Your Guide to Finding the Right Manufacturing Partner for Startups: CNC Manufacturing Insights

For startups, transforming an innovative design into a market-ready product is a monumental challenge. Without established manufacturing expertise or infrastructure, navigating production complexities can drain resources and delay launches. This is where selecting the right Manufacturing Partner for Startups becomes a strategic advantage, providing the specialized expertise and infrastructure needed to bring your designs to life efficiently.

Finding a reliable Manufacturing Partner for Startups can significantly impact your success in the market.

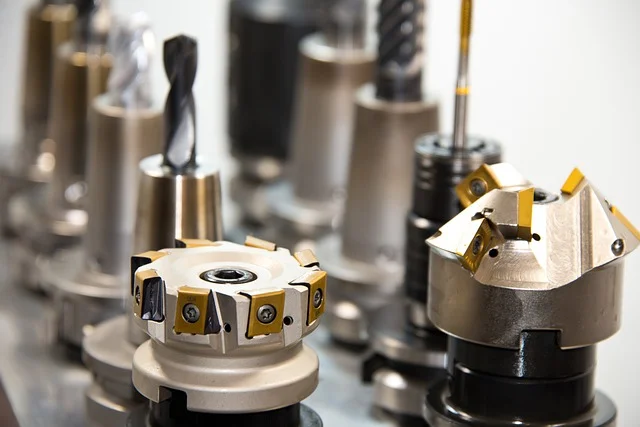

A competent manufacturing partner does more than just produce parts; they become an extension of your team, helping refine designs, select appropriate materials, enforce quality standards, and accelerate your journey from prototype to production . For startups operating in sectors like aerospace, consumer electronics, or specialized machinery, a partner with precision CNC machining capabilities is particularly valuable, offering access to advanced equipment and specialized expertise without the capital investment .

Why Startups Need Specialized Manufacturing Partners

The Capital Investment Challenge

For startup founders, the financial barrier to establishing in-house manufacturing can be prohibitive. Setting up a CNC machining operation requires significant capital investment in machinery, tooling, and facility setup.

One entrepreneur shared that just setting up a presentable workshop with office space, electrical circuits, and air system布置 can cost around $17,000, and that’s before any equipment is purchased . A basic setup with CNC machines, lathes, and milling machines can represent an investment starting at $30,000, with more comprehensive capabilities running into hundreds of thousands of dollars .

Additionally, startups must consider the ongoing operational costs beyond equipment: skilled machinists, quality control systems, and maintenance all contribute to the total cost of ownership that makes partnering with an established manufacturer financially prudent.

Speed to Market Considerations

In today’s competitive landscape, speed to market often determines success. Establishing in-house manufacturing capabilities typically takes months, while a specialized partner can often begin production within weeks, or even days for prototype stages .

The most successful manufacturing partnerships for startups combine rapid prototyping with seamless transition to production. This integrated approach allows for quick design verification and significantly shortens R&D cycles, getting products to market faster .

Key Capabilities to Look for in a CNC Manufacturing Partner

Technical Expertise and Equipment

When evaluating potential manufacturing partners, several technical capabilities should influence your decision:

Table: Essential CNC Capabilities for Startup Manufacturing Partners

| Capability | Importance for Startups | Key Considerations |

|---|---|---|

| Multi-Axis Machining | Enables complex geometries in single setups | 3+2 axis positioning vs. simultaneous 5-axis |

| Tolerance Control | Ensures parts meet design specifications | Typical tolerance capabilities: ±0.005mm to ±0.025mm |

| Material Selection | Affects part performance and cost | Range of materials available (aluminum, steel, plastics, exotic alloys) |

| Surface Finish Options | Impacts aesthetic and functional requirements | Available processes: anodizing, sandblasting, powder coating, etc. |

| Quality Assurance | Verifies part quality and consistency | Equipment: CMM, optical comparators, surface roughness testers |

Beyond the equipment itself, consider the technical expertise of their team. The most valuable partners provide design for manufacturability (DFM) feedback, suggesting modifications that reduce cost or improve producibility without compromising function .

Scalability and Flexibility

Startups need manufacturing partners who can scale production as demand grows. Look for evidence of scalable operations – the ability to transition from low-volume prototyping to medium-volume production, and eventually to high-volume manufacturing if needed .

Production flexibility is equally important. The ideal partner should accommodate frequent engineering changes and produce different part numbers in smaller batches, adapting to the iterative nature of startup development .

Quality and Certification Standards

Importance of Quality Management Systems

For startups building their reputation, consistent part quality is non-negotiable. A manufacturing partner with established quality management systems provides crucial assurance that every part will meet specifications, shipment after shipment.

ISO 9001 certification demonstrates a commitment to standardized quality processes . For startups in regulated industries like aerospace or medical devices, additional certifications like AS9100 or ISO 13485 may be necessary.

Measurement and Inspection Capabilities

Comprehensive inspection capabilities are essential for verifying part quality. Modern CNC manufacturing partners should have:

-

Coordinate Measuring Machines (CMM) for precise dimensional verification

-

Surface roughness testers to validate finish requirements

-

Optical comparators for rapid 2D feature verification

-

First-article inspection processes to validate initial production runs

These capabilities ensure that your parts are manufactured correctly the first time, reducing costly rework delays.

Cost Management Strategies for Startups

Understanding Pricing Structures

For startup founders, understanding manufacturing pricing is crucial for financial planning. CNC machining costs typically include:

-

Setup charges (one-time cost for programming and tooling)

-

Per-part pricing (based on machine time and material)

-

Secondary operations (surface treatments, special packaging)

-

Quality verification (inspection and documentation)

Many manufacturers offer prototyping packages at reduced rates to help startups minimize upfront costs while validating designs .

Maximizing Value in Manufacturing Partnerships

Beyond negotiating prices, startups can reduce costs through:

-

Design for Manufacturability – Working with your partner to optimize designs for efficient production

-

Material Selection – Choosing the most appropriate material for the application, not necessarily the highest-performing

-

Standardizing Features – Using standard tool sizes and avoiding unnecessarily tight toleratures

-

Batch Optimization – Planning production to maximize machine utilization

Case Studies: Successful Startup-Manufacturer Partnerships

Case Study 1: Electric Vehicle Component Startup

A startup developing specialized battery enclosures for electric vehicles faced challenges with thermal management channels and sealing requirements. They partnered with a CNC manufacturer offering 5-axis machining capabilities in aluminum alloy.

The manufacturer created initial prototypes for form and fit verification, followed by functional prototypes with integrated cooling channels for thermal testing. Through rapid iteration cycles, they identified design improvements that enhanced both thermal performance and sealing reliability.

Results: The startup accelerated their development timeline by approximately 40% compared to traditional methods, reaching market before larger competitors and establishing a foothold in the emerging EV component space.

Case Study 2: Robotics Hardware Startup

A robotics startup needed precision components for a new collaborative robot design, requiring exceptional dimensional stability and minimal weight. They selected a manufacturing partner with expertise in multi-axis machining and experience with robotic systems.

The partner implemented a comprehensive approach including progressive machining strategies with specialized tooling for optimal surface finish, plus custom workholding to prevent distortion during machining of thin-walled sections.

Results: The joint components achieved all dimensional requirements with surface finishes of 0.8μm Ra, exceeding the startup’s lifecycle requirements by 30%. The reliable component performance became a key selling point for their robotic systems.

Case Study 3: Medical Device Startup

A medical startup developing a novel surgical instrument needed miniature, biocompatible components capable of withstanding repeated sterilization cycles. They partnered with a manufacturer with micro-machining capabilities and experience with medical-grade materials.

The manufacturer employed high-speed spindles for precise feature generation and implemented controlled environment processing to maintain cleanliness standards, followed by electrochemical polishing for final surface enhancement.

Results: The components met all functional requirements with complete documentation for regulatory submission. The precise dimensional control ensured proper fitment in the final assembly, accelerating FDA approval and commercial launch.

Building a Strategic Manufacturing Relationship

Communication and Collaboration

The most successful manufacturing partnerships operate as true collaborations. Establish clear communication channels and regular check-ins to address issues quickly. The best partners provide proactive updates and flag potential concerns before they become problems .

Technical transparency is equally important. Sharing your design intent and performance requirements enables your manufacturing partner to suggest alternative approaches or materials that might better serve your application.

Long-term Partnership Planning

While initial prototypes may be the immediate need, discuss long-term production strategy with potential partners. Understanding how they handle production scaling, inventory management, and supply chain disruptions will help you assess their suitability as a long-term partner.

Some manufacturers offer inventory management programs where they maintain raw material or finished goods inventory, reducing lead times as your production volumes increase.

Conclusion: Selecting Your Manufacturing Partner

For startups, choosing a CNC manufacturing partner is one of the most critical decisions impacting both time to market and product quality. The right partner provides more than manufacturing capacity – they become a strategic asset, contributing technical expertise, quality assurance, and production scalability.

When evaluating potential partners, prioritize technical capabilities that match your product requirements, quality systems that ensure consistent results, and communication practices that support collaborative problem-solving. The ideal partner balances all three while offering the flexibility to adapt to your evolving startup needs.

By selecting a manufacturing partner with the right capabilities and cultural fit, startups can overcome the traditional barriers to production, accelerate their development timelines, and focus on their core innovation – bringing transformative products to market.