The Anatomy of Flight: A Technical Guide to Precision CNC Drone Frame Manufacture

Introduction: The Skeleton Dictates Performance

In the rapidly evolving world of unmanned aerial systems, the drone frame is far more than a passive housing—it is the foundational skeleton that defines every aspect of flight performance. CNC Drone Frame Manufacture represents a critical engineering discipline where the interplay of material science, structural mechanics, and advanced manufacturing converges to create platforms that can achieve the seemingly impossible: extended flight times, aggressive maneuverability, and reliable operation under punishing conditions. At JLYPT, we specialize in translating aerodynamic and structural concepts into physical reality through high-precision CNC machining, producing frames that are not simply assembled, but engineered as integrated systems.

The distinction between a mass-produced frame and a precision CNC-machined frame is not merely aesthetic; it is quantifiable in grams saved, in Hertz of vibration damped, and in Newton-meters of stiffness gained. A drone’s frame is the primary determinant of its structural resonant frequency, its mass distribution, and its aerodynamic profile—three parameters that directly control stability, efficiency, and control response. While additive manufacturing offers geometric freedom and carbon fiber layups provide lightweight potential, CNC machining delivers the unmatched combination of material integrity, dimensional precision, and repeatability necessary for professional, commercial, and defense-grade applications. This guide dissects the engineering principles, manufacturing methodologies, and validation processes that separate a hobbyist platform from a professional tool, demonstrating why precision CNC machining is the cornerstone of advanced drone frame manufacture.

Engineering the Unibody: The Case for Monolithic Construction

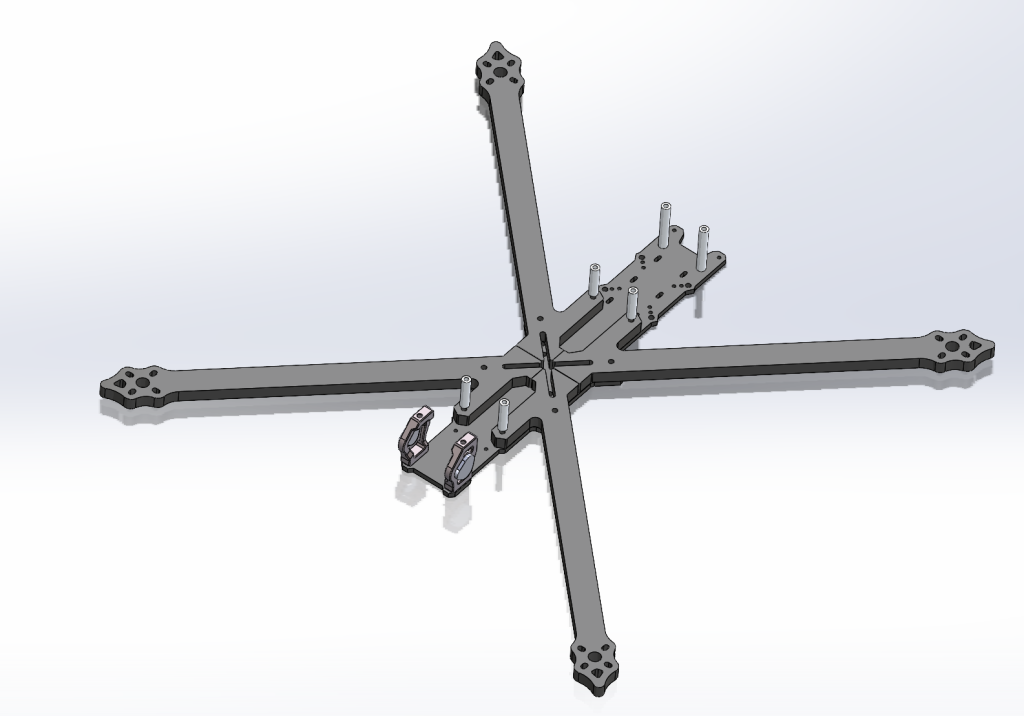

The evolution from bolted-tube or stacked-plate frames to monolithic unibody construction represents the single most significant advancement in drone frame engineering. This paradigm shift, enabled by multi-axis CNC machining, moves the design philosophy from assembly to integration.

Eliminating Assembly-Induced Error: A traditional frame assembles multiple components—arms, plates, brackets—using fasteners. Each interface introduces potential stack-up tolerance error, localized stress concentration at fastener holes, and compliance (micro-movement) under dynamic loads. A monolithic frame, machined from a single billet of aerospace aluminum (such as 7075-T6) or titanium, eliminates every bolted joint in the primary load path. The arm is not attached to the center plate; it is an organic extension of it. This results in a structure with perfect geometric alignment and uniform load transfer, directly translating to more predictable flight dynamics and eliminating “frame flex” as a variable in tuning.

Mass Optimization Through Topological Design: A unibody is not a solid block. Using Finite Element Analysis (FEA) software, engineers can subject a virtual frame model to simulated flight loads—thrust, drag, inertial forces from maneuvers. The software’s topological optimization algorithms then iteratively remove material from areas of low stress, resulting in a complex, organic-looking internal lattice or webbed structure. This generative design outcome, which resembles bone growth patterns, is often impossible to cast or mold but is perfectly suited for 3+2 axis or 5-axis CNC machining. The result is a component that achieves a target stiffness with 30-50% less mass than a prismatic design, a saving that directly converts to increased payload or flight time.

Integrated Functionality and Cable Management: A monolithic frame allows for the machining of internal conduits and channels for power and signal cables. This not only produces a clean, professional appearance but also provides critical mechanical protection for wiring, reduces electromagnetic interference (EMI) by shielding cables within the metal structure, and improves aerodynamics by eliminating external drag-inducing cable bundles. Features like embedded vibration-isolating mounts for flight controllers, sealed compartments for electronics, and customized accessory mounting points can be machined directly as part of the primary structure.

Material Selection: The Substrate of Performance

The choice of material is a primary determinant of a frame’s performance envelope, balancing the trinity of strength, stiffness, and density.

Aerospace Aluminum Alloys:

-

7075-T6: The gold standard for high-performance CNC drone frames. With a tensile strength surpassing 500 MPa and excellent fatigue resistance, it allows for extremely thin walls and aggressive lightweighting while maintaining crash resilience. Its high stiffness (modulus of elasticity) ensures minimal deflection under load, crucial for maintaining the alignment between motors and flight controller references. While more expensive and slightly denser than some alternatives, its specific strength (strength-to-density ratio) is exceptional.

-

6061-T6: A more economical and easier-to-machine alloy with good all-around properties. It is suitable for prototypes, lower-stress applications, or frames where weldability is desired. However, for a given stiffness, a 6061 part will be heavier than its 7075 counterpart.

Titanium Alloys:

-

Ti-6Al-4V (Grade 5): Used in extreme applications where its unparalleled specific strength, corrosion resistance, and ability to withstand high temperatures justify its high cost and difficult machinability. Titanium frames are niche, typically reserved for specialized military, marine, or high-temperature (e.g., engine-mounted) applications. Its lower stiffness compared to steel must be accounted for in the design.

Advanced Composites and Hybrid Approaches:

While pure carbon fiber frames are typically laid up, CNC machining plays a vital role in hybrid construction. Machined metal nodes—complex central hubs and arm connectors—are bonded or mechanically fastened to carbon fiber tubes. This combines the lightweight and dampening properties of carbon fiber with the precision, durability, and threaded-hole integrity of CNC-machined metal. These metal nodes are often intricate 5-axis parts featuring bonding surfaces with specific textures for adhesive keying, internal cable routings, and hard-point inserts for attachments.

Table 1: Drone Frame Material Performance Matrix

| Material | Density (g/cm³) | Tensile Strength (MPa) | Modulus (Stiffness) (GPa) | Best For | CNC Machining Note |

|---|---|---|---|---|---|

| 7075-T6 Aluminum | 2.81 | 500-570 | 71.7 | High-performance racing, heavy-lift, commercial inspection drones. | Excellent machinability with sharp tools. Prone to stress corrosion; avoid designs with trapped stresses. |

| 6061-T6 Aluminum | 2.70 | 310 | 68.9 | Prototypes, educational platforms, lightweight camera drones. | Very good machinability, weldable. Softer, requires more material for equal strength vs. 7075. |

| Ti-6Al-4V Titanium | 4.43 | 900-1100 | 113.8 | Military, marine, high-temperature, or maximum strength-to-weight applications. | Difficult to machine (low thermal conductivity, galling). Requires slow speeds, high pressure coolant, specialized tooling (PCD). |

| Carbon Fiber Tube (T700) | ~1.6 | 700+ (fiber direction) | ~70+ (fiber direction) | Hybrid frames where low weight and damping are prioritized; main arms. | Not machined for primary structure; companion metal nodes are CNC’d for attachment. |

| Magnesium AZ31B | 1.77 | 250-290 | 45 | Ultra-lightweight racing frames where every gram counts. | High fire risk. Requires specialized safety protocols, dry machining, and dedicated chip management. |

The Manufacturing Deep Dive: CNC Strategies for Optimal Frames

Translating a design into a physical frame requires selecting the right machining strategy for each feature, balancing efficiency, precision, and surface integrity.

Multi-Axis Machining Strategies:

-

3+2 Axis Machining: The workhorse for most frame components. The machine positions the workpiece at a fixed compound angle (using its rotary axes), then executes a 3-axis milling program. This is efficient for machining multiple sides of a center plate or arm in fewer setups, improving accuracy between features.

-

5-Axis Simultaneous Machining: Essential for complex, organic unibody frames. The tool and workpiece move dynamically along five axes simultaneously. This allows for:

-

Machining deep, undercut cavities for electronics.

-

Creating smooth, aerodynamic curves and blends.

-

Using shorter, stiffer cutting tools by tilting the spindle to maintain optimal tool engagement, crucial for machining thin, tall ribs.

-

Thin-Wall Machining and Chatter Suppression: Drone frames are the epitome of high aspect-ratio machining—thin walls (often <1.5mm) over significant heights. This is prone to chatter, a self-excited vibration that ruins surface finish and can break tools. Strategies to combat this include:

-

Trochoidal Milling: A toolpath where the end mill follows a circular, plunging path with constant, light radial engagement. This reduces cutting forces and heat.

-

Variable Helix/Variable Pitch End Mills: These tools break up harmonic vibrations by ensuring cutting edges do not engage the material at a consistent frequency.

-

Dynamic Machine Control: Advanced CNC controllers can detect the onset of chatter and automatically adjust spindle speed in real-time to move out of the resonant frequency band.

High-Speed Machining (HSM) for Efficiency and Finish: HSM utilizes high spindle RPMs and high feed rates with very low depths of cut. This technique minimizes cutting forces (beneficial for thin walls), produces excellent surface finishes often eliminating the need for secondary finishing, and reduces cycle times by removing material at a higher volumetric rate.

Post-Processing for Performance and Protection:

-

Vibratory Finishing & Tumbling: To deburr all sharp edges, which are stress concentrators and safety hazards, and to impart a uniform matte finish.

-

Thermal Aging/Stress Relieving: For complex frames, a low-temperature thermal cycle can relieve residual stresses from machining, stabilizing dimensions and preventing long-term warpage.

-

Surface Treatments:

-

Anodizing (Type II/III): Provides corrosion resistance, electrical insulation, and allows for color coding. Hardcoat anodizing increases surface wear resistance.

-

Ceramic Coating: Offers superior hardness and abrasion resistance compared to anodizing, though at higher cost.

-

Powder Coating: Provides the thickest, most durable protective layer and the widest color range, but adds more weight and must be masked from any critical dimensional interfaces.

-

The Performance Trinity: Stiffness, Vibration, and Aerodynamics

A successful frame design must simultaneously optimize three interconnected physical domains.

1. Structural Stiffness and Modal Analysis:

Stiffness is not a single number. Engineers perform modal analysis (a type of FEA) to identify the frame’s natural resonant frequencies and mode shapes—the patterns in which it wants to vibrate (e.g., first bending, first torsion). The goal is to push these resonant frequencies above the excitation frequencies produced by the motors (harmonic of RPM) and propellers (blade pass frequency). A frame whose resonance overlaps with a 4kHz motor harmonic will experience severe, destructive vibration at that specific throttle position. CNC machining allows for precise placement of material (via ribs, gussets, and variable wall thickness) to stiffen specific weak modes identified in the analysis.

2. Vibration Damping and Isolation:

Even with a stiff frame, vibration from motors and propellers is inevitable. The strategy shifts from total elimination to isolation and damping.

-

Isolation: Using soft materials like silicone or sorbothane between the motor and the frame arm is common. A more advanced, integrated approach is to machine isolated motor pods—sections of the arm connected by a thin, flexible “living hinge” of aluminum designed to filter out high-frequency vibrations.

-

Damping: The material choice and construction itself provides damping. CNC-machined aluminum has intrinsic damping properties. Hybrid carbon-fiber/metal designs can be tuned for higher damping, as the adhesive layer between materials dissipates vibrational energy.

3. Aerodynamic Optimization:

For high-speed and long-endurance drones, frame drag is a significant factor. CNC machining enables aerodynamic profiling.

-

Arm Profiling: Arms can be machined with NACA airfoil or teardrop shapes to reduce drag compared to a simple square tube.

-

Component Fairing: The frame can be designed with integrated fairings that streamline around onboard components like batteries or sensors, reducing turbulent airflow.

-

Surface Finish: A machined and polished surface has a lower skin friction coefficient than a rough composite or printed surface, marginally reducing drag at high speeds.

Table 2: CNC Frame Design Optimization Checklist

| Performance Goal | Design Strategy | CNC Manufacturing Enabler |

|---|---|---|

| Maximize Stiffness-to-Weight Ratio | Topological optimization via FEA; use of high-strength alloys (7075). | 5-axis machining to produce complex internal lattice structures; thin-wall machining. |

| Minimize Vibration Transmission | Design of isolated motor mounts; tuned mass dampers; hybrid material use. | Precision machining of interface surfaces for isolators; machining of pockets for damping weights. |

| Increase Crash Resilience | Strategic material placement; energy-absorbing crumple zones; avoidance of sharp notches. | Controlled radii on all internal corners (≥0.5mm); ability to vary material thickness in different frame zones. |

| Optimize for Aerodynamics | Airfoil-shaped arms; integrated component fairings; streamlined overall shape. | 5-axis contouring to create smooth, complex curves; high-quality surface finish from HSM. |

| Improve Thermal Management | Use of thermally conductive materials; design of cooling channels or heatsink fins. | Machining of fins and channels directly into the frame structure (e.g., under motor mounts). |

| Ensure Easy Assembly & Service | Integrated captive nut slots; fool-proof alignment features; accessible cable channels. | Precision machining of self-jigging features; machined-in labels or markings; thread milling for high-strength threads in aluminum. |

Case Studies: Applied Engineering in Frame Manufacture

Case Study 1: Heavy-Lift Cinematography Drone – Maximized Payload Rigidity

-

Challenge: A cinematography company needed a frame for carrying high-end cinema cameras (5kg+). The primary requirement was absolute rigidity to prevent any frame flex from causing “jello effect” (vibration artifacts) in footage, even during aggressive maneuvers. Weight was secondary to stiffness.

-

JLYPT Solution: We designed and manufactured a monolithic core chassis from 7075-T6. The design focused on torsional stiffness.

-

Modal Analysis was used to identify and stiffen the first torsional mode.

-

The chassis featured a “double-bubble” central structure—two horizontal plates connected by numerous closely spaced vertical ribs, forming an immensely stiff box beam.

-

The carbon fiber arms were attached via large-diameter, CNC-machined titanium clamping blocks that provided a massive, slip-free interface.

-

The camera mount was integrated directly into the core chassis, with its own isolated vibration damping system mounted on precisely machined rails.

-

-

Result: The frame’s measured torsional stiffness was over 300% higher than the previous generation bolted-aluminum design. In flight tests with a 6kg payload, high-speed camera footage showed zero visible vibration artifacts, even during rapid yaw turns, meeting the stringent demands of professional cinematography.

Case Study 2: Long-Endurance Fixed-Wing UAV – Hybrid Construction for Efficiency

-

Challenge: Develop a 3-meter wingspan fixed-wing UAV for mapping with a target 8-hour flight time. The airframe needed to be extremely light yet capable of handling 15G gust loads. Traditional all-composite construction made integrating hard points and access panels difficult.

-

JLYPT Solution: We engineered a hybrid structure.

-

The primary wing spar was a CNC-machined 7075-T6 I-beam with precisely located hard points for control surface servos and payload mounts.

-

The fuselage core was a monocoque structure machined from a solid block of lightweight foam-filled laminate, with CNC-machined aluminum bulkheads bonded in at critical load stations (engine mount, wing attachment, landing gear).

-

All complex, load-bearing metal parts were CNC-machined to precise airfoil contours and mating surfaces.

-

-

Result: The hybrid approach saved approximately 20% weight compared to an all-metal airframe and provided far more precise and robust load paths than a pure composite structure. The UAV achieved its 8-hour endurance target and demonstrated excellent durability in field operations.

Case Study 3: First-Person View (FPV) Racing Drone – Ultimate Weight and Stiffness

-

Challenge: An FPV racing team needed a frame for the Drone Racing League that was sub-250g (to meet certain class regulations), incredibly stiff for instantaneous control response, and resilient enough to survive high-speed crashes.

-

JLYPT Solution: We pushed the limits of thin-wall machining with unibody design.

-

The entire main frame (integrated arms and center section) was machined from a 3mm thick sheet of 7075-T6, with strategic pockets reducing thickness to 0.8mm in non-critical areas.

-

Topological optimization was used to create a branching, root-like structure for the arms that maximized stiffness at the motor mounts while minimizing material.

-

The frame was designed as a “sandwich” with a separate top plate, using standoffs. The primary load-bearing was handled by the monolithic bottom plate, keeping weight absolute minimal.

-

A ceramic coating was applied for hardness and a low-friction, crash-resistant surface.

-

-

Result: The final frame weight was 72g. It exhibited no measurable flex during bench testing under high thrust loads. Pilots reported a tangible improvement in “locked-in” feeling during turns and the frame survived multiple high-impact crashes with only cosmetic damage, winning a national championship.

Conclusion: The Frame as a Flight-Critical System

The modern drone frame is a flight-critical system engineered with the same rigor as an aircraft’s airframe. CNC Drone Frame Manufacture is the enabling technology that allows this engineering intent to be realized with precision, repeatability, and performance that other processes cannot match. It moves drone construction from a craft of assembly to a discipline of integrated design and precision manufacturing.

Choosing to manufacture a frame via CNC is an investment in the foundational performance of the entire aerial system. It is a decision that pays dividends in extended flight time, improved stability, enhanced durability, and ultimately, the reliability of the data or service the drone provides. At JLYPT, we partner with innovators across the UAV spectrum, from racing teams to industrial survey companies, to provide the engineering insight and manufacturing excellence required to build the physical backbone of their vision.

Ready to engineer the foundation of your next-generation UAV? Contact our team to discuss how precision CNC machining can optimize your frame design for its specific mission. From prototype to production, we provide the expertise to build lighter, stiffer, and smarter. Begin the conversation at JLYPT Custom CNC UAV Parts Manufacturer.