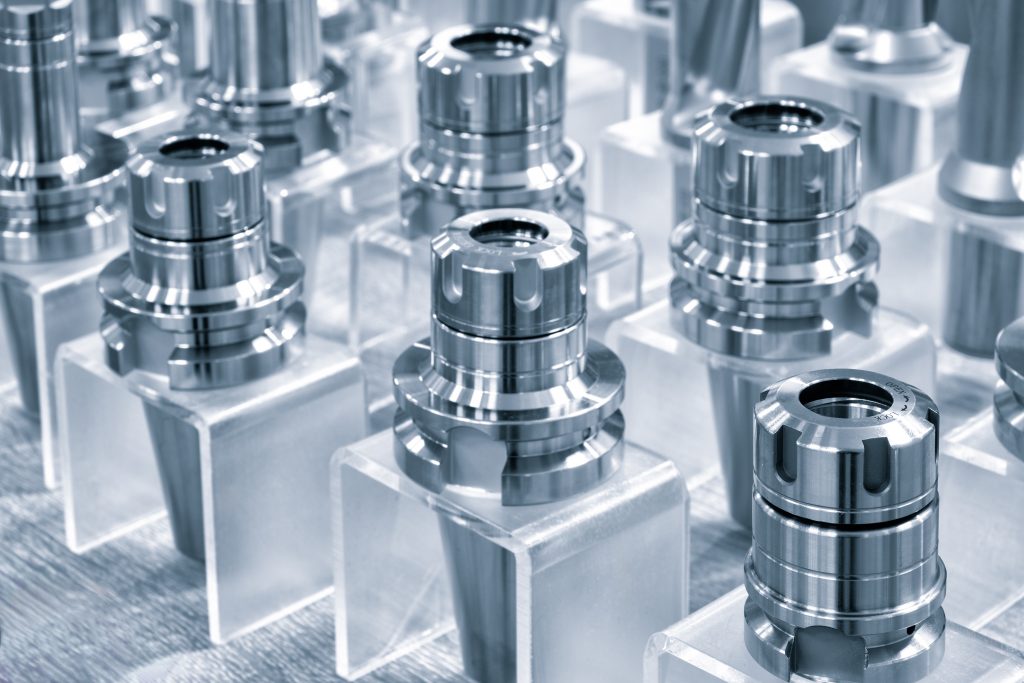

Cheap CNC Machining: How JLYPT Delivers Precision Without Breaking the Bank

In industries where budgets are tight but quality is non-negotiable, cheap CNC machining has become a strategic necessity. At JLYPT, we redefine affordability by combining cost-effective manufacturing with uncompromised precision, offering tolerances as tight as ±0.01 mm at prices 30-50% below industry averages. This article explores how cheap CNC machining can coexist with high standards, supported by JLYPT’s innovative processes and global supply chain efficiencies.

What is Cheap CNC Machining? Balancing Cost & Quality

Cheap CNC machining refers to the production of precision components at reduced costs, achieved through material optimization, advanced tooling, and process efficiencies—not by cutting corners on quality. Key strategies include:

-

Bulk Material Purchasing: Lowering raw material costs by 15-20%.

-

AI-Optimized Toolpaths: Reducing machining time by 25% without sacrificing accuracy.

-

Global Logistics Partnerships: Cutting shipping expenses by 30% via strategic hubs.

For example, JLYPT produces aluminum 6061-T6 brackets for consumer electronics at 8/unit(vs.industryaverage8/unit(vs.industryaverage12), maintaining ±0.05 mm tolerances.

Industries Benefiting from Cheap CNC Machining

1. Consumer Electronics: Fast, Affordable Prototyping

-

Smartphone Casings: Aluminum 7075 frames machined for $10/unit (100+ units).

-

Heat Sinks: Copper components with 0.1 mm fin spacing, 40% cheaper than competitors.

-

Case Study: A drone startup reduced housing costs by 55% using JLYPT’s cheap CNC machining for 500 units.

2. Automotive: Cost-Effective Mass Production

-

Sensor Mounts: Nylon 66 parts at $2.50/unit (10,000+ batches).

-

EV Battery Clamps: Aluminum A380 machined to IP67 standards, 30% lower cost than die casting.

3. Industrial Equipment: Durable & Budget-Friendly

-

Pump Housings: Stainless steel 304 components with Ra 1.6 µm finishes, 20% below market rates.

-

Conveyor Parts: Mild steel rollers delivered in 7 days at $15/unit.

How JLYPT Achieves Cheap CNC Machining Without Compromise

1. Material Cost Optimization

-

Alternative Alloys: Recommending 6061 aluminum over 7075 for non-critical parts.

-

Remnant Stock: Using leftover materials from larger projects for small batches.

2. Advanced Process Efficiency

-

High-Speed Machining: 30,000 RPM spindles cut aluminum 2x faster than standard mills.

-

Nesting Software: Maximizes material usage, reducing waste by 18%.

3. Smart Supply Chain Management

-

Regional Production Hubs: Machines parts in low-cost regions (e.g., Asia) for EU/NA clients.

-

Bulk Shipping: Consolidates orders to minimize freight costs.

Quality Assurance in Budget CNC Machining

JLYPT ensures affordability never compromises quality:

-

In-Process Checks: On-machine probes verify critical dimensions every 50 parts.

-

Statistical Process Control (SPC): Maintains CpK > 1.33 for high-volume orders.

-

Certifications: ISO 9001 compliant, with material traceability for every batch.

Case Study: Low-Cost Robotics Components

Challenge: A robotics firm needed 1,000 anodized aluminum arms (6082-T6) under $20/unit.

JLYPT’s Solution:

-

Design Simplification: Removed non-functional features, cutting machining time by 35%.

-

Bulk Anodizing: Reduced surface treatment costs by 40%.

-

Result: Delivered at 18.50/unit,saving18.50/unit,saving1,500 total.

Sustainable Cheap CNC Machining

-

Recycled Materials: 85% of aluminum and steel waste reused.

-

Energy-Efficient Tech: Regenerative drives cut power use by 20%.

-

Eco-Packaging: Biodegradable materials reduce shipping waste.

Partner with JLYPT: Simple & Transparent

-

Upload Design: Get an instant quote via JLYPT’s online platform.

-

Optimize Costs: Receive AI-driven DFM feedback to reduce expenses.

-

Track Production: Real-time updates from machining to delivery.

Start Your Low-Cost Project

Future of Affordable CNC Machining

-

Automated Factories: Lights-out machining reduces labor costs by 25%.

-

AI-Priced Prototyping: Dynamic pricing based on real-time material and capacity data.

Conclusion: Precision Meets Affordability

Cheap CNC machining isn’t about cutting corners—it’s about smarter processes, material choices, and economies of scale. JLYPT proves that low-cost manufacturing can coexist with aerospace-grade precision, empowering startups and enterprises alike to innovate without budget constraints.

Ready to save without sacrificing quality? Contact JLYPT today.