Solution: Developed proprietary two-stage anodizing process: initial 15-minute low-current density cycle creating rough oxide structure, followed by standard anodizing and heavy black dye loading. Post-seal micro-bead blasting with 220-grit aluminum oxide further reduced surface reflectivity.

Results:

- Reflectivity reduced to 1.8% at 550nm (specification: <2%)

- Surface roughness Ra 55 microinches created ideal light-trapping texture

- Maintained dimensional tolerance ±0.002″ on 0.625″ ID lens mounting surfaces

- Customer awarded 5-year supply contract for 12 lens barrel variants

Technical Details: Complex extrusion profiles with internal stepped diameters required custom rack fixtures preventing electrolyte trapping. Implemented ultrasonic agitation during rinsing reducing rinse water consumption 60% while improving chemistry removal from deep recesses. Optical testing using integrating sphere photometer validated reflectivity specification compliance on every production batch.

Environmental Compliance & Sustainability in Black Anodizing

Our black anodize service for aluminum parts maintains strict environmental stewardship:

Closed-Loop Water Recycling: Reverse osmosis systems recover 85% of rinse water for reuse, reducing municipal water consumption to <500 gallons per 1000 square feet processed. Concentrated rinse water feeds evaporators recovering aluminum sulfate for resale as industrial coagulant.

Sulfuric Acid Recovery: Spent anodizing electrolyte undergoes ultrafiltration removing dissolved aluminum before acid concentration adjustment and tank return. We recover 92% of sulfuric acid reducing virgin acid purchases and disposal costs.

Zero Chromium Chemistry: Unlike traditional sealing processes using hexavalent chromium, our nickel acetate and hot water sealing eliminates Cr(VI) exposure risks. All chemistry selections comply with RoHS, REACH, and California Proposition 65 requirements.

Energy Optimization: Variable-frequency drive rectifiers reduce electrical consumption 30% compared to transformer-based systems through power factor optimization and reactive load compensation. Heat recovery from rectifier cooling provides dye bath heating reducing natural gas consumption.

Selecting the Right Black Anodize Service Partner

When evaluating black anodize service for aluminum parts providers, consider these critical factors:

Certification & Compliance: Verify ISO 9001 quality management, AS9100 aerospace certification if applicable, and NADCAP accreditation for special processes. Request certificate copies and audit records demonstrating active certification status.

Process Control Capabilities: Tour facilities examining automated process control systems, statistical process control implementation, and real-time monitoring equipment. Manual operations without automated controls cannot achieve aerospace-grade consistency.

Testing & Validation: Confirm in-house testing capabilities including coating thickness measurement, salt spray chambers, adhesion testing, and colorimetric measurement. External lab dependence delays quality verification and increases costs.

Material Traceability: Review documentation systems tracking material certifications, processing parameters, and test results for every production batch. Medical and aerospace applications require complete traceability from raw material through finished part.

Technical Support: Evaluate engineering support capabilities including design-for-manufacturing guidance, specification interpretation, and failure analysis expertise. Reactive vendors waiting for problems differ from proactive partners preventing issues.

JLYPT’s custom aluminum anodizing services at https://www.jlypt.com/custom-aluminum-anodizing-services/ combine advanced process control, comprehensive testing, and experienced engineering support ensuring your black anodizing projects achieve specification compliance and production efficiency.

Conclusion: Maximizing Value from Black Anodize Service

Strategic implementation of black anodize service for aluminum parts delivers measurable benefits across product performance, manufacturing efficiency, and total cost of ownership. Understanding electrochemical fundamentals, specification requirements, and design optimization enables informed decisions maximizing anodizing value.

Our facility processes 15,000-25,000 square feet monthly across aerospace, medical, consumer electronics, and industrial sectors. This production volume supports economies of scale while maintaining flexibility for prototype and low-volume specialty projects.

Whether you require MIL-A-8625 Type II for consumer products, Type III hard coat for aerospace structures, or specialized variants like matte black or laser-markable anodizing, JLYPT’s comprehensive capabilities and technical expertise ensure successful project execution.

Contact our applications engineering team for design review, specification consultation, and project quotation. We provide detailed manufacturing analysis including dimensional compensation recommendations, masking requirements, and cost optimization strategies tailored to your specific application.

Ready to start your black anodizing project? Request a quote today for premium black anodize service for aluminum parts backed by AS9100D certification, comprehensive testing, and experienced technical support. Visit https://www.jlypt.com/custom-aluminum-anodizing-services/ or contact our engineering team at [your contact information].

Related Services:

- Precision CNC Machining – Pre-anodizing component manufacturing

- Custom Aluminum Anodizing – Complete finishing solutions

- Quality Inspection Services – Third-party verification and testing

Industry Resources:

- ASTM B580 – Standard Specification for Anodic Oxide Coatings on Aluminum

- MIL-A-8625 – Military Specification for Anodic Coatings for Aluminum and Aluminum Alloys

- AMS 2469 – Aerospace Material Specification for Hard Anodic Coatings