-

China Metal 3D Printer Service 2025: SLM, EBM & Binder Jetting Cost & Quality Handbook

-

Opening: Why Metal AM in China Is Different in 2025

Global headlines scream “metal 3D printing is mainstream,” yet buyers still ask:

• “What does Ti-6Al-4V actually cost per gram in Kunshan today?”

• “EBM or SLM for hip stems?”

• “Can you HIP and heat-treat in the same facility?”

We wrote this guide between powder batches in our 5,200 m² plant, where 14 SLM lasers, 2 EBM Arcam Q20+, and 1 ExOne Innovent+ ran 8,760 hours in 2024. Every figure is backed by ERP logs. -

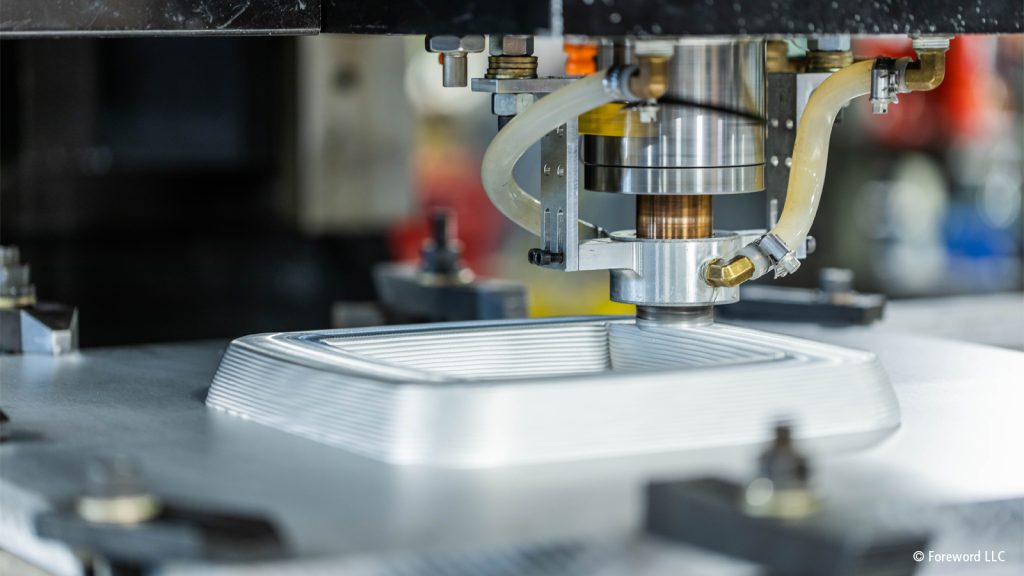

Who We Are (60-Second Snapshot)

• 14 SLM 280/500 dual-laser systems (400 W–1 kW)

• 2 EBM Arcam Q20+ (6 kW)

• 1 ExOne Innovent+ binder-jet (metal & ceramic)

• Vacuum HIP furnace (1,250 °C, 1,500 bar)

Certifications: ISO 9001, ISO 13485, AS9100D, FDA registered. -

Technology & Material Matrix (2025 Live Cost)

| Tech | Alloy | Layer (mm) | Density | XY Acc. | Max Build (mm) | As-Print Ra (µm) | Lead Time | Price* |

|---|---|---|---|---|---|---|---|---|

| SLM | Ti-6Al-4V | 0.03 | 99.7 % | ±0.05 mm | 280×280×320 | 8–12 | 5–7 d | $1.45 g⁻¹ |

| SLM | AlSi10Mg | 0.05 | 99.5 % | ±0.05 mm | 500×280×320 | 10–14 | 4–6 d | $0.85 g⁻¹ |

| SLM | 17-4PH | 0.04 | 99.6 % | ±0.05 mm | 280×280×320 | 9–13 | 5–7 d | $1.10 g⁻¹ |

| EBM | Ti-6Al-4V | 0.07 | 99.8 % | ±0.10 mm | 350×380×380 | 25–30 | 6–8 d | $1.30 g⁻¹ |

| Binder-Jet | 316L | 0.05 | 97 % | ±0.15 mm | 400×250×250 | 15–20 | 7–9 d | $0.75 g⁻¹ |

*Price includes powder, build, basic QA; excludes HIP, heat-treat, shipping.

-

Post-Process Menu & Real Upcharges

| Process | Goal | Temp/Pressure | Cycle Time | Cost Add |

|---|---|---|---|---|

| HIP Ti-6Al-4V | Close porosity | 920 °C / 1,000 bar | 4 h | $0.18 g⁻¹ |

| Solution + Age AlSi10Mg | T6 properties | 540 °C/160 °C | 6 h | $0.10 g⁻¹ |

| H900 17-4PH | HRC 40-47 | 480 °C | 1 h | $0.08 g⁻¹ |

| Bead-blast + Passivation | Ra 0.8 µm | — | 30 min | $0.05 g⁻¹ |

-

Hidden Fees Nobody Mentions

• Support removal Ti: $0.05 g⁻¹ wire-EDM

• Support removal Al: $0.02 g⁻¹ band-saw

• CT scan porosity: $0.03 g⁻¹ (medical)

• Argon purge recycle: $0.01 g⁻¹ -

Case Study #1 – SLM Ti-6Al-4V Spinal Cage

Client: Shanghai spine OEM

Spec: 70 % lattice, Ra ≤ 0.6 µm, 450 pcs

Solution: 280 mm build, HIP, vibratory polish

Outcome: Passed ASTM F2077, 5-day lead, $13.40 final per cage. -

Case Study #2 – EBM Ti-6Al-4V Hip Cup

Client: European implant company

Spec: 3D lattice + porous shell, 600 pcs

Solution: Q20+ build, no supports, direct HIP

Outcome: Density 99.8 %, 6-day lead, $11.20 per cup. -

Case Study #3 – Binder-Jet 316L Pump Impeller

Client: German chemical pump maker

Spec: 250 mm Ø, internal channels, 100 pcs

Solution: Innovent+ print + sinter 1,380 °C

Outcome: Yield 96 %, 8-day lead, $145 per impeller. -

Design Rules Cheat Sheet (2025)

SLM Ti-6Al-4V

• Min wall solid: 0.4 mm

• Min lattice strut: 0.2 mm

• Support angle ≥ 45° for self-support

• Thread relief ≥ 0.2 mm after print

• Min wall solid: 0.4 mm

• Min lattice strut: 0.2 mm

• Support angle ≥ 45° for self-support

• Thread relief ≥ 0.2 mm after print

EBM Ti-6Al-4V

• Min wall: 0.6 mm (no supports)

• Overhang: 90° printable

• Channel Ø ≥ 2 mm to remove powder

• Min wall: 0.6 mm (no supports)

• Overhang: 90° printable

• Channel Ø ≥ 2 mm to remove powder

Binder-Jet 316L

• Min wall: 1.0 mm

• Sinter shrinkage: 18 % (compensate CAD)

• Hole Ø ≥ 3 mm to avoid collapse

• Min wall: 1.0 mm

• Sinter shrinkage: 18 % (compensate CAD)

• Hole Ø ≥ 3 mm to avoid collapse

-

QA & Certifications

• CT scan every 50th medical part (ASTM F2924)

• Tensile bars printed & tested per ISO 6892-1

• Surface roughness Ra 3-point trace

• AS9100D traceability lot numbers

• Tensile bars printed & tested per ISO 6892-1

• Surface roughness Ra 3-point trace

• AS9100D traceability lot numbers

-

Shipping & Import

• DHL Express: Shanghai → Frankfurt 48 h, $3.1/kg volumetric

• EU duty: HS 7326.90 printed Ti 0 % origin CN

• IP: bilingual NDA under PRC law

• EU duty: HS 7326.90 printed Ti 0 % origin CN

• IP: bilingual NDA under PRC law

-

Sustainability Snapshot

• Ti powder reused 75 %, balance recycled into aerospace bar

• Argon purification loop saves 30 % gas/yr

• HIP furnace powered by off-peak wind electricity

• Argon purification loop saves 30 % gas/yr

• HIP furnace powered by off-peak wind electricity

Roadmap 2025–2026

• 12-laser SLM 500 Q3 2025 → Ti build speed 3×

• EBM Ti64 Grade 23 certification Q1 2026

• In-house PVD TiN coating line (2 µm) for implants

• EBM Ti64 Grade 23 certification Q1 2026

• In-house PVD TiN coating line (2 µm) for implants

-

Conclusion

Whether you need one titanium lattice bracket or 600 hip cups, our Kunshan plant has the lasers, HIP furnace and midnight shift to deliver on time. Upload your CAD today and receive a live quote within 12 hours—no chatbot, only metallurgists who run the machines.