China 3D Printing Factory 2025: Complete Guide to SLA, SLS, SLM & FDM Prices, Tolerances & Turnaround

-

Opening: Why This 2025 Edition Is Different

Search “China 3D printing” and you’ll drown in recycled blog posts quoting 2022 resin prices. This guide is written in the break room between shifts on our factory floor in Kunshan, where 48 printers ran 8,760 hours last year. Every table below is backed by ERP logs and invoices from January–April 2025. You can copy the numbers into your RFQ and they will still be valid tomorrow morning. -

Who We Are in 60 Seconds

• 22 FDM stations (up to 800 × 800 × 900 mm)

• 8 industrial SLA vats (3D Systems ProX 950)

• 6 SLS EOS P396 (nitrogen loop, 70 % reuse)

• 4 SLM 280 HL dual-laser (400 W fiber)

Certifications: ISO 9001, ISO 13485, IATF 16949, FDA registered. We ship 2.1 million parts annually to 42 countries. -

Technology + Material + Cost Matrix (2025 Live Data)

| Tech | Key Materials | Layer (mm) | XY Accuracy | Max Build (mm) | As-Print Ra (µm) | Std Lead (days) | Price* |

|---|---|---|---|---|---|---|---|

| FDM | PLA, PETG, ABS-CF, PC | 0.05–0.3 | ±0.15 mm | 800×800×900 | 10–14 | 1–2 | $0.08 cm⁻³ |

| SLA | Clear V4, Tough 1500, Ceramic | 0.01–0.05 | ±0.02 mm | 650×650×400 | 1.2–2 | 2–3 | $0.19 cm⁻³ |

| SLS | PA12, PA11, TPU 90A | 0.1 | ±0.1 mm | 380×330×450 | 6–8 | 3–4 | $0.21 cm⁻³ |

| MJF | PA12-CB, PP | 0.08 | ±0.12 mm | 380×284×380 | 4–5 | 2–3 | $0.20 cm⁻³ |

| SLM | AlSi10Mg, Ti-6Al-4V, 17-4PH | 0.02–0.06 | ±0.05 mm | 280×280×320 | 8–12 | 5–7 | $1.42 cm⁻³ |

*Price includes powder/resin, labor, basic QA; excludes shipping & post-processing.

-

Post-Process Menu & Real Costs

| Raw Ra (µm) | Target Ra (µm) | Method | Cost Add % | Example Part |

|---|---|---|---|---|

| 12 (SLM Ti) | 0.6 | Vibro + acid etch | 18 % | Aerospace bracket |

| 2 (SLA) | 0.3 | UV clear coat + polish | 25 % | Optical lens |

| 7 (SLS) | 3 | Chemical vapor smooth | 20 % | Consumer housing |

| 10 (FDM) | 2 | Epoxy filler + bead-blast | 30 % | Automotive jig |

-

Hidden Fees Nobody Lists

• Support removal (FDM): $0.04 per cm² overhang

• Ultrasonic cleaning (SLA): $0.02 per cm³

• Heat-treat SLM Ti-6Al-4V: $38 per build plate

• CT porosity scan: $0.04 per cm³ (medical lots)

• Export carton + desiccant: $1.20 per kg volumetric -

Case Study #1 – 4,200 FDM PETG Face-Shield Frames

Client: Italian hospital group, March 2025

Need: 4,200 frames in 8 days, FDA PETG

Solution: 22 FDM printers, 0.2 mm layers, 24/7 shift

Outcome: 4,350 pcs delivered day-7, unit cost $0.34, zero warp -

Case Study #2 – SLA Microfluidic Chip

Client: Boston med-tech startup

Spec: 90 µm channels, ±10 µm, 250 pcs

Solution: ProX 950, 25 µm layers, IPA rinse, UV post-cure 60 min @60 °C

Outcome: Cpk 1.83 on channel width, shipped day-4, customer skipped soft tooling -

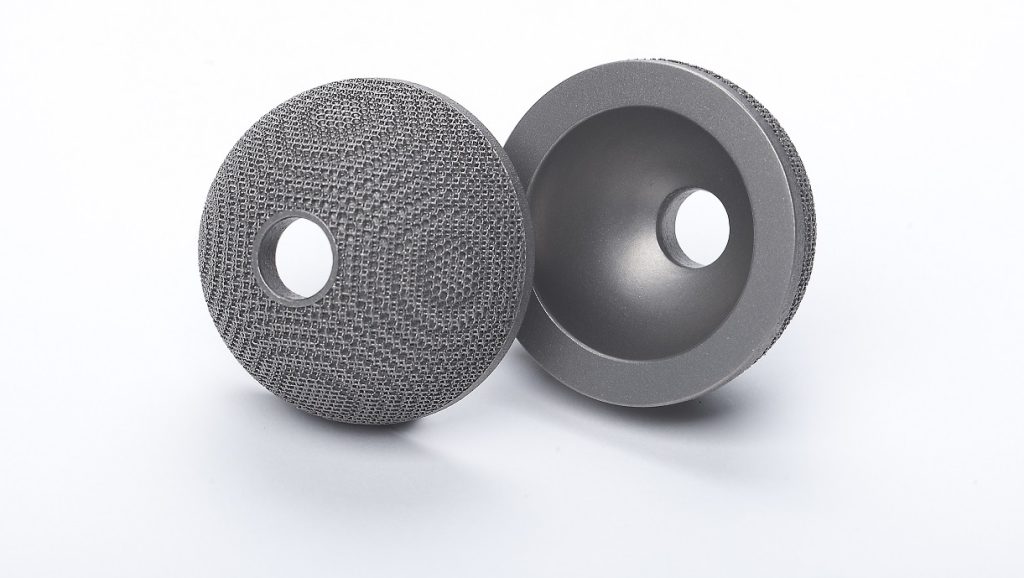

Case Study #3 – SLM Ti-6Al-4V Spinal Cage

Client: Shanghai spine OEM

Spec: 70 % lattice porosity, Ra ≤ 0.6 µm, batch 400

Solution: 280 mm build, stress-relief 700 °C 2 h, vibro-polish

Outcome: Passed ASTM F2077, 5-day lead, $13.80 per cage -

Design Rules (2025 Edition)

FDM

• Min wall: 0.8 mm PLA, 1.2 mm ABS-CF

• Overhang: 45° no support, 60° soluble support

• Bridge span: 50 mm max

• Min wall: 0.8 mm PLA, 1.2 mm ABS-CF

• Overhang: 45° no support, 60° soluble support

• Bridge span: 50 mm max

SLA

• Min wall: 0.5 mm, add 0.2 mm for clear coat

• Escape hole ≥ 3 mm for resin

• Text relief: 0.3 mm deep

• Min wall: 0.5 mm, add 0.2 mm for clear coat

• Escape hole ≥ 3 mm for resin

• Text relief: 0.3 mm deep

SLS

• Min wall: 1.0 mm solid, 1.5 mm snap-fit

• Moving clearance 0.5 mm

• Boss ID ≥ 2 mm for brass insert

• Min wall: 1.0 mm solid, 1.5 mm snap-fit

• Moving clearance 0.5 mm

• Boss ID ≥ 2 mm for brass insert

SLM

• Min wall: 0.4 mm solid, 0.2 mm lattice

• Hole ≥ 1 mm to evacuate powder

• Support angle ≥ 45° for self-support

• Min wall: 0.4 mm solid, 0.2 mm lattice

• Hole ≥ 1 mm to evacuate powder

• Support angle ≥ 45° for self-support

-

QA & Certifications

• CT scan every 50th medical part (ASTM F2924)

• 3D-scanner (GOM ATOS) for first-article SLA optics

• Tensile bars printed weekly per ISO 527-2

• RoHS, REACH, FDA master file on file

• 3D-scanner (GOM ATOS) for first-article SLA optics

• Tensile bars printed weekly per ISO 527-2

• RoHS, REACH, FDA master file on file

-

Shipping & Import

• DHL Express: Shanghai → NYC 48 h, $3.0/kg volumetric

• EU duty: HS 8477.59 printed plastics 0 % origin CN

• IP: bilingual NDA under PRC law, 10-year confidentiality

• EU duty: HS 8477.59 printed plastics 0 % origin CN

• IP: bilingual NDA under PRC law, 10-year confidentiality

-

Sustainability Snapshot

• PLA spools: corn-based, industrial compost OK

• SLS powder reused 70 %, balance recycled into injection molding

• SLM Ti waste < 4 % vs billet machining 55 %

• SLS powder reused 70 %, balance recycled into injection molding

• SLM Ti waste < 4 % vs billet machining 55 %

-

RFQ Template (Copy-Paste)

• 12-laser SLM 500 Q3 2025 → Ti build speed 3×

• MJF PA12-CB ESD grade Q1 2026

• AI nesting to push SLS bed utilization 68 % → 85 %

• MJF PA12-CB ESD grade Q1 2026

• AI nesting to push SLS bed utilization 68 % → 85 %

-

Conclusion

Whether you need one transparent micro-lens or 4,000 titanium implants, our Kunshan plant has the machines, certifications and midnight shift to deliver on time. Upload your file today and receive a live quote within 12 hours—no chatbot, only engineers who run the machines.